Rheometer

A technology of rheometer and magnetorheological fluid, which is applied in the field of rheometer and can solve problems such as limiting the measurement range of rheometer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

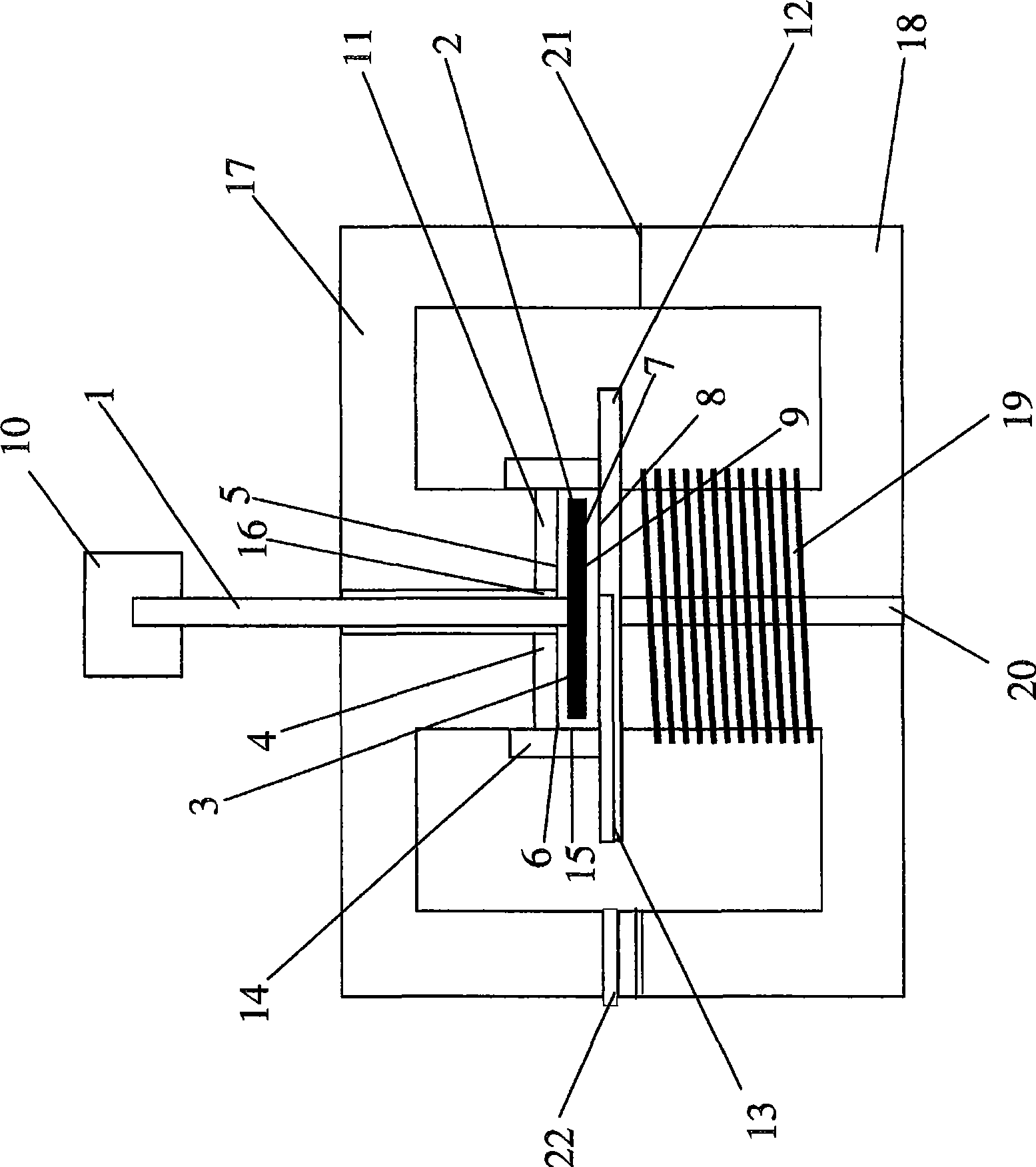

[0040] The rheometer comprises a rotating shaft 1 made of non-magnetizable material, eg austenitic stainless steel material number 1.4571. The rotary shaft 1 is connected to a motor (not shown) that drives the shaft 1 . The shaft is preferably supported using air bearings (not shown). A rotor disk 2 made of a magnetizable material (for example steel material number 1.0037) is attached to the end of the shaft 1 . exist figure 1 Between the upper side (first side 3 ) of the rotor disk 2 and the first shear plane 4 , a first measurement gap 5 containing a substance 6 to be investigated (for example a magnetorheological fluid) is located. Between the underside (second side 7 ) of the rotor disk 2 and the second shear plane 8 there is formed a second measuring gap 9 which also accommodates the substance 6 to be investigated.

[0041] The rheometer also includes a measuring device 10 , which measures the rotational speed and the torque of the motor and thus also indirectly detec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com