Method for manufacturing stand column type temporary sleeper supporting device

A manufacturing method and temporary support technology, which can be applied to track, track laying, track maintenance, etc., and can solve problems such as high support cost, slow operation speed, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

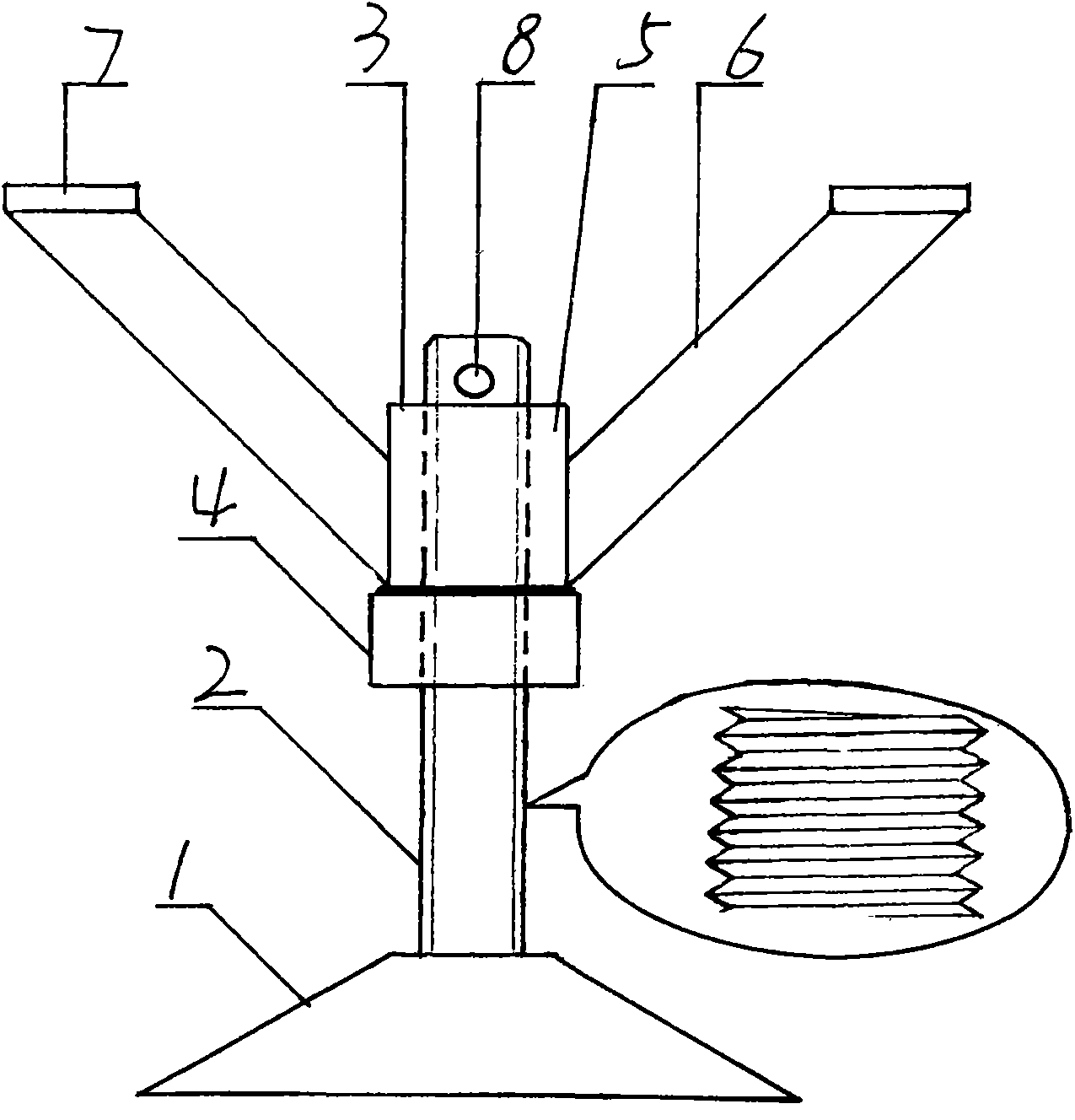

[0007] A kind of manufacturing method of column type sleeper temporary supporter, such as figure 1 , shown, the column type sleeper temporary supporter is made of steel, and the structure is made up of base 1, bolt column 2 and support 3. The base 1 is a circular or elliptical plate body, which is stamped and formed by a punch press, and the formed base 1 is bell-shaped. The bottom length of the base 1 is more than 20 centimeters. In the middle of the base 1, a peg post 2 is arranged. The peg post 2 is a threaded cylinder. The peg post 2 is made of round steel, and the peg post 2 and the base 1 are vertically welded into one. A nut 4 is provided on the thread of the peg 2 , and the nut 4 can rotate and move on the peg 2 . Mount the bracket 3 on the peg 2, the bracket 3 is welded with steel, the shape of the bracket 3 is Y-shaped, the bracket 3 is composed of two oblique arms 6 and a conduit 5 welded, the oblique arm 6 and the conduit 5 are welded together On the plane of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com