Curtain wall hook member

A curtain wall and component technology, which is applied in the field of curtain wall hooks, can solve problems such as lack of welders and outstanding construction quality problems, and achieve the effects of simple structure, lower curtain wall installation costs, and lower quality risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

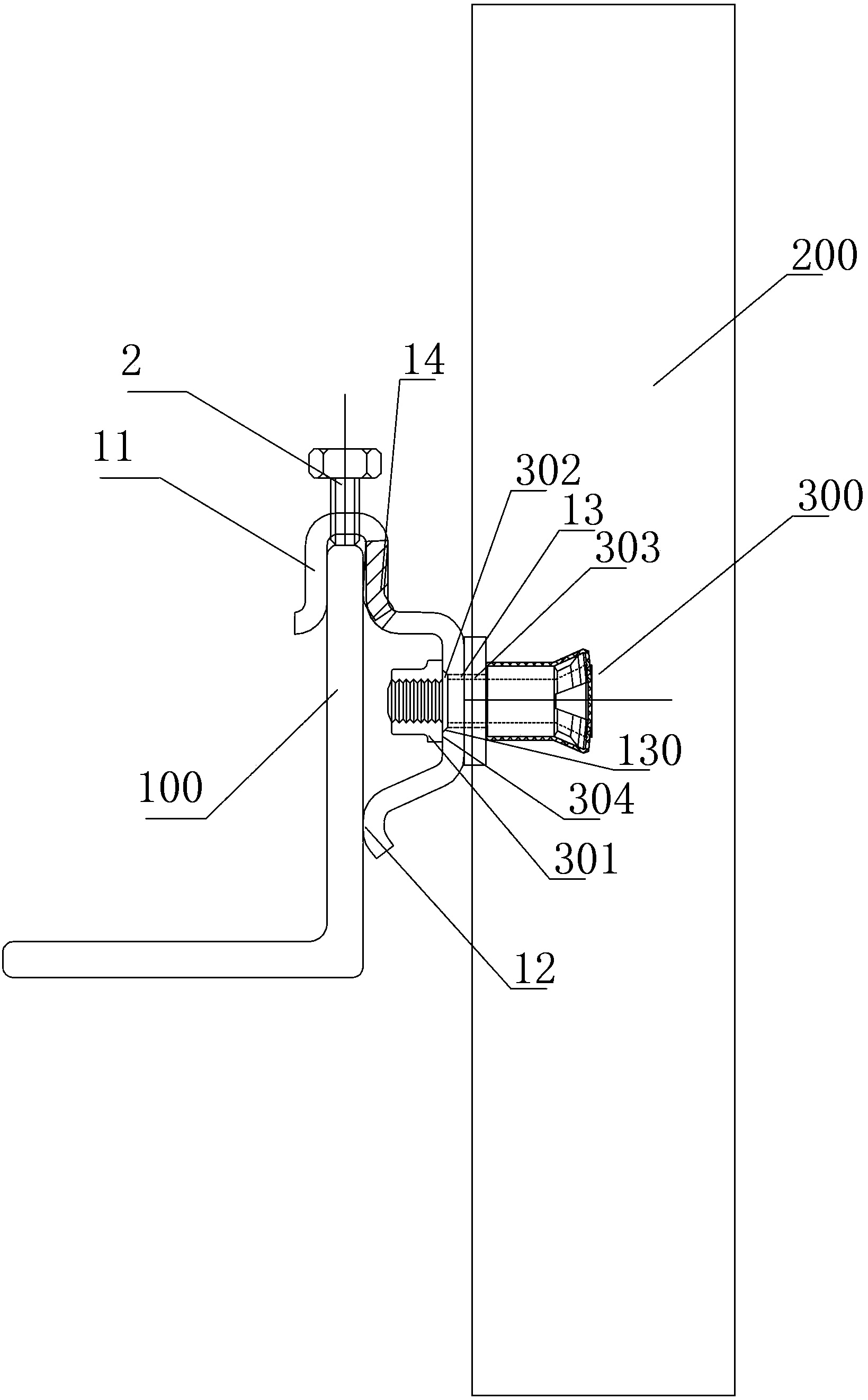

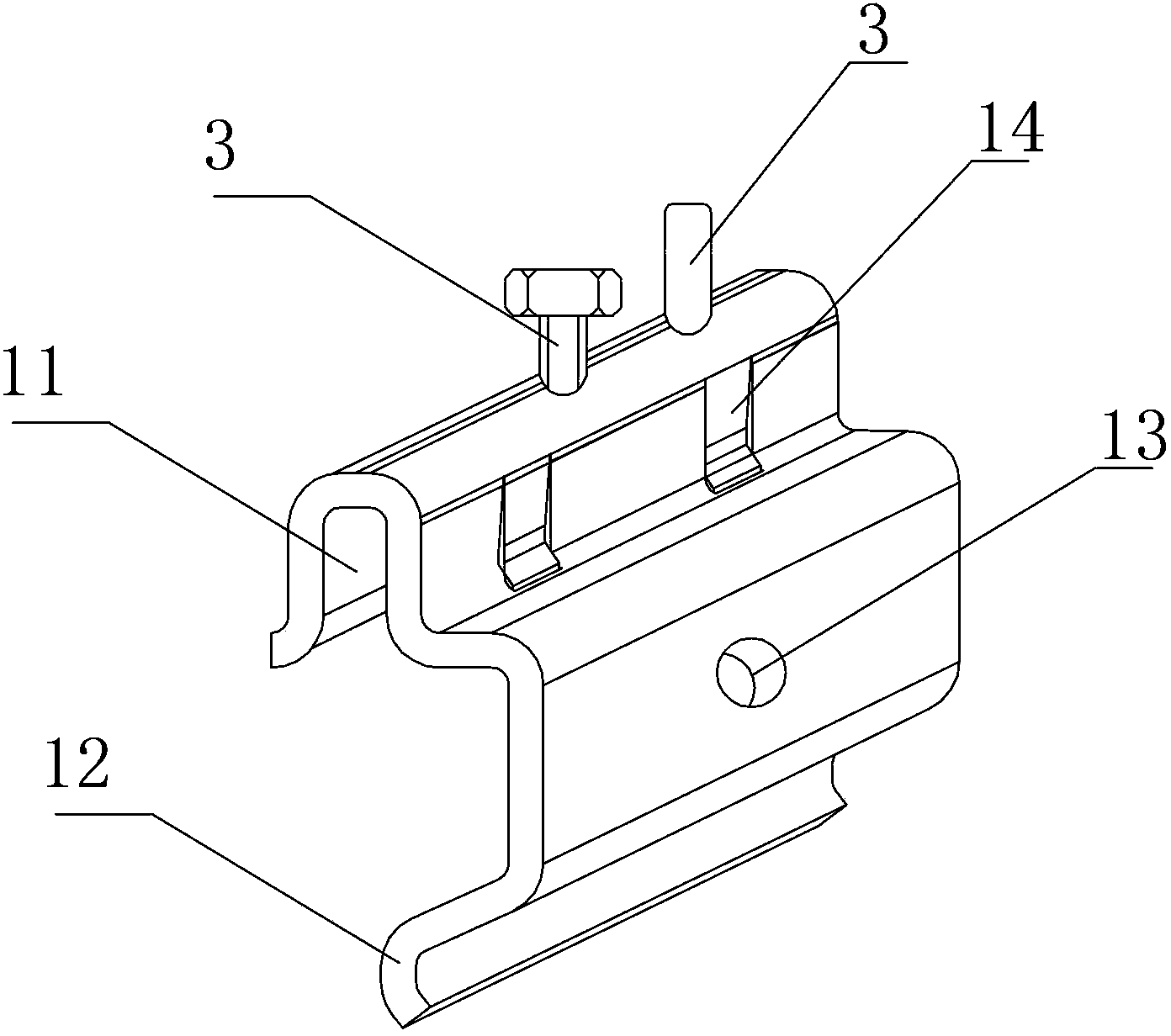

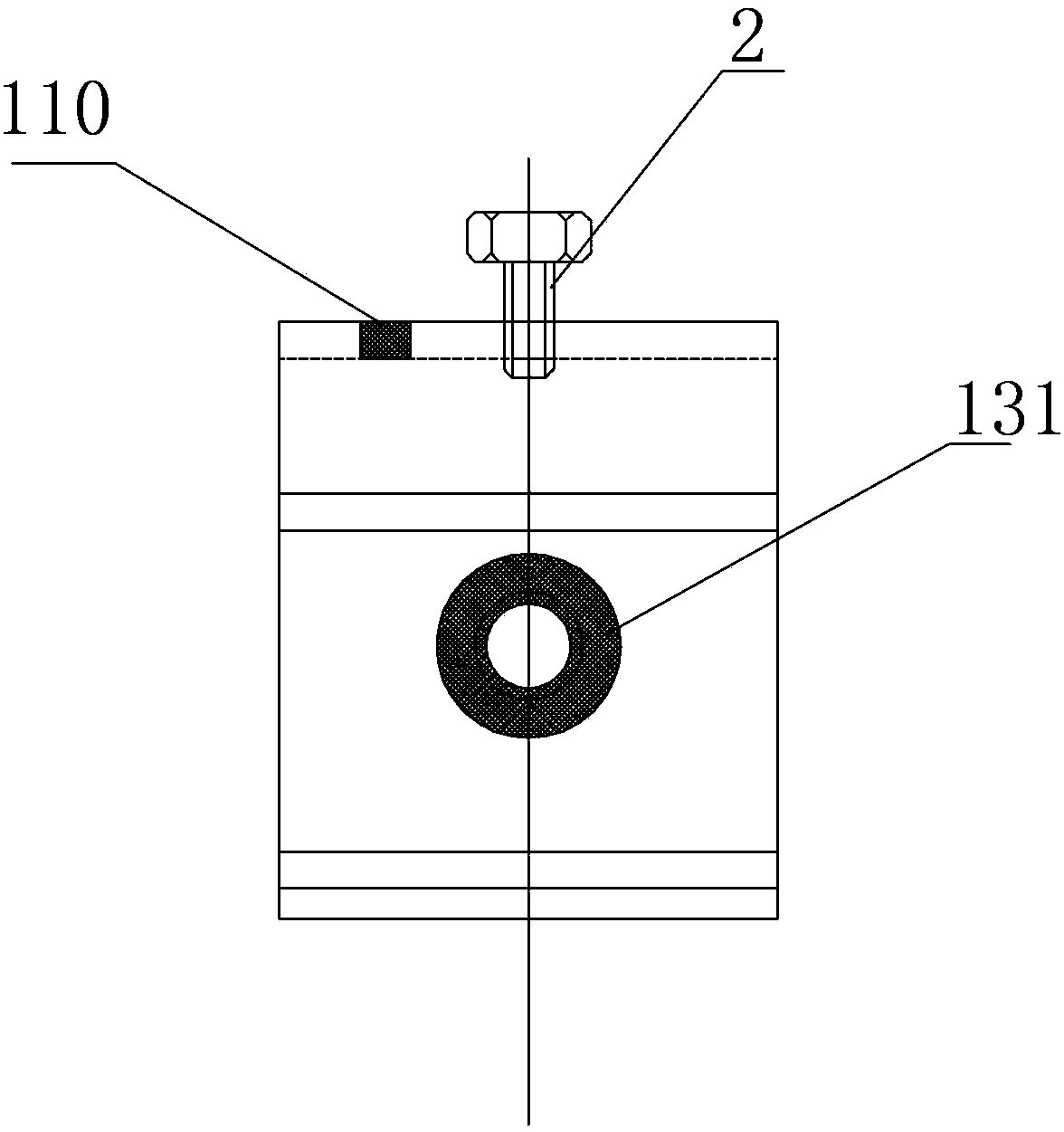

[0026] Embodiment 1, with reference to attached figure 1 , 2 , 3.

[0027] A curtain wall hook piece provided by the present invention, it is made of metal plate as a material to form a main body 1, in the main body, its upper part has a hook part 11, in the said main body, its lower part has an abutting part 12, and the middle part There is a connection hole 13, and the metal plate on its top is also punched and bent into an elastic part 14. The elastic part 14 is formed on the side of the entry direction of the part 100 that accepts the hook piece, and is an elastic tongue with a leading shape; the elastic part 14 is used To supplement the dimensional tolerance between the part 100 receiving the hook and the hook 11 of the hook. In the figure, reference numeral 200 is a curtain wall panel, and reference numeral 300 is a fastener connecting the curtain wall panel and the hook.

[0028] The abutting portion 12 may directly abut against the component 100 receiving the hook o...

Embodiment 2

[0035] Embodiment 2, with reference to attached Figure 4 .

[0036] The upper metal plate of the hook is provided with a hole 15 for installing an elastic part 16, and the elastic part 16 is installed in the hole 15, and the elastic part 16 is used to supplement the size between the part receiving the hook part and the hook part of the hook part tolerance. .

[0037] In this embodiment, the elastic member 16 adopts a spring sheet or a spring steel wire, and its installation part 18 is inserted in the hole 15. When a spring steel wire is used, there is at least one left and one left, which can be independent or continuous.

[0038] One end 19 of the elastic part 16 is in the hook portion, and when the hook portion is hung on the part receiving the hanging member, it is sandwiched between the hook part and the part receiving the hanging member.

[0039] Other parts of this embodiment are the same as Embodiment 1, Figure 4 in, with figure 1 , 2 , 3 The same label represen...

Embodiment 3

[0040] Embodiment 3, refer to Figure 5 , 6 .

[0041] In this embodiment, the elastic component is a flexible pad 17 whose cross section is T-shaped, and whose installation part 170 is stuck in the hole 15 .

[0042] Other parts of this embodiment are the same as Embodiment 1, Figure 5 , 6 in, with figure 1 , 2 , 3, and 4 have the same meanings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com