Series welding device for solar photovoltaic cells and series welding method

A photovoltaic cell, solar energy technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of manual welding, reduce the production efficiency of components, reduce product performance, etc., to save manpower, reduce quality risks, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0031] Preferred embodiment:

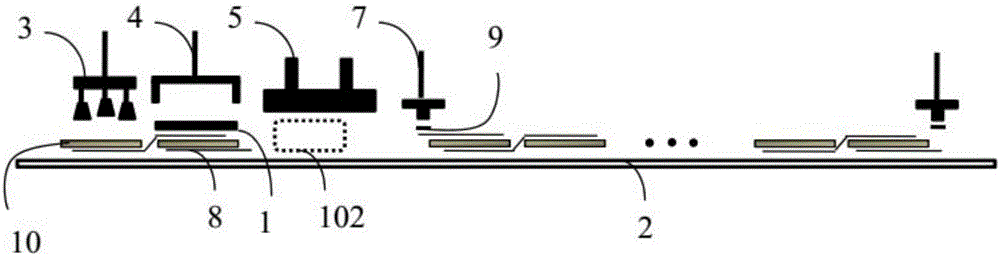

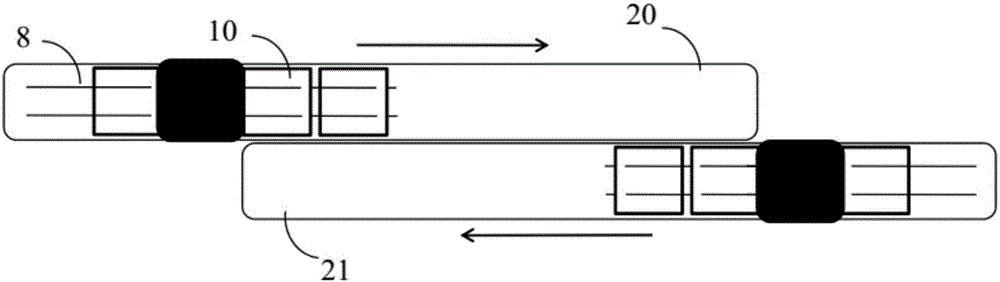

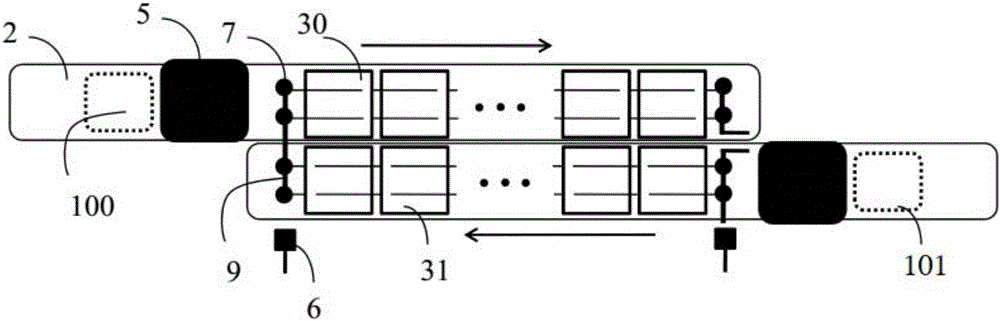

[0032] This preferred embodiment provides a stringer welding device for solar photovoltaic cells. Such as Figure 1 to Figure 3 As shown, the solar photovoltaic cell stringing device includes a conveyor belt 2, a cell gripper 3 arranged above the conveyor belt 2, a welding seat module, an interconnection bar welding station 5, a busbar welding station 7, and a conveyor belt 2 side. The confluence belt gripper 6. The cell gripper 3 is used to put the battery sheet 10 to be welded into the predetermined area of the conveyor belt 2 ; the interconnection bar welding station 5 is used to weld the interconnection bar 8 to be welded and the battery sheet 10 to be welded.

[0033] The welding seat module includes a welding seat 1 for clamping the interconnection bar 8 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com