A high-yielding glucosamine engineering bacterium and its construction method through homologous recombination knockout of manx

A technology of glucosamine and genetically engineered bacteria, applied in the field of bioengineering, can solve the problems of low conversion efficiency of chitin hydrolysis, not yet reached industrialized production, and high product cost, and achieve low production cost, high production intensity, and low environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] 1. Construction of recombinant plasmid pET-28a(+)-glmS-gna1

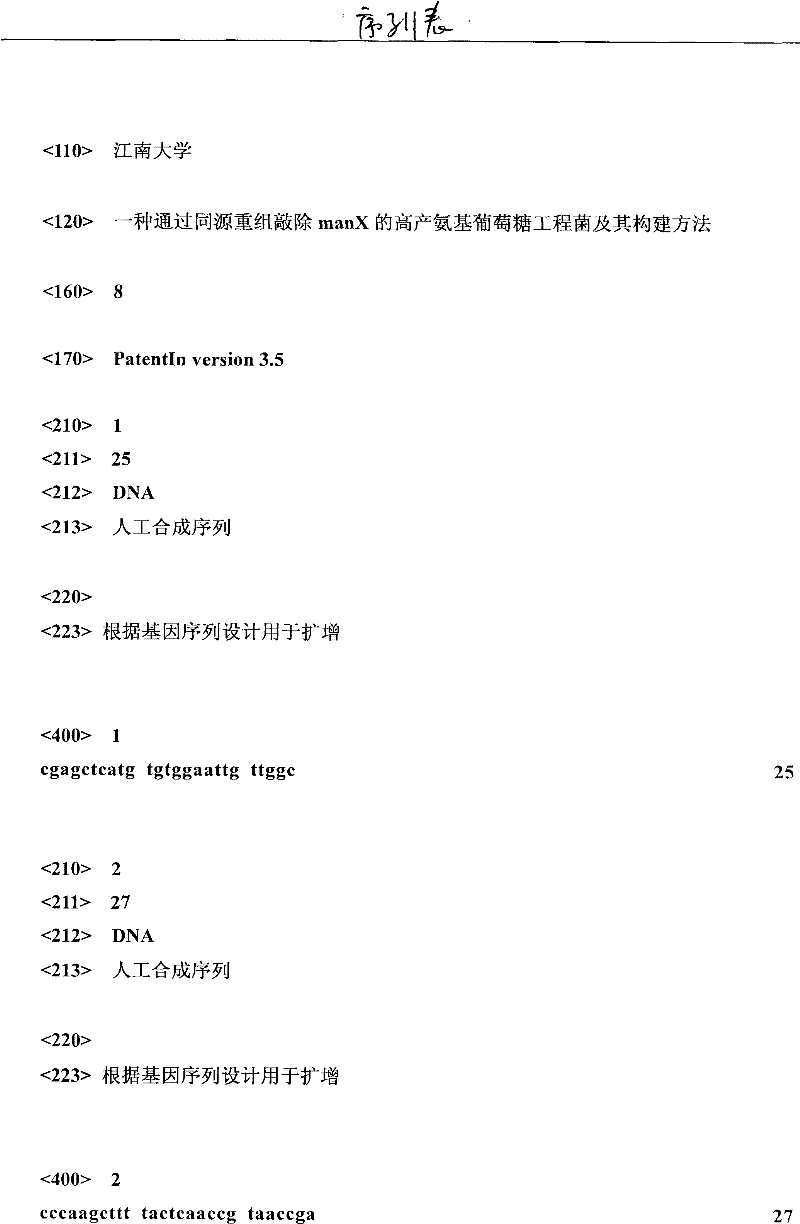

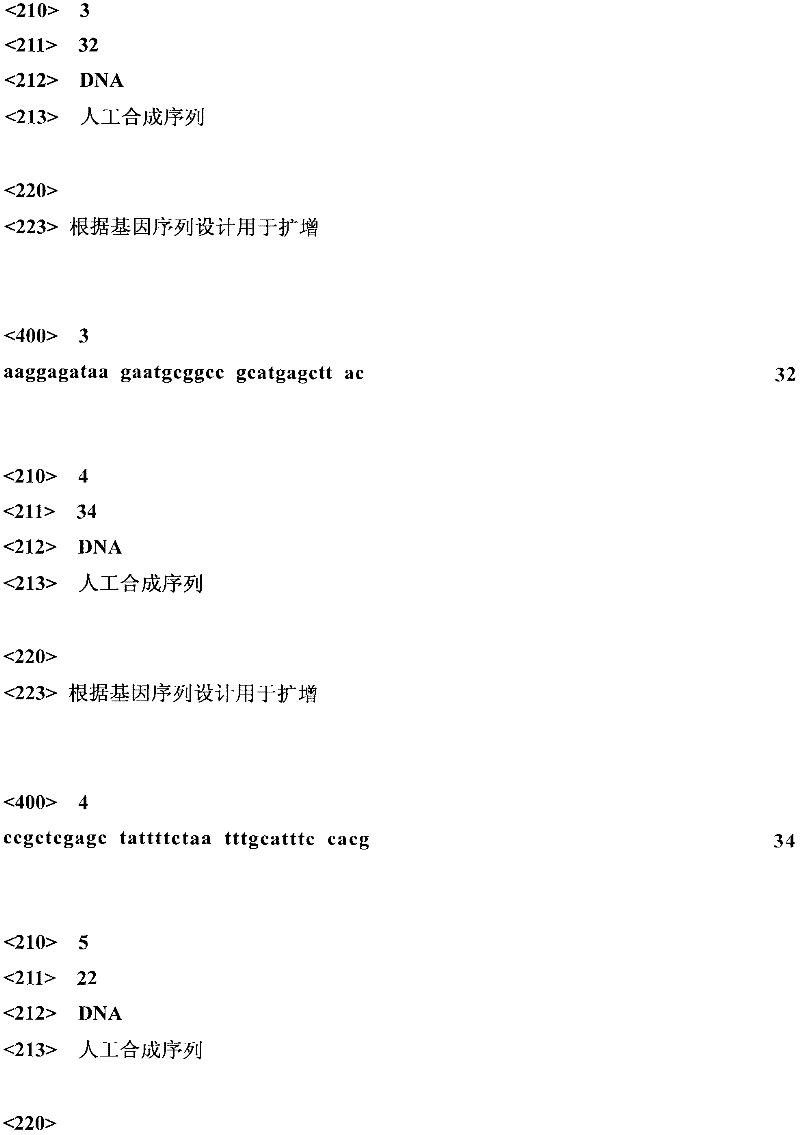

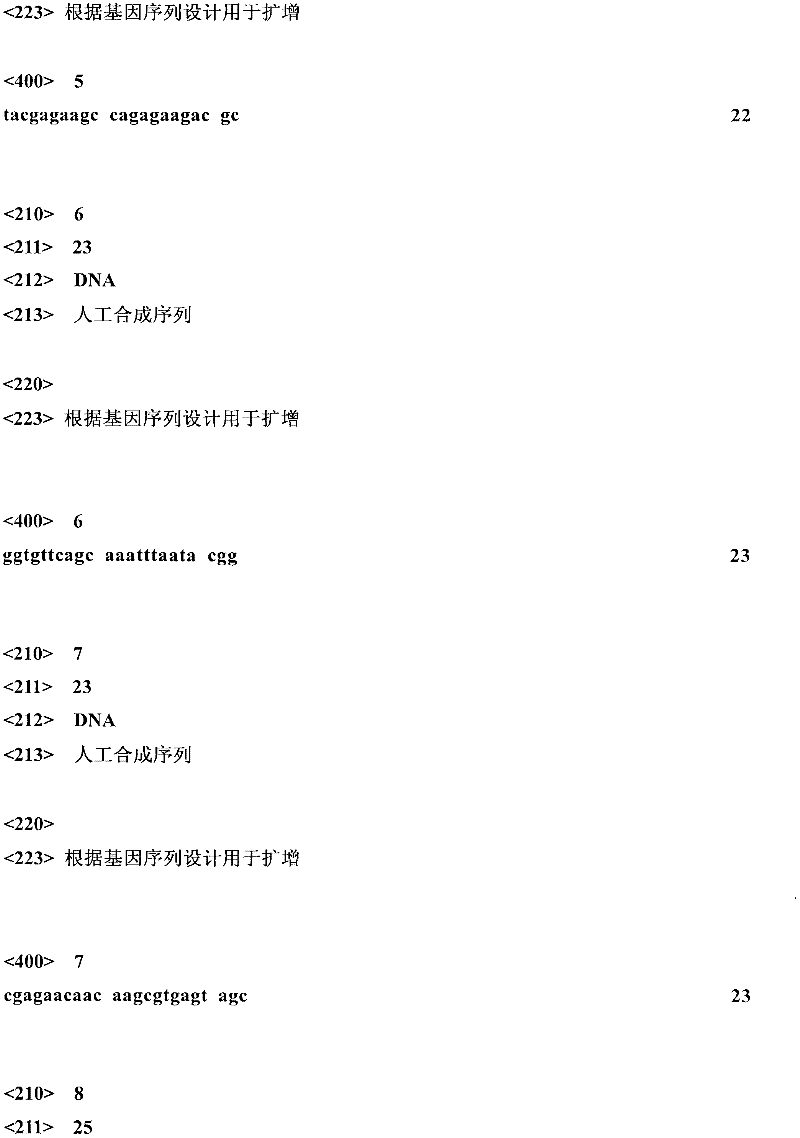

[0016] Primers used to amplify the glmS gene:

[0017] Upstream: 5'-C GA GCT C AT GTG TGG AAT TGT TGG C-3' (underlined sequence indicates restriction endonuclease recognition site Sac I)

[0018] Downstream: 5'-CCC AAG CTT TTA CTC AAC CGT AAC CGA-3' (the underlined sequence represents the restriction enzyme site Hind III).

[0019] Glucosamine synthase gene glmS was obtained by PCR using E. coli BL21 (DE3) genome (GenBank No. CP001509.3) as a template. Digest the glmS gene fragment and pET-28a(+) with restriction endonucleases Sac I and Hind III, and insert the glmS gene fragment into the Sac I and Hind III sites of plasmid pET-28a(+) by ligation reaction In between, the recombinant plasmid pET-28a(+)-glmS was obtained.

[0020] Primers used to amplify the gna1 gene:

[0021] Upstream: 5'-AAGGAGATAAGAAT GCGGCCGC ATGAGCTTAC-3' (underlined sequence indicates restriction endonuclease recognition site No...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com