Feedback and control system and method for rheometer shearing stress in unsteady test phase

A shear stress, testing stage technology, applied in non-electric variable control, control/regulation system, torque/mechanical power control, etc. The effect of measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

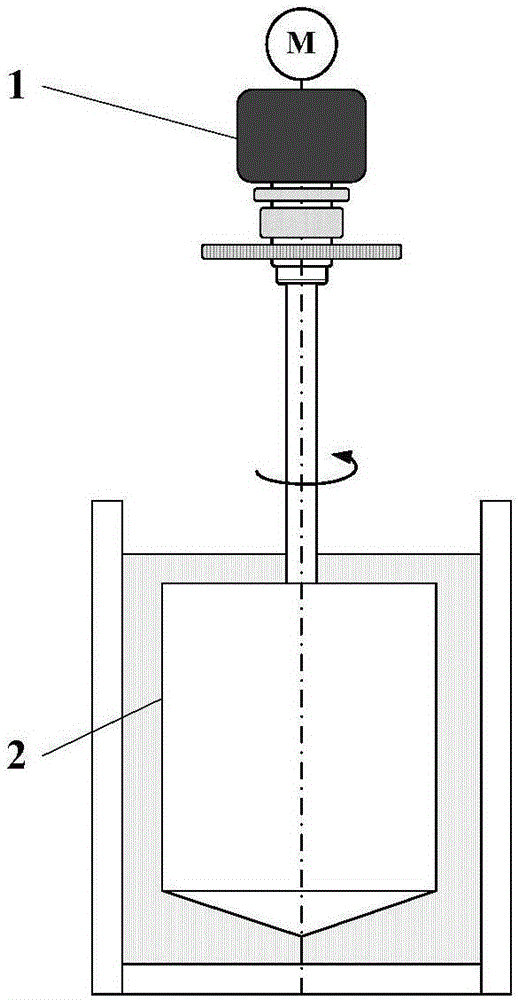

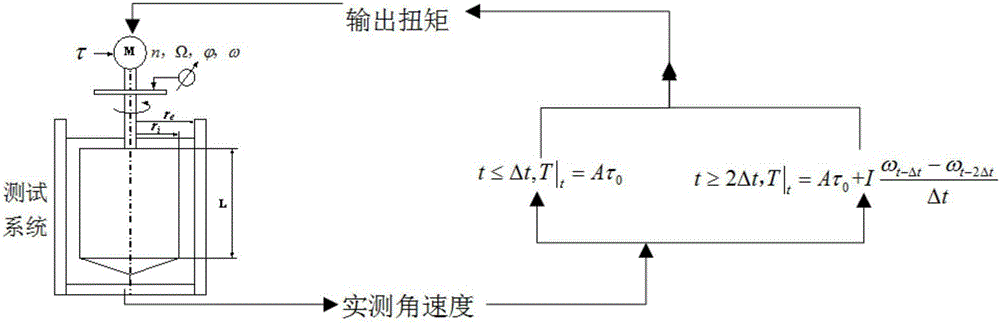

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0031] During the rheometer test, the moment of inertia of the rotating part should include the moment of inertia of the rotating part and the moment of inertia of the motor. The moment of inertia of the entire measurement system can be obtained when the test is carried out under no load.

[0032] I=I geometry +I rheometer (5)

[0033] In the unsteady rotation stage, if the preset shear stress value is to be achieved, the corresponding torque should not be applied according to formula (1). Instead, the torque value to be applied should be calculated according to formula (4), combining the angular velocity of the rotating system and the preset shear stress value. In order to make the preset shear stress acting on the material change according to the preset law from the beginning of shearing, the output torque of the motor needs to be continuously ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com