Preparation method of casting polyurethane tire

A polyurethane tire and polyurethane elastomer technology, applied in tires, other household appliances, household appliances, etc., can solve the problem of difficult positioning of the bead ring, achieve convenient positioning, realize automation, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

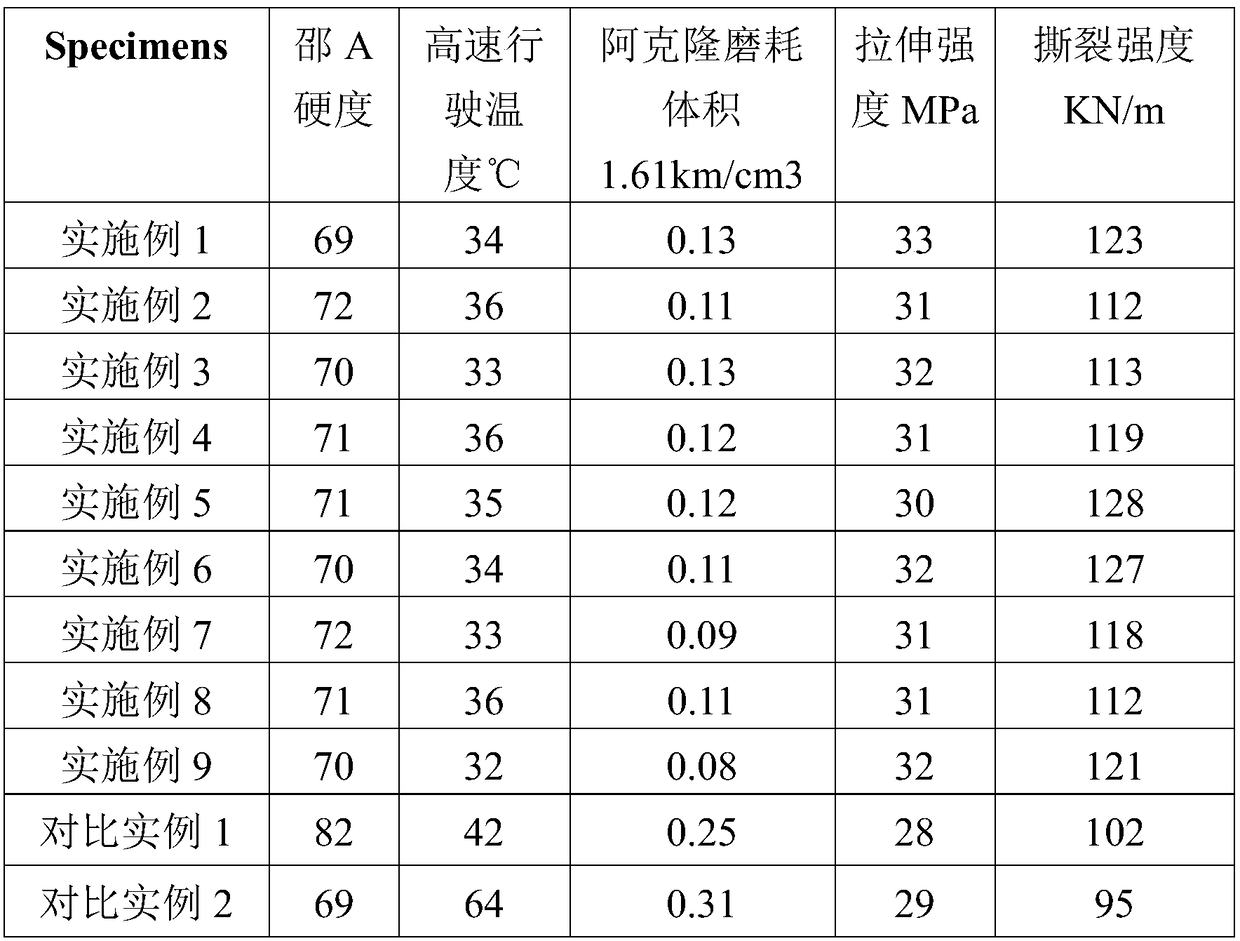

Examples

Embodiment 1

[0051] The polyadipate-1,4-butanediol and toluene diisocyanate mass ratio is 100:40 to prepare prepolymer, heat to 80℃, add 1% white pigment of prepolymer mass to give the tire white, inside the mold The frame material is fixed in the tire mold by three-point positioning, the positioning deviation is 0.01mm, the electromagnetic force is adjusted to 1.1T, the inner wall is sprayed with a layer of 0.01mm thick polyvinyl alcohol release agent, the frame material is composed of steel wire, and laminated The mesh structure is woven, and the casting machine is started to pour into the tire mold. The mold is filled to maintain a pressure of 0.1MPa, and the temperature is 80°C. After 8 minutes, the mold is ejected. The tire matrix is obtained by cooling and molding. The layer is precisely sprayed on the inner wall of the tire with a thickness of 1.7mm; the surface of the tire matrix pattern is coated with 0.01mm thick trichloroisocyanuric acid and ethyl acetate is used as a solvent fo...

Embodiment 2

[0053] The mass ratio of tetrahydrofuran polyether glycol and 1,4-phenylene diisocyanate is 100:30 to prepare a prepolymer, and it is heated to 180°C, and 1% of the mass of the prepolymer is added to give the tire a red color. The frame material is fixed in the tire mold by a two-point positioning method, the positioning deviation is 0.05mm, the electromagnetic force is adjusted to 0.1T, the inner wall is sprayed with a layer of 0.5mm thick paraffin release agent, the frame material is a single-layer net cylinder structure, and the casting starts The machine is poured into the tire mold, the mold is filled to maintain the pressure 22MPa, the temperature is 170°C, and the mold is ejected after 10 minutes. The tire matrix is obtained by cooling and molding. A layer of polyvinyl alcohol gas barrier film is compounded inside the tire with a thickness of 1.5mm; The surface of the tire base pattern is coated with a 0.03mm-thick solution of trichloroisocyanuric acid in methyl ethyl k...

Embodiment 3

[0055] The caprolactone-modified polyrotaxane and hydrogenated xylylene diisocyanate were prepared into a prepolymer with a mass ratio of 100:48, heated to 120°C, and 1% yellow pigment of the prepolymer mass was added to give the tire yellow. In the mold, the frame material is fixed in the tire mold by surface matching positioning method, the positioning deviation is 0.04mm, the permanent magnet is 0.4T, the inner wall is sprayed with a layer of 0.02mm thick silicone oil release agent, and the frame material uses a single-layer net cylinder structure. Start the pouring machine to pour into the tire mold, fill the mold with a pressure of 0.3MPa, keep the temperature at 120°C, and release the mold after 30 minutes. The fatty acid memory composite rubber is used as a puncture-resistant protective layer to be precisely sprayed on the inner wall of the tire with a thickness of 1.2mm , Place the casted tire matrix in a drying tunnel at 120°C for 0.5h post-treatment, then cool and soli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com