Anti-slipping supporting rail assembly

A technology for supporting rails and anti-falling off, which is applied to rack/frame structure, furniture parts, household appliances, etc., can solve the problem of not revealing anti-falling safety devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

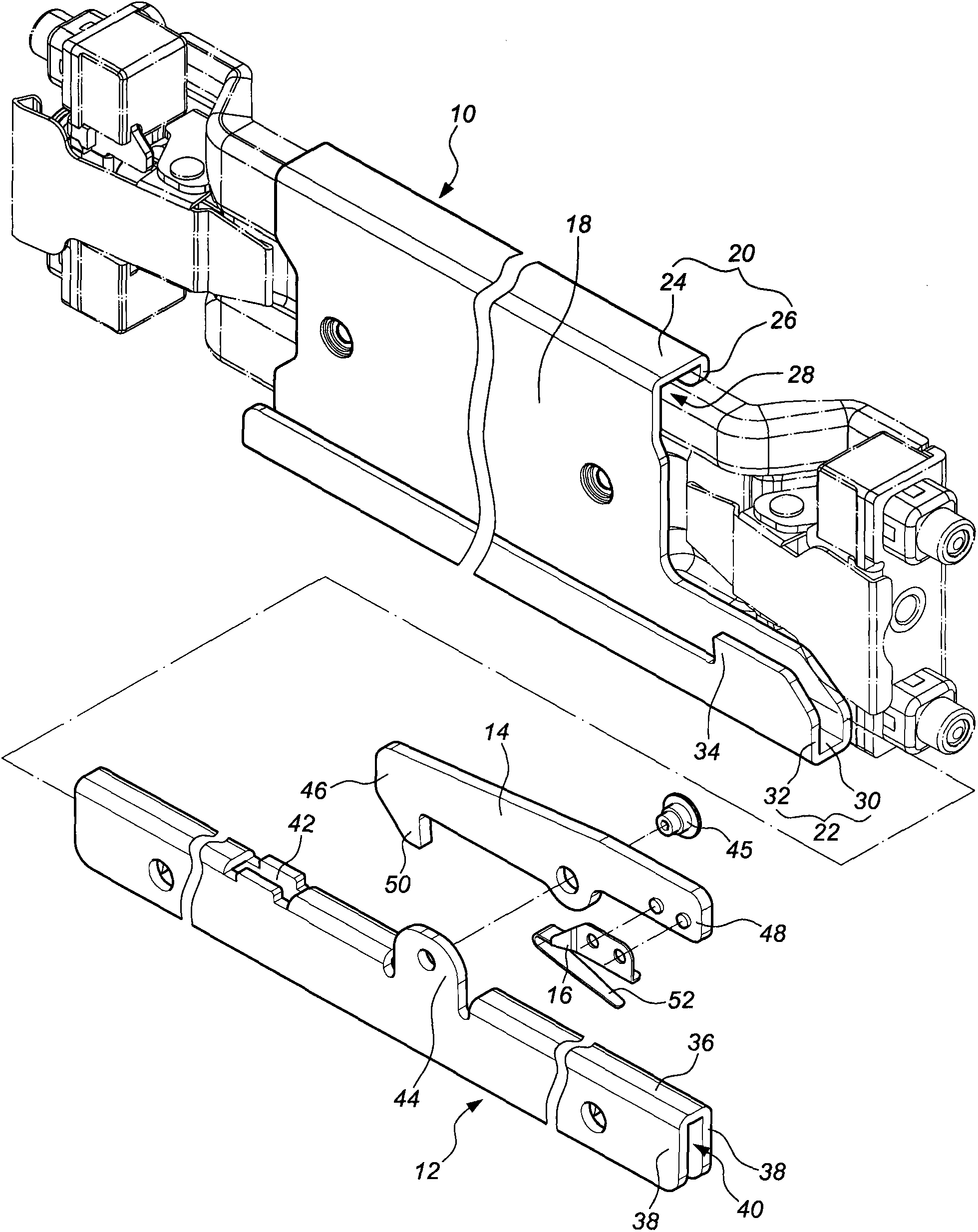

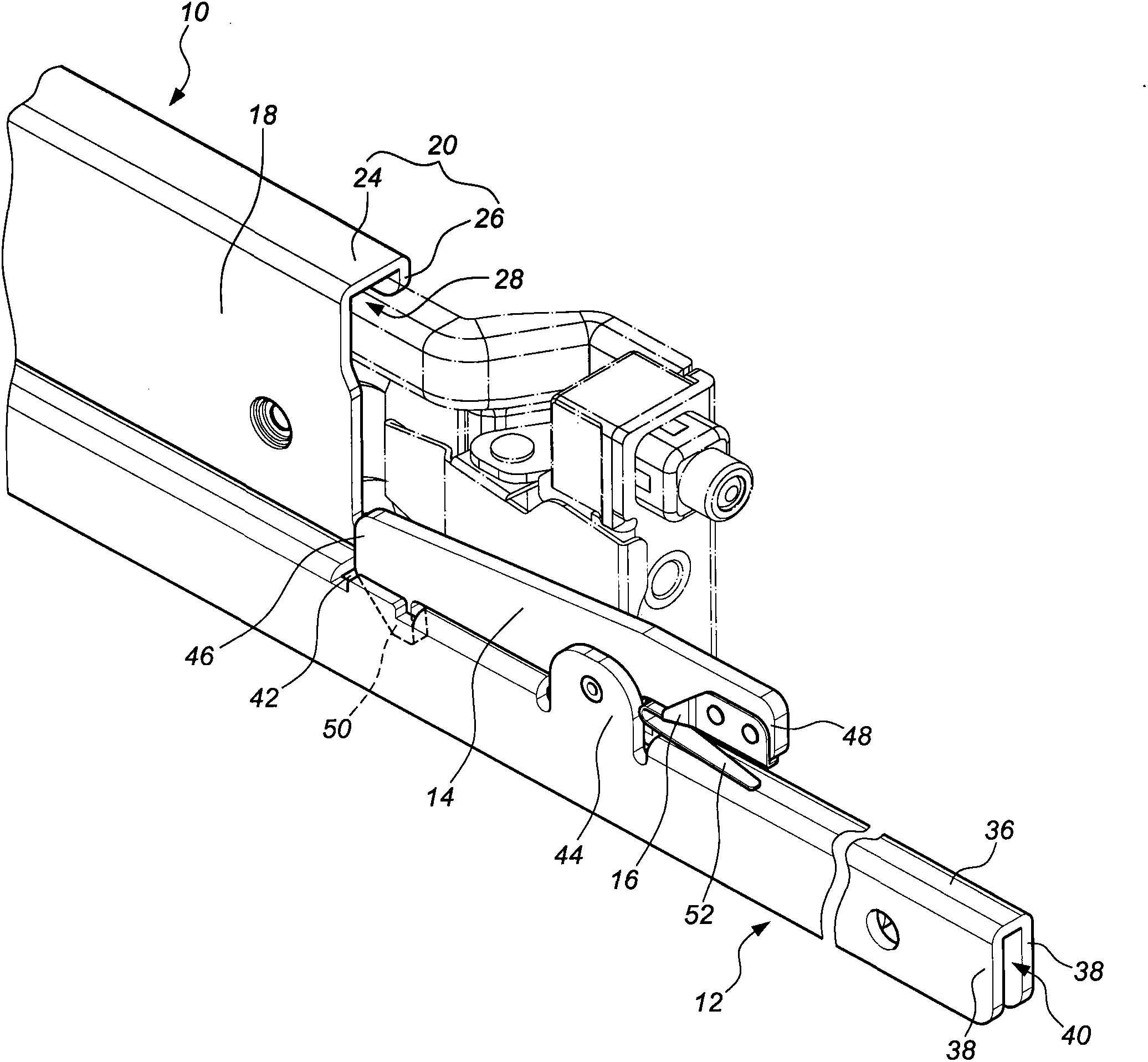

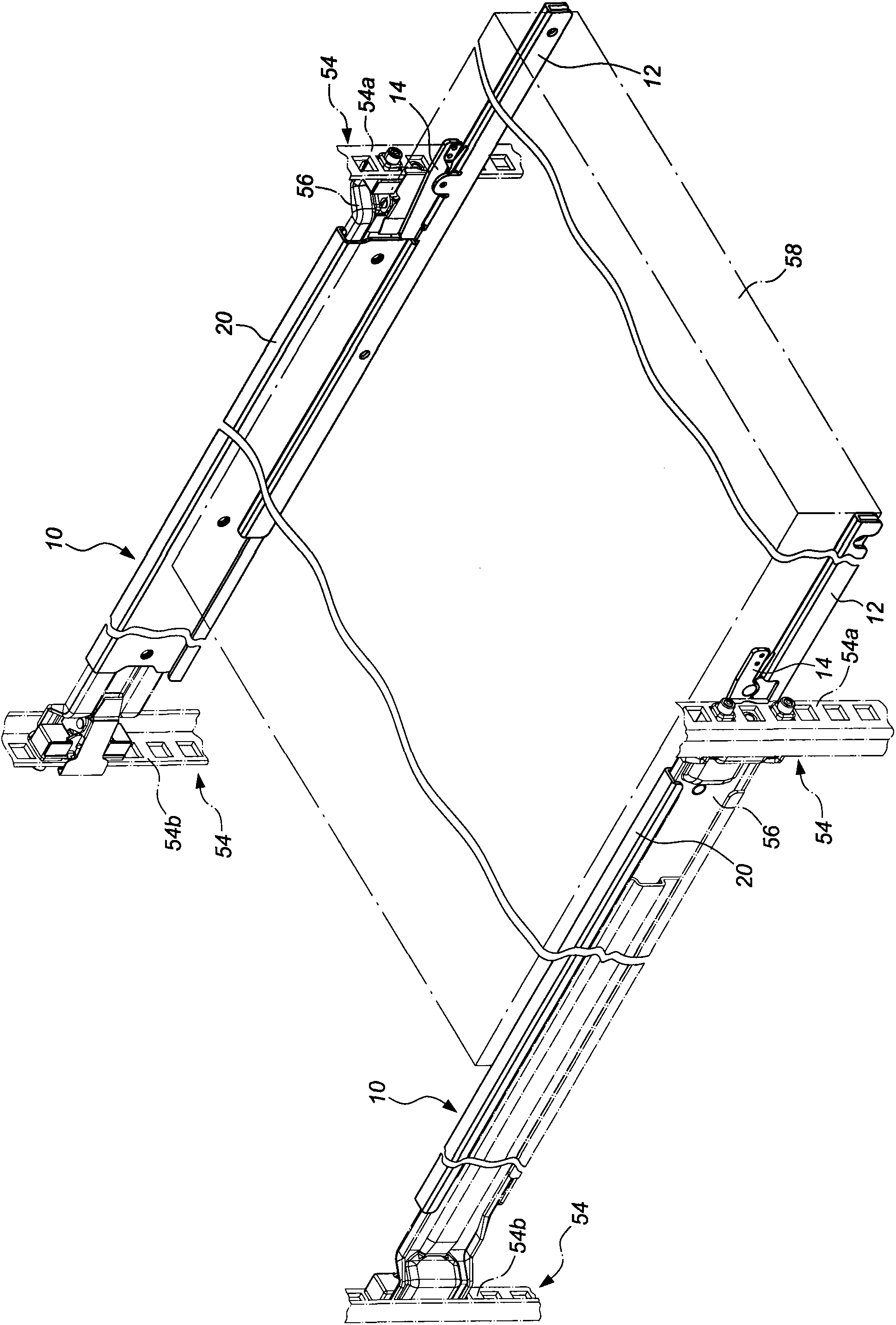

[0018] Such as figure 1 and figure 2 A supporting rail assembly showing a preferred embodiment of the present invention includes a first rail 10 , a second rail 12 , a locking member 14 and an elastic member 16 . in:

[0019] The first rail 10 includes a vertical board 18 , an upper rail body 20 and a lower rail body 22 ; the upper rail body 20 extends transversely from the top of the vertical board 18 toward a first direction and is bent downward. The lower rail body 22 extends transversely from the bottom end of the vertical plate 18 toward a second direction and is bent upward, and the second direction is opposite to the first direction. Wherein, the upper rail body 20 includes a first horizontal section 24 and a first vertical section 26 extending vertically downward from the end of the first horizontal section 24, the first vertical plate 18 and the first horizontal section 24 and the first vertical section 26 jointly form a first channel 28; the lower rail body 22 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com