Method for testing vibration rheological properties of cement mortar

A technology of rheological properties and cement mortar, which is applied in vibration testing, flow characteristics, testing of machine/structural components, etc., can solve problems such as excavating the rheological properties of concrete materials, difficult problems, etc., and achieves wide testing range and easy operation , good reproducibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

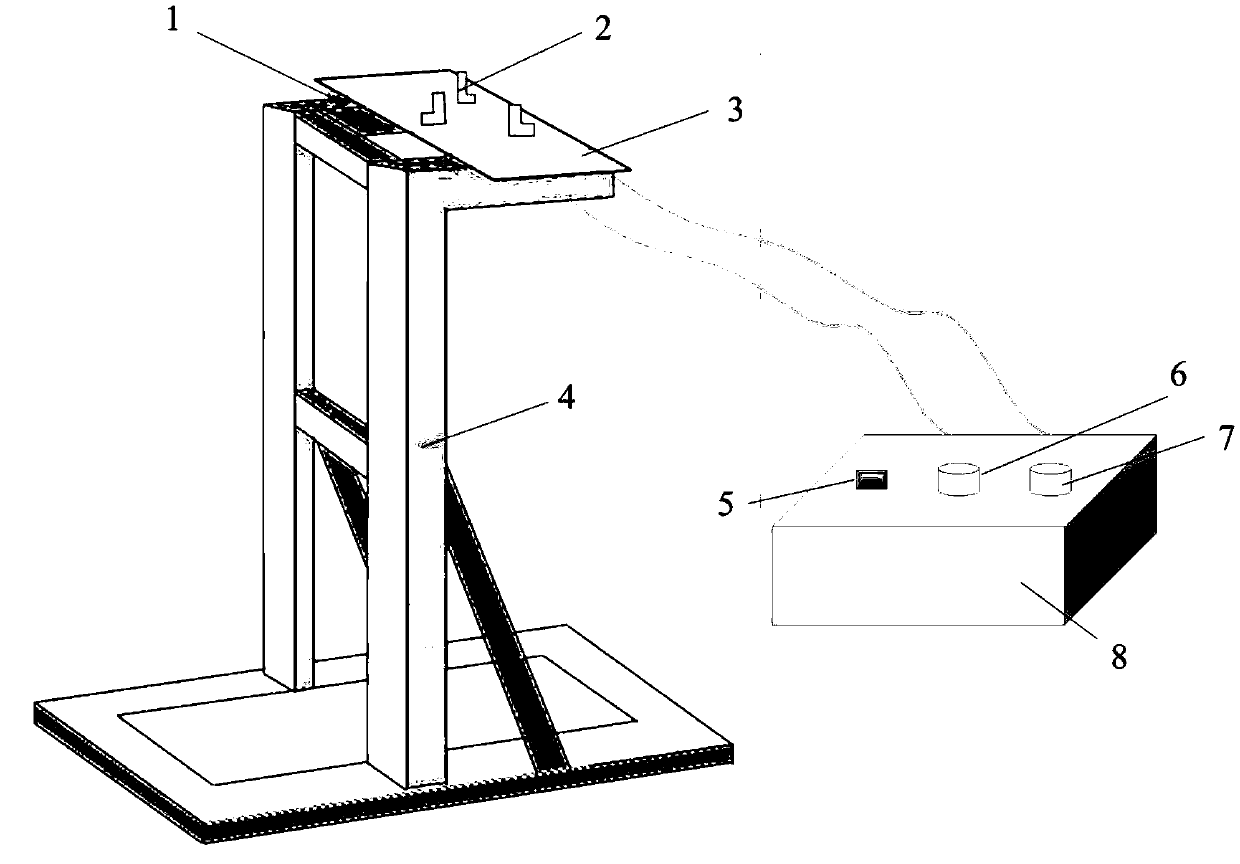

Method used

Image

Examples

Embodiment 1

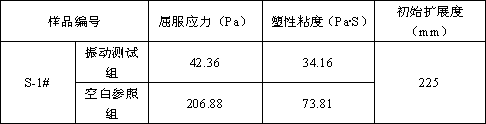

[0020] Table 1 S-1# cement mortar vibration rheological test parameters

[0021] Sample serial number Test duration (s) Vibration frequency (Hz) Amplitude (mm) S-1# 30 70 ±1

[0022] Table 2 S-1# cement mortar mix ratio

[0023] Sample serial number Cement (g) Fly ash (g) Fine aggregate (g) water-binder ratio Water reducer (g) S-1# 250 / 500 0.45 /

[0024] Set up the test program of the rheometer and the vibration process parameters such as the amplitude and frequency of the frequency conversion vibration equipment, as shown in Table 1. According to the mix ratio in Table 2, cement mortar was prepared, in which the cement was P·II 52.5 cement, the fine aggregate was continuously graded natural river sand with a particle size range of 0.16-5.0 mm, and the water was tap water. The prepared cement mortar sample was quickly loaded into the test cylinder, the test rotor was installed, and the rheometer and frequency conve...

Embodiment 2

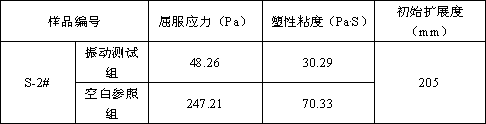

[0029] Table 4 S-2# cement mortar vibration rheological test parameters

[0030] Sample serial number Test duration (s) Vibration frequency (Hz) Amplitude (mm) S-2# 30 50 ±1

[0031] Table 5 S-2# cement mortar mix ratio

[0032] Sample serial number Cement (g) Fly ash (g) River sand (g) water-binder ratio Water reducer (g) S-2# 200 50 500 0.45 /

[0033] Set the test program of the rheometer and the vibration process parameters such as the amplitude and frequency of the frequency conversion vibration equipment, as shown in Table 4. According to the mix ratio in Table 5, cement mortar was prepared, in which the cement was P II 52.5 cement, the fine aggregate was continuously graded natural river sand with a particle size range of 0.16-5.0 mm, the fly ash was class I ash, and the water was tap water. The prepared cement mortar sample was quickly loaded into the test cylinder, the test rotor was installed, and the rheome...

Embodiment 3

[0038] Table 7 S-3# cement mortar vibration rheological test parameters

[0039] Sample serial number Test duration (s) Vibration frequency (Hz) Amplitude (mm) S-3# 20 50 ±2

[0040] Table 8 S-3# cement mortar mix ratio

[0041] Sample serial number Cement (g) Fly ash (g) River sand (g) water-binder ratio Water reducer (g) S-3# 250 / 500 0.35 2

[0042] Set the test program of the rheometer and the vibration process parameters such as the amplitude and frequency of the frequency conversion vibration equipment, as shown in Table 7. Prepare cement mortar according to the mix ratio in Table 8, in which the cement is P II 52.5 cement, the fine aggregate is continuously graded natural river sand with a particle size range of 0.16-5.0 mm, the water is tap water, and the water reducer is polycarboxylic acid high-efficiency Superplasticizer, solid content 40%. Quickly put the prepared cement sample into the test cylinder, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com