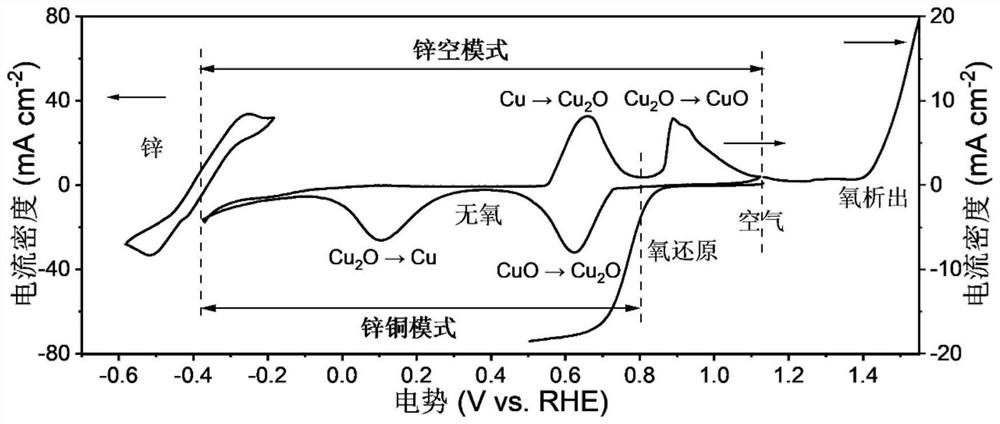

Composite zinc-air secondary battery capable of being used in oxygen-free environment and capable of being self-charged in aerobic environment

A secondary battery, zinc-air technology, applied in fuel cell type half cells and primary cell type half cells, electrical components, battery electrodes, etc., can solve the problems of limited electric energy, poor conductivity, low redox potential, etc. , to achieve the effect of extending the range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

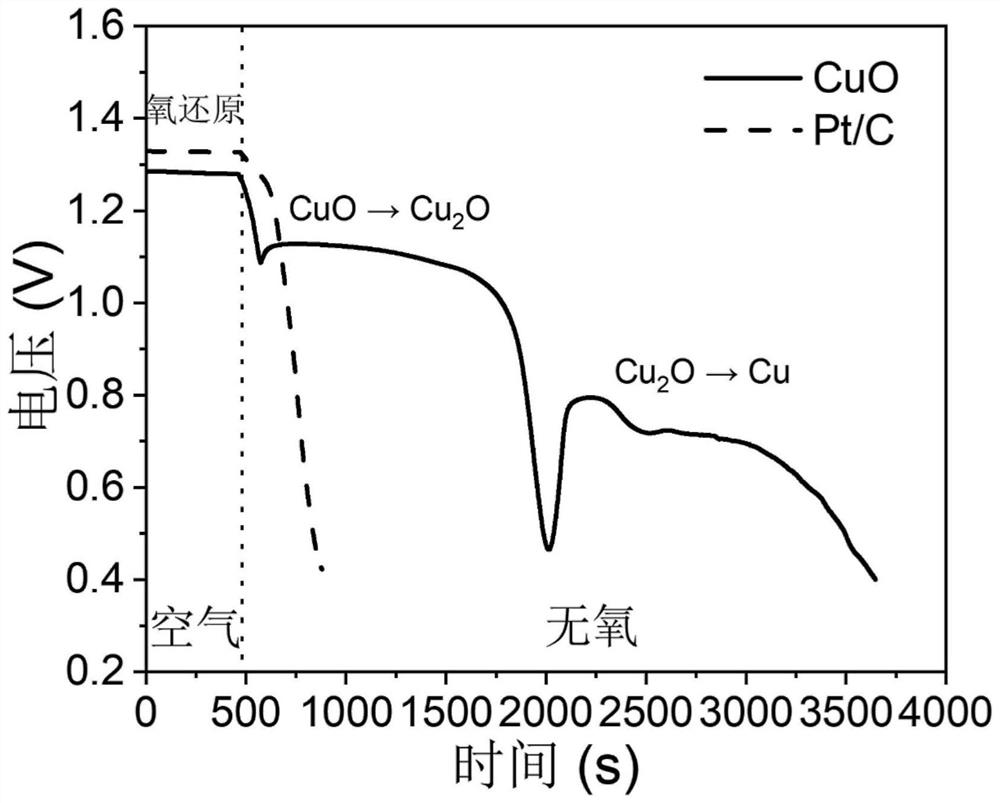

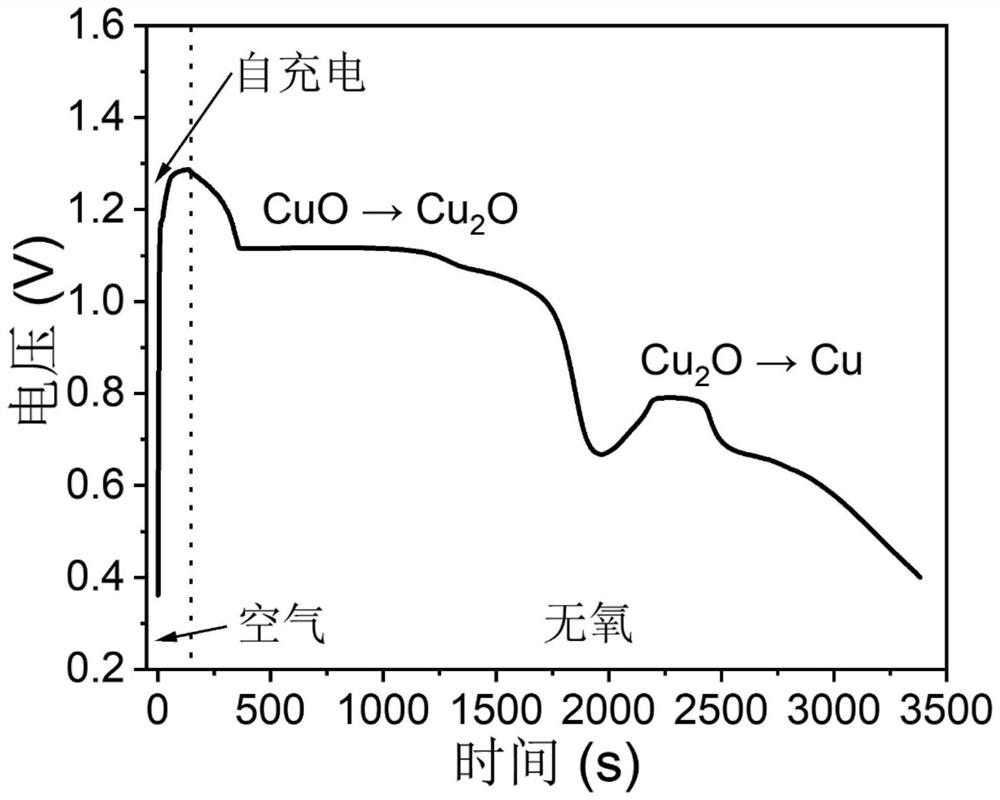

[0031] The composite zinc-air secondary battery of this embodiment is composed of negative pole, alkaline electrolyte and positive pole, wherein the negative pole is a zinc plate with a purity of more than 99% and a thickness of 0.1 mm; the alkaline electrolyte is prepared from potassium hydroxide, zinc acetate and water The concentration of potassium hydroxide is 6mol / L, and the concentration of zinc acetate is 0.2mol / L; the positive electrode is an air electrode, which is prepared by hot pressing of waterproof and breathable membrane, current collector layer and positive electrode material; the waterproof and breathable membrane is polytetrafluoroethylene Vinyl film with a thickness of 100 μm and a pore size of 0.1 μm; the current collector layer is a nickel foam plate.

[0032] The making of positive electrode material: 2.1mg purity 99.9%, copper oxide (CuO) nanopowder of average particle diameter 40nm, 0.6mg gac, 0.3mg polytetrafluoroethylene nanopowder (binder) of average ...

Embodiment 2

[0036] The composite zinc-air secondary battery of this embodiment is composed of negative pole, alkaline electrolyte and positive pole, wherein the negative pole is a zinc plate with a purity of more than 99% and a thickness of 0.1 mm; the alkaline electrolyte is prepared from potassium hydroxide, zinc acetate and water The concentration of potassium hydroxide is 6mol / L, and the concentration of zinc acetate is 0.2mol / L; the positive electrode is an air electrode, which is prepared by hot pressing of waterproof and breathable membrane, current collector layer and positive electrode material; the waterproof and breathable membrane is polytetrafluoroethylene Vinyl film with a thickness of 100 μm and a pore size of 0.1 μm; the current collector layer is a nickel foam plate.

[0037] Preparation of positive electrode material: 1 mg of copper oxide (CuO) nanopowder with a purity of 99.9% and an average particle size of 40 nm, 10 mg of acetylene black, and 10 mg of polytetrafluoroet...

Embodiment 3

[0040] The composite zinc-air secondary battery of this embodiment is composed of negative pole, alkaline electrolyte and positive pole, wherein the negative pole is a zinc plate with a purity of more than 99% and a thickness of 0.1 mm; the alkaline electrolyte is prepared from potassium hydroxide, zinc acetate and water The concentration of potassium hydroxide is 6mol / L, and the concentration of zinc acetate is 0.2mol / L; the positive electrode is an air electrode, which is prepared by hot pressing of waterproof and breathable membrane, current collector layer and positive electrode material; the waterproof and breathable membrane is polytetrafluoroethylene Vinyl film with a thickness of 200 μm and a pore size of 1 μm; the current collector layer is a nickel foam plate.

[0041] The making of positive electrode material: 5mg purity 99.9%, copper oxide (CuO) nano-powder of average particle diameter 40nm, 0.125mg carbon nanotube, 0.125mg polytetrafluoroethylene nano-powder (bindi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com