Viscometer and methods for using the same

A technology of viscometer and viscosity value, which is applied to the flow characteristics of non-Newtonian fluids, the measurement of DC flow characteristics, instruments, etc., and can solve the problems of undisclosed portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

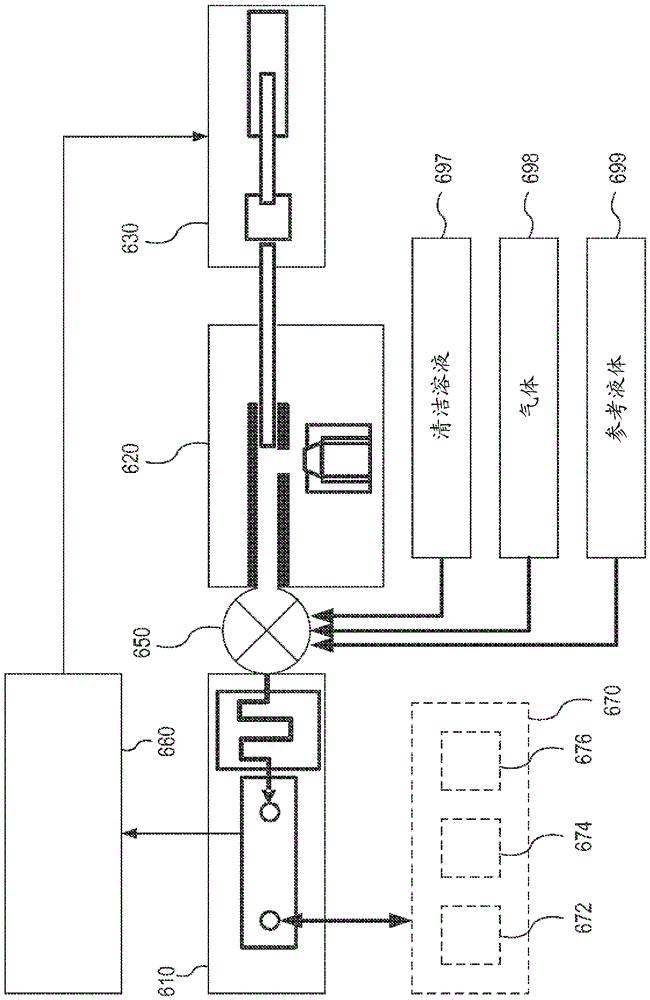

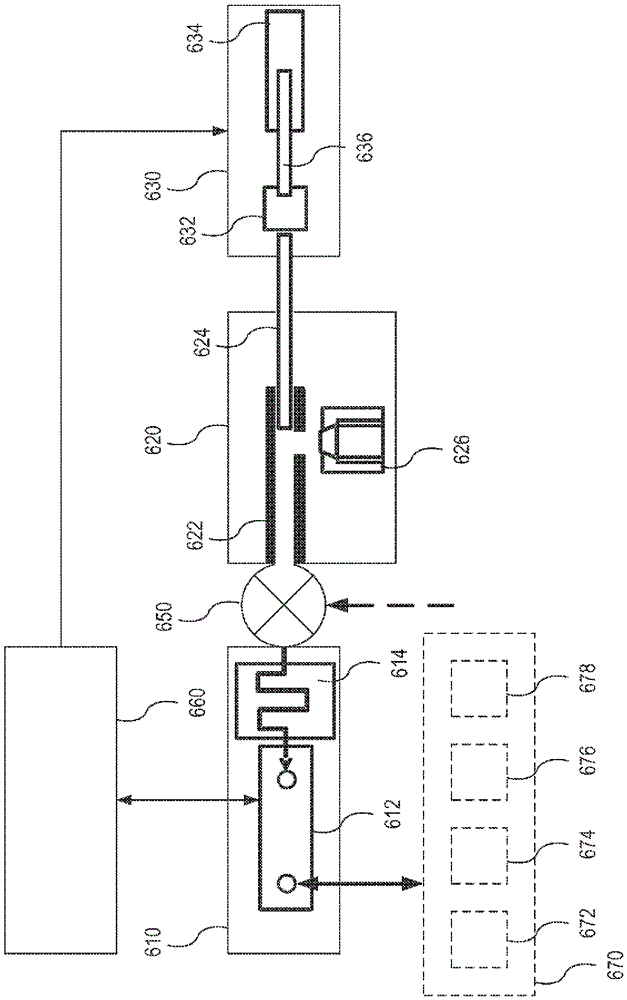

[0045] According to some embodiments, an improved viscometer is described that is portable, easier to use, more accurate, and has a faster method of measuring the viscosity of liquid samples than prior art viscometers method. refer to figure 1 , a viscometer 22 comprising: a precision pump, generally indicated by reference numeral 20; a liquid container 14 for supplying a liquid sample desired for viscosity measurement; a flow through a viscosity sensor 15; a controller 18; and a display 19.

[0046] The pump 20 is used in conjunction with the illustrated sample container, referred to as a pipette 14, and the pipette 14 has a pipette barrel or body 13 and a plunger 12 slidably positioned in Pipette barrel 13 , and plunger tip 24 extends from the end of barrel 13 . The pipette 14 can be removably positioned and retained in the viscometer by means of the mounting mechanism 28 so that the pipette can be removed, filled with a liquid sample to be tested, and then placed back i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com