Composite fireproof insulation board and preparation method thereof

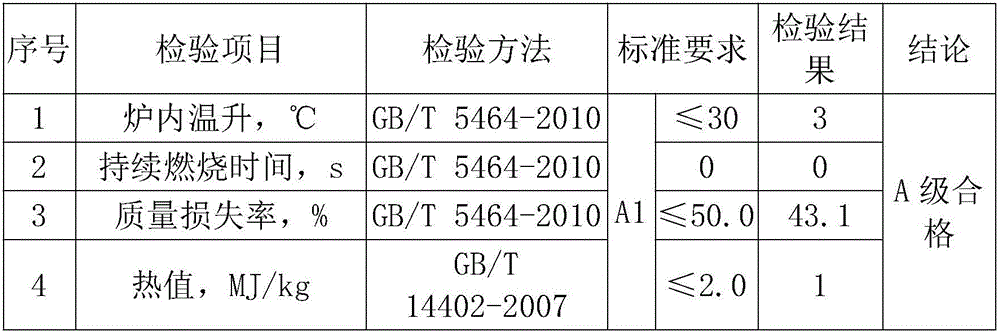

A technology of fire-proof insulation board and insulation layer, which is applied in the field of wall insulation materials, can solve the problems of only reaching B1 and B2 grade standards, and cannot achieve fire prevention, etc., and achieve long water release time, convenient and simple construction, and good foaming effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

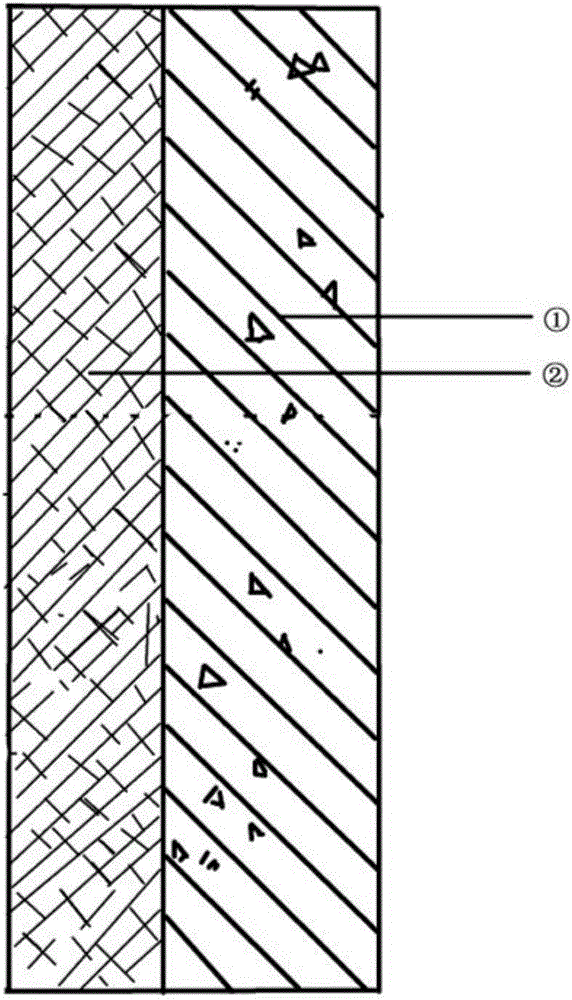

[0034] A composite fireproof and thermal insulation board, comprising a thermal insulation layer and an inorganic fireproof thermal insulation layer;

[0035] The insulation layer is polyurethane board;

[0036] The inorganic fireproof insulation layer is prepared according to the following method:

[0037] First weigh the following raw materials according to parts by mass: 80 parts of magnesium oxide, 60 parts of magnesium chloride, 40 parts of water, 80 parts of mineral powder, 1 part of modifier, 8 parts of hydrophobic agent, 2 parts of hydrophobic powder, and 8 parts of polystyrene particles; Take by weighing foaming agent and water a total of 25 parts, the mass part ratio of foaming agent and water is 1:40;

[0038] The above-mentioned raw materials are mixed and evenly extruded after proportioning, and the inorganic fire-proof and heat-preserving layer with a thickness of 45 mm is made after natural drying by a plate making machine.

[0039] The thermal insulation laye...

Embodiment 2

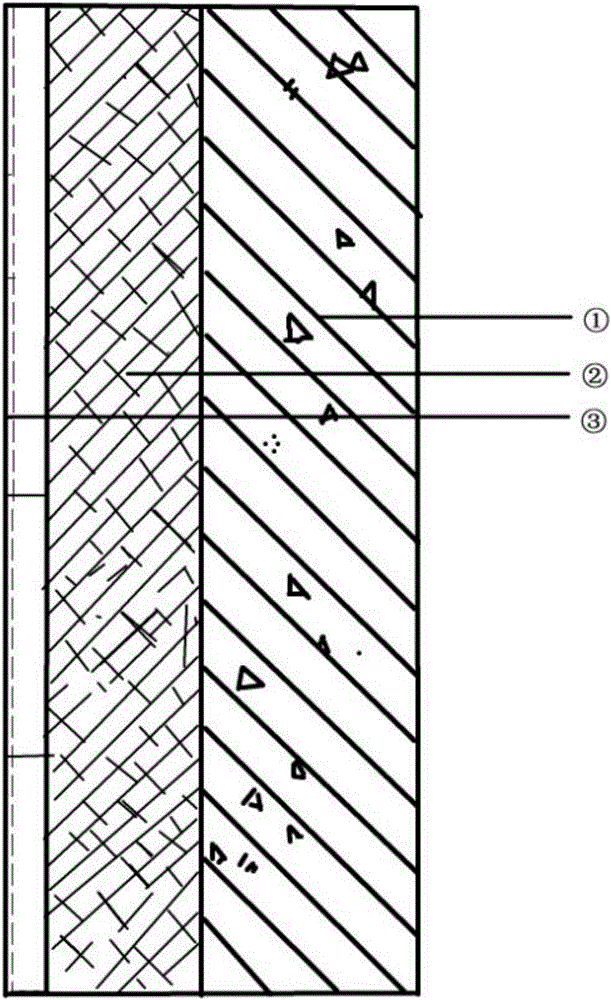

[0041] A composite fireproof and thermal insulation board, comprising a thermal insulation layer and an inorganic fireproof thermal insulation layer;

[0042] The insulation layer is extruded board;

[0043] The inorganic fireproof insulation layer is prepared according to the following method:

[0044] First weigh the following raw materials according to parts by mass: 80 parts of magnesium oxide, 60 parts of magnesium chloride, 40 parts of water, 80 parts of mineral powder, 1 part of modifier, 8 parts of hydrophobic agent, 2 parts of hydrophobic powder, and 9 parts of polystyrene particles; Take by weighing foaming agent and water a total of 25 parts, the mass part ratio of foaming agent and water is 1:50;

[0045] The above-mentioned raw materials are mixed and evenly extruded after proportioning, and an inorganic fire-proof and heat-preserving layer with a thickness of 45 mm is made after natural drying by a plate making machine.

[0046] The thermal insulation layer and...

Embodiment 3

[0048] A composite fireproof and thermal insulation board, comprising a thermal insulation layer and an inorganic fireproof thermal insulation layer;

[0049] The insulation layer is polystyrene board;

[0050] The inorganic fireproof insulation layer is prepared according to the following method:

[0051] First weigh the following raw materials according to parts by mass: 80 parts of magnesium oxide, 60 parts of magnesium chloride, 40 parts of water, 80 parts of mineral powder, 1 part of modifier, 8 parts of hydrophobic agent, 2 parts of hydrophobic powder, and 10 parts of polystyrene particles; Take by weighing foaming agent and water a total of 25 parts, the mass part ratio of foaming agent and water is 1:60;

[0052] The above-mentioned raw materials are mixed and evenly extruded after proportioning, and the inorganic fire-proof and heat-preserving layer with a thickness of 45 mm is made after natural drying by a plate making machine.

[0053] The thermal insulation layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com