Device and method for continuously mixing liquid preparations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

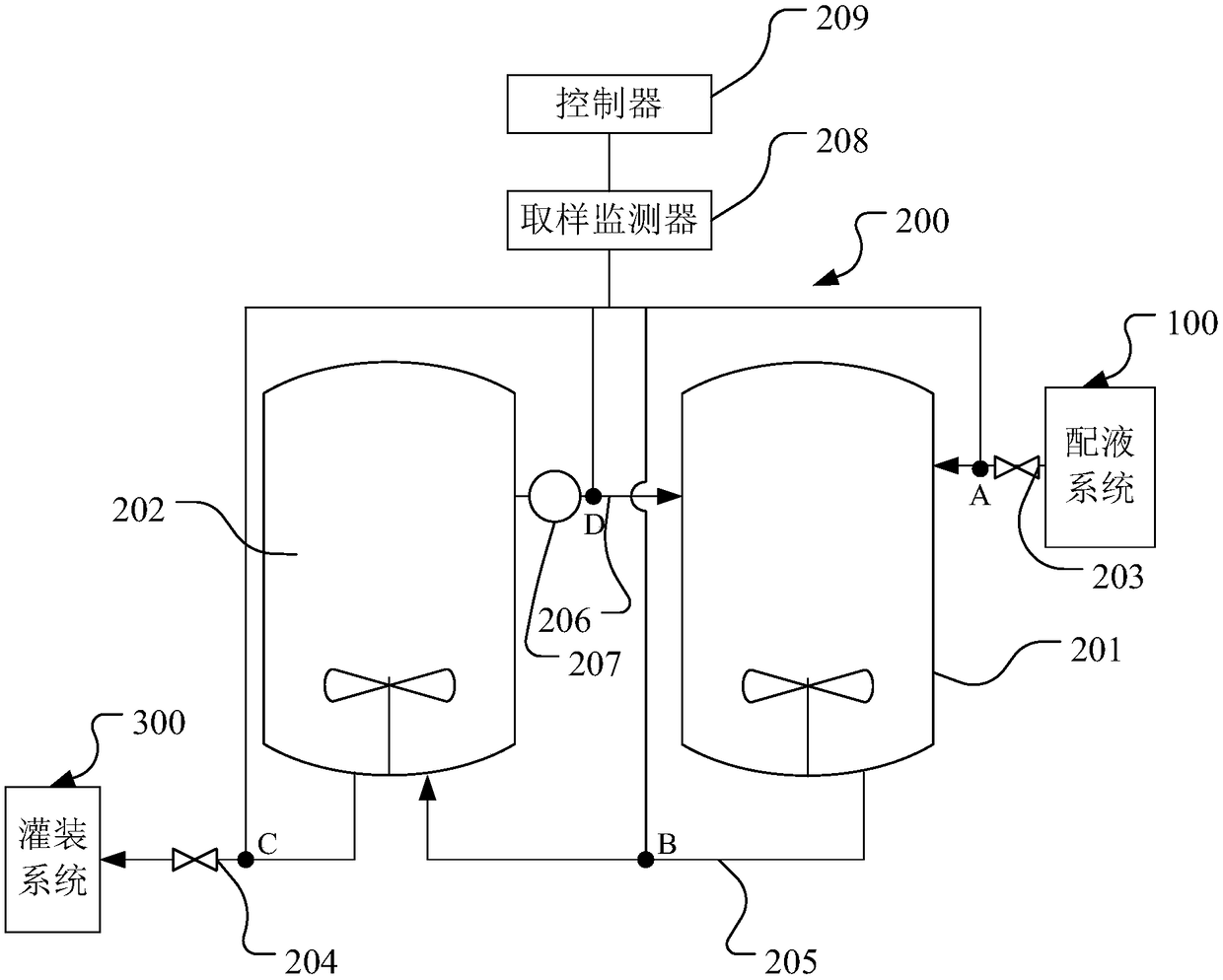

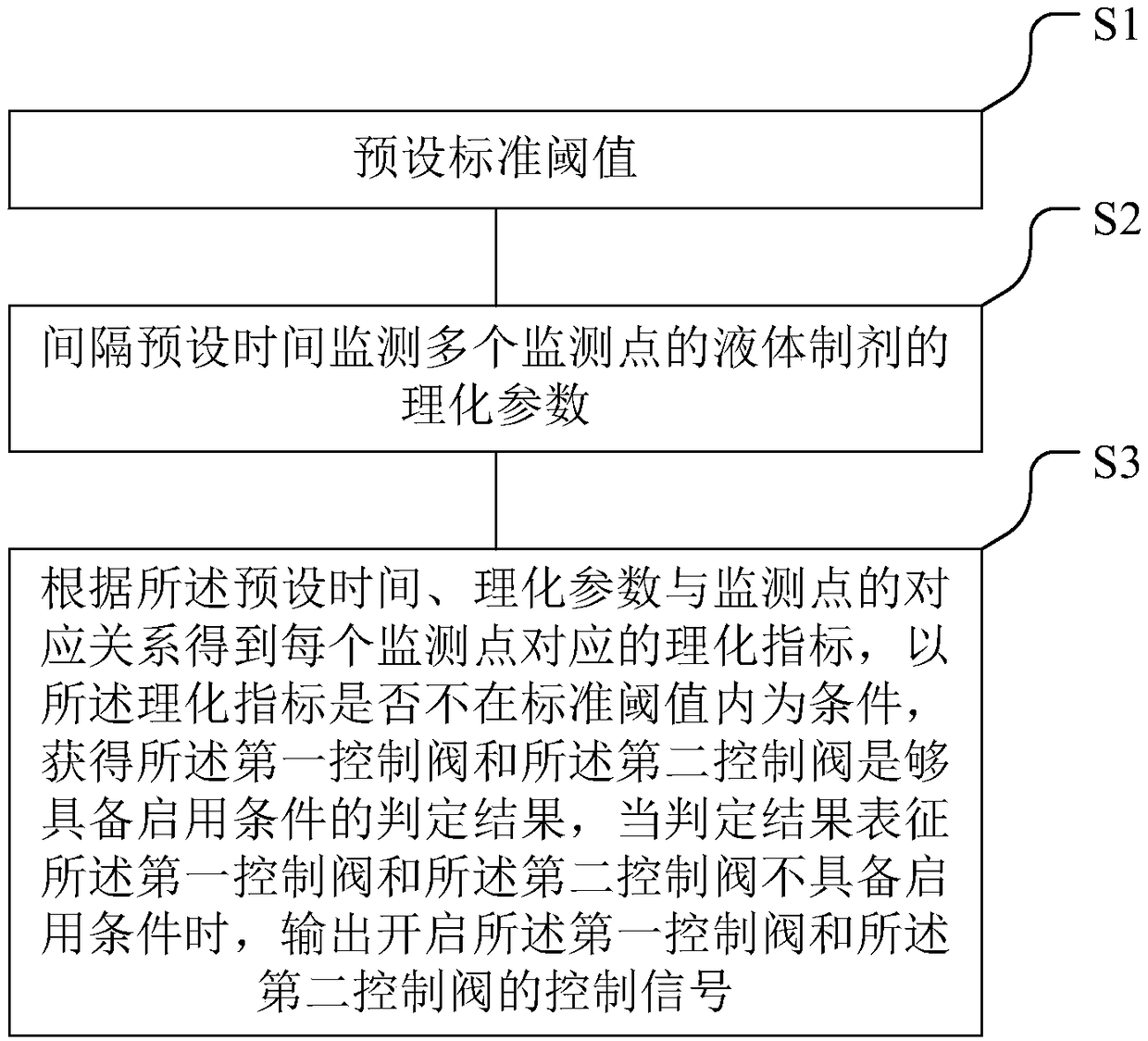

Method used

Image

Examples

Embodiment Construction

[0033] The traditional oral liquid preparation production mode is a batch production mode, that is, there will be a pause in the middle of each process for intermediate testing, and the next process can only be entered after passing the test. This production mode has the disadvantages of long production time, high inventory, and a large amount of inventory in intermediate products, which directly causes intermittent production, long batch change time, and high production loss. However, due to the provisions of the production regulations (5.2 of the 2017 edition of the "Detailed Rules for the Examination of Health Food Production License", "*5.2 Enterprises should establish a production batch management system, and the production of health foods shall be organized according to the same process. For homogeneous products produced by the equipment once mixed, a unique production batch number should be compiled. Continuous production within the same production cycle can ensure the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com