Duodenal internal covering membrane made of degradable biocompatible material and application thereof

A duodenal, biocompatible technology, applied in the human tubular structure device, medical science, non-surgical orthopedic surgery, etc., can solve the problems of organ tissue damage, unavoidable, jejunal content reflux, etc., to slow down The effect of rebound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

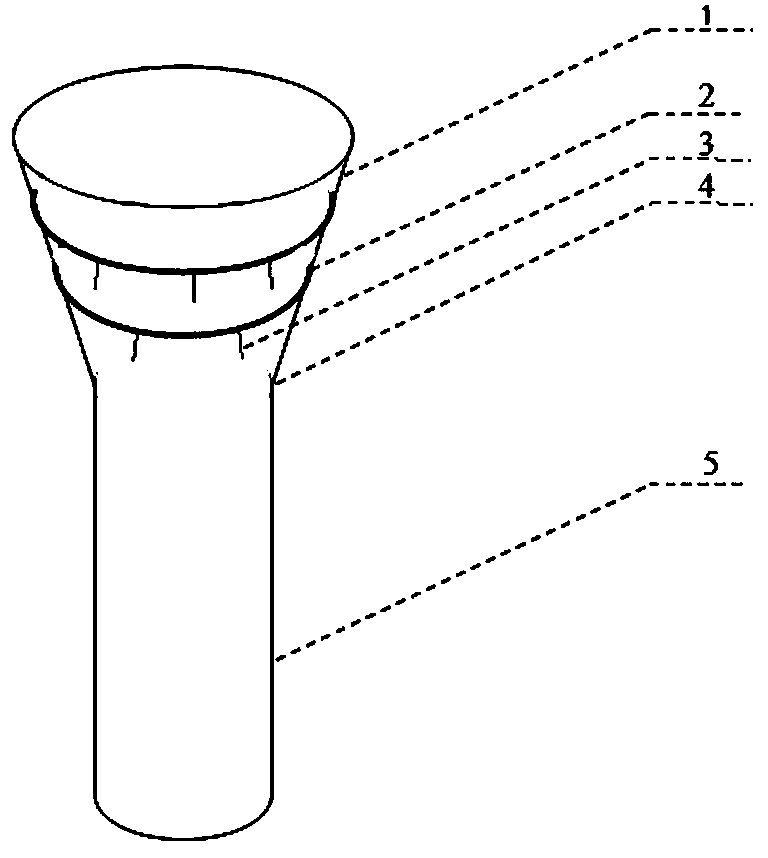

[0046] An inner membrane of the duodenum, which can be obtained from a thermosetting degradable shape memory biocompatible material, mainly consists of a tubular part 5 and an ampulla 1 of an elastic wire 2 with an anchor hook 3 surrounded by a trumpet-shaped outer side composition.

[0047] The different The hydroxyl-terminated star prepolymer with composition, relative molecular mass and functionality is reacted with aliphatic diisocyanate at 80°C to prepare a thermosetting degradable shape-memory biocompatible material with a cross-linked structure.

[0048]The thickness of the inner coating of the ampulla 1 and the tubular part 5 is both 0.005mm-1mm. The diameter and length of the tubular part 5 match the duodenum and jejunum in different populations. A section of jejunum connected to the duodenum, with a length of 80-700mm. The trumpet-shaped connecting ampulla 1 has a height of 6mm-100mm, and the trumpet-shaped connecting tubular part 5 has a gradually opening acute an...

Embodiment 2

[0053] A duodenal inner membrane, which can be obtained from thermoplastic degradable shape memory biocompatible materials, mainly consists of a tubular part 5 and a trumpet-shaped connected outer side surrounding the ampulla 1 with an elastic wire 2 with an anchor hook 3 composition.

[0054] Using MDI, 1, 4-butanediol and polyε-caprolactone diol as raw materials to synthesize thermoplastic shape memory biocompatible materials through prepolymerization method, in which carbamate is the hard segment, and the formed physical intersection The linked structure constitutes the stationary phase of the material, and polyε-caprolactone constitutes the reversible phase of the material, and its number-average molecular weight is 1600-8000. By changing the content and relative molecular weight of polyε-caprolactone, the material’s transition temperature.

[0055] The thickness of the inner coating of the ampulla 1 and the tubular part 5 is both 0.005mm-1mm. The diameter and length of t...

Embodiment 3

[0059] Embodiment 3——in vitro degradation test

[0060] Polymer samples, blocky, dry, placed in 37±1°C, 0.1 mol / L NaOH aqueous solution and pH=7.6 imitation duodenum solution (replace the degradation solution every 2 weeks), take out the sample, and use Rinse with distilled water, dry in vacuum at 40°C for 10 and weigh, and calculate the weight loss rate. The degradation behavior of polyester polyurethane (PE-U) copolymer at 37°C shows that the proportion of PE-U3 with the strongest water absorption capacity is large, and the degradation is fast, but the degradation speed of PE-Ul and PE-U2 and their water absorption capacity On the contrary, it shows that the degradation behavior of PE-U copolymer is related to the water absorption capacity of the polymer and the hydrolysis capacity of the ester bond on each segment in the polymer, and the degradation rate can be set accordingly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com