Ecological anti-felting finishing method for wools

An anti-felting and wool technology, which is applied in fiber treatment, textiles and papermaking, animal fibers, etc., can solve the problems of heavy pollution, long process flow, dark color, etc., to improve the anti-felting ability, simplify the processing process, The effect of shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Wool yarn specifications: 66s Australian wool, spun into 54 counts / 2 strands of yarn

[0028] Put 20g of the above-mentioned wool yarn in a beaker with a concentration of hydrogen peroxide solution of 6g / L, a sodium silicate solution of 4g / L, a temperature of 40°C, and a bath ratio of solution to wool of 20:1. After stirring and soaking for 20 minutes, take out the fabric Rinse with clear water, and then the fabric is padded with a mixed solution of silk fibroin and chitosan (two dips and two pads, the pass ratio is 70%-80%), wherein, silk fibroin finishing agent SP1 10g / L, chitosan solution 7g / L L, then pre-baked at 80°C for 2min, baked at 120°C for 1min, washed with water at 80°C, softened with 0.5g softener, dehydrated and woven. The test results are shown in Table 1.

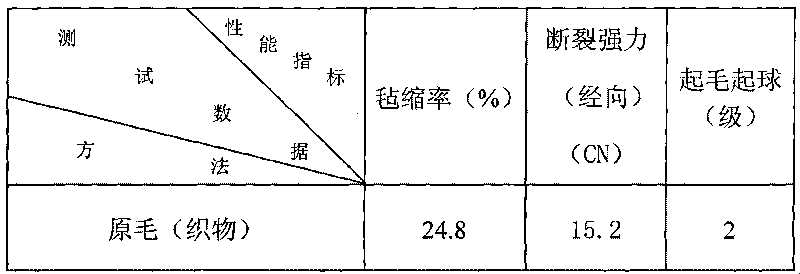

[0029] Table 1

[0030]

[0031]

Embodiment 2

[0033] Wool yarn specifications: 66s Australian wool tops, spun into 48 counts / 2 strands of yarn

[0034] Put 20g of the above-mentioned wool tops in a beaker with a concentration of hydrogen peroxide solution of 6g / L, a sodium silicate solution of 4g / L, a temperature of 45°C, and a bath ratio of the solution to wool of 15:1. After stirring and soaking for 20 minutes, take out the fabric Rinse with clear water, and then the fabric is padded with a mixed solution of silk fibroin and chitosan (two dips and two pads, the pass ratio is 70%-80%), wherein, silk fibroin finishing agent SP1 10g / L, chitosan solution 7g / L L, then pre-baked at 80°C for 3min, baked at 120°C for 2min, washed with water at 80°C, softened with 0.4g softener, dehydrated and woven. The test results are shown in Table 2.

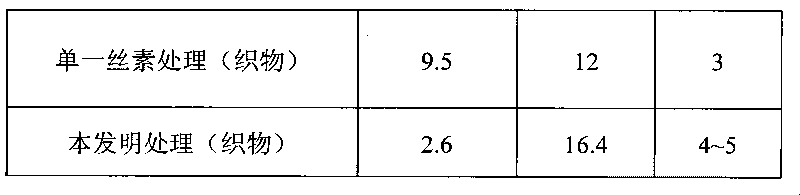

[0035] Table 2

[0036]

Embodiment 3

[0038] Specifications of wool and nitrile blended yarn: wool / nitrile ratio is 7 / 3, spun into 36 counts / share yarn

[0039] Put 20g of the above-mentioned wool tops in a beaker with a concentration of hydrogen peroxide solution of 6g / L and a sodium silicate solution of 4g / L at a temperature of 50°C. The bath ratio of the solution to wool is 20:1. After stirring and soaking for 20 minutes, take out the fabric Rinse with clear water, then the fabric is padded with silk fibroin and chitosan mixed solution (two dips and two pads, the remaining rate is 80%), wherein, silk fibroin finishing agent SP1 10g / L, chitosan solution 7g / L, after that Pre-baked at 80°C for 3 minutes, baked at 120°C for 3 minutes, washed with water at 80°C, softened with 0.2g softener, dehydrated and woven. The test results are shown in Table 3.

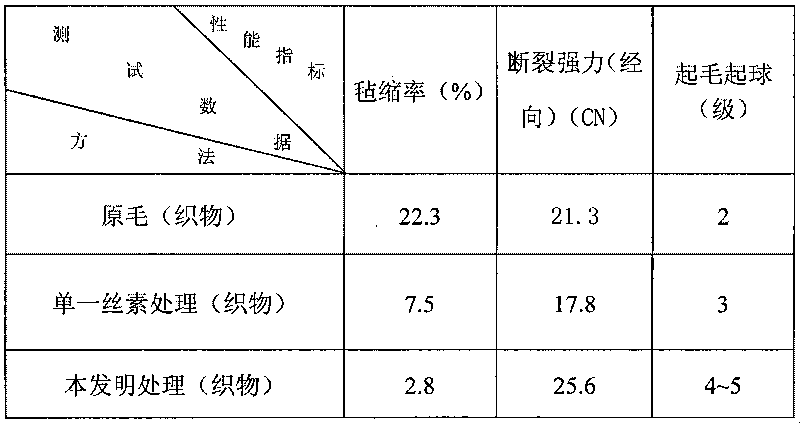

[0040] table 3

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com