Polyether amide modified silicane sol, preparation method and use thereof

A polyetheramine, propyl trimethoxysiloxane sol technology, applied in textiles and papermaking, fiber processing, animal fibers, etc., can solve the problems of wool fabric damage, wool fabric feel hard, not meeting the requirements of cleaner production, etc. , to achieve the effect of improving softness, washability and anti-felt shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

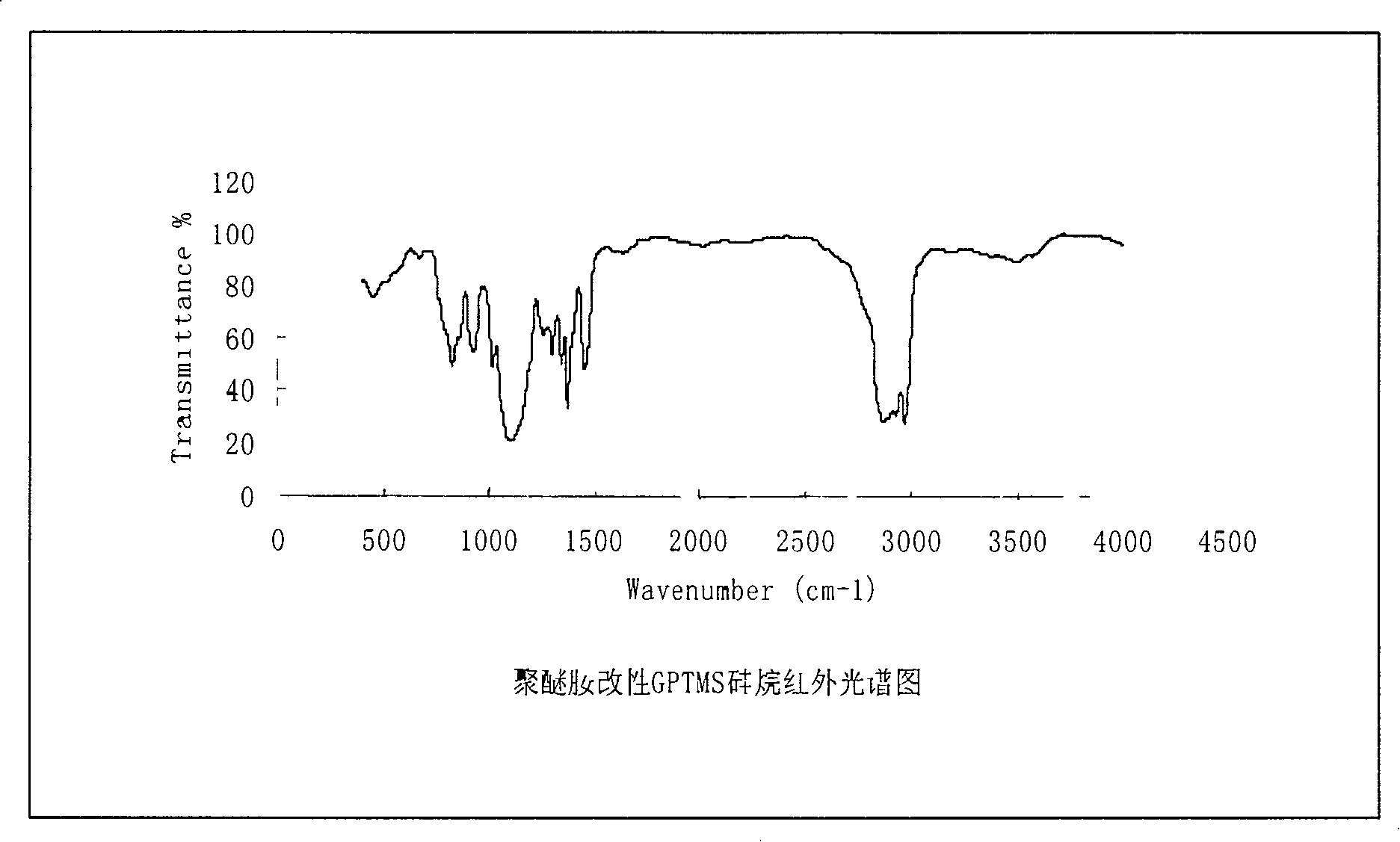

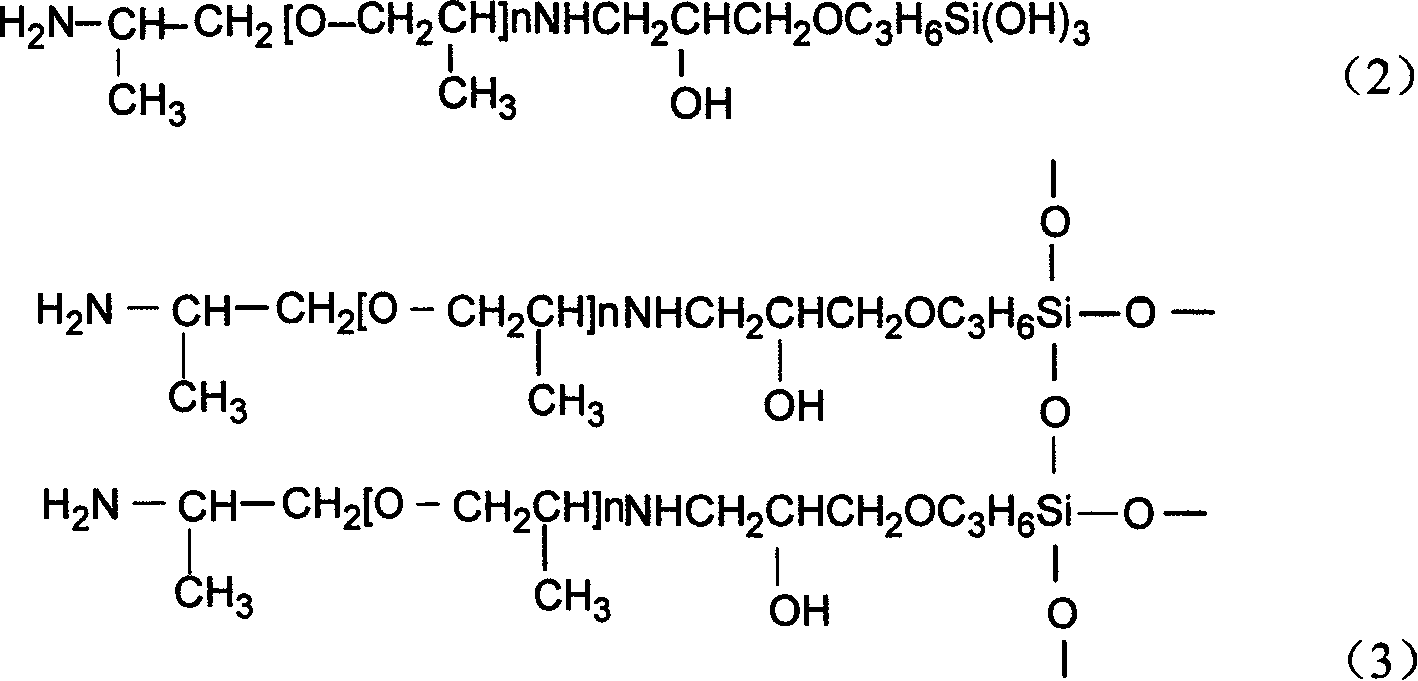

[0030] Preparation of polyetheramine (molecular weight 400) modified γ-(2,3-glycidoxy)propyltrimethoxysilane.

[0031] At 80°C, 29.5 grams of γ-(2,3-glycidoxy)propyltrimethoxysilane was added dropwise to 52.46 grams of polyetheramine with a molecular weight of 400 within 0.5 hours. Keep the polyetheramine solution stirred evenly under the heating condition of 80°C. After the dropwise addition is completed, continue to stir under the same conditions for 2 hours to obtain the polyetheramine modified γ-(2,3-glycidoxy)propyl Precursor of trimethoxysilane.

Embodiment 2

[0033] Preparation of polyetheramine (molecular weight: 2000) modified γ-(2,3-glycidoxy)propyltrimethoxysilane.

[0034] At 85°C, 20 grams of γ-(2,3-glycidoxy)propyltrimethoxysilane was added dropwise to 177.9 grams of polyetheramine with a molecular weight of 2000 within 1 hour. Keep the polyetheramine solution stirred evenly under the heating condition of 85°C. After the dropwise addition is completed, continue to stir under the same conditions for 1.5 hours to obtain the polyetheramine modified γ-(2,3-glycidoxy)propyl Precursor of trimethoxysilane.

Embodiment 3

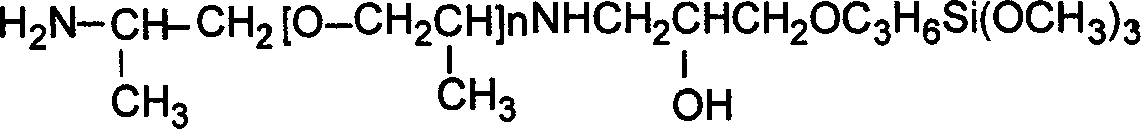

[0036] (1) Preparation of sol

[0037] will contain 40ml water and 40ml C 1-4 Add the alcohol aqueous solution of alcohol dropwise to 20ml of the polyetheramine modified precursor solution in Example 1, complete the dropwise addition within 1 hour under normal temperature stirring conditions, then continue to stir for 1 hour, adjust the pH to 3-4, and place it for aging After several hours of curing, a transparent stable sol with a hydrolyzate content greater than 50% was obtained.

[0038] (2) Anti-felting finish

[0039] Dip all wool gabardine twice in the above sol finishing solution and roll twice, the pressure is 3Kg / cm 2 Then dry in an oven at 80°C for 10 minutes, wash with water and then dry for the second time.

[0040] (3) Anti-felting effect test

[0041] Referring to the IWS TM NO.31 test standard and method, the felt shrinkage can reach within 1-2%.

[0042] (4) Evaluation of softening effect

[0043] Based on subjective evaluation, the softness of the cloth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com