A double-tension-source type yield stress measuring system for a magnetorheological fluid

A magnetorheological fluid and yield stress technology, applied in the field of magnetorheological fluid performance research, can solve problems such as different data, and achieve the effect of convenient operation, easy observation, and accurate yield stress value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

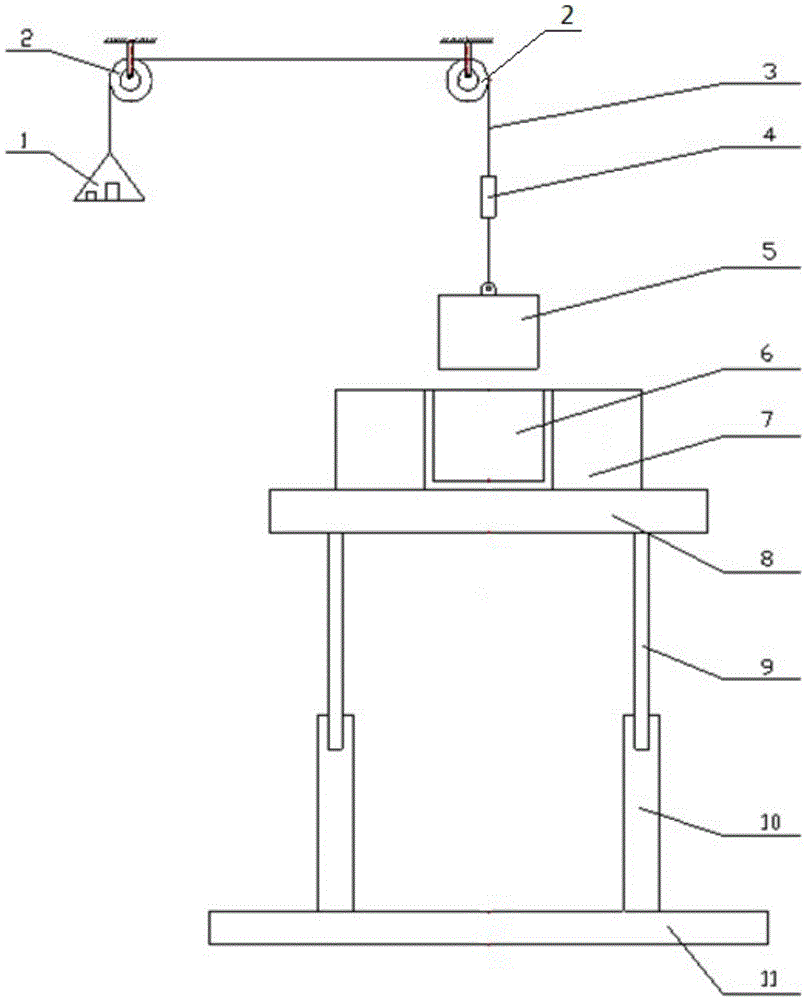

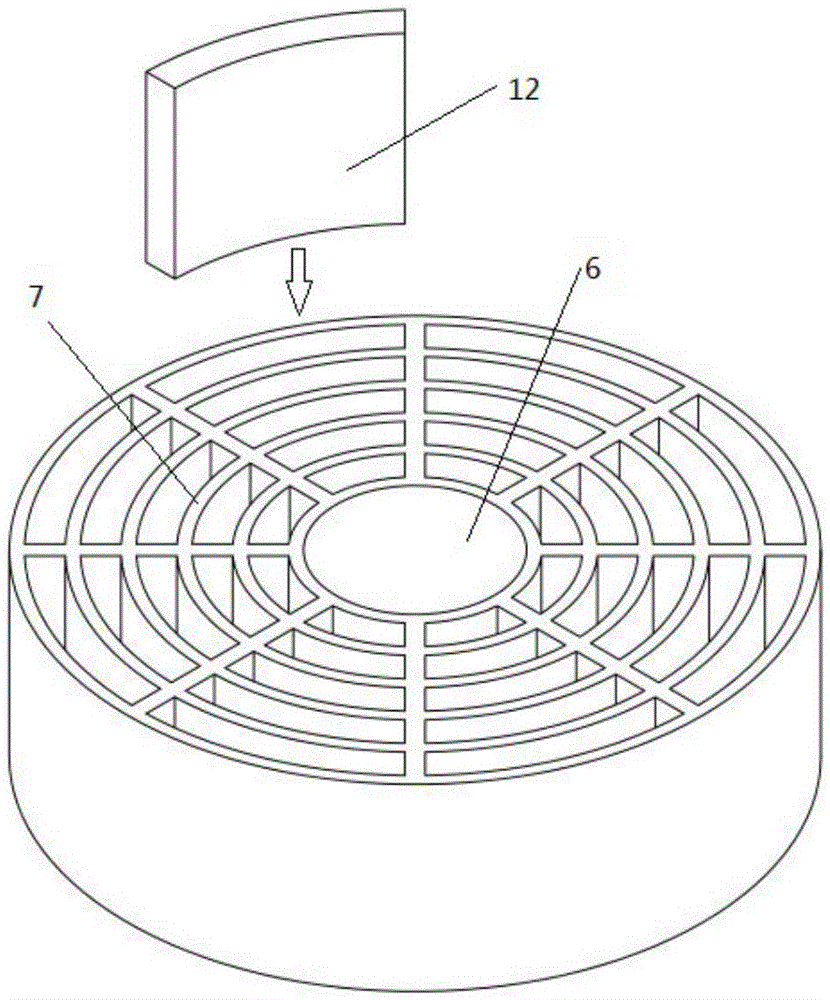

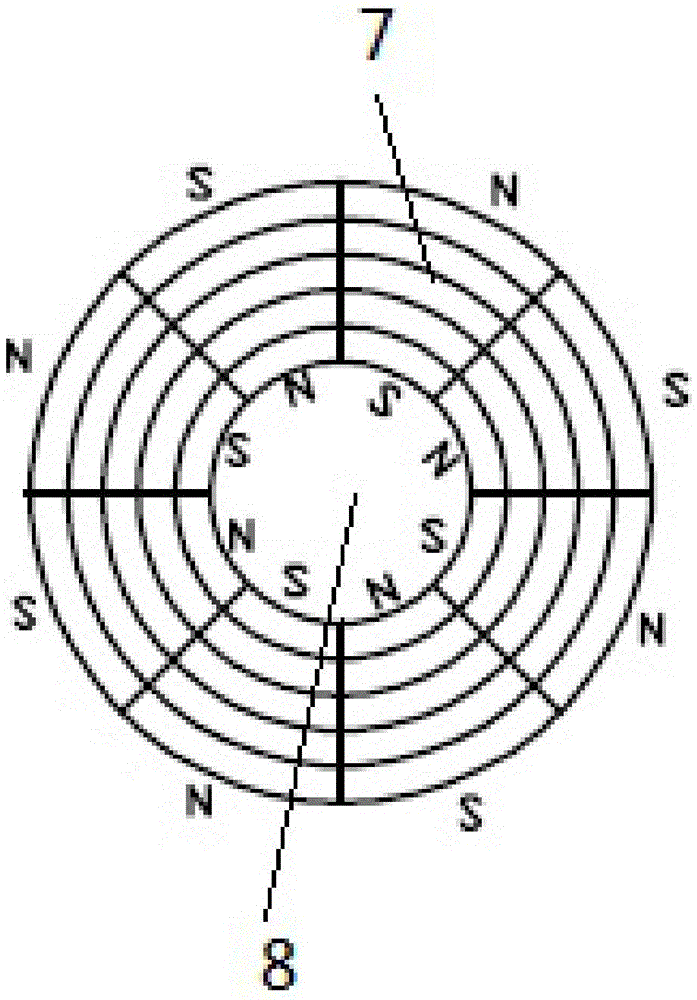

[0042] A dual tension source magnetorheological fluid yield stress measurement system, such as figure 1 As shown, it includes a lifting device, a magnetic field generating device and a lifting block 5. Magnetic field generators such as Figure 2~3 As shown, it is composed of a radial multi-stage magnetic ring and a magneto-rheological fluid tank 6. The radial multi-stage magnetic ring is composed of a plurality of radial multi-stage magnetic ring units coaxially arranged in a plane, and the radial multi-stage magnetic ring The ring unit is in the shape of a ring and is surrounded by a plurality of arc-shaped permanent magnets 12. The arc-shaped permanent magnets 12 are placed in the permanent magnet grid groove 7, and the permanent magnet grid groove 7 is fixed on the flat plate 8. The number of multi-stage magnetic ring units is used to change the magnitude of the magnetic field strength. The magnetorheological fluid tank 6 is cylindrical, located in the radial multi-stage ...

Embodiment 2

[0045] This embodiment is basically the same as the embodiment, except that the side of the pull block 5 in this embodiment is provided with a plurality of toothed grooves arranged along the axial direction of the pull block 5 around its side, such as Figure 7-8 As shown, the toothed groove has a width of 2 mm and a depth of 1 mm. The method for measuring the yield stress of the magnetorheological fluid is similar to that of Example 1.

Embodiment 3

[0047]A kind of dual tension source type magnetorheological fluid yield stress measurement system of this embodiment is basically the same as that of Embodiment 1, the difference is that the method of measuring the yield stress of magnetorheological fluid in this embodiment is to lift the block 5. After inserting into the magnetorheological fluid, fix the pull rope 3 on the fixed pulley 2 so that it does not move, start the lifting device, make it descend slowly at a constant speed, and generate a relative pulling force on the lifting block 5, and the pulling force is measured by the pulling force sensor 4 size, the yield stress of the magnetorheological fluid can be converted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com