Patents

Literature

81results about How to "Anti-shedding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

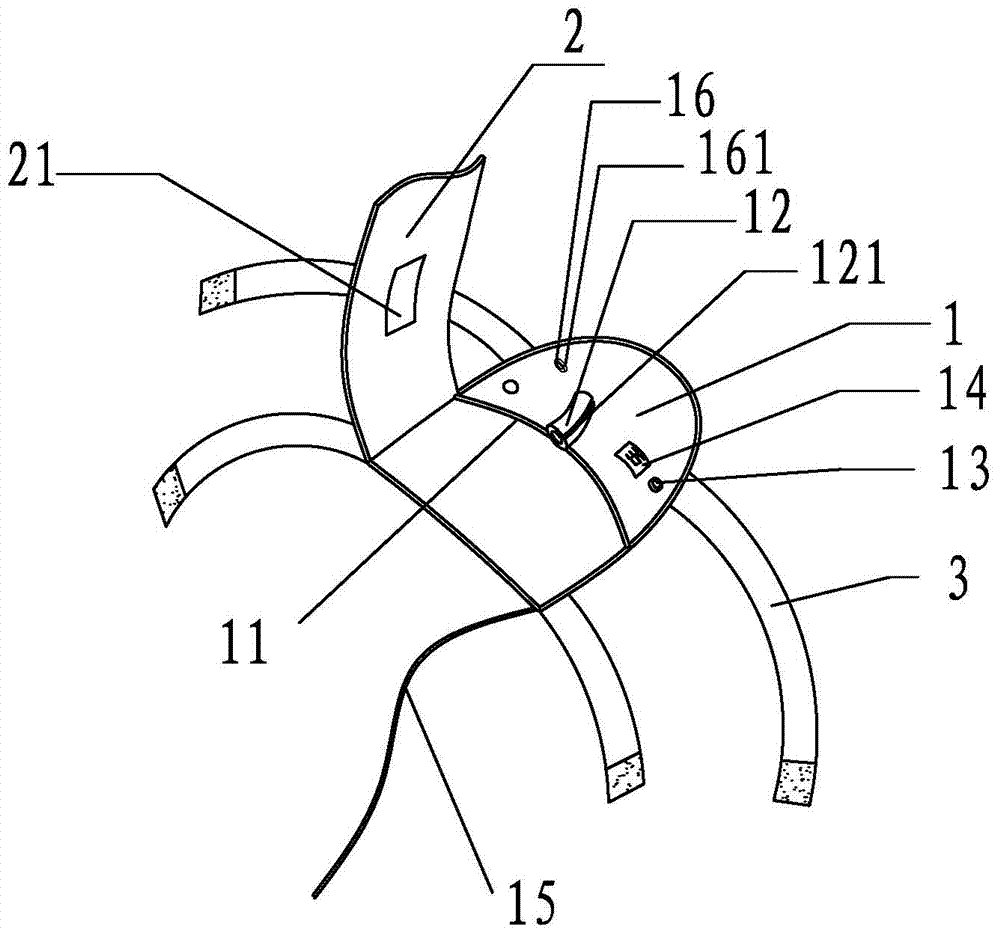

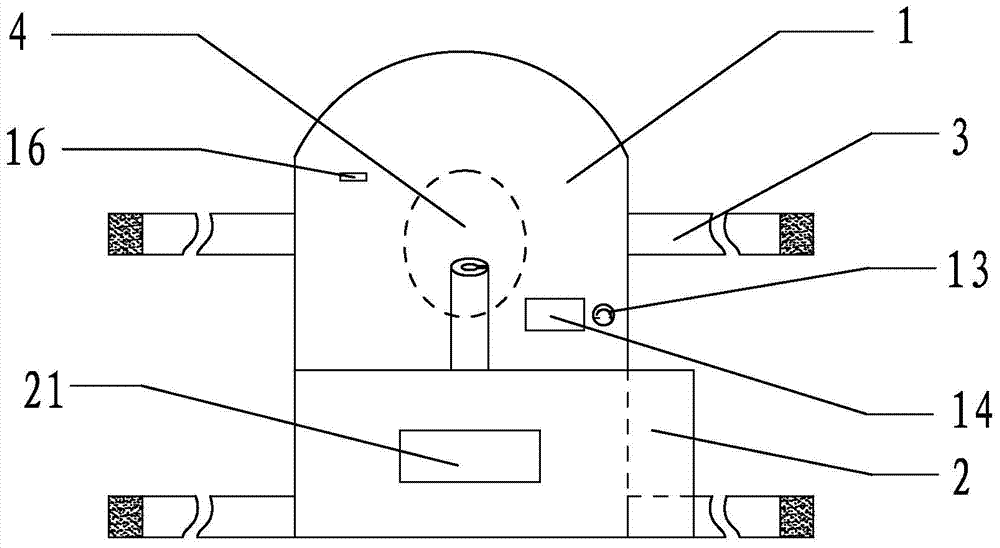

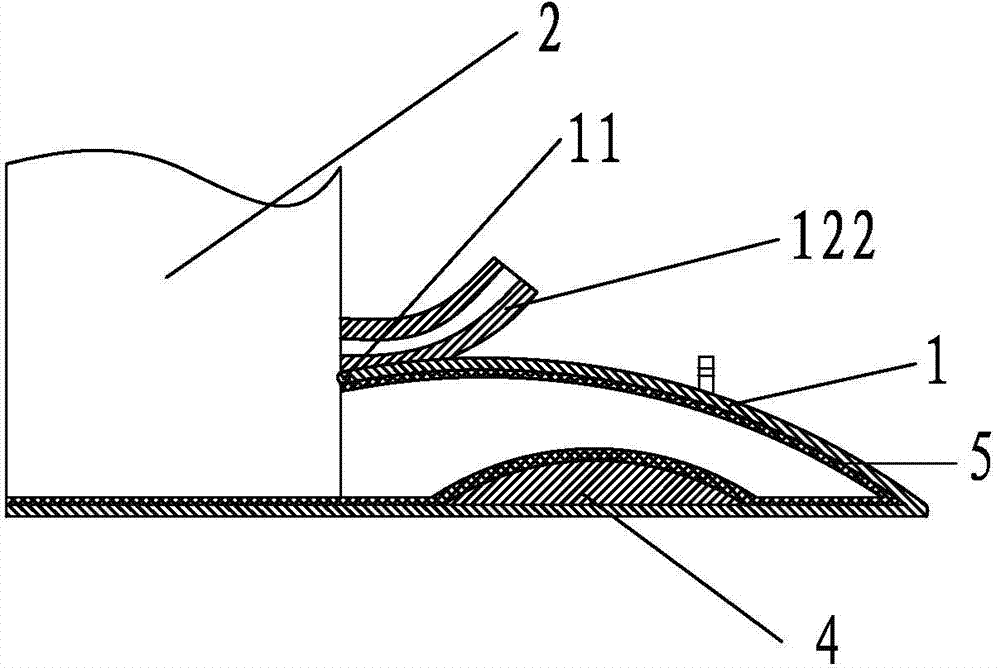

Internal tectorial membrane made by electrospinning for duodenum

The invention provides an internal tectorial membrane for duodenum, and relates to a built-in degradable medical instrument in a digestive tract. The internal tectorial membrane can be made of biocompatible materials by electrospinning. The internal tectorial membrane is placed in the duodenum of a patient, not only can stop food from contacting with the intestinal mucosae of the patient during dissection, but also avoids affecting functions of cells of the intestinal mucosae physiologically, can be obtained by hybrid electrospinning or / and multi-layered electrospinning or / and core-shell electrospinning or / and dry-method electrospinning, and can be manufactured into a medical instrument which can reduce injury, prevent dropping, avoid being removed and restrain bounce and can be used for treating diabetes mellitus and adiposis.

Owner:万平

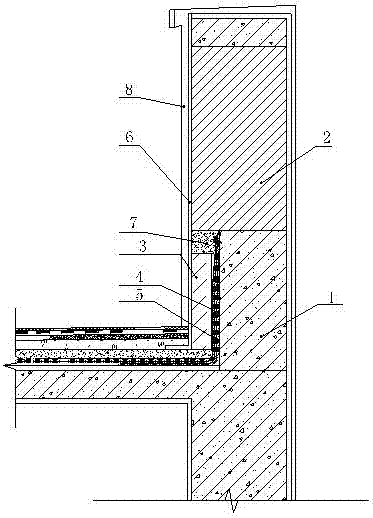

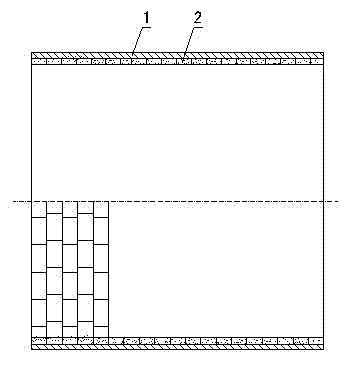

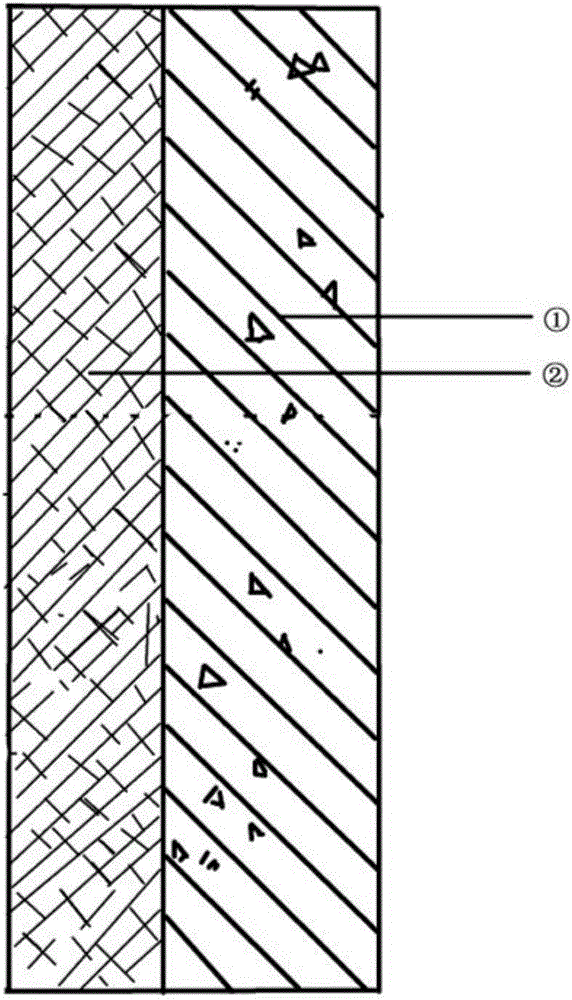

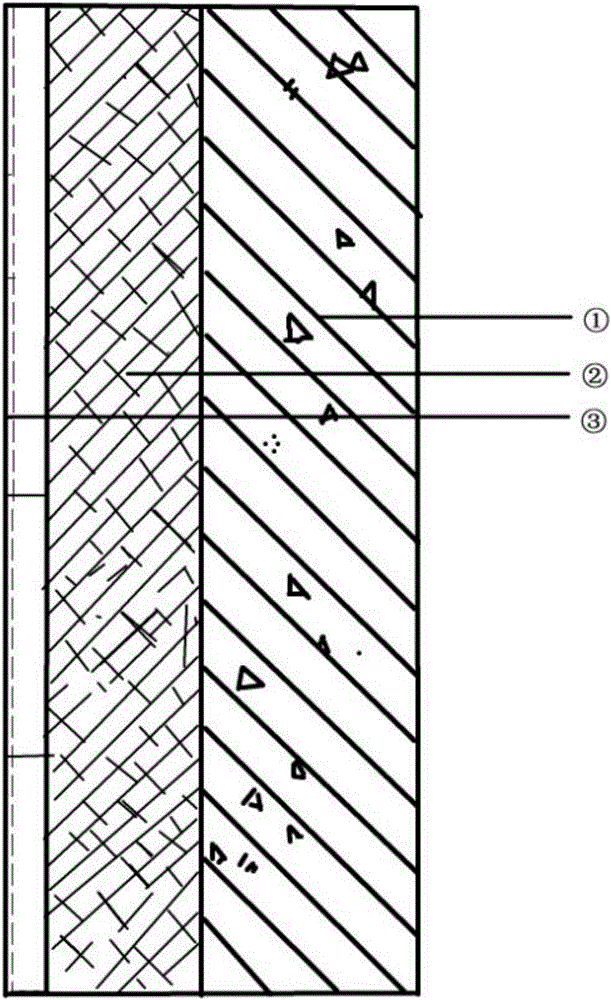

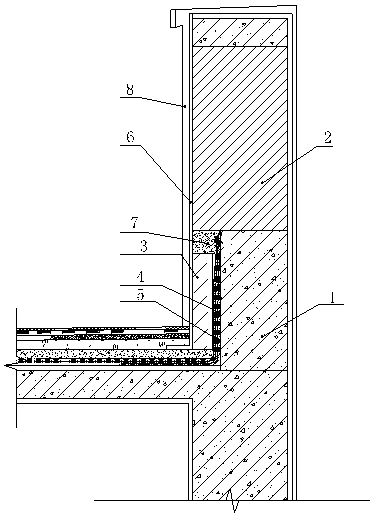

Building roof parapet wall flashing construction process

ActiveCN106906962ALow costEconomical cost, convenient operation and economicalSnow trapsBrickReinforced concrete

The invention relates to a flashing structure construction process, in particular to a building roof parapet wall flashing construction process. The building roof parapet wall flashing construction process comprises the following steps that step one, a flashing wall body of a reinforced concrete structure is poured on a building roof; step two, a waterproof roll is paved and pasted on the inner facades of the roof and the flashing wall body to form a waterproof layer, and the upper end of the waterproof roll is subjected to head retraction treatment; step three, a protective brick wall is laid on the outer facade of the waterproof layer through solid bricks, the inner facade of the protective brick wall is tightly attached to the waterproof roll, and the waterproof roll is tightly pressed on the flashing wall body, wherein the protective brick wall is no larger than the flashing wall body; and step four, a parapet wall is laid on the flashing wall body through solid bricks on the basis of the top of the flashing wall body, wherein the thickness of the wall body of the parapet wall is equal to the distance between the outer facade of the flashing wall body and the outer facade of the protective brick wall. A flashing structure built through the building roof parapet wall flashing construction process has the advantages of being resistant to cracking and falling-off and long in guarantee period and is convenient to construct and low in cost, and materials are convenient to obtain.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

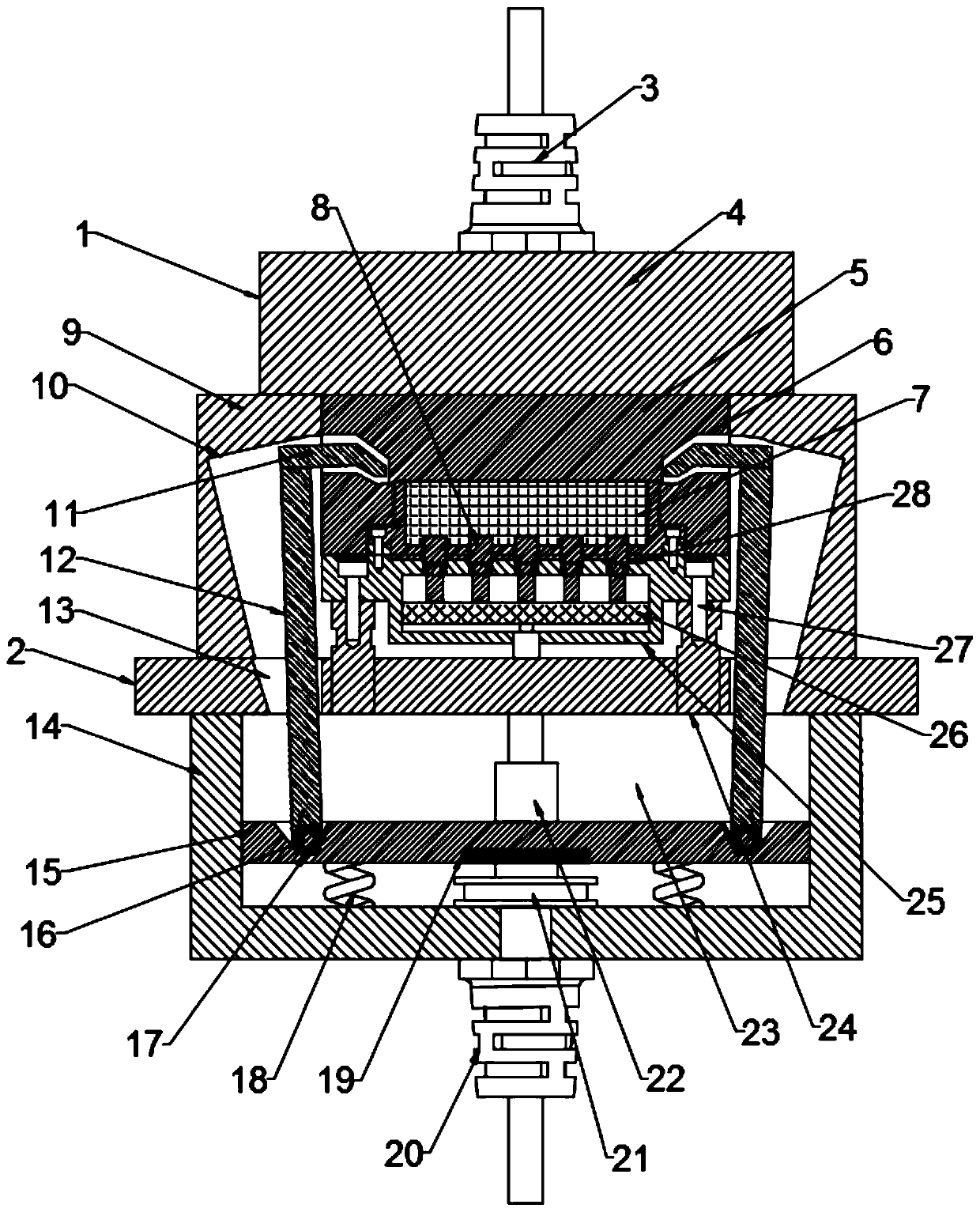

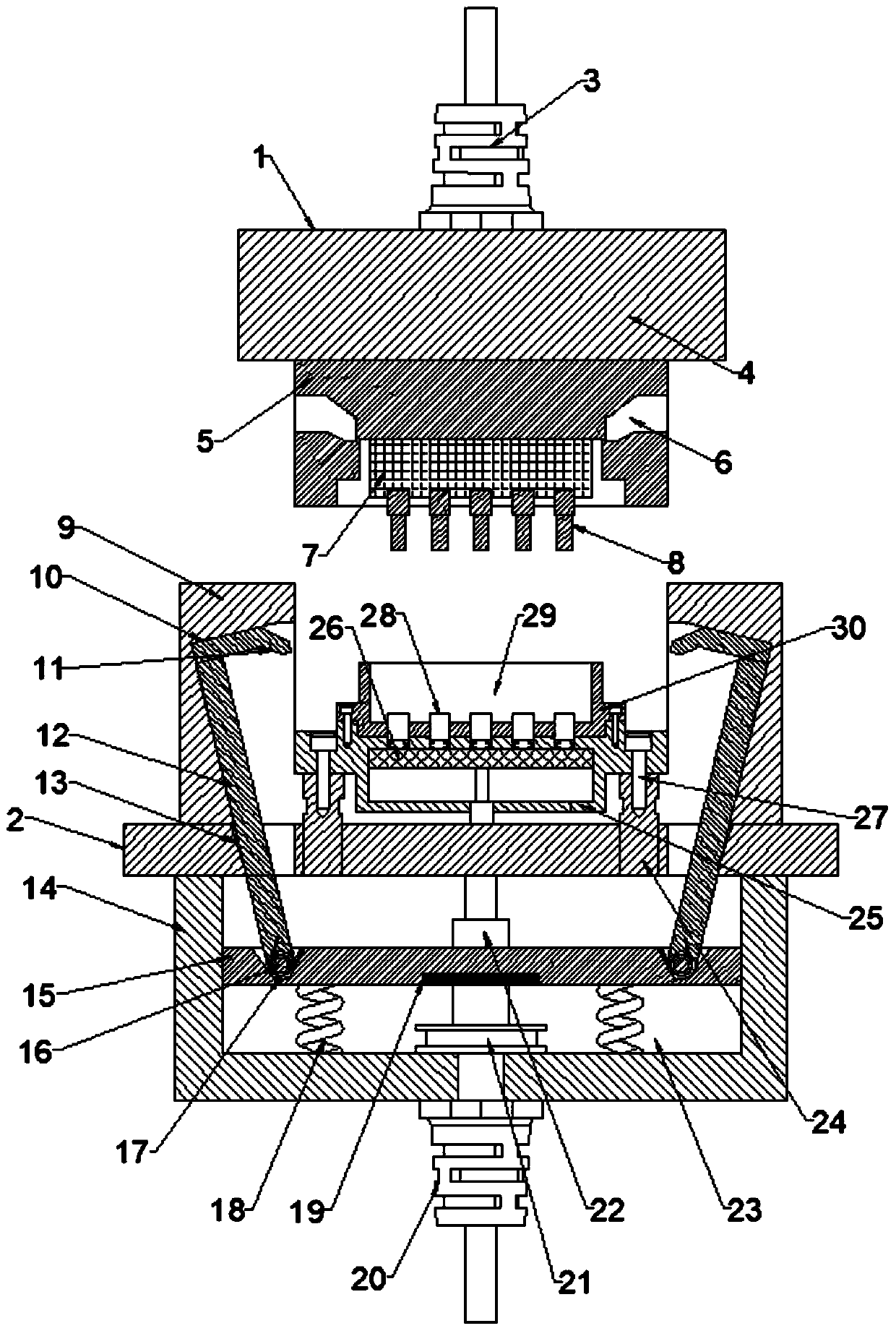

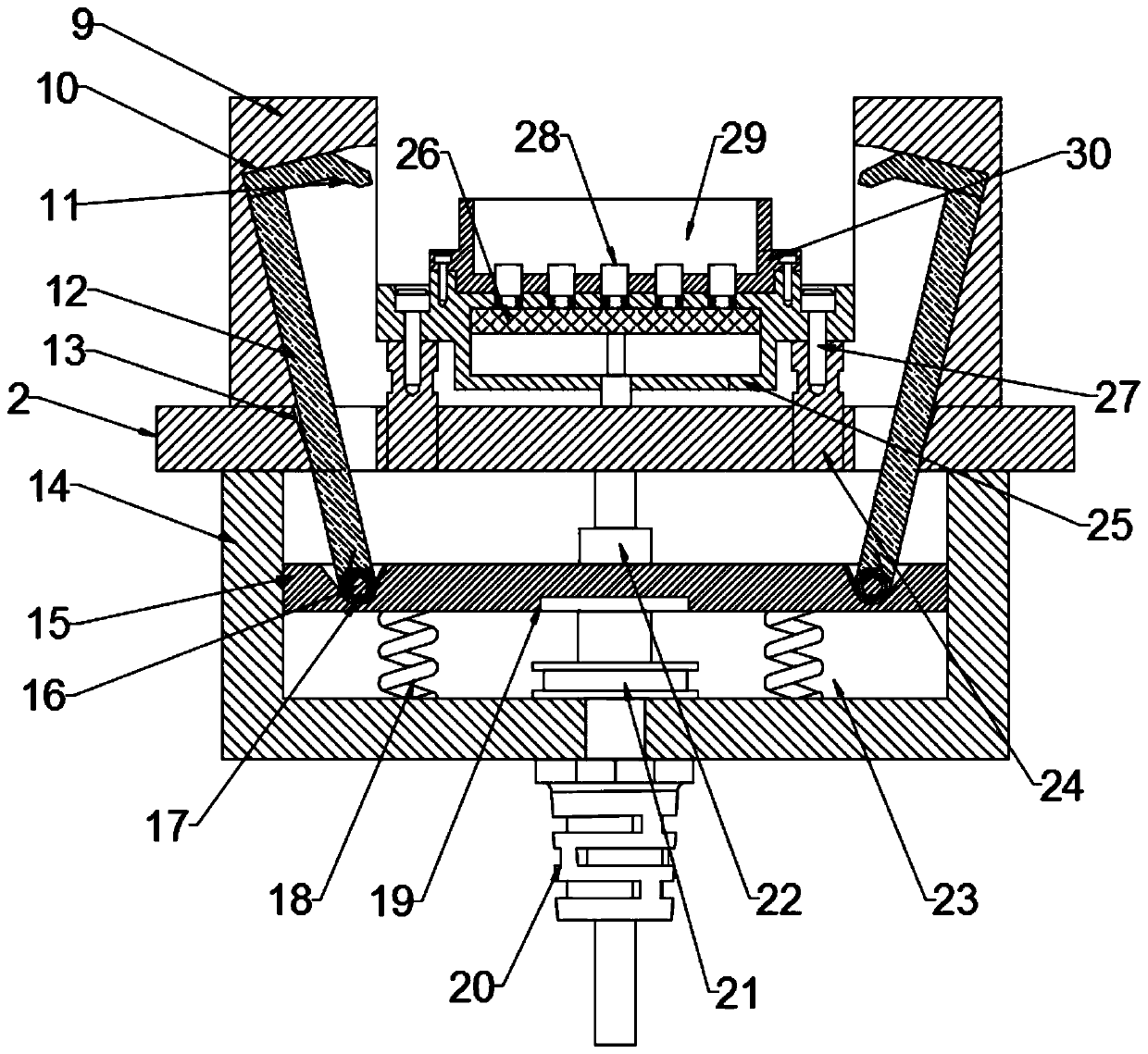

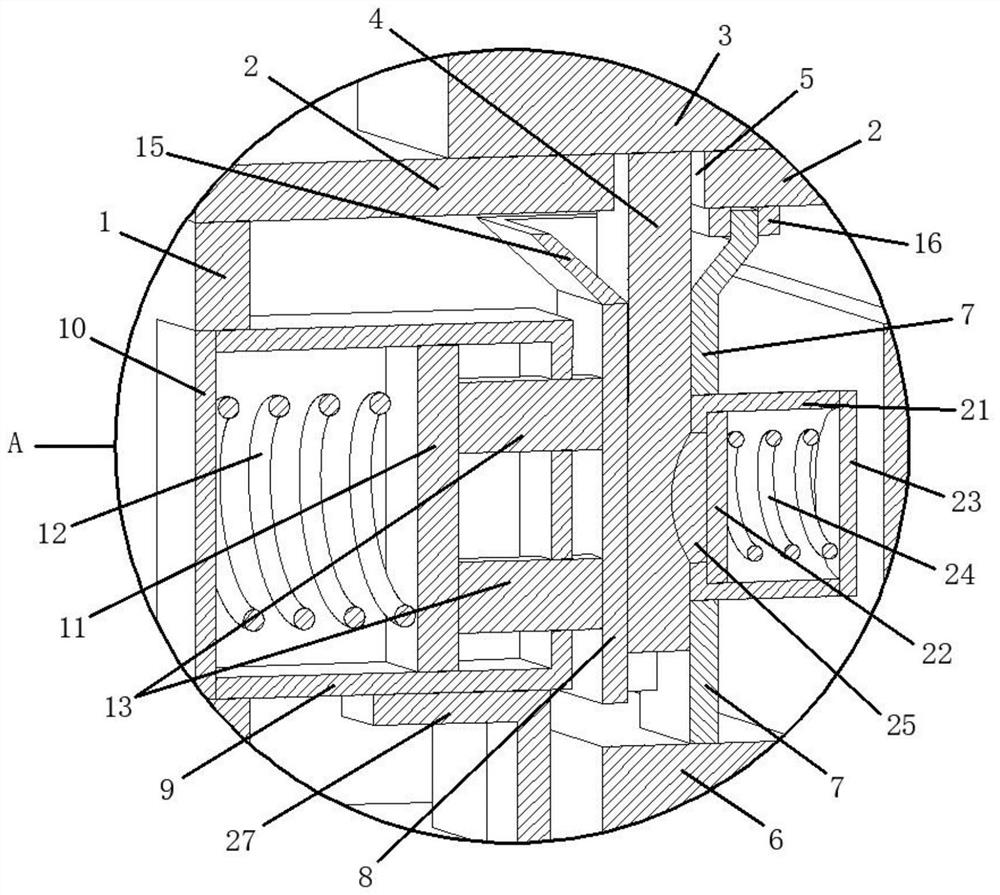

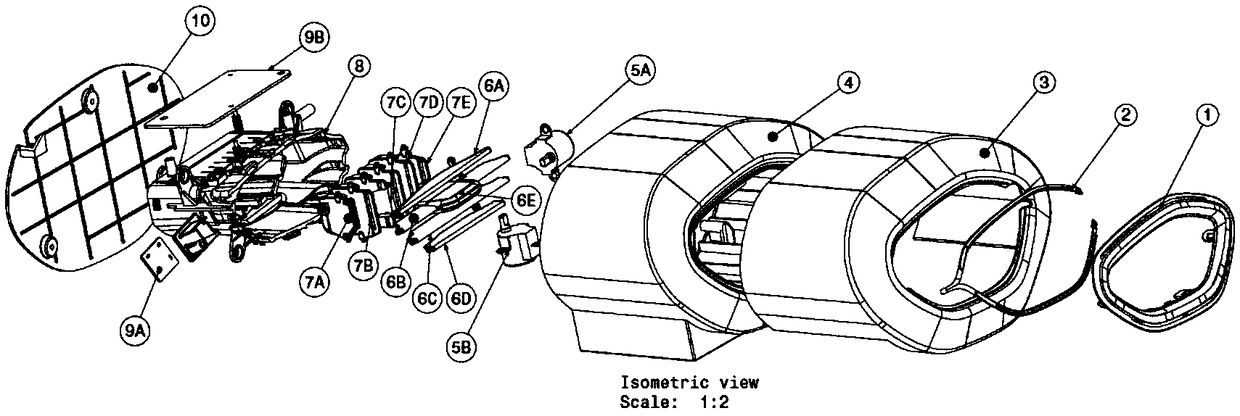

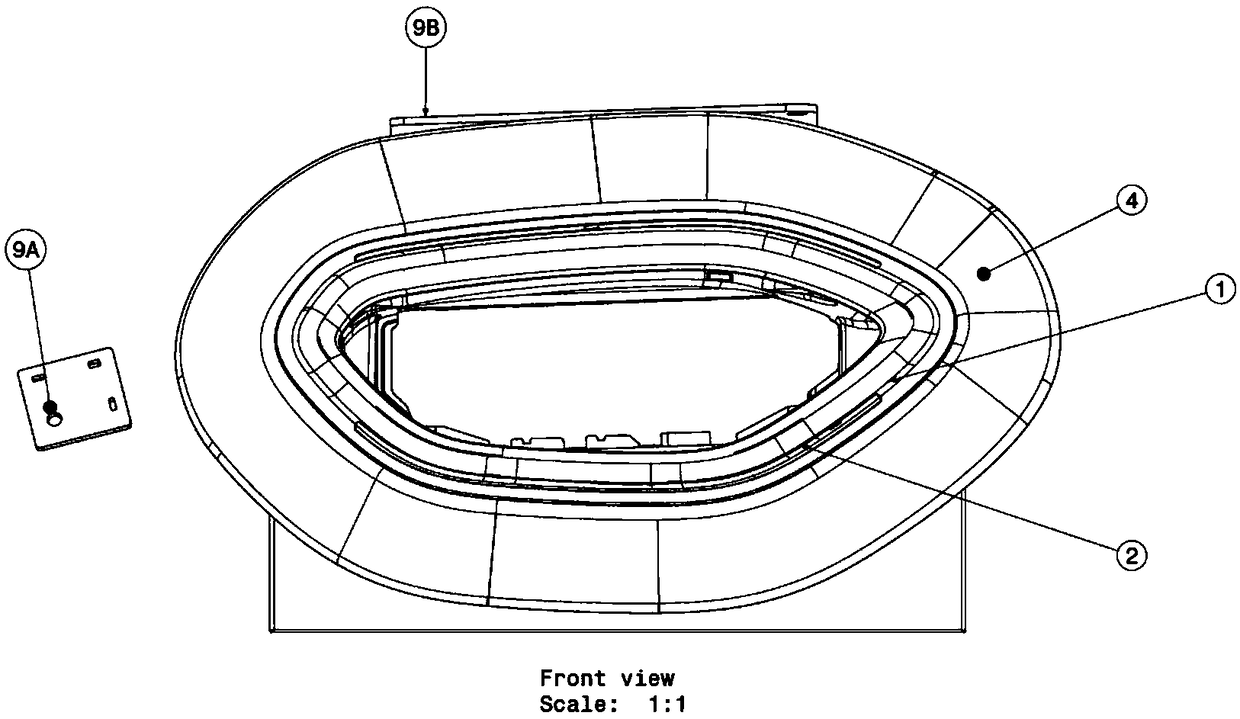

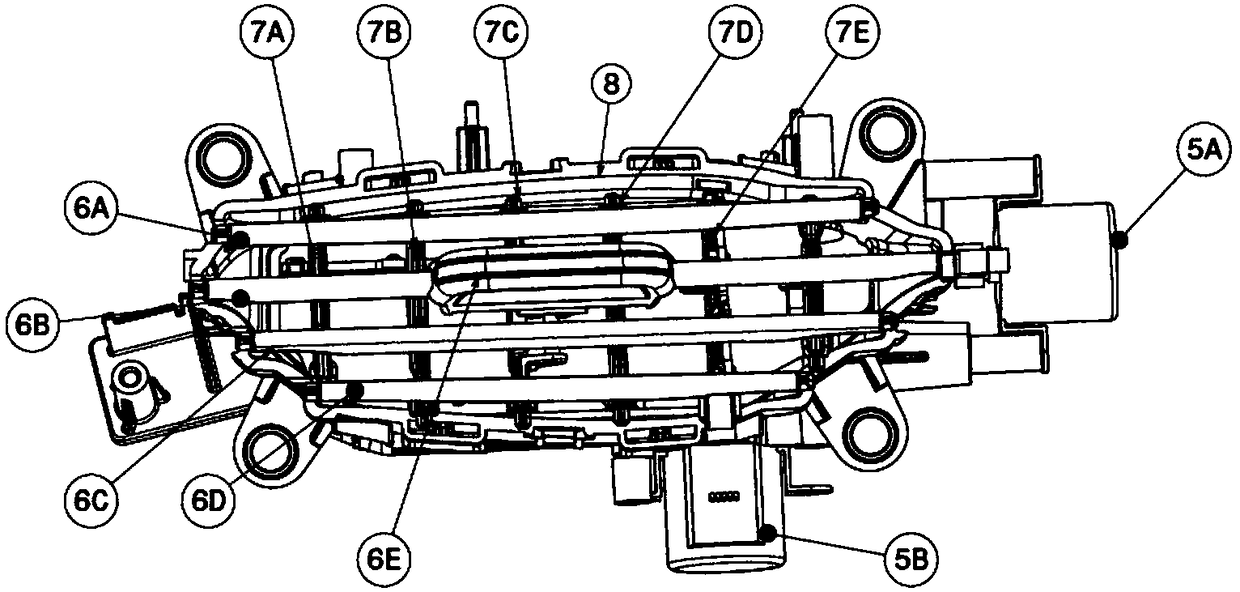

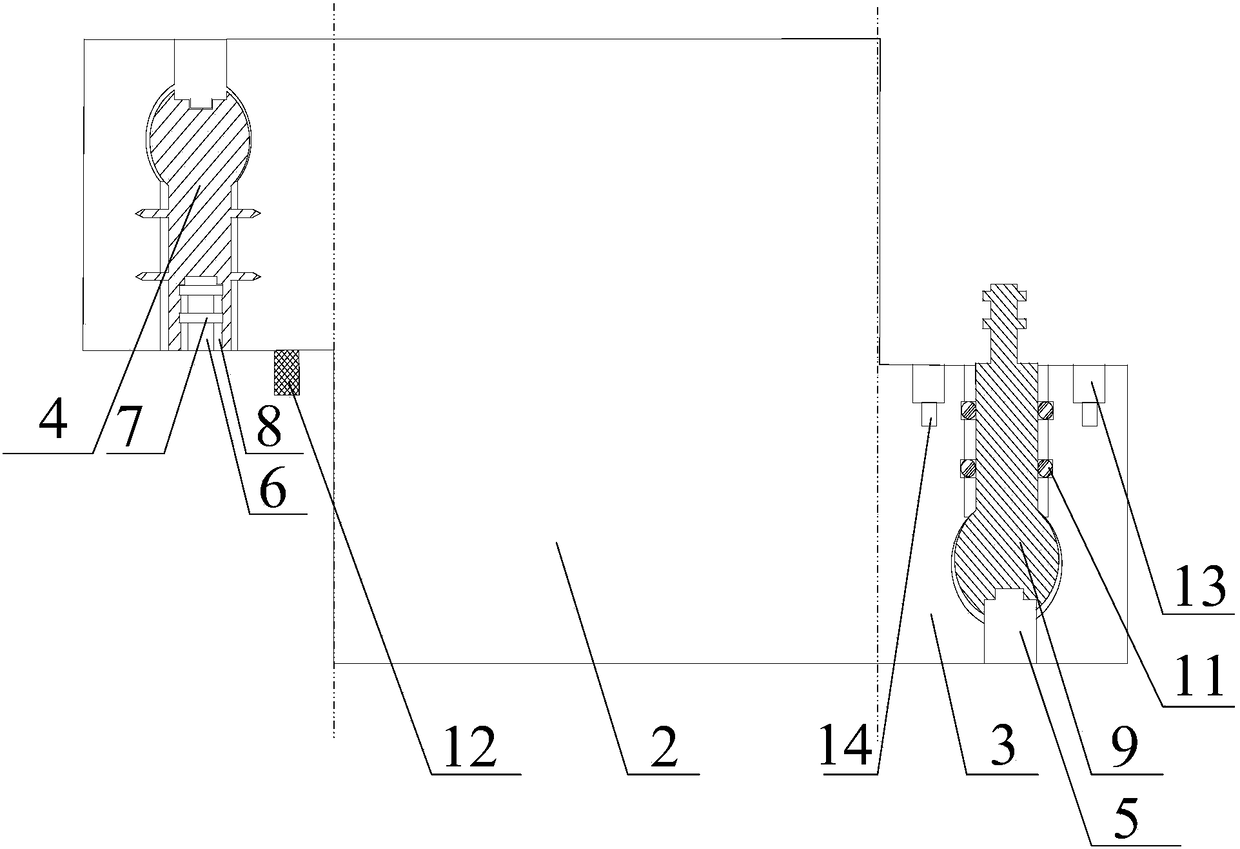

Computer interface magnetic attraction assembly and anti-falling computer interface device

InactiveCN111370939AAnti-sheddingImprove stabilityEngagement/disengagement of coupling partsComputer periphery connectorsMechanical engineeringPhysics

The invention discloses an anti-falling computer interface device. The invention belongs to the technical field of computers, and the problem that when the computer interface is connected with the plug, the computer interface is easily dragged off due to external force is solved; the device is characterized by comprising a computer interface magnetic attraction assembly, a plug mechanism and an interface mechanism, clamping arms of the computer interface magnetic attraction assembly are symmetrically arranged on the lifting plate. The clamping arms are connected with a clamping jaw; a computerinterface magnetic attraction assembly provided with the clamping jaw and the clamping arms is installed on an interface mechanism. According to the invention, the anti-falling clamping grooves usedfor clamping the clamping jaws are formed in the plug mechanism, after the plug mechanism is inserted into the interface mechanism, the clamping jaws are clamped into the anti-falling clamping grooves, falling prevention of the computer interface device is achieved, stability is good, the plug mechanism is effectively prevented from being dragged by external force to fall off, and the anti-fallingeffect is good.

Owner:ZHEJIANG GUANGSHA COLLEGE OF APPLIED CONSTRTECH

Environmental-protection energy-saving thermal-insulated external-wall coating

InactiveCN1850922AImprove fire characteristicsHigh quality fire protection propertiesCellulose coatingsEmulsion paintsPolyvinyl alcoholSlurry

The invention supplies a environment protection energy saving heat preservation exterior wall coating material that contains polyvinyl alcohol 5-10%, acryloid cement 20-40%, cellulose liquor 10-20%, wollastonite in powder 10-30%, see-bubble powder 2-5%, asbestos fiber 1-4%, expanded perlite 5-12%, and water 10-30%. The raw material taking fully mixing to form thick slurry, it could be coated onto the wall. The invention has strong adhesion, high alkali resistance and high water resistance.

Owner:福建创美新材料科技有限公司

Heat preservation glove for safe infusion

The invention discloses a heat preservation glove for safe infusion. The heat preservation glove for the safe infusion comprises a glove body, a front palm heat preservation part is arranged on the heat portion of the glove body, and an opening part capable of being opened is arranged on the tail portion of the glove body. The heat preservation glove for the safe infusion is characterized in that a rigid shape fixing bar is arranged on the boundary of the tail end of the front palm heat preservation portion, an infusion tube fixing tube is arranged on the rigid shape fixing bar, the head portion of the infusion tube fixing tube is an arc-shaped part, an opening is formed in the side face of the infusion tube fixing tube, and thus medical staff can fix an infusion tube on the heat preservation glove in the infusion process to prevent the situation that a syringe needle drops due to the careless pull of other people.

Owner:平湖市晟丰制衣有限公司

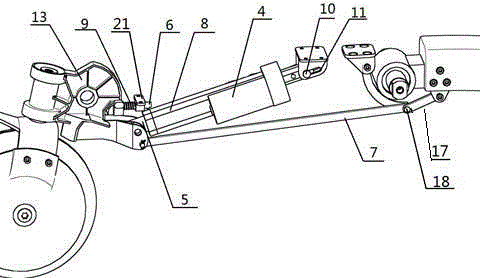

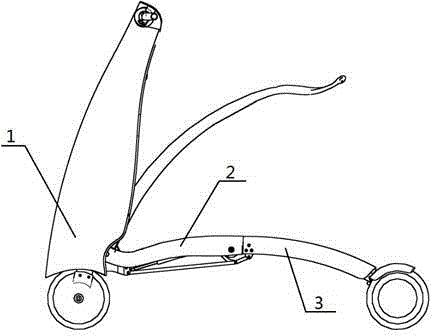

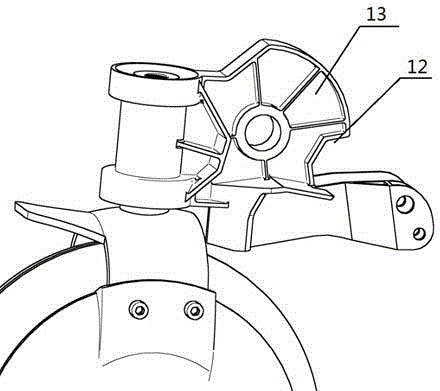

Automatic foldable vehicle

The invention discloses an automatic foldable vehicle. The automatic foldable vehicle comprises a front handle frame, a foldable chassis and a foldable wheel frame, and is characterized in that a driving motor is arranged on the foldable chassis and connected with a telescopic arm, the telescopic arm is connected with a locking pin, the locking pin comprises a spring, the telescopic arm has a reserved travel distance where the locking pin is pulled out of a pin hole, and a connecting rod is arranged between the foldable chassis and the foldable wheel frame. By the application of the automatic foldable vehicle, one-key automatic folding and unfolding of the whole vehicle are achieved, and the automatic foldable vehicle is high in automation degree, rapid and convenient to use, small in size after the being folded in place, small in occupied space and convenient to carry, and saves labor.

Owner:罗梓珊

Water heater water tank inner container fluororesin coating corrosion preventing method

InactiveCN105312215AWith anti-corrosion functionCrack resistantLiquid surface applicatorsAnti-corrosive paintsCorrosion resistantCorrosion prevention

The invention relates to a method for conducting corrosion preventing protection on an inner container of a water heater water tank by adopting a fluororesin coating having a certain flexibility. The fluororesin coating has better protecting performance than an enamel coating. A coating process comprises the three steps of surface pretreatment, coating and sintering. The coated fluororesin coating has the advantages that the fluororesin coating has better corrosion resistance, heat resistance, humidity resistance, abrasion resistance and non-sticking performance compared with the enamel coating of the inner container of a water heater.

Owner:浙江融乐数字化太阳能有限公司

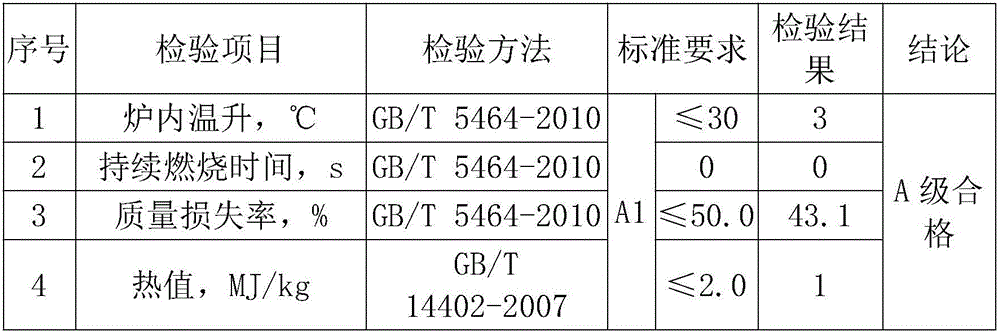

Novel wall heat-preservation and heat-insulation material

The invention relates to a class-A incombustible inorganic active wall heat-preservation and heat-insulation material, which comprises the following raw materials in parts by weight: 12-21 parts of micropore calcium silicate, 15-20 parts of closed pearl pine seeds, 5-11 parts of modified sepiolite, 6-12 parts of lightweight calcium powder, 1-3 parts of industrial synthetic fibers, 8-17 parts of modified lightweight gypsum powder, 5-8 parts of model-24-88 rubber powder, 3-11 parts of wood fibers, 1-3 parts of food film forming agents, 2-6 parts of hydroxymethyl cellulose, 0.2-1.1 parts of sodium formate and 1-2 parts of inorganic solidification agents. The class-A incombustible inorganic active wall heat-preservation and heat-insulation material has the characteristics of heat preservation, heat insulation, fire prevention, light weight, sound insulation, water resistance, cracking resistance, hollowing resistance, falling-off resistance, no cold and hot bridge generated and the like.

Owner:CANGZHOU DONGLE THERMAL INSULATION MATERIAL

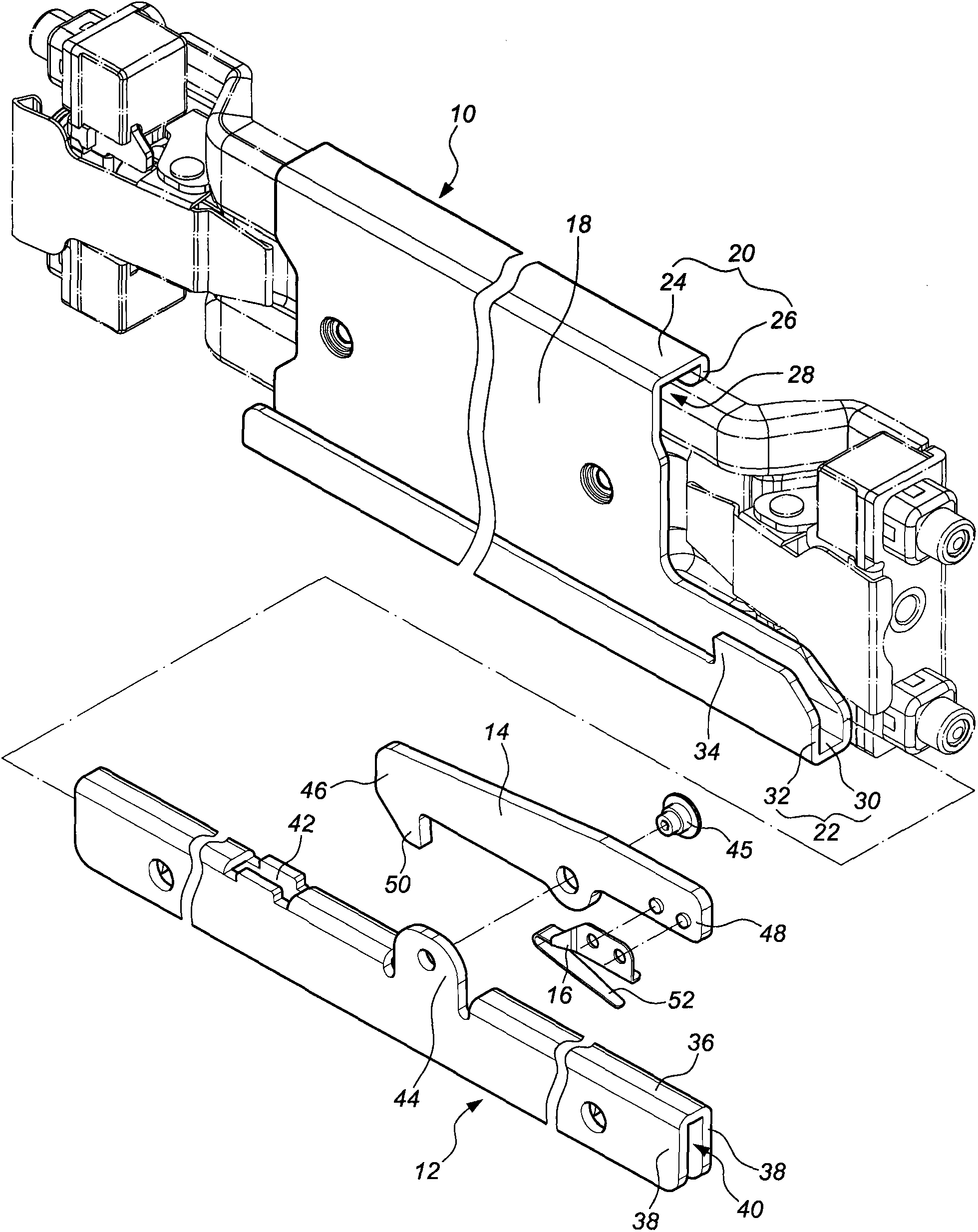

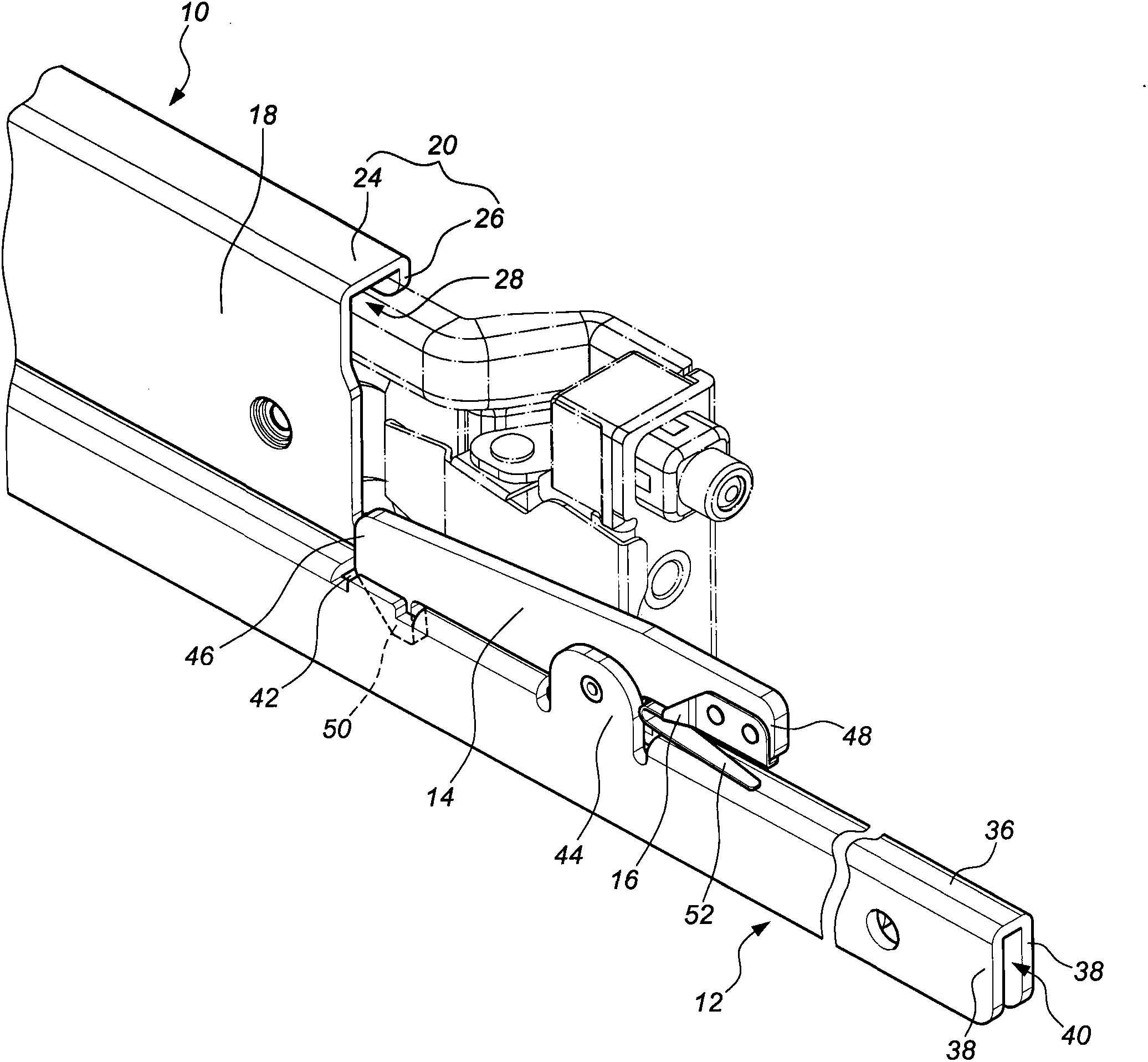

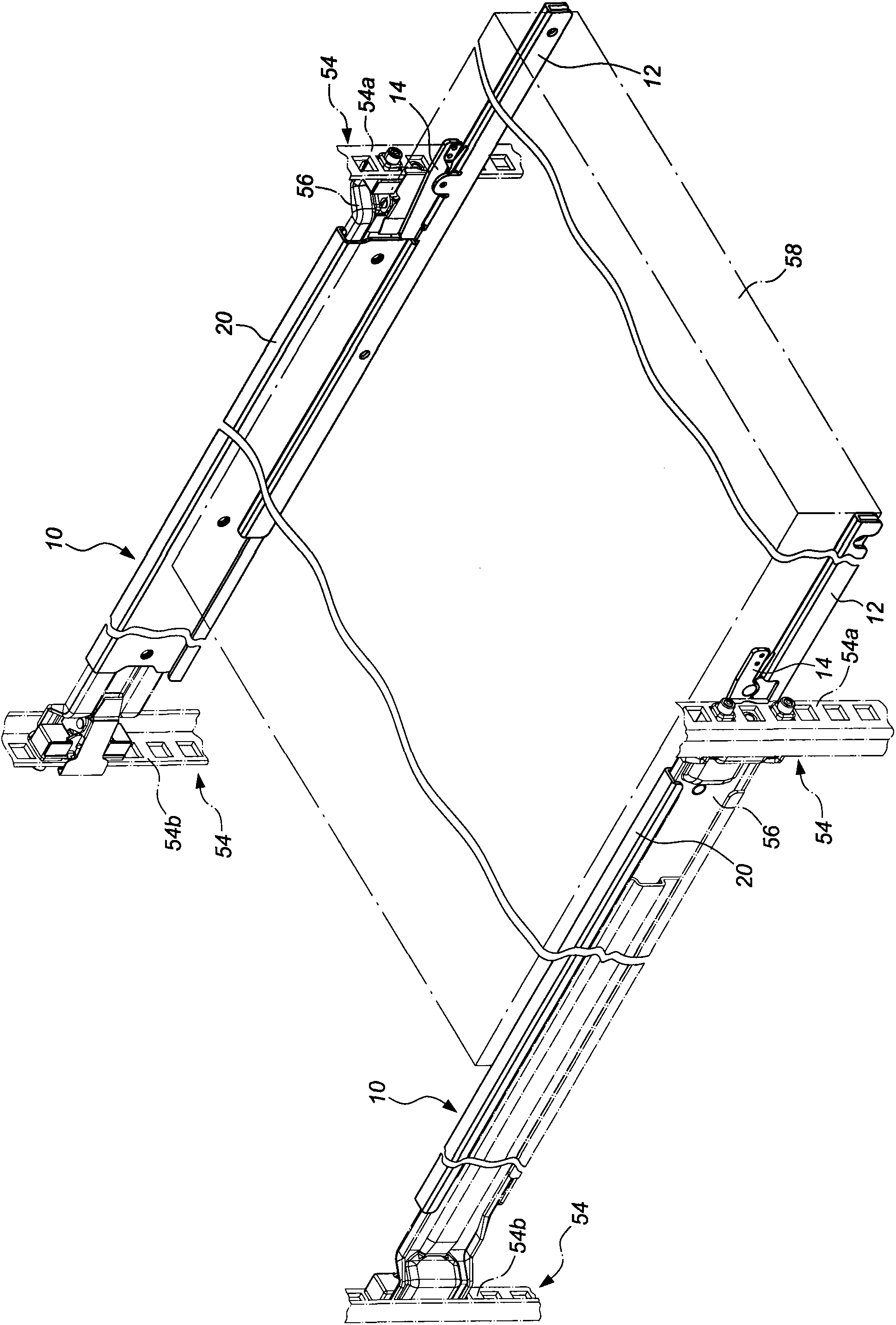

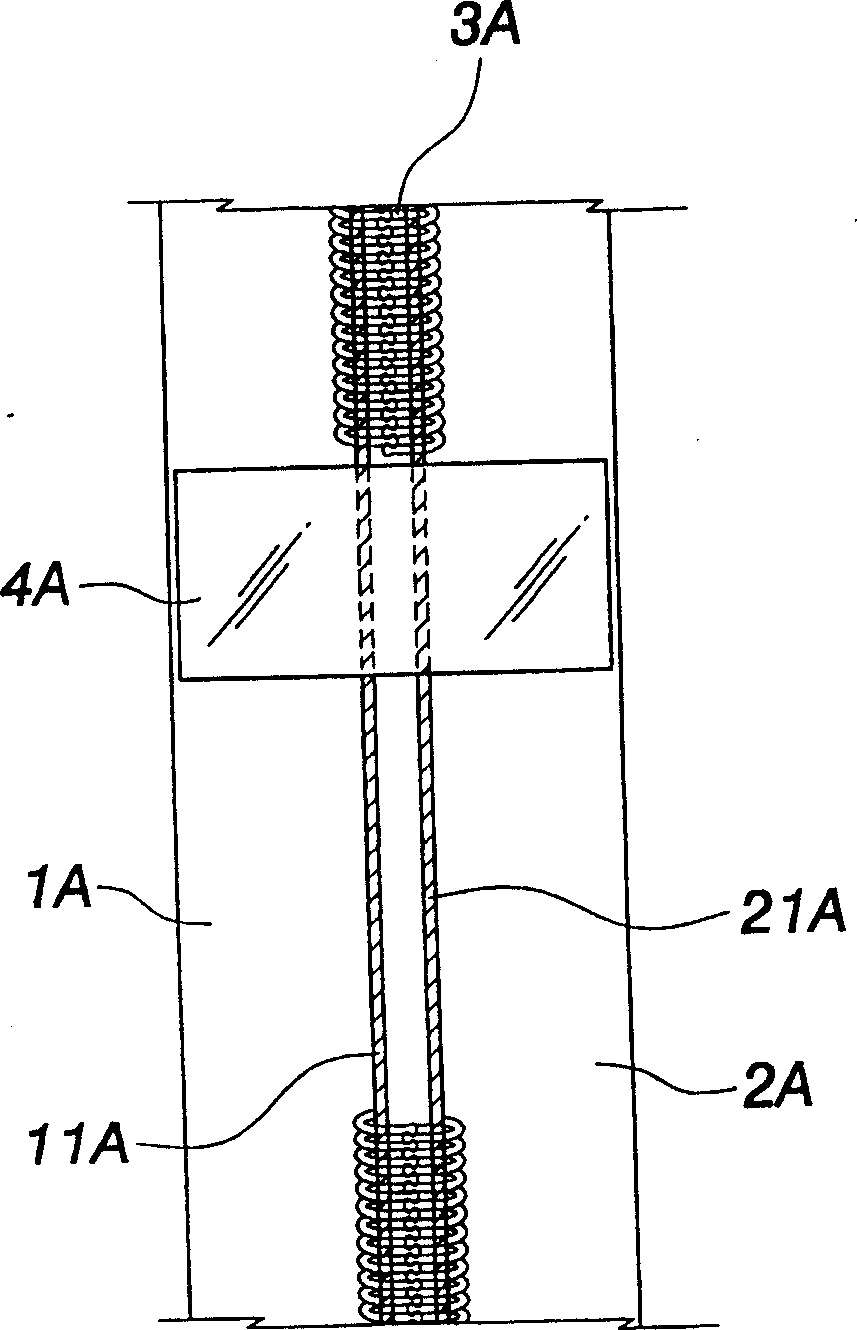

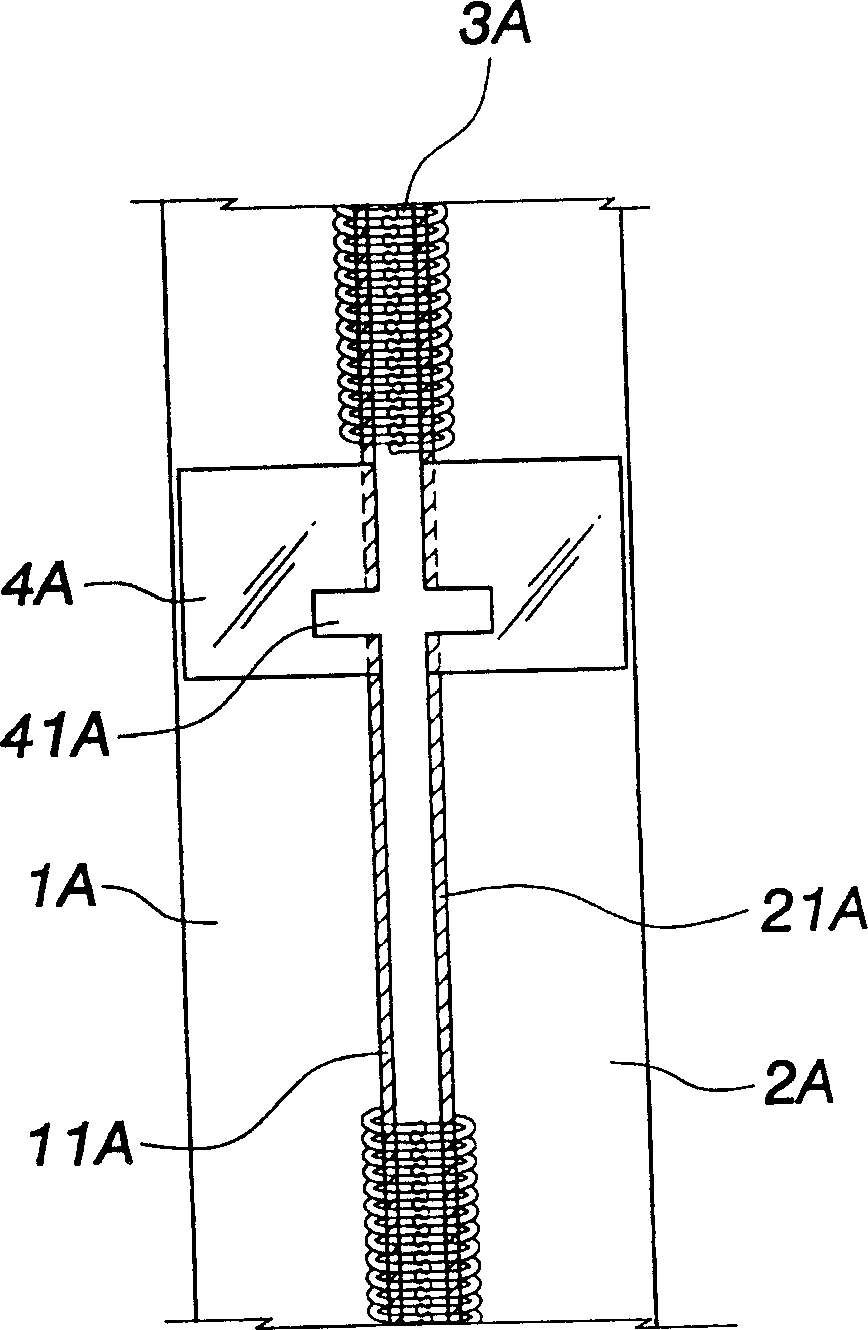

Anti-slipping supporting rail assembly

ActiveCN102846045AFacilitated releaseAnti-sheddingRack/frame constructionDrawersEngineeringMechanical engineering

The invention relates to an anti-slipping supporting rail assembly which comprises a first rail, a second rail, a snapping piece and an elastic piece. The first rail comprises a blocking wall; the second rail is hung on the first rail for sliding and provided with a sliding groove; the snapping piece is connected with the second rail in a pivoting mode and provided with a first end and a second end, and the first end of the snapping piece is provided with a blocking portion; and the elastic piece is arranged between the second end of the snapping piece and the second rail to provide an elastic force for acting on the snapping piece, the blocking portion of the first end of the snapping piece extends into the sliding groove of the second rail by means of the elastic force of the elastic piece, the blocking portion longitudinally corresponds to the blocking wall of the first rail, and the second rail abuts against the blocking wall of the first rail by means of the blocking portion of the snapping piece to form a positioning blocking point when the second rail extends out to slide to a preset position relative to the first rail.

Owner:KING SLIDE WORKS CO LTD +1

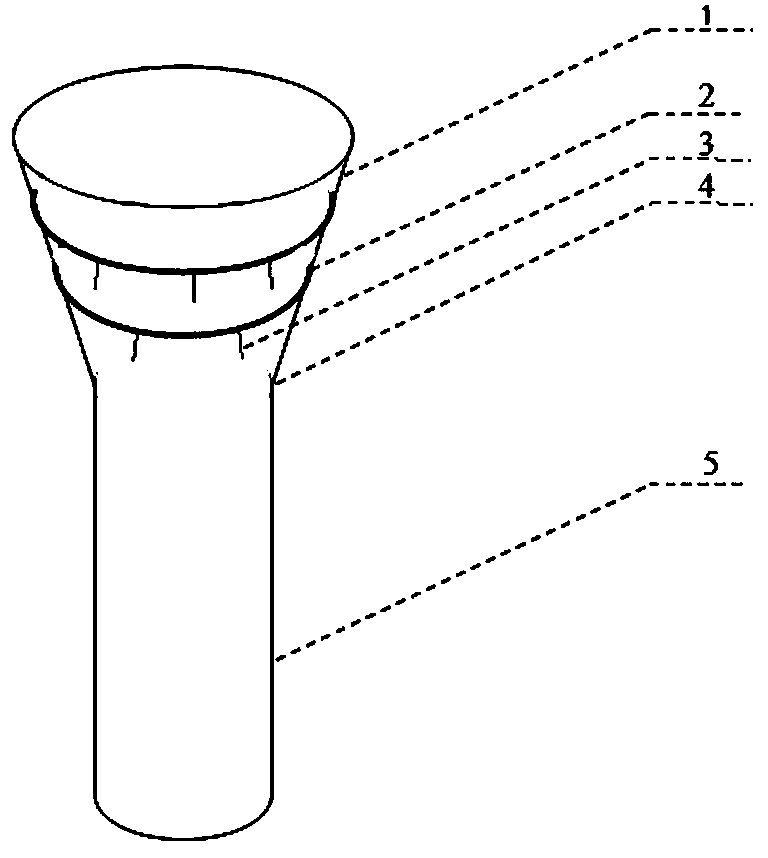

Conveniently-assembled cowl with self-tightening function

InactiveCN102305399ANot easy to fall offFix damageFluidized bed combustionApparatus for fluidised bed combustionEngineeringLarge particle

The invention discloses a conveniently-assembled cowl with a self-tightening function. The cowl comprises a main air duct, the main air duct stretches into a cowl head, and the main air duct is hermetically connected with the cowl head; the circumference of the cowl head is uniformly provided with multiple cowl-head spiral air vents, and a certain included angle is formed between the direction of each cowl-head spiral air vent and the cross section of the cowl head; and the cowl also comprises a branch air duct, the branch air duct in the cowl head is detachably connected with the main air duct, the top of the branch air duct is closed, and the side wall of the branch air duct is provided with a branch-air-duct air vents. The cowl disclosed by the invention has the characteristics of drop prevention, good abrasive resistance and capability of preventing large particles from depositing, and is convenient to install, replace and maintain, and the like.

Owner:HUANENG CLEAN ENERGY RES INST

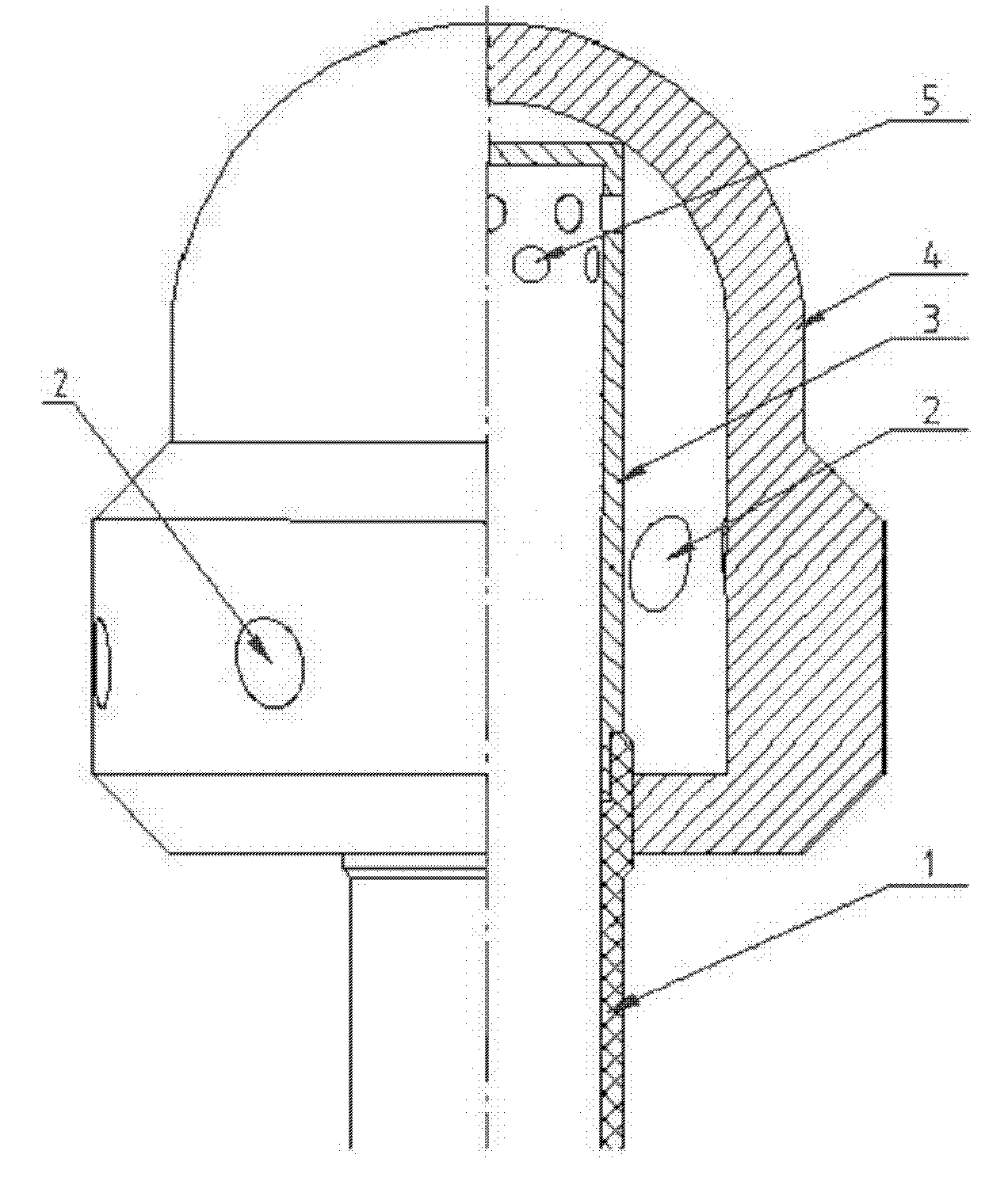

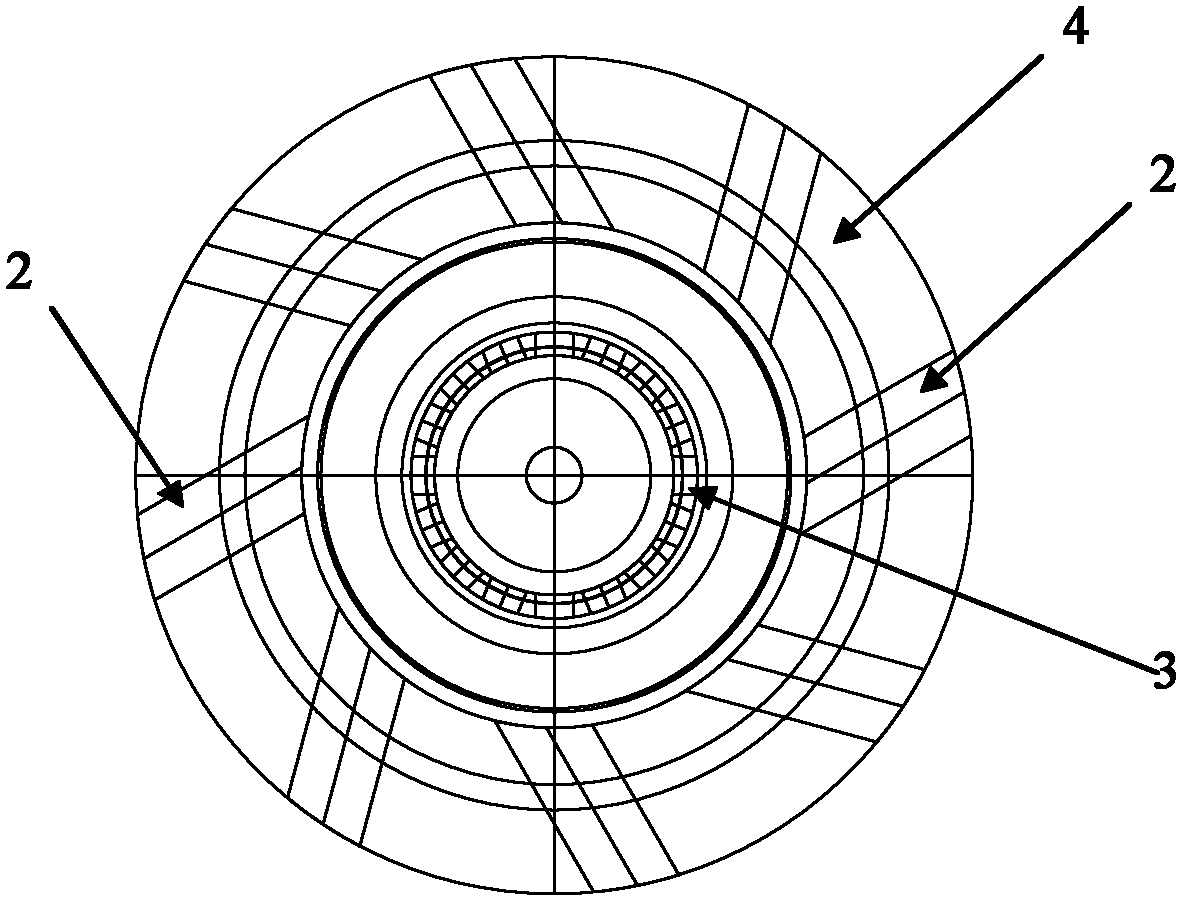

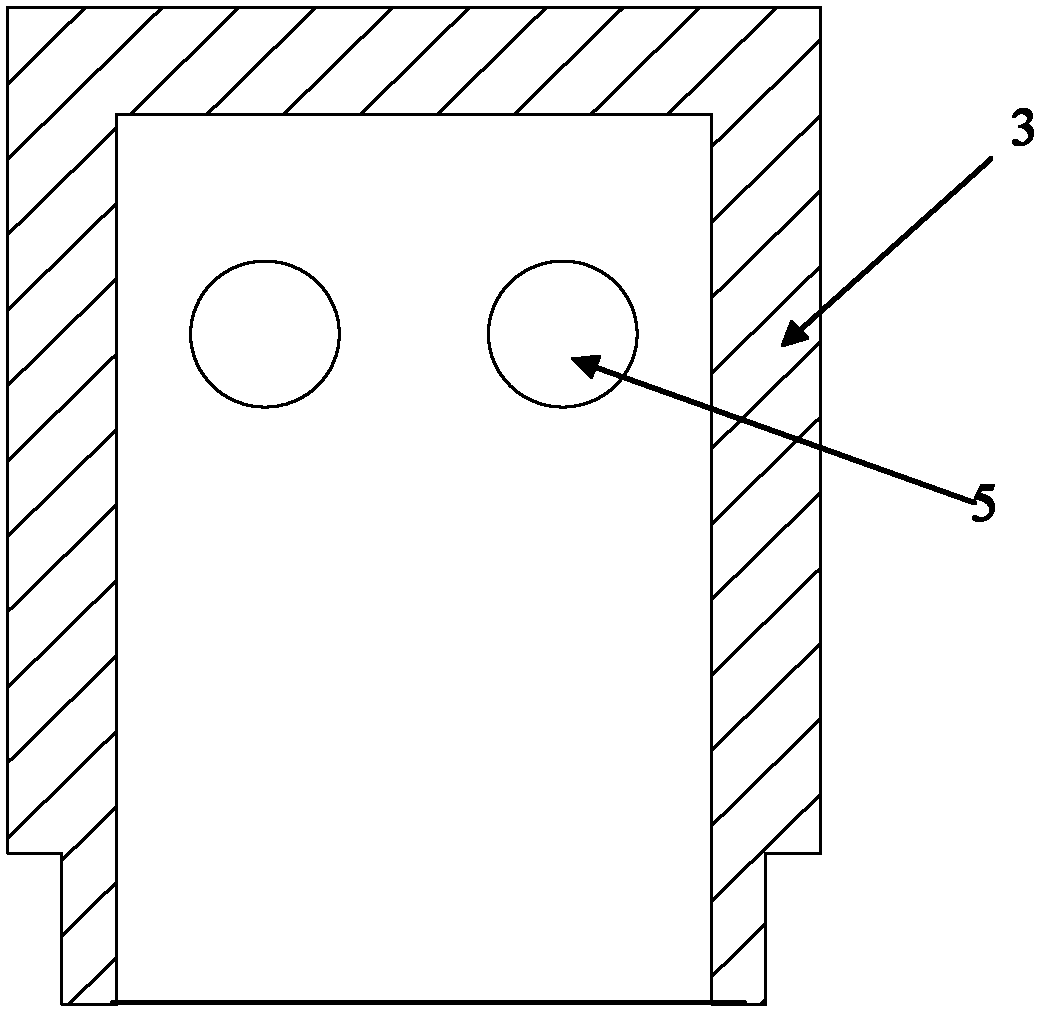

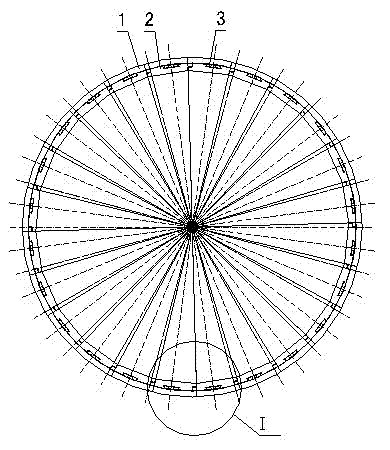

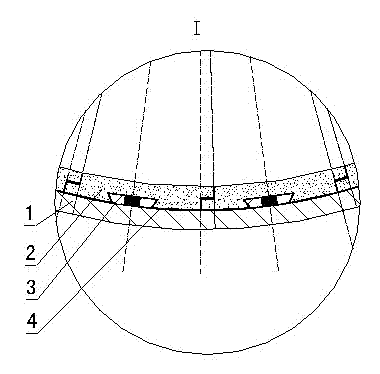

Scour and corrosion resistant anti-drop ceramic abrasion-resisting structure

ActiveCN102774056AWear-resistantCorrosion resistantCeramic layered productsMetal layered productsAdhesiveEconomic benefits

The invention discloses a scour and corrosion resistant anti-drop ceramic abrasion-resisting structure which comprises a metal substrate, wherein a plurality of steel bar reinforcing ribs are arranged on the surface of the metal substrate at intervals; a ceramic component which is formed by splicing a plurality of ceramic sheets is adhered to the metal substrate opposite to the side of the steel bar reinforcing ribs; the splicing of every two adjacent rows of ceramic sheets is stepped splicing, concave-convex splicing or linear splicing; high temperature resistant inorganic adhesive is filled between the contact surfaces of the ceramic component and the metal substrate; grooves corresponding to the steel bar reinforcing ribs are arranged at the middle parts of the ceramic sheets; and an anti-drop baffle ring is arranged at the end of the ceramic component. The scour and corrosion resistant anti-drop ceramic abrasion-resisting structure is suitable for the working conditions of frequently bearing high-speed impact abrasion of fine hard grain in the electric industry, petrifaction industry, metallurgy industry, building material industry and the like, and has the characteristics of high abrasion resistance, corrosion resistance and drop resistance, long service life, convenience in maintenance, high comprehensive economic benefit and the like.

Owner:徐州燃烧控制研究院有限公司

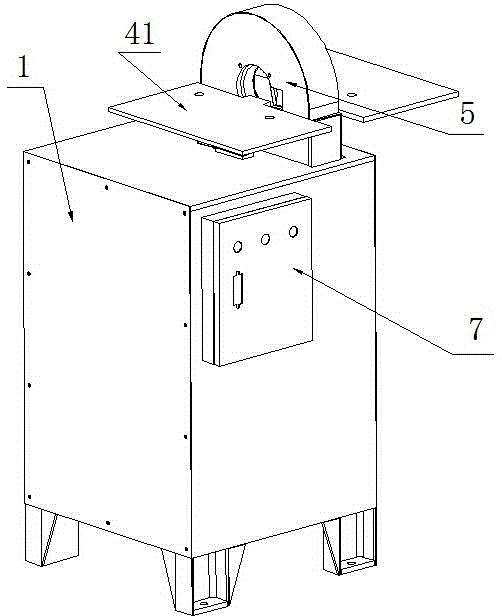

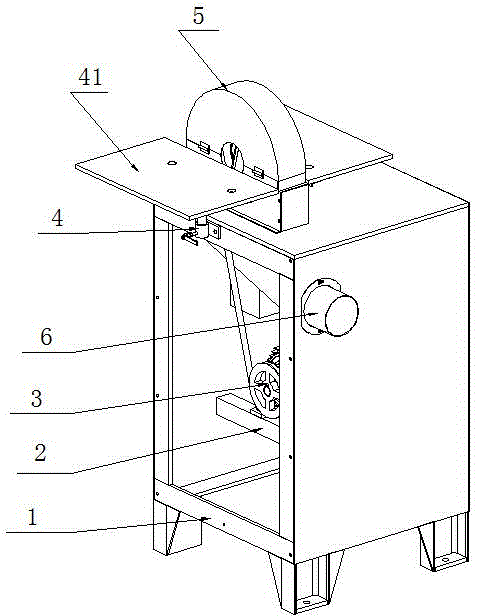

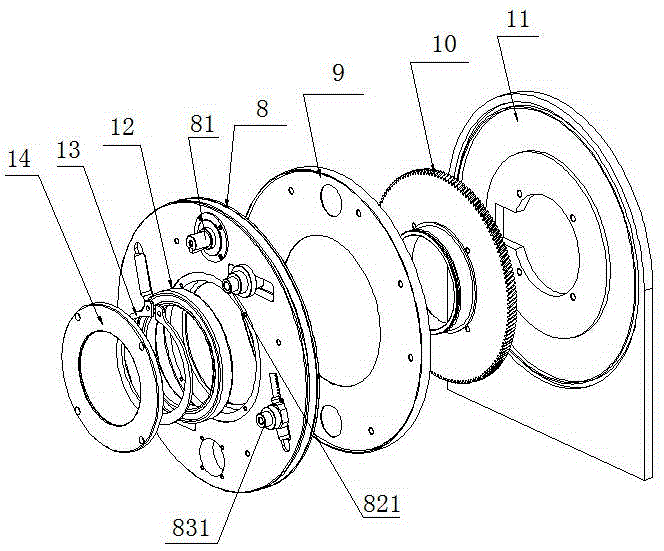

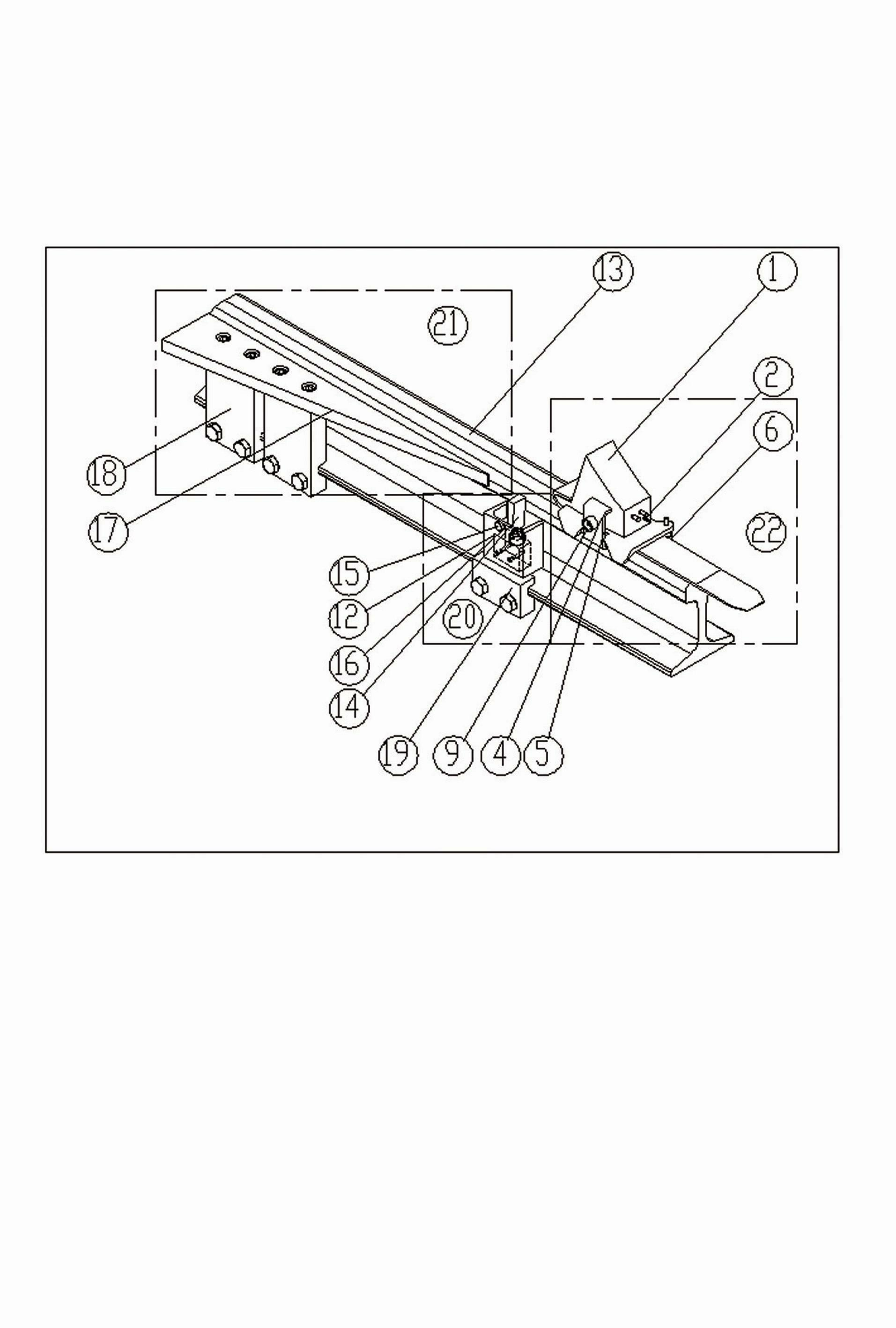

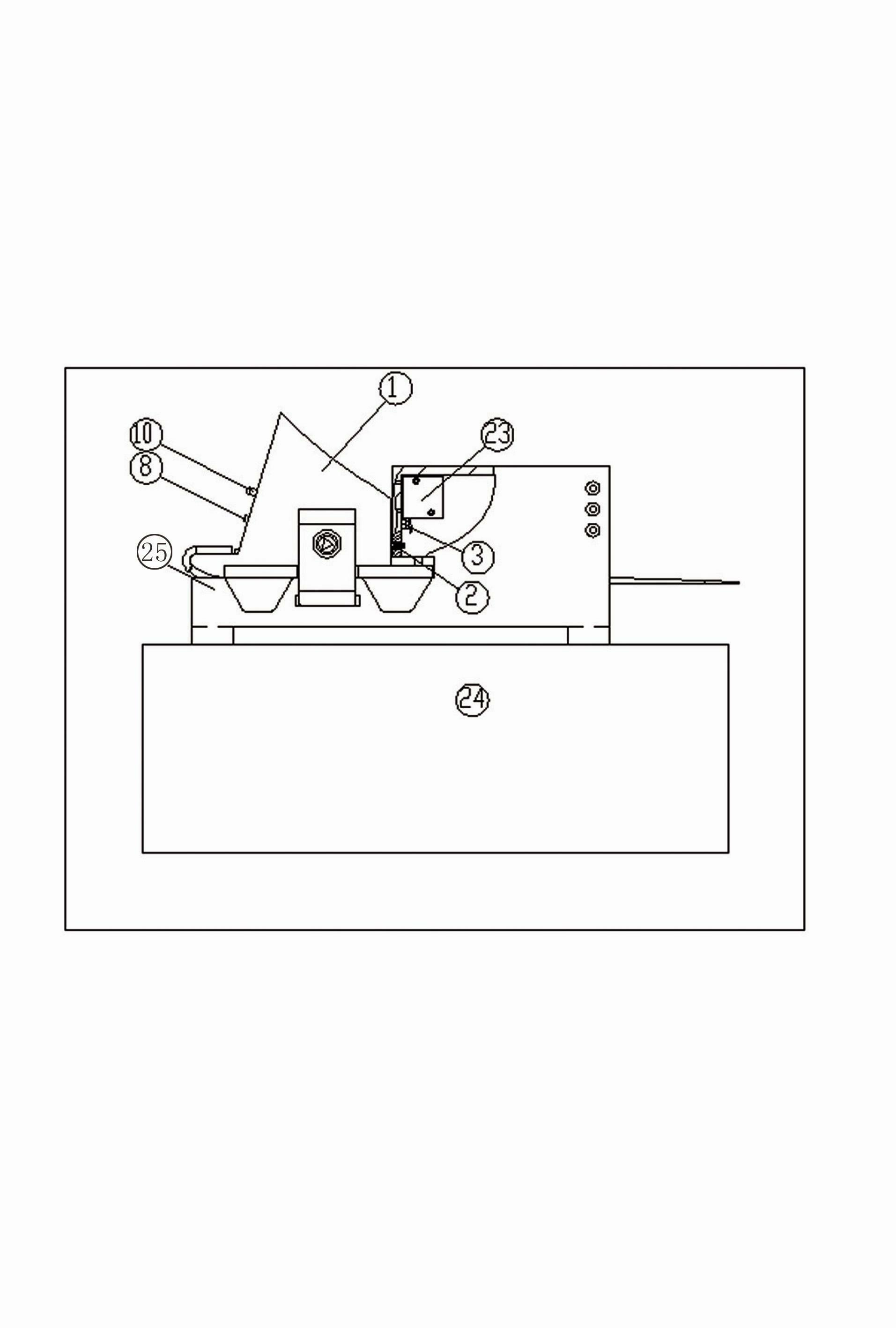

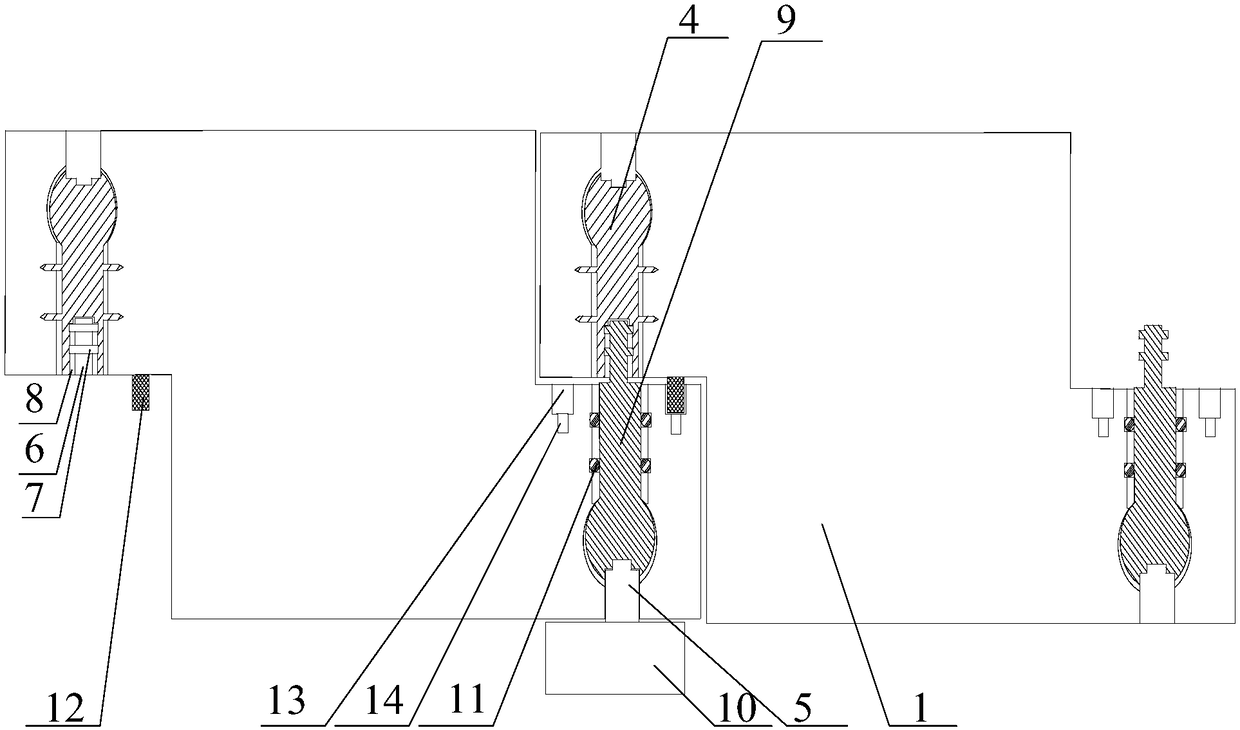

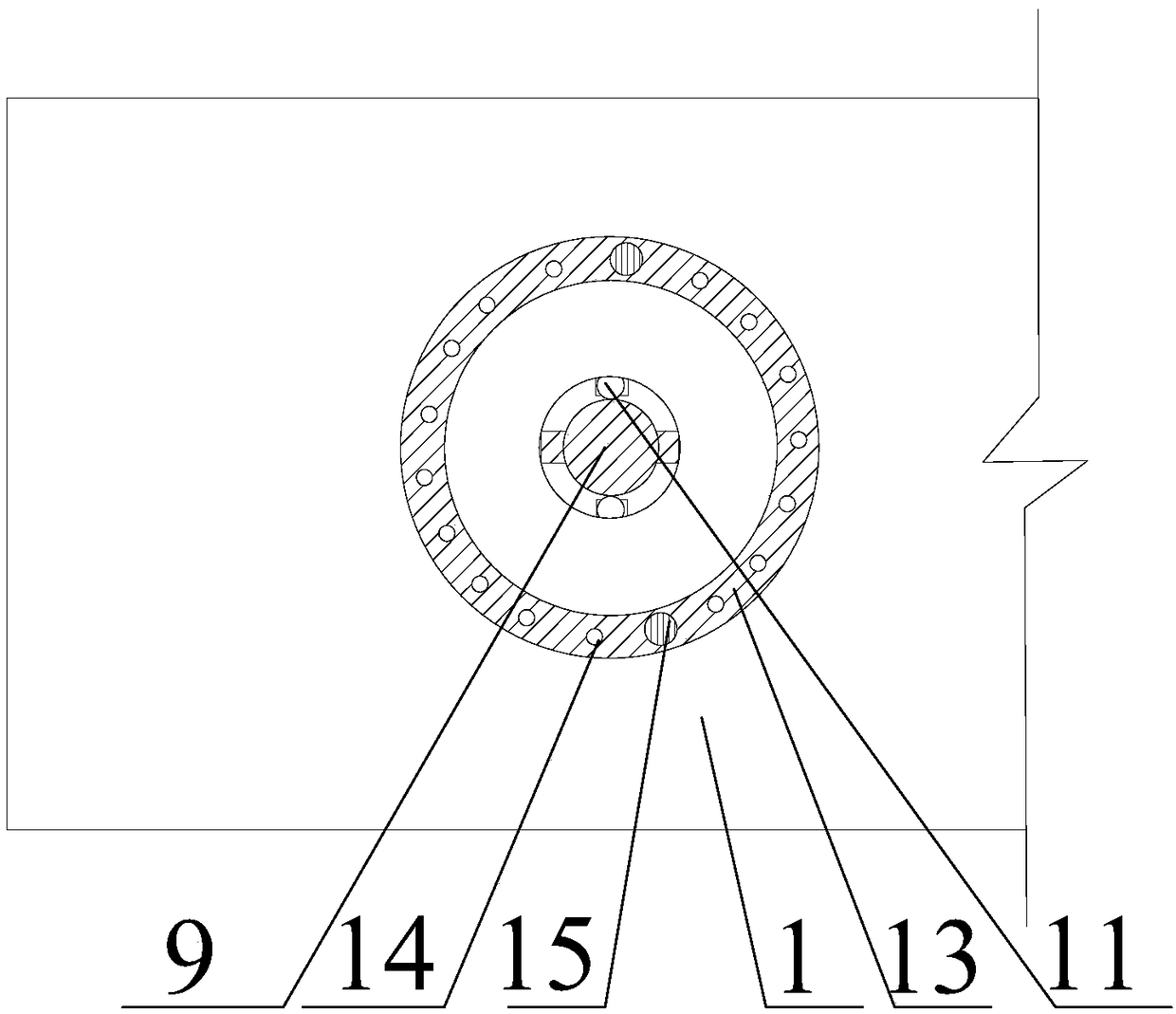

Bent pipe sanding machine

The invention provides a bent pipe sanding machine which comprises a machine frame, a motor fixing frame, a motor, a retainer plate fixing seat, a retainer plate, a sanding wheel, a dust collection pipe, a control box, a disc, a dustproof disc, a fixed gear, a gear fixing disc, a bearing, an outer snap spring, a snap spring check ring, abrasive belt power wheels, a driven gear shaft, abrasive belt distance deviation preventing wheels, an abrasive belt gap adjusting component, abrasive belt tightness deviation preventing wheels, an abrasive belt tightness adjusting component and abrasive belts. The abrasive belt gap adjusting component can adjust the gap between the two abrasive belts so that the abrasive belts can be used for sanding and polishing bent pipes of different sizes. V-shaped grooves are formed in the circumference of the curved surface of each abrasive belt deviation preventing wheel and achieve the functions of deviation prevention, sliding prevention and falling prevention for the abrasive belts. The problem that in traditional bent pipe polishing operation, a whole bent pipe can only be sanded and polished by continuously changing the polished face of the bent pipe is solved, the production cycle is shortened, work efficiency is greatly improved, labor cost is lowered, and the rate of finished products is high.

Owner:康天龙

Jointly-controlled wheel stopping anti-skid device and anti-skid method thereof

ActiveCN102658826APrevent rollingPrevent shoe pulling accidentsRailway signalling and safetyTrack-braking member co-operationEngineeringMechanical engineering

The invention belongs to the field of railway safety protection equipment and mainly relates to a jointly-controlled wheel stopping anti-skid device and an anti-skid method thereof. The jointly-controlled wheel stopping anti-skid device comprises a multifunctional iron shoe, a skid alarm switch, a shoe taking-off device and a jointly-controlled swing frame, wherein both the skid alarm switch and the shoe taking-off device are mounted on the outer side of a steel rail, and the jointly-controlled swing frame is arranged beside a station track needing skid prevention. When in the anti-skid state, the multifunctional iron shoe is mounted on the steel rail, and the skid alarm switch and the shoe taking-off device are respectively positioned in front of the multifunctional iron shoe. When not in the anti-skid state, the multifunctional iron shoe is mounted on the jointly-controlled swing frame. The jointly-controlled wheel stopping anti-skid device and the anti-skid method thereof have the advantages that theft, omitted placement, shedding can be prevented, shoe patrolling at night can be facilitated, the iron shoe can be taken off automatically when forgotten to be removed, shoe pulling accidents can be effectively prevented, and the jointly-controlled wheel stopping anti-skid device and the anti-skid method thereof are applicable to popularization and application.

Owner:吕贵刚

Environmental-protection energy-saving thermal-insulated external-wall coating

InactiveCN100392030CImprove fire characteristicsHigh quality fire protection propertiesCellulose coatingsEmulsion paintsFiberPolyvinyl alcohol

Owner:福建创美新材料科技有限公司

Composite fireproof insulation board and preparation method thereof

InactiveCN105948692AWide range of hardnessImprove shock absorptionSolid waste managementCeramicwareCelluloseInsulation layer

The invention discloses a composite fireproof insulation board and a preparation method thereof. The composite fireproof insulation board can be selected from a two-layer structure including an insulation layer and an inorganic fireproof insulation layer or a three-layer structure including an insulation layer, an inorganic fireproof insulation layer and a mortar protection layer; the insulation layer is selected from one of a polyurethane plate, an extruded plate, an expanded polystyrene plate and a thermosetting polystyrene foamed plastic; the inorganic fireproof insulation layer is prepared by selecting 80 parts by mass of magnesium oxide, 60 parts by mass of magnesium chloride, 40 parts by mass of water, 80 parts by mass of a mineral powder, 1 part by mass of a modifier, 8 parts by mass of a hydrophobic agent, 2 parts by mass of a hydrophobic powder, 8-10 parts by mass of expanded polystyrene particles, and 25 parts by mass of a foaming agent and water; the mortar protection layer is prepared from 350 parts by mass of cement, 650 parts by mass of quartz sand or washed-out sand, 1 part by mass of hydroxypropyl methyl cellulose, 1 part by mass of cellulose ether, 20 parts by mass of a rubber powder, and 7 parts by mass of a hydrophobic agent. The composite fireproof insulation layer provided by the invention has the advantages of fire prevention, thermal insulation, environmental friendliness and the like.

Owner:曹芳芹

Colored mortar and preparation method thereof

The invention provides colored mortar. The colored mortar is prepared from the following raw materials in parts by weight: 500 to 600 parts of cement, 300 to 400 parts of quartz sand, 100 to 200 partsof coarse whiting, 10 to 15 parts of toner and 6 to 10 parts of a lubricant. When the colored mortar prepared by the invention is applied to an outer wall, the outer wall is allowed to be rich and durable in color and free of discoloring; as applied to the outer wall, the colored mortar has anti-falling, anti-cracking and waterproof properties; and finally, the colored mortar can resist high temperature and low temperature. Therefore, the colored mortar disclosed by the invention can be widely applied to high-grade communities, bridges, school walls and the like. Meanwhile, the preparation method of the colored mortar is simple, the construction operation of the colored mortar is easy, and the raw materials for preparing the mortar are cheap and easily available.

Owner:王信平

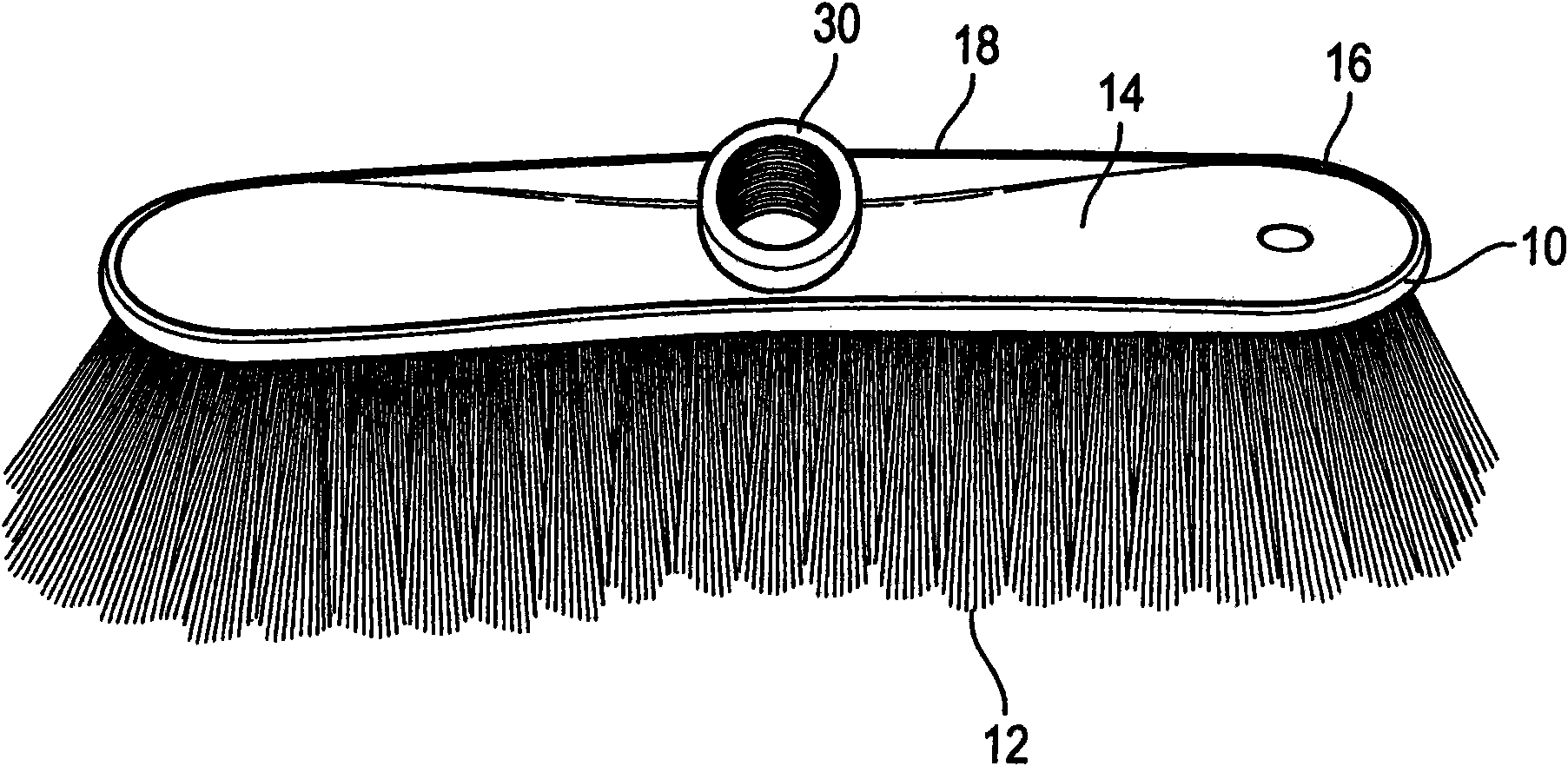

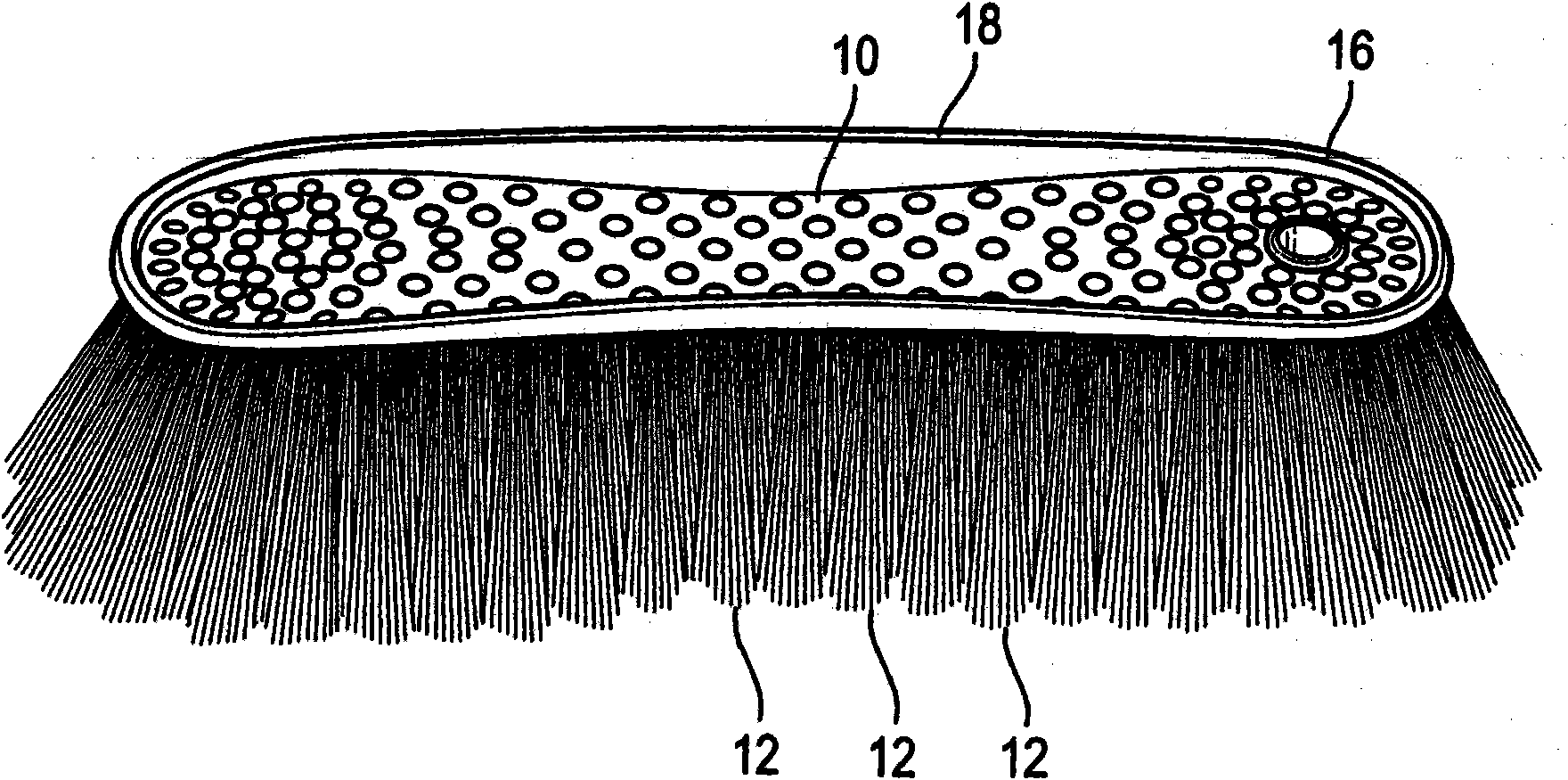

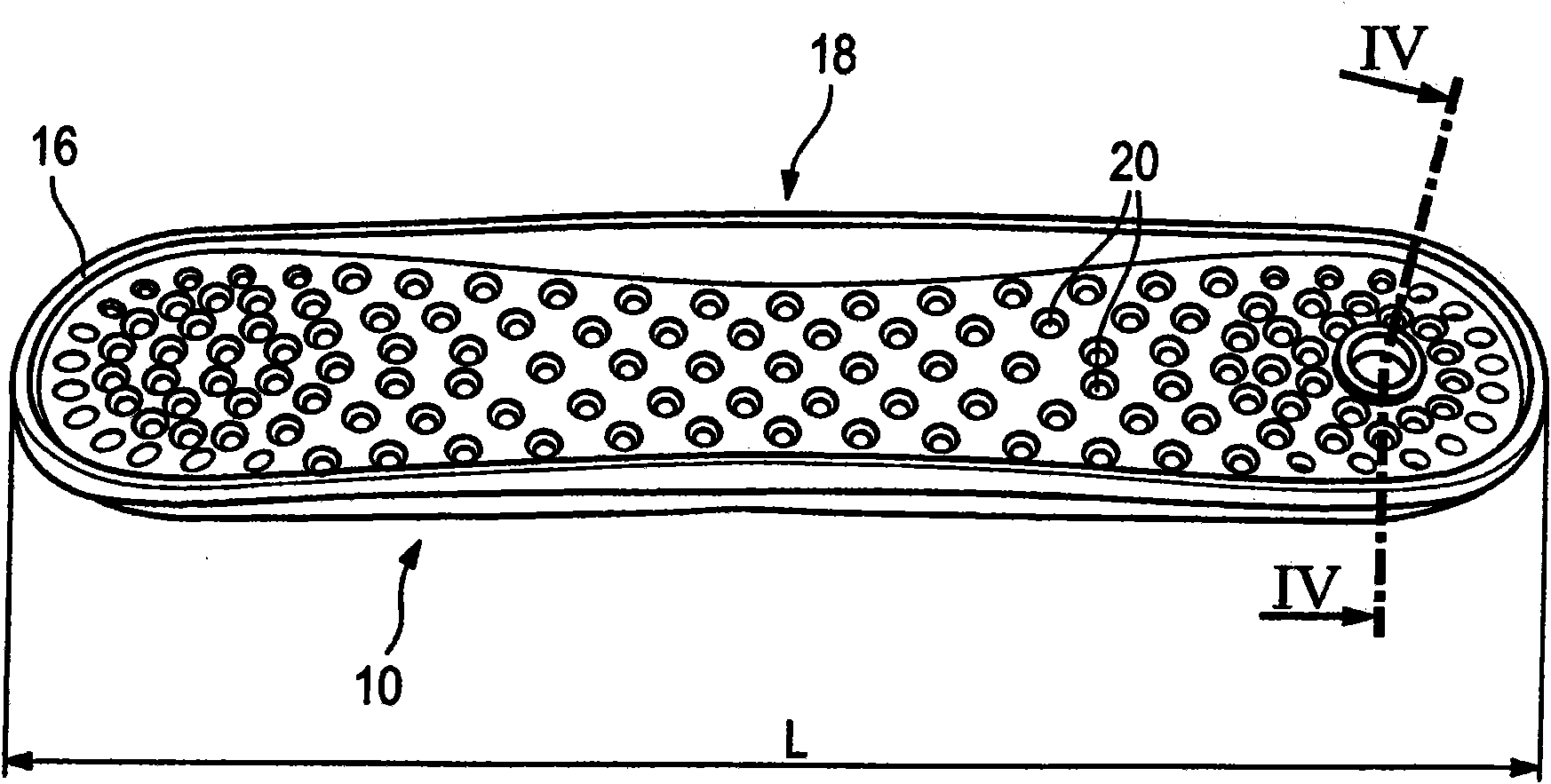

Brush, particularly for household or industrial applications

The invention relates to a brush, particularly for household or industrial applications, comprising a bristle carrier plate (10) made of plastic, a plurality of bristle bundles (12) that are attached to the bristle carrier plate (10), and at least one reinforcement plate (14), which is likewise made of plastic and is attached to the bristle carrier plate (10).

Owner:FIRMA G B BOURCHERIE NV

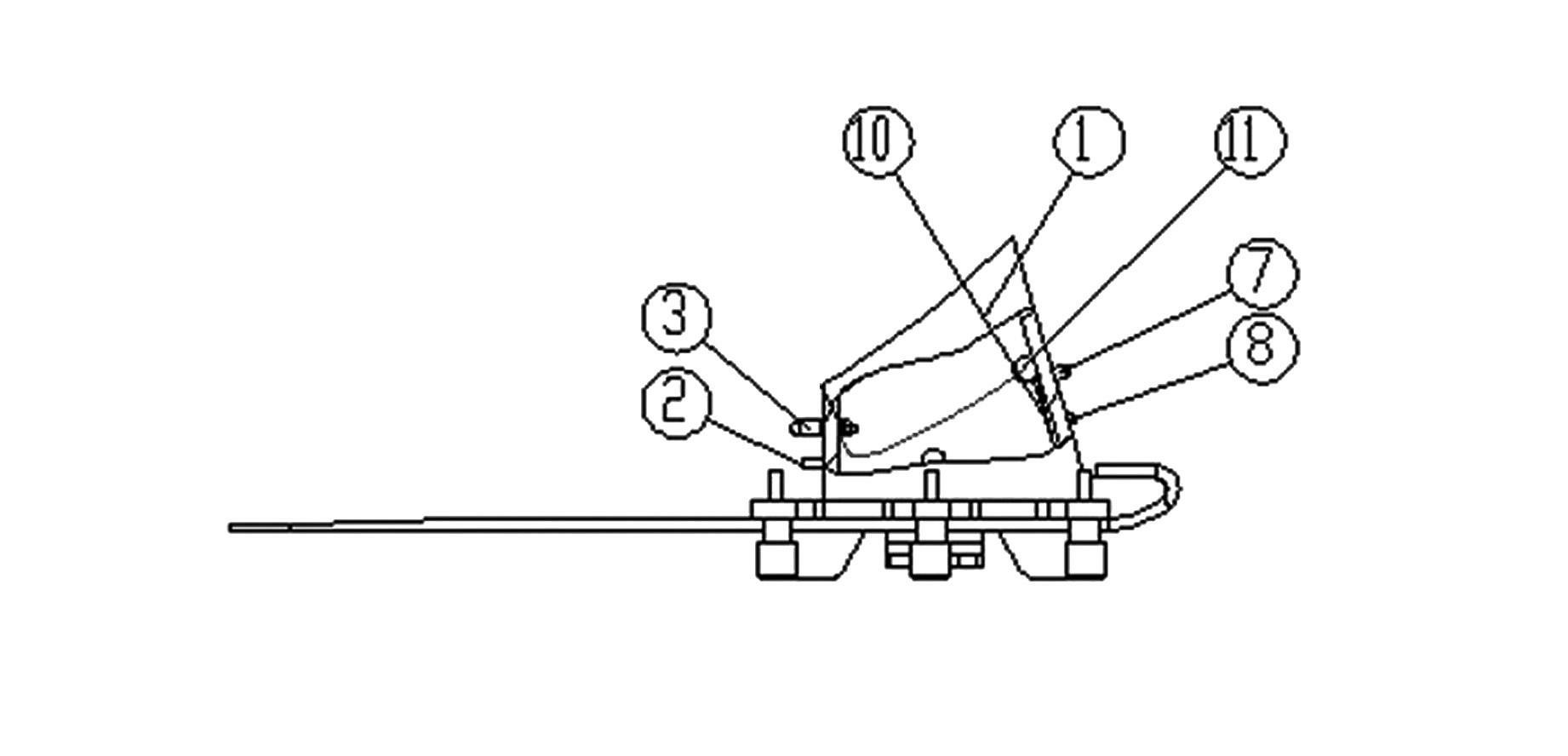

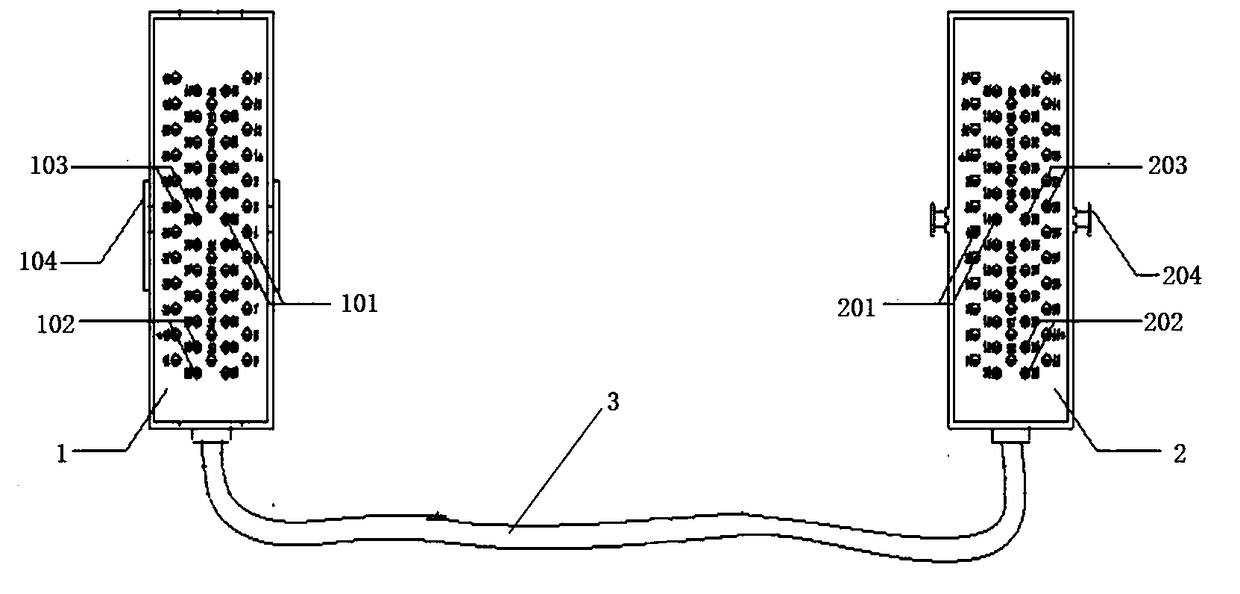

Aviation connector capable of facilitating 10kV trolley breaker mechanical feature testing

PendingCN108254684AAvoid accidental touchAnti-sheddingCircuit interrupters testingFastenerEngineering

The invention provides an aviation connector capable of facilitating 10kV trolley breaker mechanical feature testing. The aviation connector comprises a male terminal base, a female terminal base anda connecting cable and is characterized in that the male terminal base comprises a group of switch-off testing male terminals, a group of switch-on testing male terminals and a group of energy storagepower supply male terminals, the female terminal base comprises a group of switch-off testing female terminals, a group of switch-on testing female terminals and a group of energy storage power supply female terminals, the switch-off testing male terminals are connected with the switch-off testing female terminals, the switch-on testing male terminals are connected with the switch-on testing female terminals and the energy storage power supply male terminals are connected with the energy storage power supply female terminals through the connecting cable, and the male terminal base and the female terminal base are provided with corresponding fastener structures. By the fastening structures, corresponding aviation connectors can be tightly fastened together to allow the aviation connectorsto be able to prevent disconnection and dampness.

Owner:GUANGDONG POWER GRID CO LTD +1

A kind of water-flooding construction technology of building roof parapet wall

The invention relates to a flashing structure construction process, in particular to a building roof parapet wall flashing construction process. The building roof parapet wall flashing construction process comprises the following steps that step one, a flashing wall body of a reinforced concrete structure is poured on a building roof; step two, a waterproof roll is paved and pasted on the inner facades of the roof and the flashing wall body to form a waterproof layer, and the upper end of the waterproof roll is subjected to head retraction treatment; step three, a protective brick wall is laid on the outer facade of the waterproof layer through solid bricks, the inner facade of the protective brick wall is tightly attached to the waterproof roll, and the waterproof roll is tightly pressed on the flashing wall body, wherein the protective brick wall is no larger than the flashing wall body; and step four, a parapet wall is laid on the flashing wall body through solid bricks on the basis of the top of the flashing wall body, wherein the thickness of the wall body of the parapet wall is equal to the distance between the outer facade of the flashing wall body and the outer facade of the protective brick wall. A flashing structure built through the building roof parapet wall flashing construction process has the advantages of being resistant to cracking and falling-off and long in guarantee period and is convenient to construct and low in cost, and materials are convenient to obtain.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

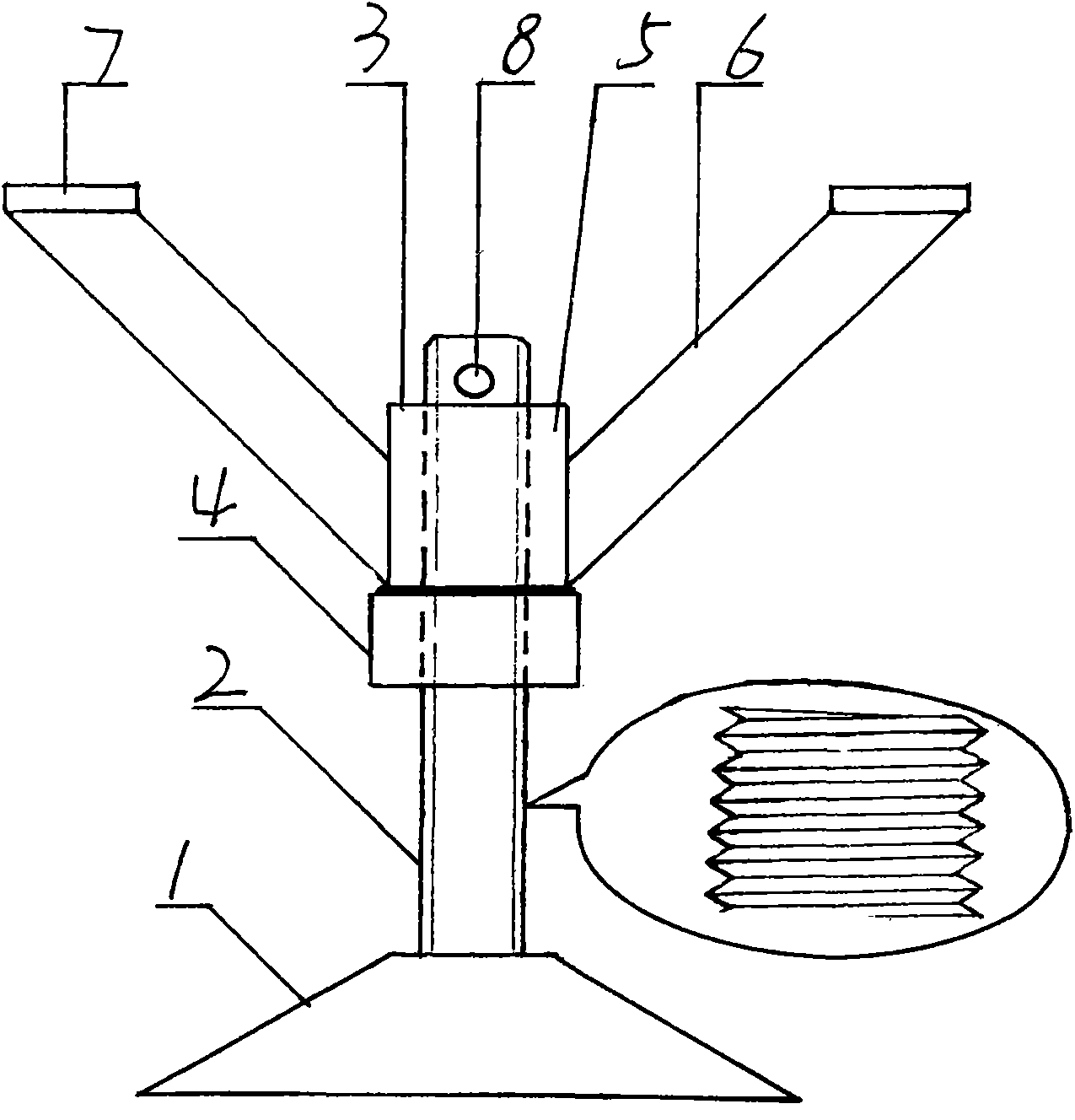

Method for manufacturing stand column type temporary sleeper supporting device

The invention discloses a method for manufacturing a stand column type temporary sleeper supporting device. The stand column type temporary sleeper supporting device is structurally composed of a base, a bolt type column and a support, the base is a round plate, the bolt type column is arranged in the middle of the base, a nut is arranged on threads of the bolt type column, the Y-shaped support is arranged on the bolt type support, a guide pipe of the support can adjust the vertical direction between the support and the base along with the vertical movement of the nut, slabs are arranged at the upper ends of oblique arms, the upper end of the bolt type column is provided with a pin hole and a pin, and disengagement of the support and the bolt type column is prevented.

Owner:启东市益晴蔬菜专业合作社

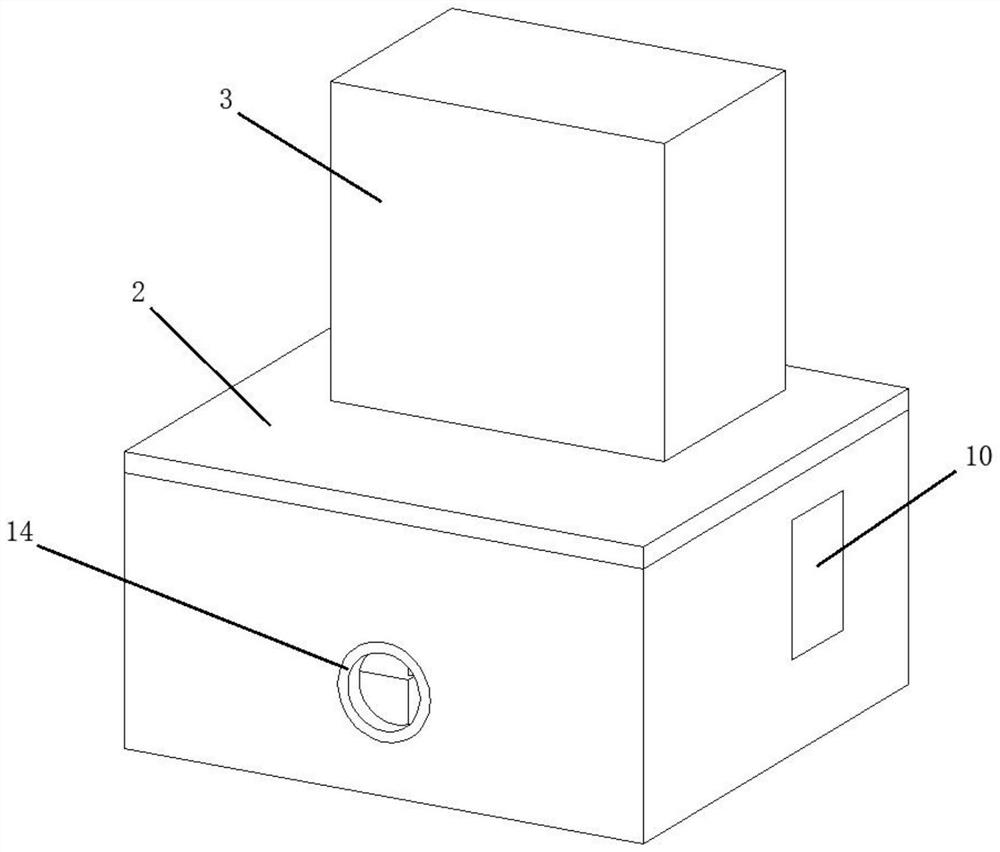

Convenient-to-plug long-life socket and plug for socket

ActiveCN112003056AEasy to insertAvoid wear and tearSecuring/insulating coupling contact membersCoupling contact membersEngineeringSlide plate

The invention relates to the technical field of sockets and in particular to a convenient-to-plug long-life socket and a plug for the socket. The socket comprises a socket box, wherein a box cover isdetachably arranged on one side of the socket box; a plug is arranged on one side of the socket box, two copper insertion pieces are fixedly arranged on one side of the plug, two insertion holes are formed in one side of the box cover, the copper insertion pieces are detachably connected to the inner sides of the insertion holes, two conductive columns are fixedly arranged on one side in the socket box, wire pressing devices are arranged on one sides of the conductive columns, conductive plates are fixedly arranged on one sides of the conductive columns, and U-shaped conductive frames are arranged. By arranging the conductive columns, the conductive plates, the U-shaped conductive frames, the insulating boxes, the cover plates, the sliding plates, the springs A, the insulating columns, theconvenient-to-insert bevel edge blocking frames, the fixing frames, the wire pressing devices and the clamping devices, the novel electric connector has high safety and long service life; the sockethas the functions of convenient insertion, automatic clamping, convenient wiring, falling prevention and the like.

Owner:惠州吉顺康实业有限公司

Control method of vehicle-mounted air outlet capable of automatic swing

InactiveCN108482071AImprove aestheticsChoose liberalizationAir-treating devicesPassenger/driving compartment lightingsMotor driveControl signal

The invention discloses a control method of a vehicle-mounted air outlet capable of automatic swing. The control method comprises the following steps: (1) receiving a signal input by a vehicle-mountedterminal or a mobile terminal through a control circuit board and setting a swing rate mode of horizontal blades and vertical blades and a horizontal blade swing mode or a vertical blade swing mode;(2) using the control circuit board to transmit the signal to a motor driving module built in the control circuit board; (3) accepting the control signal of the control circuit board by the driving module and driving a horizontal motor or a vertical motor to work. The control method of the vehicle-mounted air outlet capable of automatic swing can realize the automatic swing of the horizontal blades and the vertical blades according to control commands, and is more humanized in design; and in addition, different colors can be displayed according to a light bar and the interior appearance is improved.

Owner:PROD DEV ENGINEERNANJING TATA AUTOCOMP SYST LTD

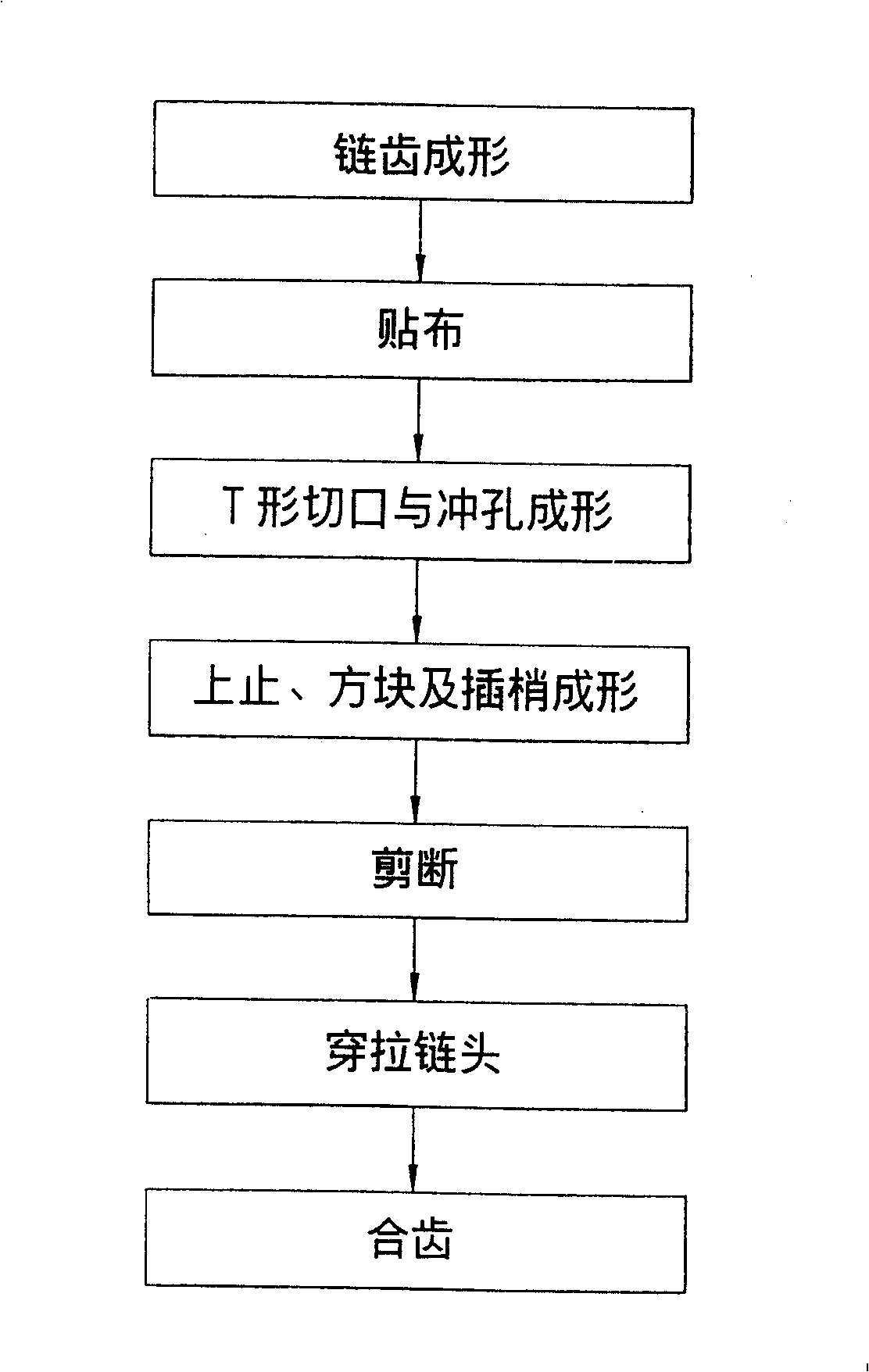

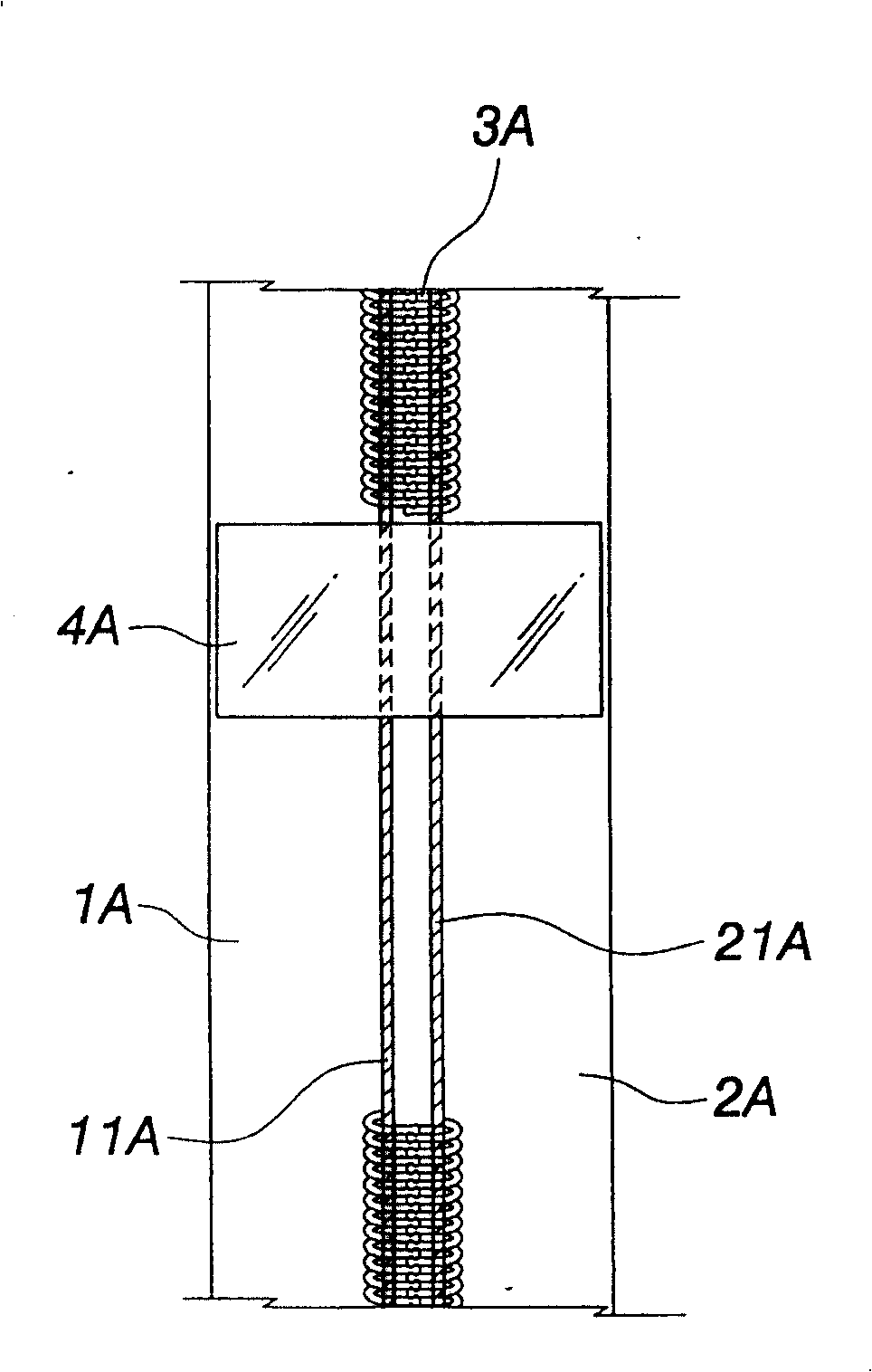

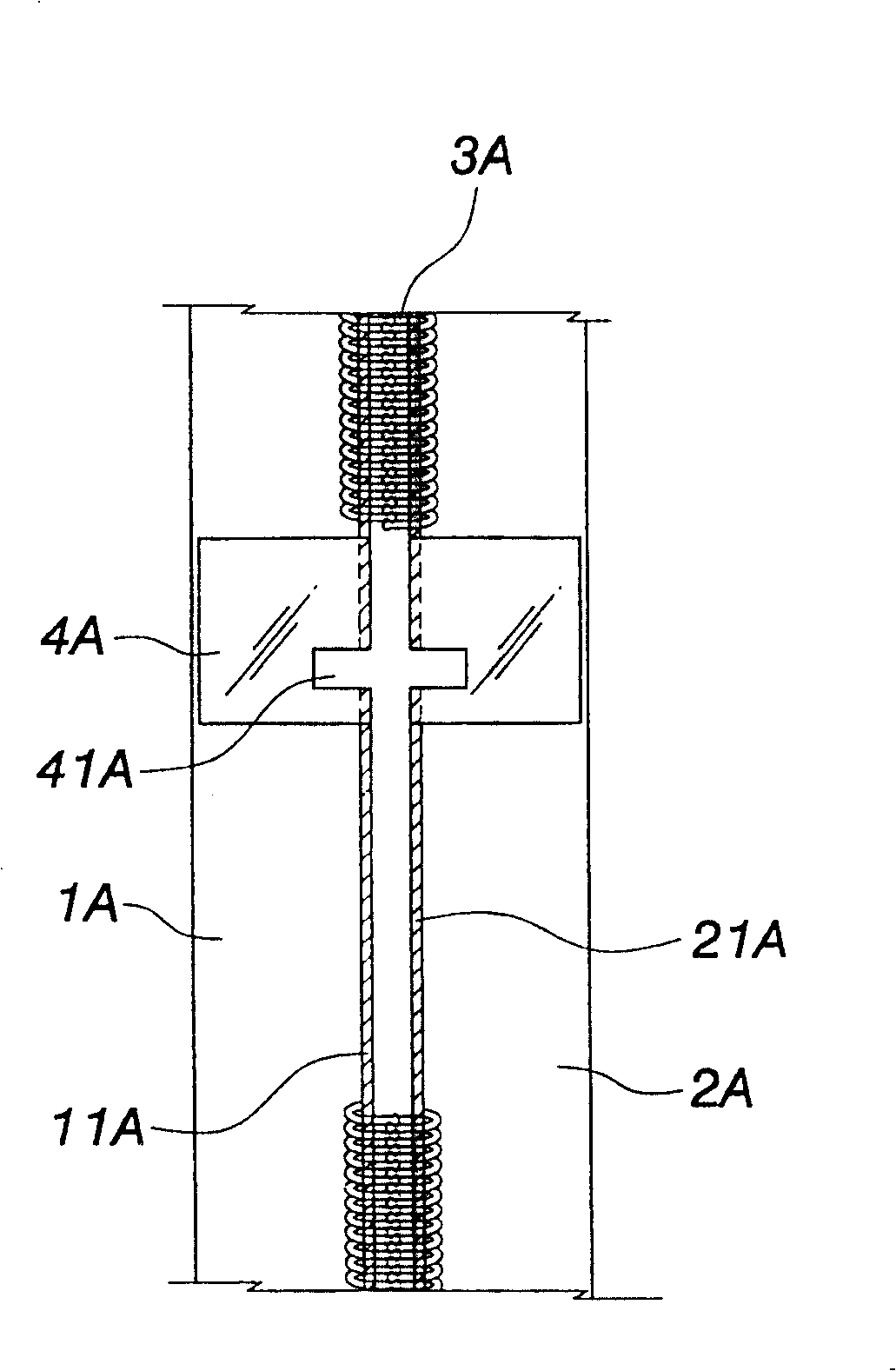

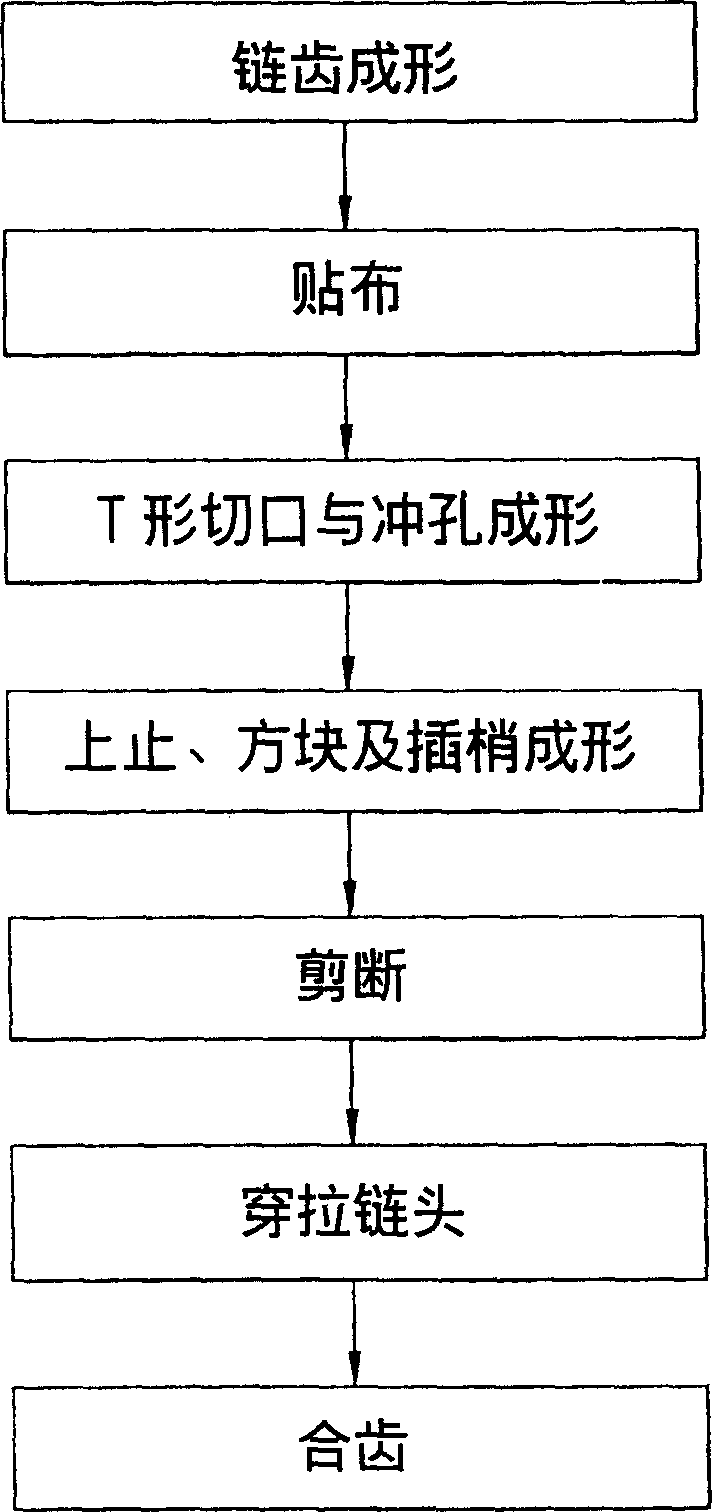

Method for producing zip fastener

InactiveCN100417514CAnti-sheddingEliminate positioning errorsDomestic slide fastenersPunchingEngineering

A technology for manufacturing zipper includes forming teeth of zipper, providing fabric belt with cord at edge, radially cutting, punching holes, ejection moulding of upper stops, plug pins and fixed pins while directly fixing them on said cords, inserting its start end, engaging the teeth, fixing lower stop block, and cutting short by needed size. Its advantage is high positioning accuracy.

Owner:GENMORE ZIPPER CORP

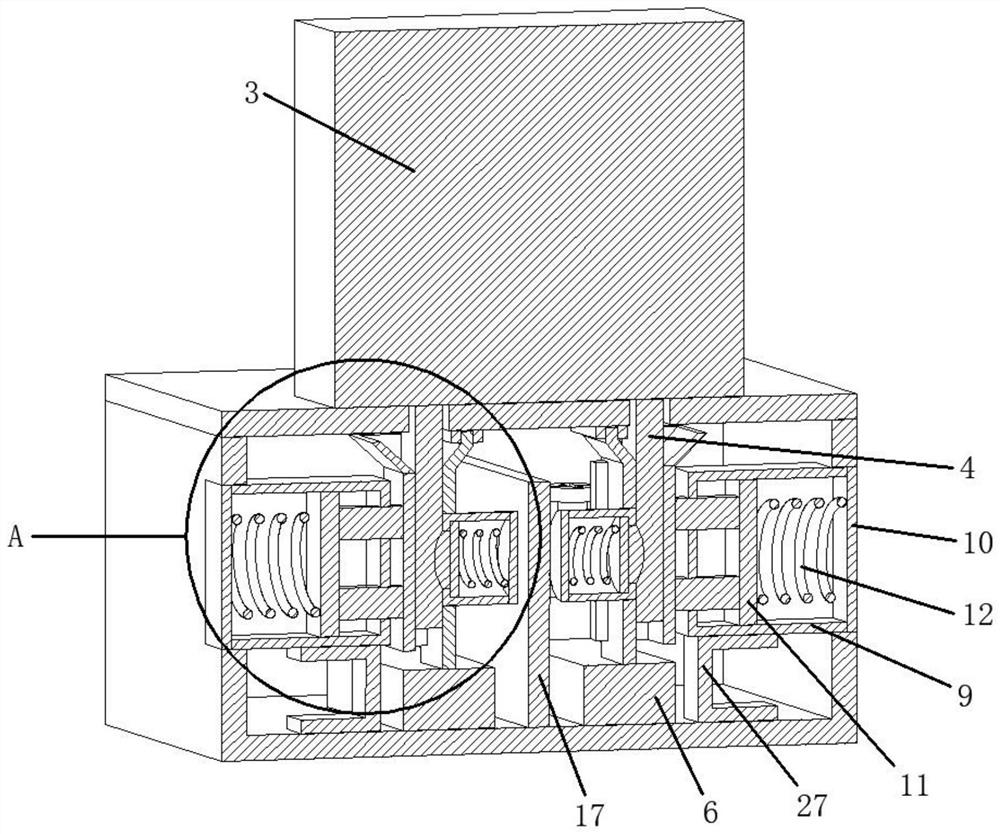

Robot modular assemble mechanical arm

ActiveCN108481317ARealize different driving functionsIncrease the lengthProgramme-controlled manipulatorJointsEngineeringMechanical engineering

The invention discloses a robot modular assemble mechanical arm. The robot modular assemble mechanical arm comprises an arm body which includes a plurality of arm sections connected with one another;each arm section comprises a rectangular block, the opposite ends of the rectangular block are each provided with a convex block, a fixed rotation shaft is fixed into one of the convex blocks, one endof the fixed rotation shaft is provided with a driving installation hole communicating with the outside, the other end of the fixed rotation shaft is provided with a fixing hole, the inner wall of the fixing hole is provided with at least one annular groove and a slide groove, one end of the slide groove communicates with the annular grooves, the other end of the slide groove is flush with an opening of the fixing hole, a moving rotation shaft is arranged in the other convex block, one end of the moving rotation shaft protrudes out of the surface of the convex block, and the protruding end ismatched with the fixing hole, can enter the annular grooves along the slide groove and is limited in the annular grooves. The robot modular assemble mechanical arm is formed by assembling the moduledetachable structure, can be freely assembled and lengthened according to the operation environment and is high in flexibility and universality and capable of adapting to various operations.

Owner:浙江中驱电气有限公司

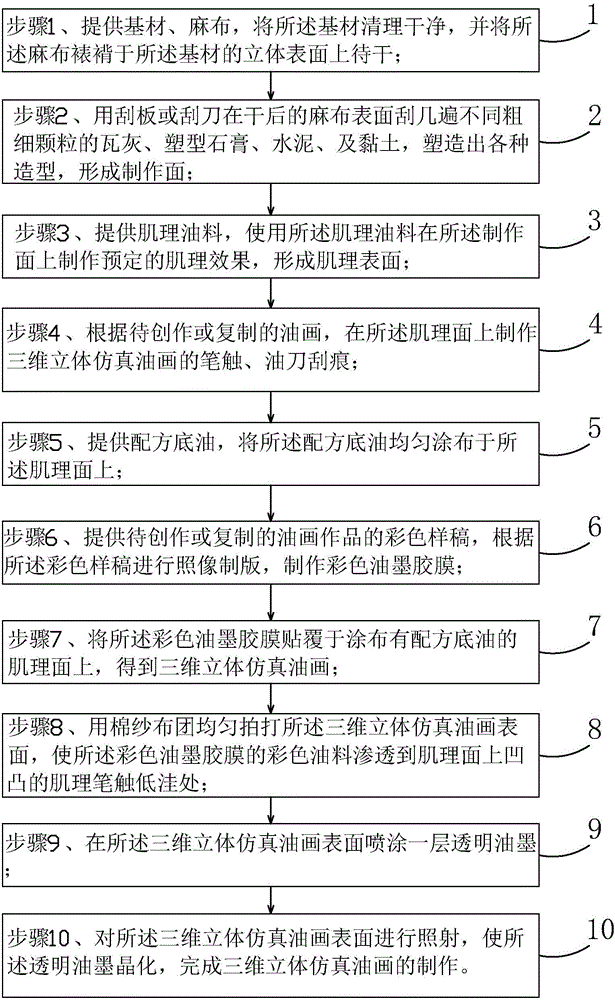

Production method of three-dimensional simulation oil painting

ActiveCN104589898ARealistic effectStrong simulationDecorative surface effectsSpecial ornamental structuresThree dimensional simulationPrinting ink

The invention provides a production method of a three-dimensional simulation oil painting. The production method comprises the following steps: 1. providing a substrate and a linen, and mounting the linen on the substrate to be dried; 2. moulding various shapes, and forming a production surface; 3. producing a predetermined texture effect on the production surface to form a texture surface; 4. producing brushwork and oil scraper scratches on the texture surface; 5. coating a formula base oil on the texture surface; 6. producing a colorful printing ink glue film; 7. pasting and covering the colorful printing ink glue film on the texture surface; 8. beating the three-dimensional oil painting so that the colorful oil paint penetrates into a low-lying part of the brushwork of a texture; 9. spraying a transparent oil ink; and 10. irradiating the surface of the three-dimensional oil painting so that the transparent oil ink is crystallized. The three-dimensional simulation oil painting produced by the method has the advantages of strong simulation performance, clear brushwork, vivid effect, and obvious texture effect, is suitable for different substrates, and can restore the original work to the best effect.

Owner:中孚泰文化建筑股份有限公司

Surface thermal treatment process for metal workpiece

InactiveCN110592328AQuality assuranceReduce consumptionQuenching agentsHeating furnaceAqueous solution

The invention discloses a surface thermal treatment process for a metal workpiece. The process comprises the following steps: pickling the metal workpiece in a hydrochloric acid solution, performing ultrasonic treatment at a post-treatment period, and sequentially putting metal plates to be subjected to thermal treatment into a heating furnace to burn for later use; soaking the metal plates subjected to thermal treatment through an aqueous solution, and realizing metal surface thermal treatment rust-removal; putting the metal workpiece into a vacuum heater to heat by laser flame spraying, transferring a normalized metal workpiece into a salt bath furnace, transferring the metal workpiece into an air furnace to preserve heat, and transferring the annealed metal workpiece into a quenching furnace to perform high-temperature quenching. On the premise of guaranteeing performance, the surface thermal treatment process for the metal workpiece saves energy consumption, reduces production cost, improves tensile strength and percentage elongation after fracture, prevents dropping of oxide skin, reduces metal workpiece deformation, and guarantees metal workpiece quality.

Owner:徐州彭圆锻造有限公司

High-temperature abrasion-resistant coating

The invention relates to a refractory material, in particular to a high-temperature abrasion-resistant coating. The high-temperature abrasion-resistant coating is prepared from15-22 parts of white corundum superfine powder, 6-11 parts of cement, 4-14 parts of raw clay, 9-15 parts of titanium dioxide, 9-14 parts of sillimanite, 5-7 parts of borax, 3-9 parts of magnesium hexasilicate, 4-9 parts of aluminum dihydrogen phosphate, 2.3-4.5 parts of sodium persulfate,0.9-1.3 parts of PA-80 high temperature plaster, 6-9 parts of aluminum oxide, 0.3-1.5 parts of silicon powder and 3-5 parts of phosphoric acid. The mechanical properties and shock resistance properties of the high-temperature abrasion-resistant coating are improved, the high-temperature abrasion-resistant coating is resistant to high temperature, does not easily shed and has good adhesion, and the coating formed in a high-temperature furnace can be resistant to abrasion and is prevented from shedding.

Owner:YIXING GUOQIANG FURNACE IND

Method for producing zip fastener

InactiveCN1498747AAnti-sheddingEliminate positioning errorsDomestic slide fastenersPunchingEngineering

A technology for manufacturing zipper includes forming teeth of zipper, providing fabric belt with cord at edge, radially cutting, punching holes, ejection moulding of upper stops, plug pins and fixed pins while directly fixing them on said cords, inserting its start end, engaging the teeth, fixing lower stop block, and cutting short by needed size. Its advantage is high positioning accuracy.

Owner:GENMORE ZIPPER CORP

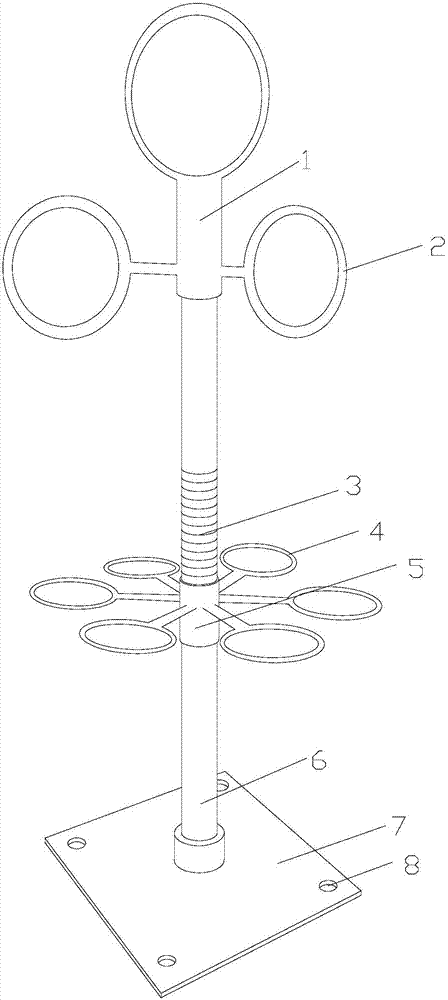

Hanging rack capable of rotating 360 degrees

The invention provides a hanging rack capable of rotating 360 degrees. The hanging rack is provided with a base. Through holes are disposed around the base, and a vertical supporting rod is arranged on the middle portion of the upper end surface of the base. The outer cylindrical surface of the middle portion of the supporting rod is provided with an external thread and is connected with a sleeve tube in a spinning mode through the external thread, wherein the sleeve tube can rotate radially along the supporting rod and can move linearly along the axis direction of the supporting rod. The outer circumferential surface of the sleeve tube is evenly distributed along the radial direction of the sleeve tube and is provided with a plurality of small rings which are arranged horizontally. The top of the supporting rod is provided with a sleeve barrel capable of rotating around the supporting rod. Three large rings arranged vertically are arranged on the left side, right side and top of the sleeve barrel respectively. The hanging rack capable of rotating 360 degrees has the advantages that the hanging rack is strong and durable; and the height of the suspension can be adjusted according to the different size and length of hanged clothes to make full use of the space; the hanging rack can also rotate 360 degrees freely in the horizontal direction; the hanging rack is anti-fall, rotatable, easy to hang and strong in practicability.

Owner:赵婷

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com