No-fluff wool fabric of fiber with surface nano structure and its prepn

An anti-pilling, fiber surface technology, applied in ultrasonic/sonic fiber treatment and other directions, can solve problems such as easy pilling, and achieve improved cohesion, excellent anti-pilling, anti-pilling and excellent hand feel Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

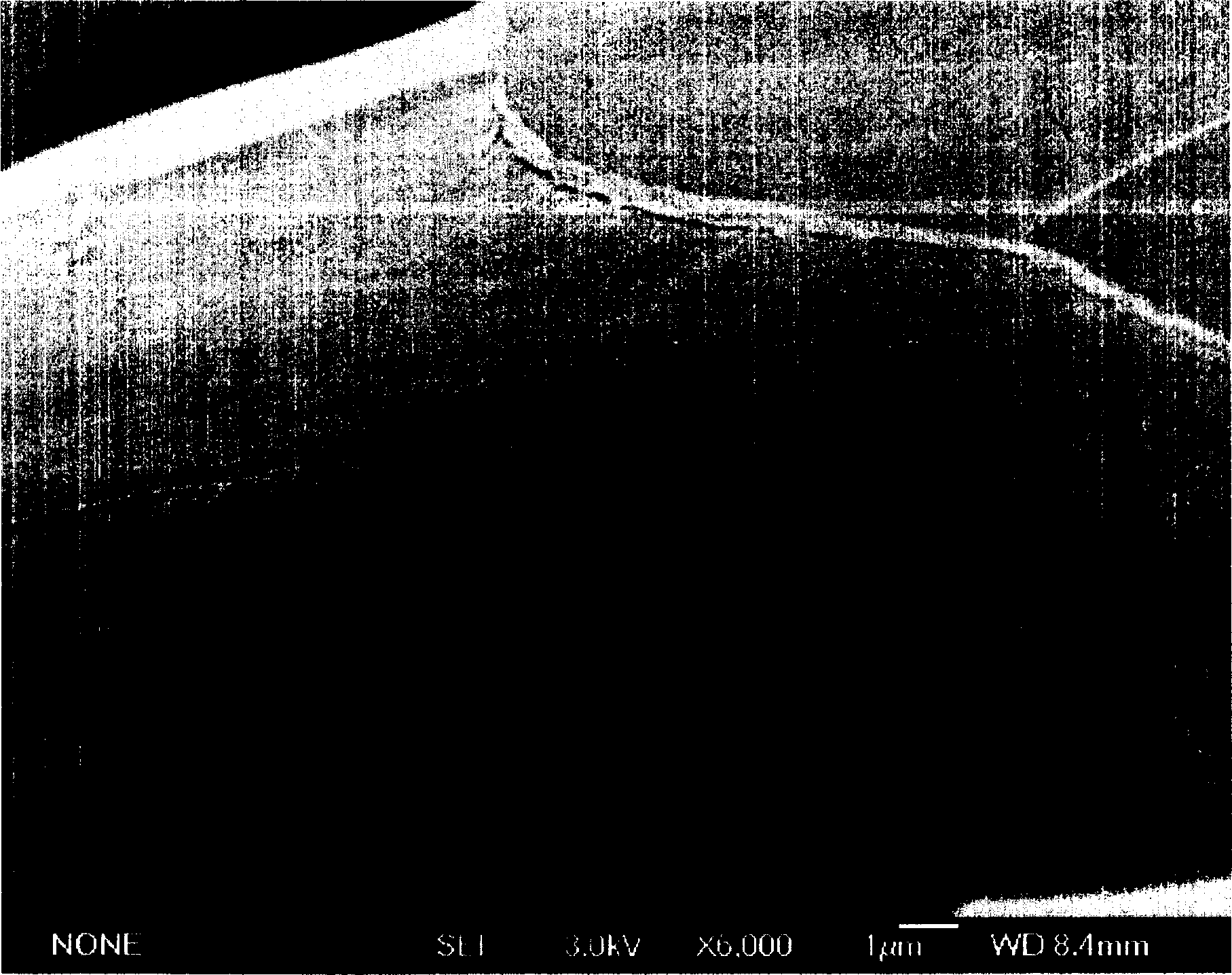

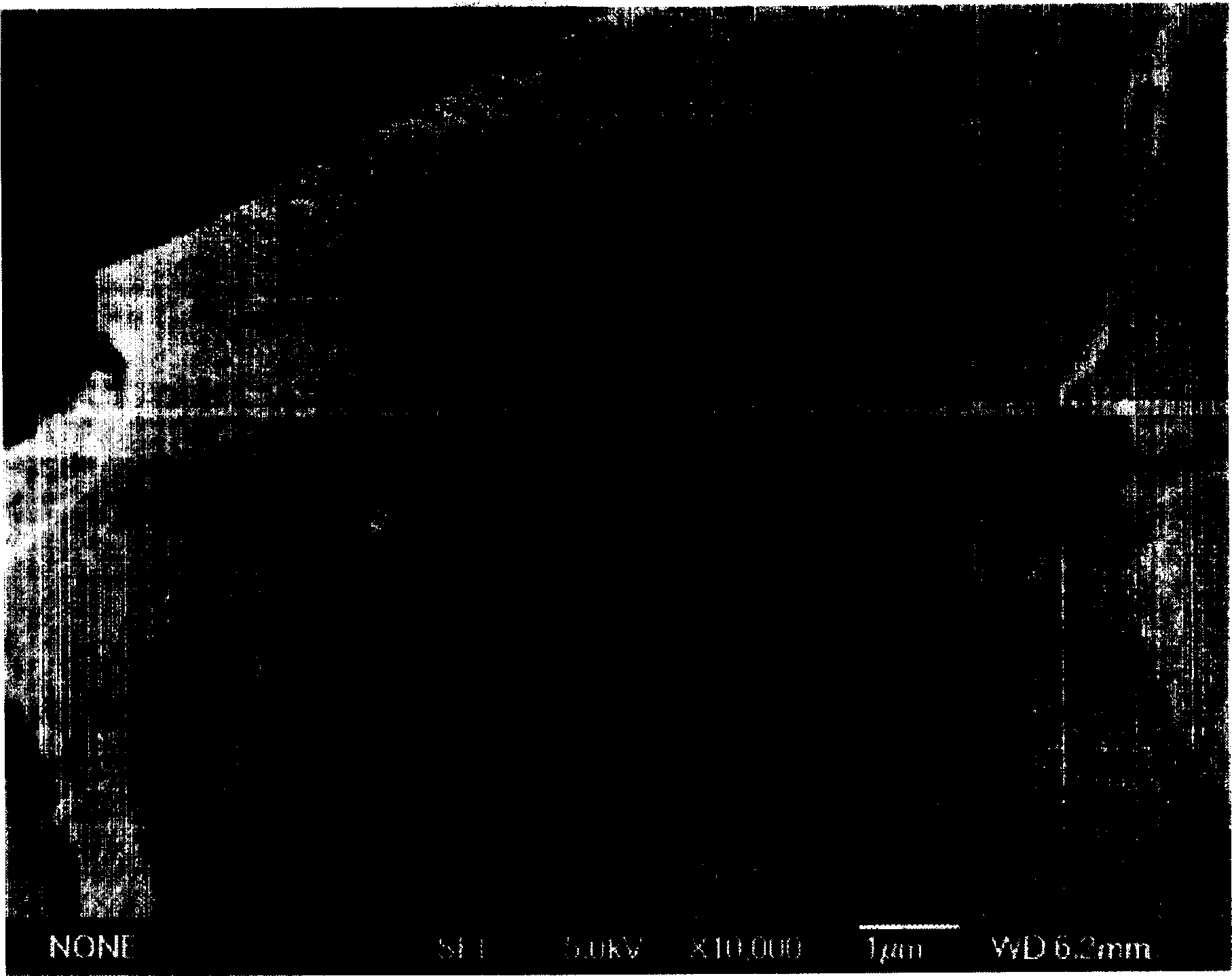

[0021] Cut the wool fabric into a circular sample with a diameter of 13cm, put it in a low-temperature plasma reaction chamber, and vacuumize it. When the pressure in the reaction chamber reaches 4Pa, start to introduce air to balance the vacuum degree in the reaction chamber at 26Pa, and then start discharging to conduct low-temperature plasma reaction. Plasma treatment, 30min discharge treatment with 200W power. The surface of the obtained fiber has a nano-scale concave-convex structure, and the diameter or width of the concave is 30-200nm.

Embodiment 2

[0023] Cut the wool fabric into a circular sample with a diameter of 13cm, put it into the low-temperature plasma reaction chamber, and vacuumize it. When the pressure in the reaction chamber reaches 7Pa, start to introduce oxygen to balance the vacuum degree in the reaction chamber at 160Pa, and then start discharging to carry out low-temperature plasma reaction. For plasma treatment, discharge treatment was performed for 60 minutes with 50W power. The surface of the obtained fiber has a nano-scale concave-convex structure, and the diameter or width of the concave is 30-200nm.

Embodiment 3

[0025] Cut the wool fabric into a circular sample with a diameter of 13 cm, put it into a low-temperature plasma reaction chamber, and evacuate it. When the pressure in the reaction chamber reaches 7Pa, start to feed helium / nitrogen (volume ratio is 6 / 4) to make the reaction chamber vacuum The temperature is balanced at 67Pa, and then the discharge is started, and low-temperature plasma treatment is performed, and the discharge treatment is performed for 1min with 300W power. The surface of the obtained fiber has a nano-scale concave-convex structure, and the diameter or width of the concave is 30-200nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge power | aaaaa | aaaaa |

| Discharge power | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com