Wind-power blade preparation method capable of controlling mass distribution

A mass distribution, wind power blade technology, applied in the direction of household components, household appliances, other household appliances, etc., can solve the problems of increasing quality and safety, blade improvement, etc., and achieve the effect of reducing quality and safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

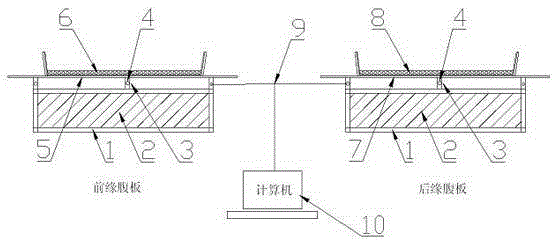

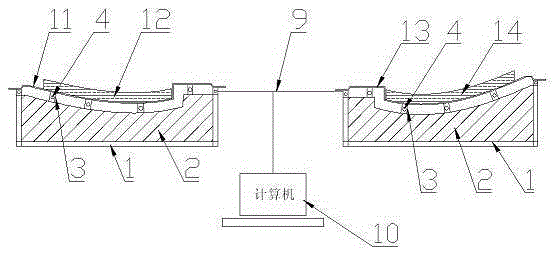

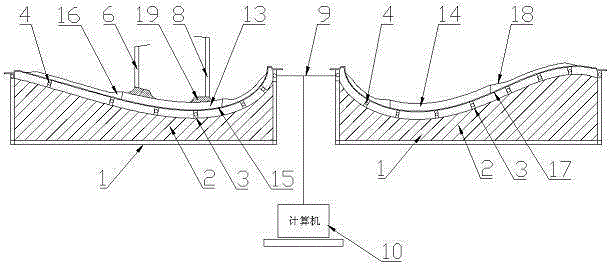

[0030] The present invention is described in conjunction with accompanying drawing and specific embodiment:

[0031] Such as figure 1 , 2 , 3, and 4, a method for preparing wind power blades to control the mass distribution of wind power blades, the method for preparing wind power blades includes the preparation of the upper shell of the blade, the preparation of the lower shell of the blade, the preparation of the leading edge web, the rear The preparation of the edge web, the preparation of the girder, and the bonding and molding of the blade; through the preparation of the upper shell of the blade, the preparation of the lower shell of the blade, the preparation of the leading edge web, the preparation of the trailing edge web, and the preparation of the girder Control the weight and mass distribution during the preparation and blade clamping and bonding process, so as to complete the control of the mass distribution of wind power blades;

[0032] The specific steps of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com