A method for crushing wool fiber scale tips

A wool fiber and crushing method technology, applied in the direction of animal fiber, fiber treatment, anti-shrinkage fiber, etc., can solve the problems of poor alkali resistance of wool fiber, main body damage, harmful wool fiber, etc., and achieve anti-felting performance and dyeing performance. The effect of lifting, weakening the directional friction effect and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for breaking the scale tips of wool fibers:

[0036] (1) Immerse the wool fiber in the nano-barium titanate suspension, and pretreat it for 60 minutes under the action of 40 kHz frequency ultrasonic vibration at a temperature of 50°C. Stir continuously during soaking. Wherein, the pretreatment suspension includes the following components in weight percentage: 1% of nano-barium titanate particles, and the balance is deionized water.

[0037] (2) Spin dry the pretreated wool fiber in step (1) until no water comes out, then put it into a microwave vacuum drier for microwave treatment. Microwave treatment temperature: 40°C, vacuum degree: -0.09MPa, treatment time: 6min, microwave power 1000W.

[0038] (3) Immerse the wool fiber after the microwave treatment in step (2) in deionized water, and perform ultrasonic cleaning at 50° C. with 40 kHz ultrasonic vibration for 30 min. Change the water every 5 minutes during the cleaning process.

[0039] (4) Dry the wool ...

Embodiment 2

[0041] A method for breaking the scale tips of wool fibers:

[0042] (1) Immerse the wool fiber in the nano-barium titanate suspension, and pretreat it for 30 minutes under the action of 40 kHz frequency ultrasonic vibration at a temperature of 60°C. Stir continuously during soaking. Wherein, the pretreatment suspension includes the following components in weight percentage: 5% of nano-barium titanate particles, and the balance is deionized water.

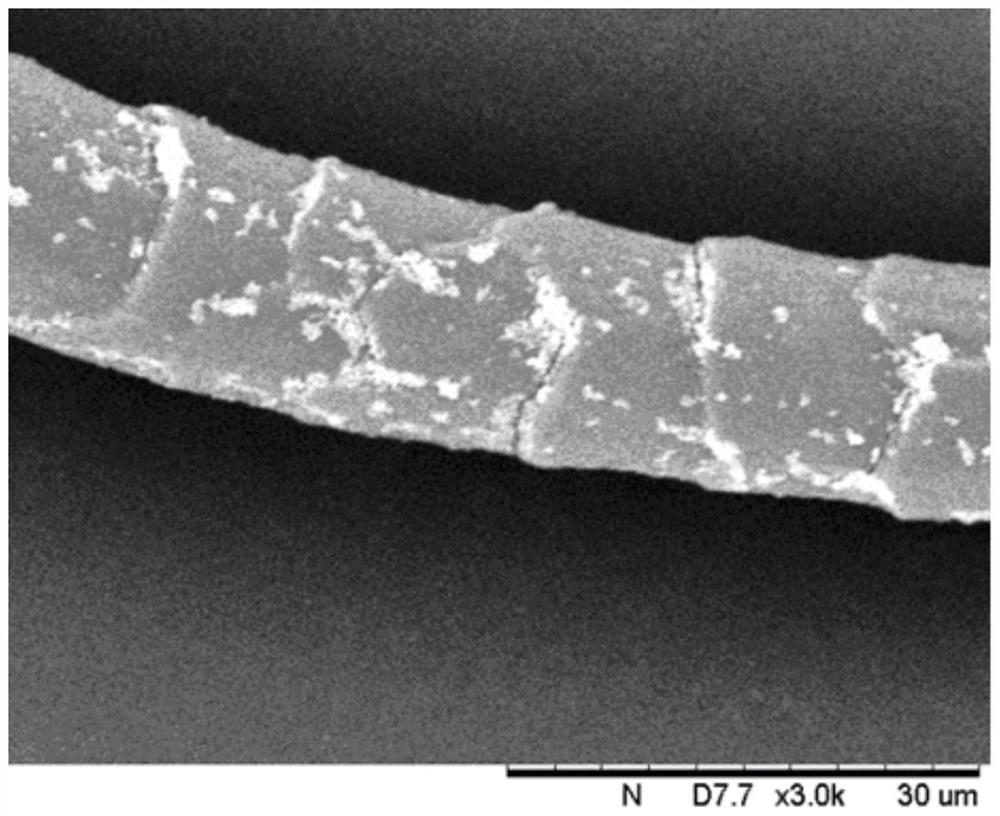

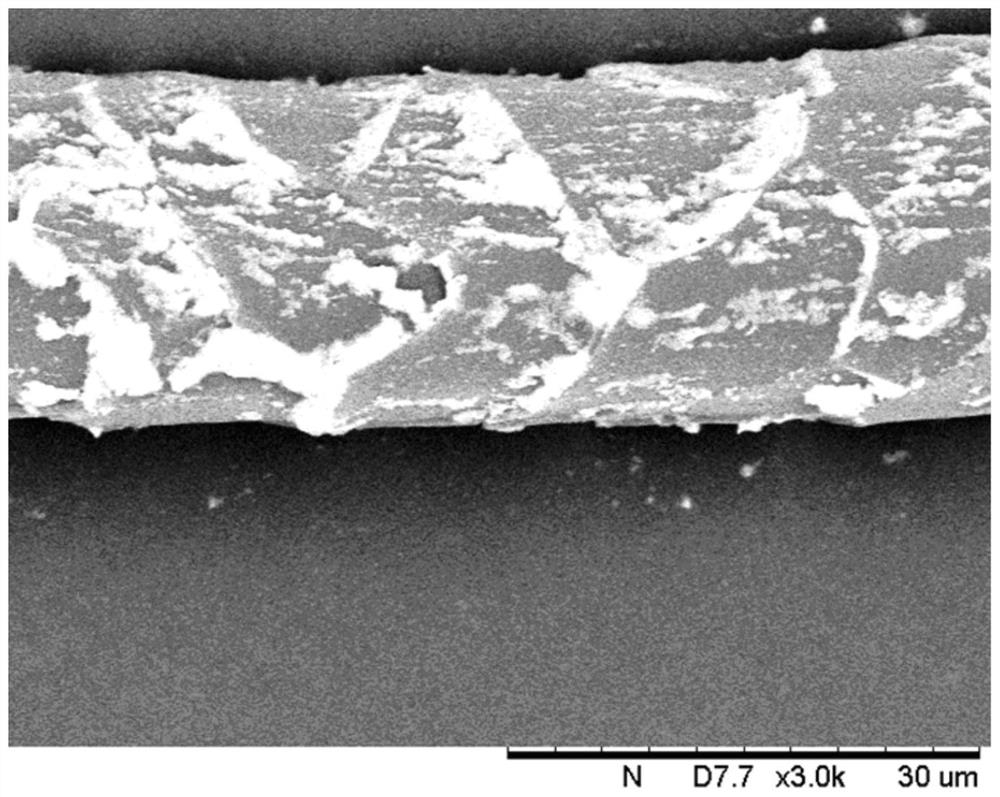

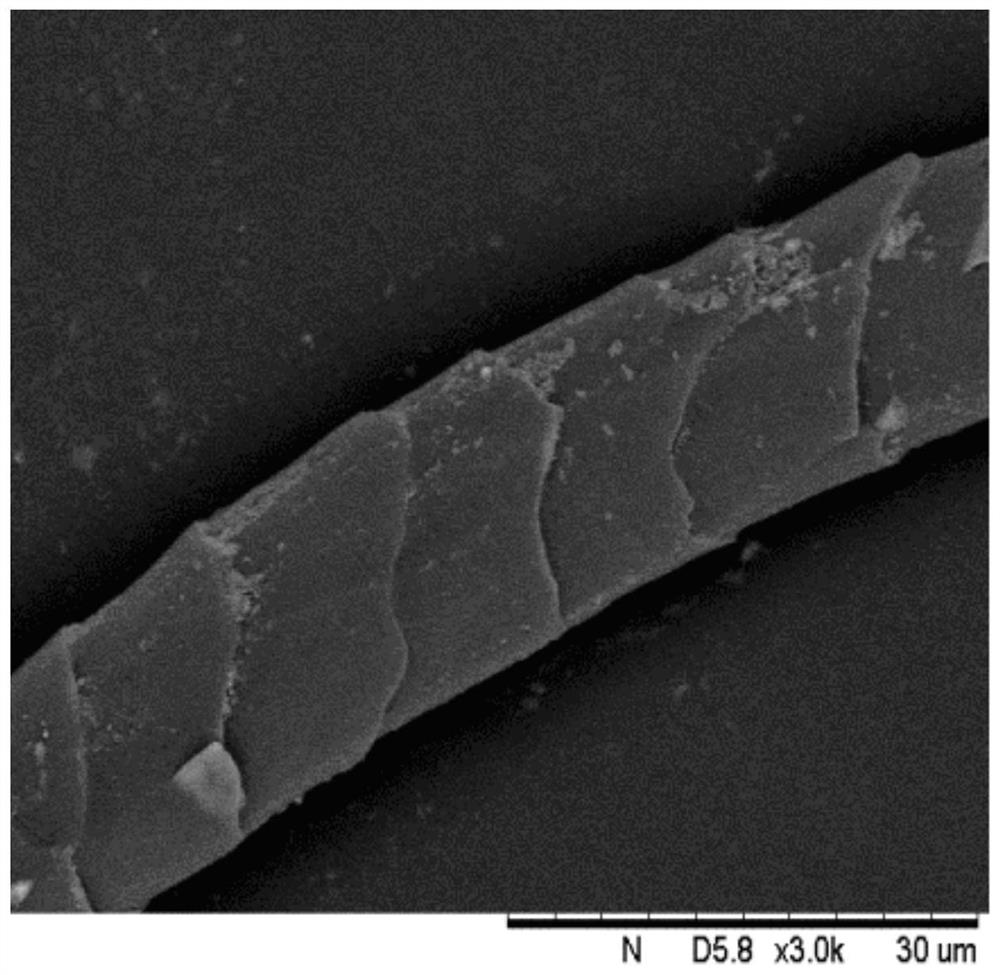

[0043] (3) Spin dry the pretreated wool fiber in step (1) until water does not come out, and then put it into a microwave vacuum dryer for microwave treatment. Microwave treatment temperature: 40°C, vacuum degree: -0.075MPa, treatment time: 10min, microwave power 1000W. Wool fibers before and after treatment are as follows: figure 1 , 2 shown.

[0044] (4) Immerse the wool fiber after the microwave treatment in step (3) into deionized water, and perform ultrasonic cleaning at 40° C. with 40 kHz ultrasonic vibration for 60 min....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com