Weighing sensor with anti-deviation function

A load cell and anti-offset technology, applied in the field of load cells, can solve the problems of load cell data deviation, position offset, uneven force distribution, etc., to increase stability, avoid offset, and save operation the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

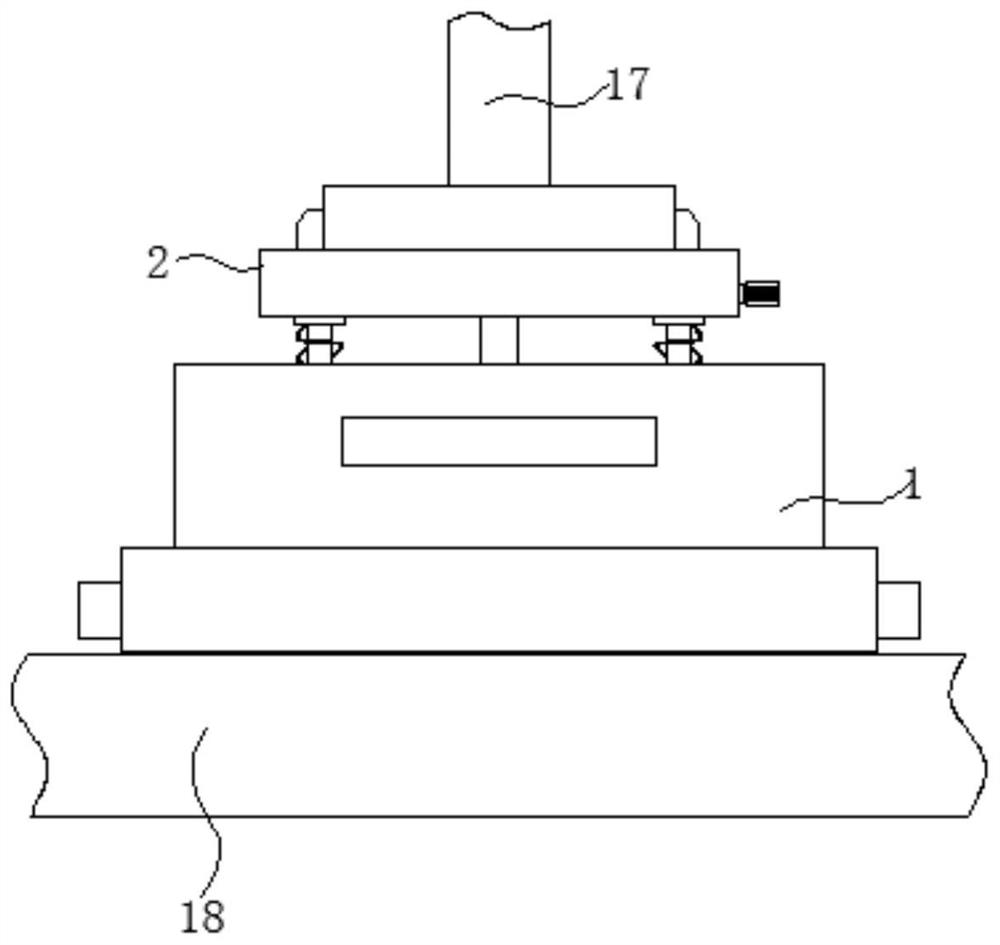

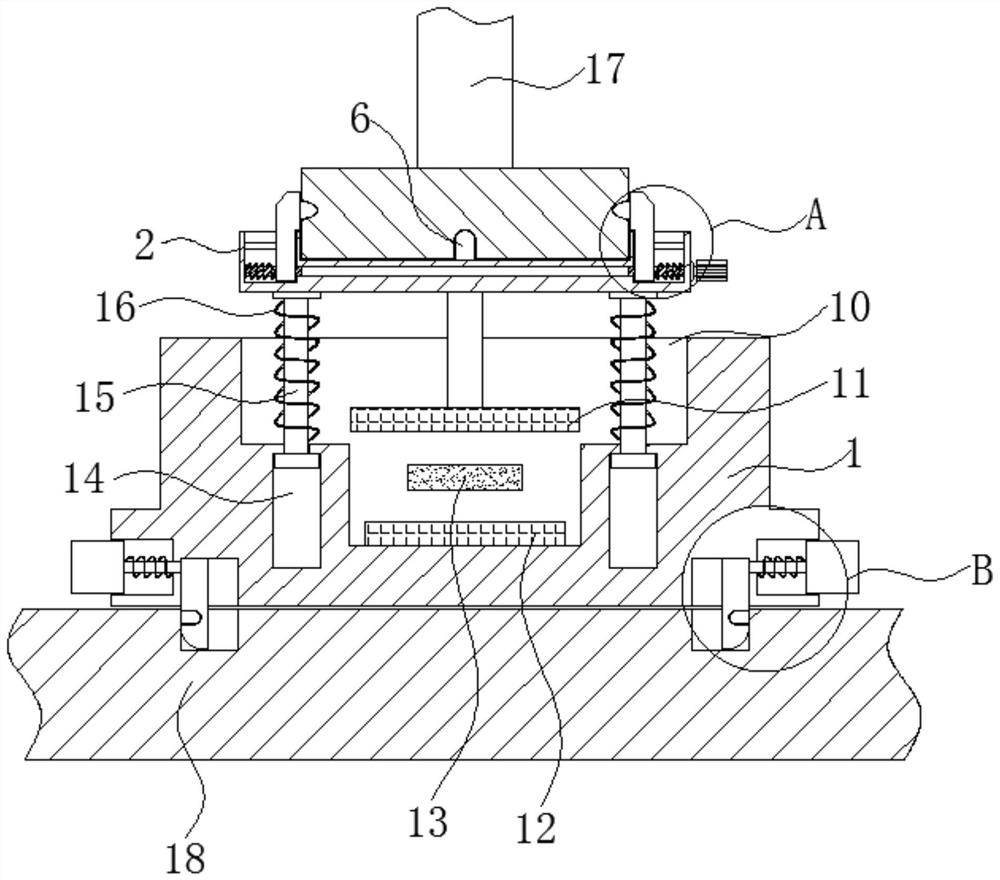

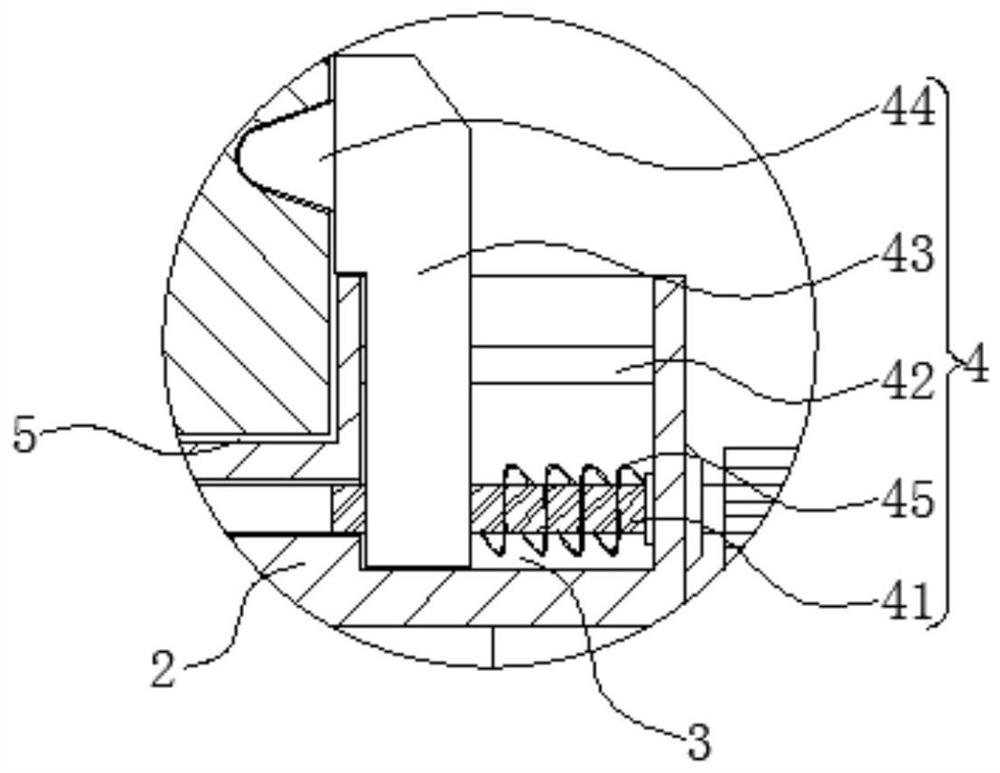

[0027] Please refer to figure 1 , figure 2 , image 3 and Figure 4 ,in, figure 1 Schematic diagram of the external structure of the load cell with anti-offset provided by the present invention; figure 2 Schematic diagram of the internal structure of the load cell with anti-offset provided by the present invention; image 3 for figure 2 The enlarged schematic diagram of part A shown; Figure 4 for figure 2 The enlarged schematic diagram of part B is shown. Load cells with anti-skew, including:

[0028] Shell 1 and bearing plate 2;

[0029] Movable slots 3, the two movable slots 3 are opened on both sides of the inside of the load-bearing plate 2, the inside of the load-bearing plate 2 is provided with a clamping structure 4, and the clamping structure 4 includes a threaded rotating rod 41 and Two limit rods 42, both sides of the outer sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com