Bent pipe sanding machine

A technology of sand passing machine and abrasive belt, which is applied in the direction of abrasive belt grinder, grinding machine, metal processing equipment, etc., and can solve the problems of uneven polishing, inconsistent polishing degree, non-deflection, anti-slip, anti-falling of elbows, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

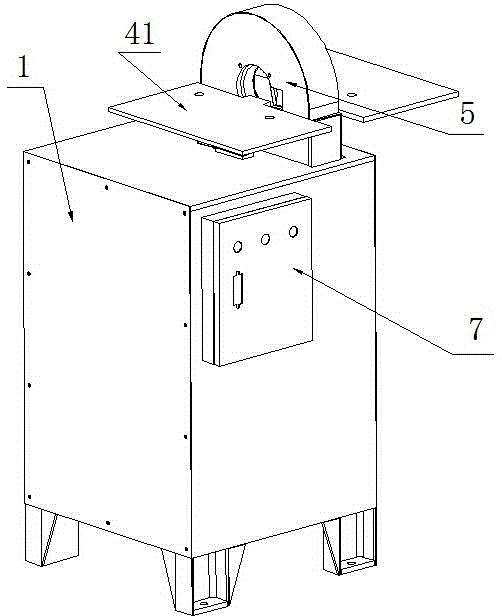

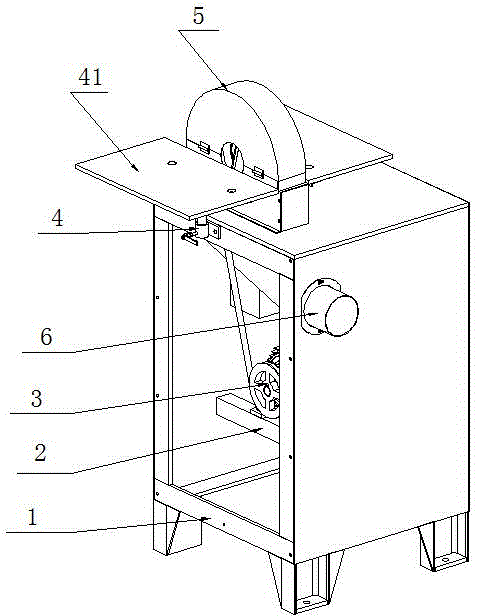

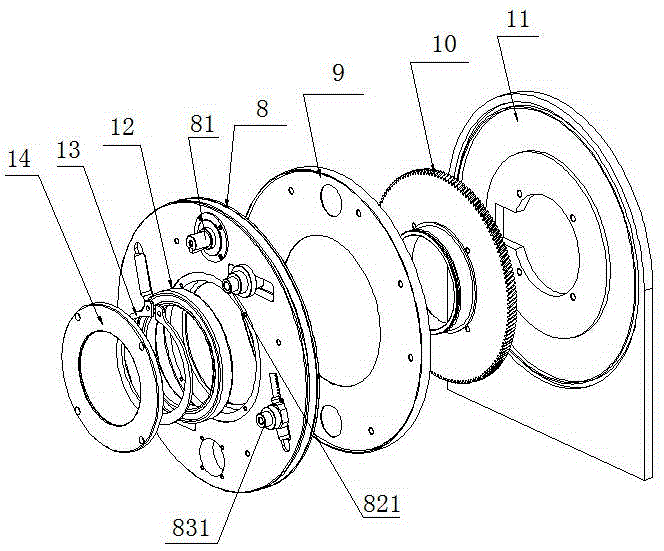

[0020] In this example, if Figure 1 to Figure 9 As shown, a kind of bent pipe sand passing machine of the present invention comprises a frame 1, and a motor fixing frame 2 arranged in the frame 1, and a motor 3 arranged on the motor fixing frame 2, and a motor 3 arranged on the frame 1 The supporting plate fixing seat 4 on the top, the supporting plate 41 arranged on the supporting plate fixing seat 4, the grinding wheel 5 arranged in the middle of the supporting plate 41, and the dust suction pipe arranged on one side of the frame 1 6, and the control box 7 arranged on the other side of the frame 1; the grinding wheel 5 is provided with a disk 8, a dustproof disk 9, a fixed gear 10 and a gear fixed disk 11, and the disk 8, dustproof disk 9. The connection between the fixed gear 10 and the gear fixed disc 11 is provided with a bearing 12, the side of the bearing 12 is provided with an outer circlip 13, and the side of the outer circlip 13 is provided with a circlip ring 14; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com