Thin breathable warm fabric and manufacture method thereof

A kind of fabric, light and thin technology, applied in the field of textile fabrics and processing, can solve the problems of static electricity, reduce heat generation, fleece fabrics are prone to hair loss, etc., and achieve the effect of antistatic warmth, light weight, and full touch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

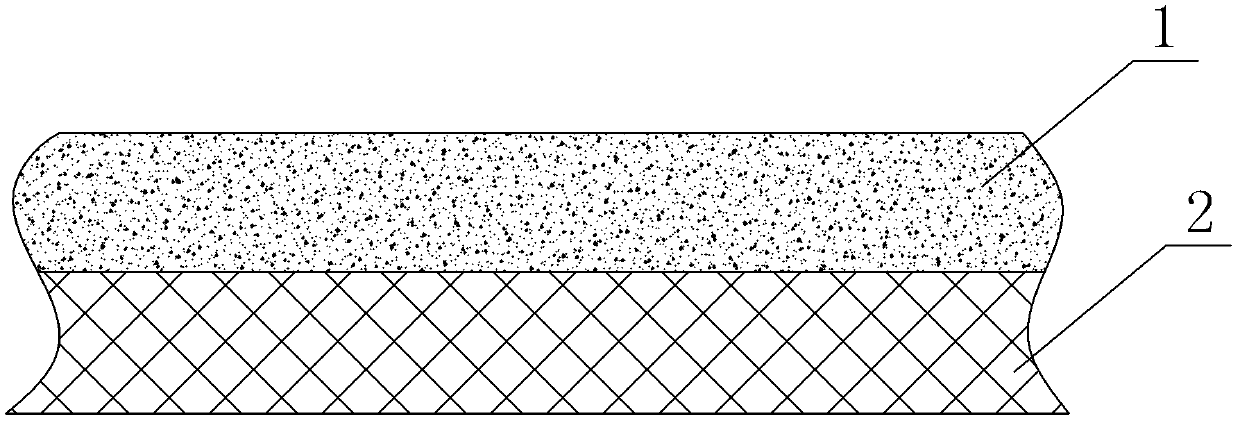

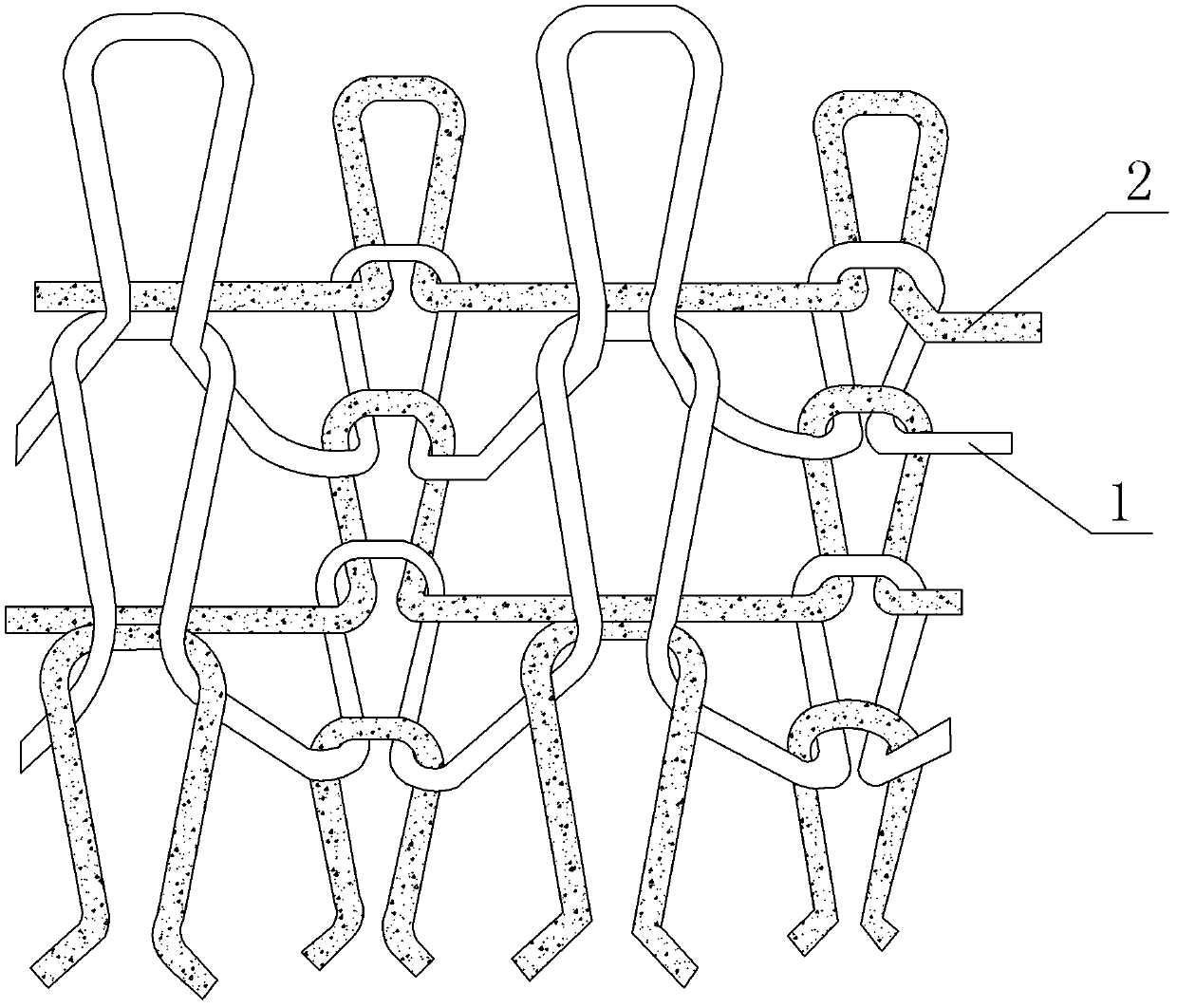

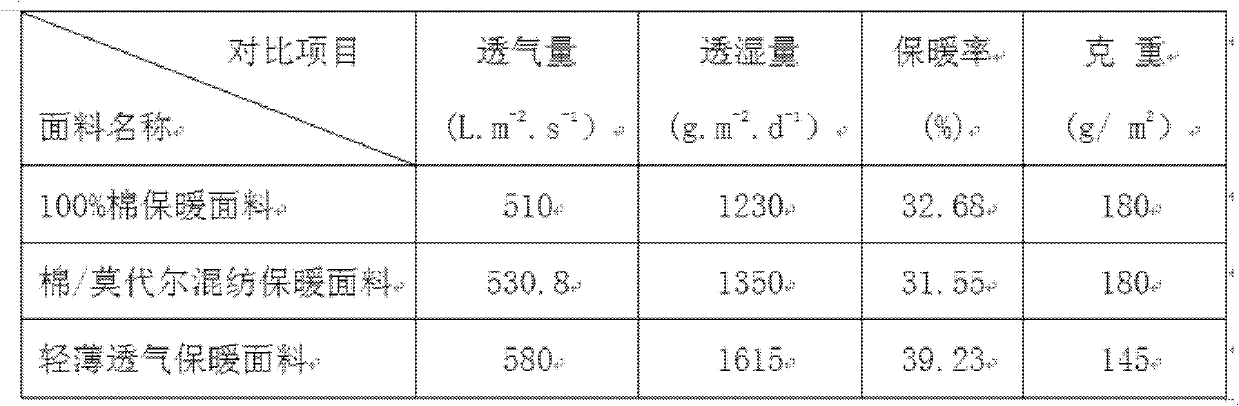

[0035] See Figure 1 ~ Figure 2 As shown, a lightweight, breathable and warmth-keeping fabric is composed of a surface layer fabric 1 and an inner layer fabric 2. The inner layer 2 is a moisture-absorbing and heating layer, and the surface layer 1 is a warm and breathable and moisture-conducting layer; the moisture-absorbing and heating layer is composed of 30% moisture-absorbing and heating EKS fiber is blended with 70% ordinary acrylic fiber, and the heat-retaining, breathable and moisture-conducting layer is blended with 20% expanded acrylic fiber, 50% superfine acrylic fiber and 30% modal fiber.

[0036] The inner layer fabric 2 composed of 30% moisture-absorbing and heat-generating EKS fiber and 70% ordinary acrylic fiber blended is a sanded fabric that has undergone a sanding treatment.

[0037] Another technical problem solved by the present invention is to provide a method for manufacturing a thin, breathable and warm fabric. The steps are as follows:

[0038] 1. Yarn prepar...

Embodiment 2

[0052] A light and thin air-permeable and warm-keeping fabric. The difference from Example 1 is that the moisture-absorbing and heating layer is composed of 60% moisture-absorbing and heating-generating EKS fiber and 40% ordinary acrylic fiber blended. Body acrylic fiber blended with 60% superfine acrylic fiber.

[0053] The inner layer fabric 2 composed of 60% moisture-absorbing and heat-generating EKS fiber and 40% ordinary acrylic fiber blended is a sanded fabric that has undergone a sanding treatment.

[0054] Another technical problem solved by the present invention is to provide a method for manufacturing a thin, breathable and warm fabric. The steps are as follows:

[0055] 1. Yarn preparation:

[0056] After mixing 40% expanded acrylic fiber and 60% superfine acrylic fiber, the yarn count is 80S and Z-twisted by the Siro spinning process as the surface layer of the fabric for use;

[0057] At the same time, after mixing 60% moisture-absorbing and heat-generating EKS fiber with ...

Embodiment 3

[0069] A light and thin air-permeable and warm-keeping fabric. The difference from Example 1 is that the moisture-absorbing and heating layer is composed of 45% moisture-absorbing and heating-generating EKS fiber and 55% ordinary acrylic fiber blended, and the warm and breathable and moisture-conducting layer is made of 27.5% expansion. Body acrylic fiber, 40% ultrafine acrylic fiber and 32.5% modal fiber blended.

[0070] The inner layer fabric 2 composed of 45% moisture-absorbing and heat-generating EKS fiber and 55% ordinary acrylic fiber blended is a brushed fabric that has been subjected to a brushing treatment.

[0071] Another technical problem solved by the present invention is to provide a method for manufacturing a thin, breathable and warm fabric. The steps are as follows:

[0072] 1. Yarn preparation:

[0073] After mixing 27.5% expanded acrylic fiber, 40% ultrafine acrylic fiber and 32.5% modal fiber, the yarn count is 30S and Z twist is made by the Siro spinning process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com