Fully-vulcanized polypropylene/acrylate rubber thermoplastic elastomer and preparation method thereof

A technology of thermoplastic elastomers and acrylic esters, which is applied in the preparation of fully vulcanized thermoplastic elastomers, and in the field of fully vulcanized polypropylene/acrylate rubber thermoplastic elastomers, which can solve the problem of inability to prepare oil-resistant thermoplastic elastomers with comprehensive performance and long-term Continuously prepare thermoplastic elastomers, and the elongation at break cannot be high enough to achieve the effects of expanding the hardness range, strong competitiveness, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

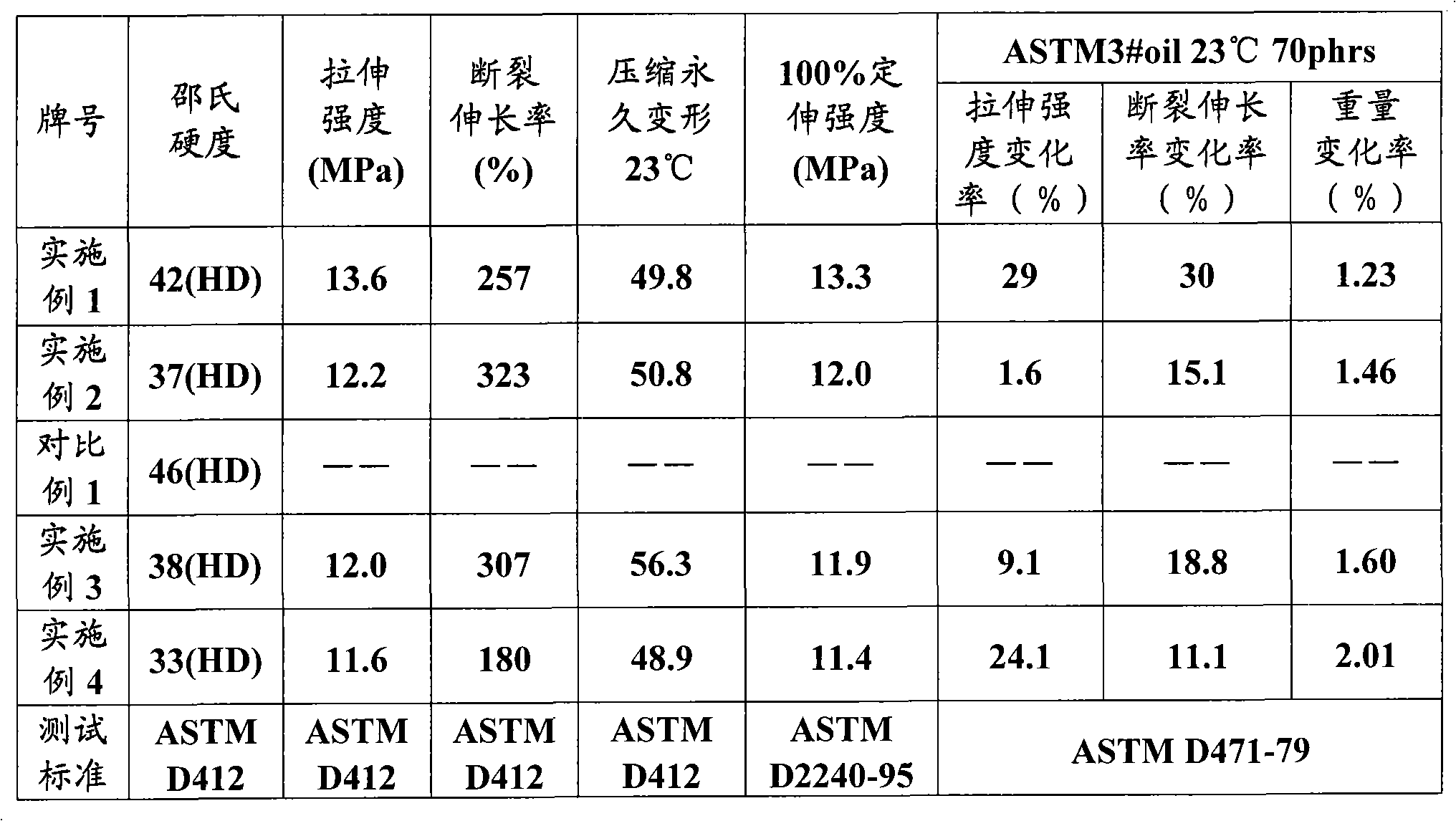

[0018] Fully vulcanized powdered acrylate powder rubber with an average particle size of about 0.1 μm (produced by Beijing Chemical Research Institute of China Petroleum and Chemical Industry Co., Ltd. - Ethylhexyl) ester (produced by South Korean LG company) is fully mixed in a ratio of 100 / 30, and polypropylene plastic (Yanshan Petrochemical, brand PPR) is mixed in a ratio of 50 / 50, and then 0.5% antioxidant 1010 ( Produced by Ciba Jiaji in Switzerland), extruded and granulated with ZSK-25 twin-screw extruder of German WP company. and 195°C (head temperature). The pellets were made into standard specimens by injection molding, and various performance tests were carried out. The measured results of the fully vulcanized polypropylene / acrylic rubber thermoplastic elastomer are listed in Table 1.

Embodiment 2

[0020] Except that fully vulcanized acrylate powder rubber and trimellitate tris (2-ethylhexyl) ester are mixed in a ratio of 100 / 50, all the others are the same as in Example 1, and the measured fully vulcanized polypropylene / acrylate rubber The thermoplastic elastomer results are listed in Table 1.

Embodiment 3

[0024] Fully vulcanized acrylate powder rubber with an average particle size of about 0.1 μm (produced by Beijing Chemical Research Institute of China Petroleum and Chemical Industry Co., Ltd. Ethylhexyl) ester (produced by South Korean LG company) is fully mixed in a ratio of 100 / 30, mixed with polypropylene (Yanshan Petrochemical, brand PPR) in a ratio of 60 / 40, and then 0.5% antioxidant 1010 (Swiss Automobile Co., Ltd.) is added. produced by Bagaki), extruded and granulated with ZSK-25 twin-screw extruder of German WP company, and the temperatures of each section of the extruder were: 170°C, 190°C, 190°C, 190°C, 190°C and 195°C ℃ (head temperature). Granules are made into standard specimens by injection molding, and various performance tests are carried out. The results of the fully vulcanized polypropylene / acrylate rubber thermoplastic elastomer recorded are listed in Table 1 (if the method of the patent of the present invention is not adopted, then the The samples prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com