High-shrinkage cation normal-pressure easy-to-dye polyester chip and preparation method thereof

A polyester chip, cationic technology, applied in the field of high shrinkage cationic normal pressure easy-dyeing polyester chips and its preparation, can solve the problems of lack of high shrinkage performance, dyeing, difficulty in dyeing, etc., and achieves bright color and complete chromatogram. , the effect of good spinnability and drafting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

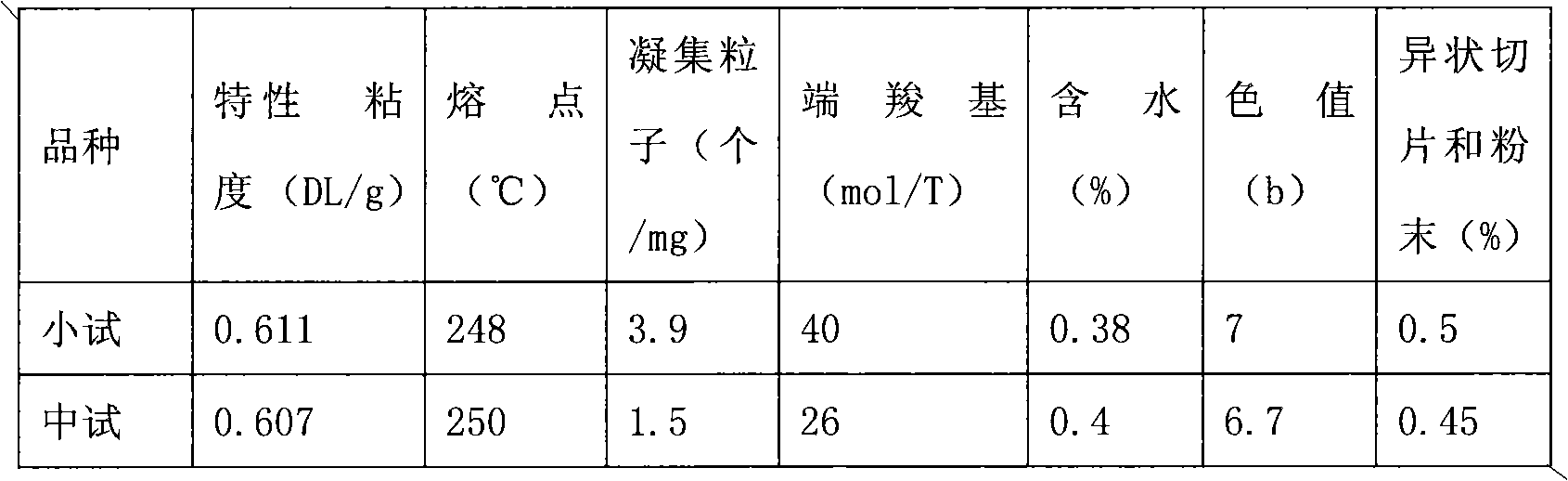

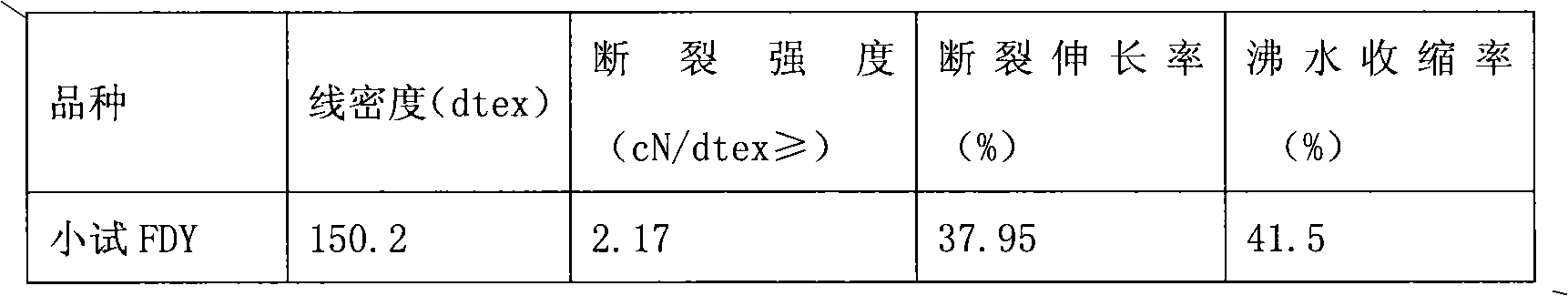

[0021] 2.5 liter small test reactor test process:

[0022] The quality of purified terephthalic acid 500g

[0023] Mass of ethylene glycol 164g

[0024] The mass of the third monomer SIPE 30.6g

[0025] The quality of the fourth monomer PEG 16.4g

[0026] The mass of the fifth monomer is 5g

[0027] The mass of the sixth monomer is 30g

[0028] The mass of catalyst antimony acetate 0.11g

[0029] Antioxidant mass 0.12g

[0030] The polyester test device is a batch polyester test device consisting of an esterification tank and a polycondensation tank. Add purified terephthalic acid and ethylene glycol in proportion to the esterification tank, and at the same time add the fourth, fifth and sixth monomers and antioxidants to control the pressure of the esterification tank at 0.25-0.3Mpa. When the amount of reaction water reaches 100-130ml, add a certain amount of ethylene glycol to depolymerize and homogenize the oligomers, control the temperature of the esterification tan...

Embodiment 2

[0032] 20 liter reactor test process:

[0033] The quality of purified terephthalic acid 5000g

[0034] Mass of ethylene glycol 1640g

[0035] The quality of the third monomer SIPE 300g

[0036] The quality of the fourth monomer PEG 164g

[0037] The mass of the fifth monomer is 50g

[0038] The mass of the sixth monomer is 300g

[0039] Mass of antimony acetate 1.1g

[0040] Antioxidant mass 1.2g

[0041] The polyester test device is a batch polyester test device consisting of an esterification tank and a polycondensation tank. Add purified terephthalic acid and ethylene glycol in proportion to the esterification tank, and at the same time add the fourth, fifth and sixth monomers and antioxidants to control the pressure of the esterification tank at 0.25-0.3Mpa. When the amount of reaction water reaches 100-130ml, add ethylene glycol to depolymerize and homogenize the oligomer, control the temperature of the esterification tank at 250-260°C, and after 15-35 minutes of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com