Viscosity detector

A detector and viscosity technology, used in viscometer maintenance, instruments, temperature control, etc., can solve the problems of inability to detect high temperature oil and low temperature deicing liquid, influence of discharge speed, poor measurement accuracy, etc., and achieve touch screen interface. Friendly, small sample size, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

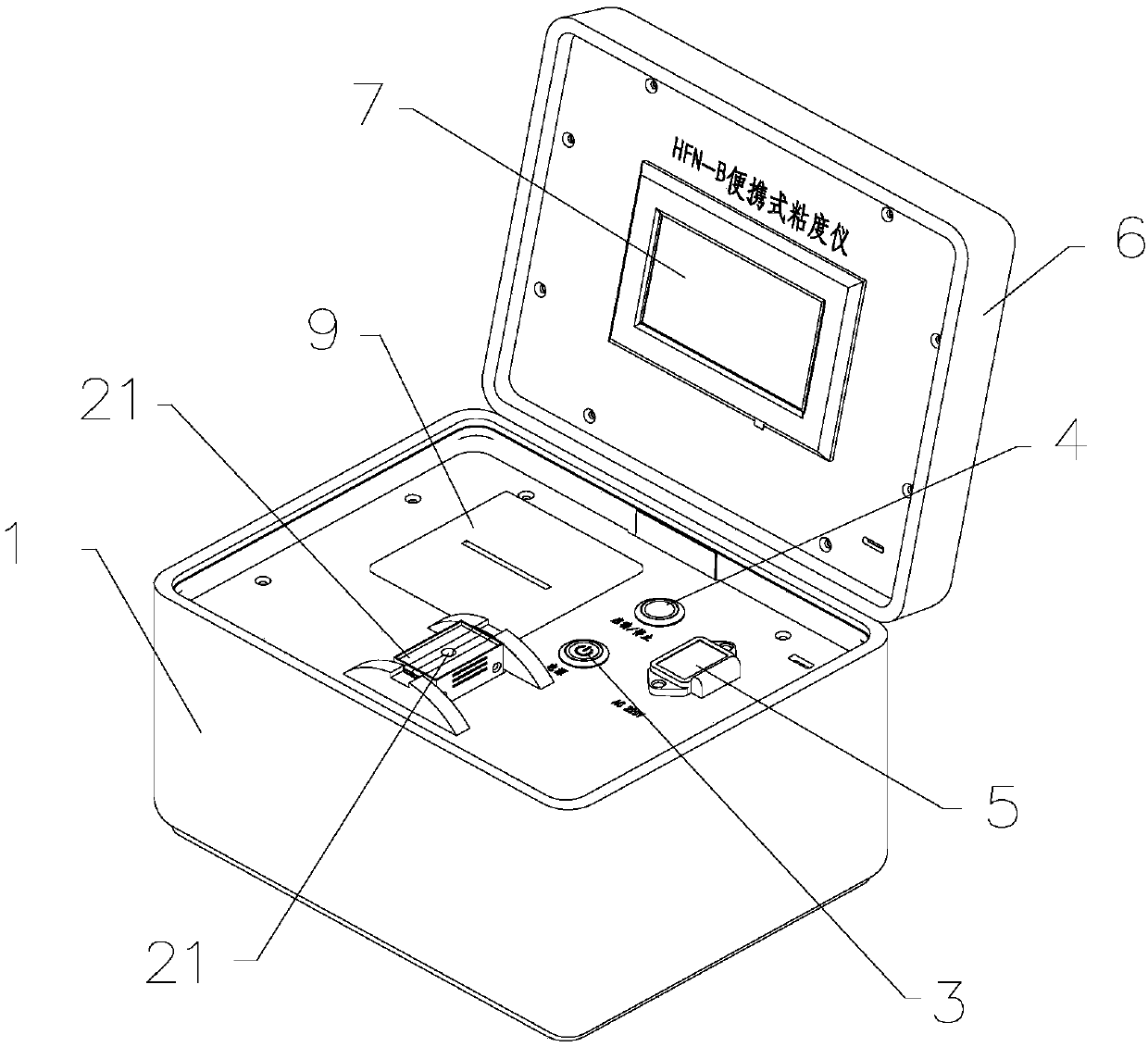

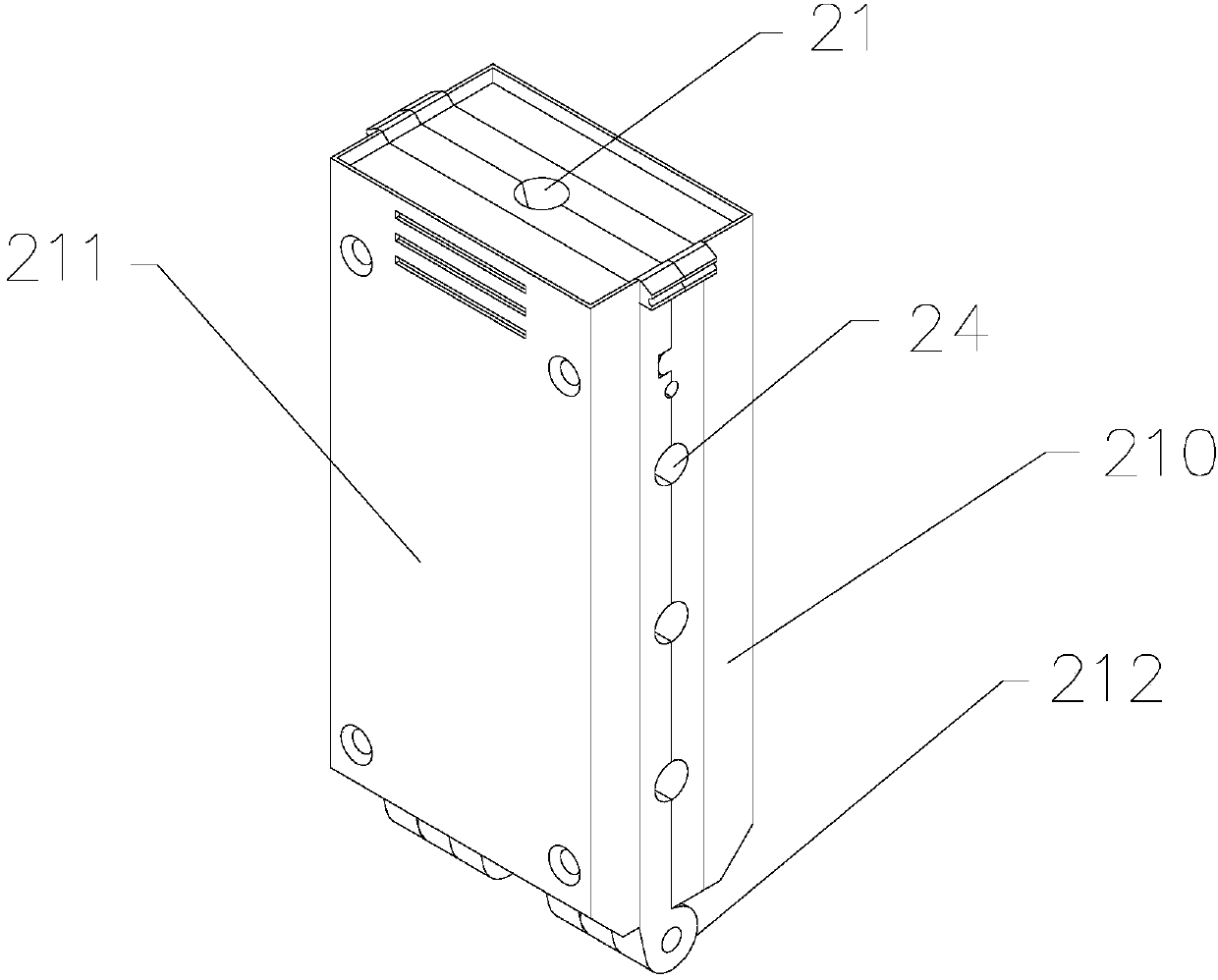

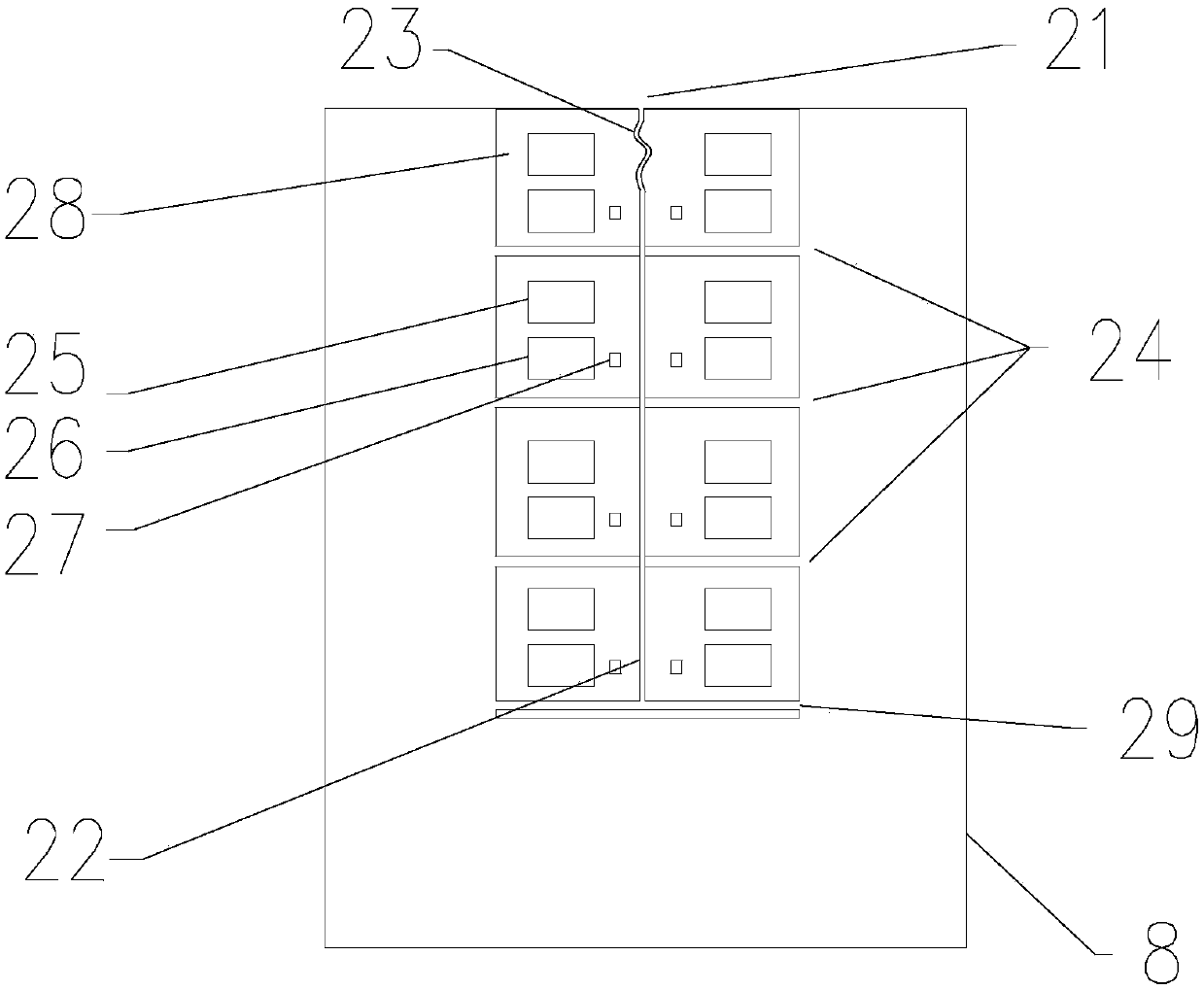

[0035] A viscosity detector, comprising a main frame 1, a control device, a display device, and a detection device arranged in the main frame 1, the detection device includes a detection platform 2 fixed in the casing 1, and the detection platform 2 consists of a first platform 210 and the second platform 211, one end of the first platform 210 and one end of the second platform 211 are connected by a connecting shaft 211, the first platform 210 can rotate along the connecting shaft 211, an injection hole 21 is provided above the detection platform 2, and a capillary 22 is provided In the detection platform 2, the capillary 22 is connected to the injection hole 21 through a labyrinth channel 23, and a detection hole 24 for detecting the viscosity of the liquid in the capillary is provided on the side of the detection platform 2, and a detection hole 24 is provided on both sides of the capillary 22 inside the detection platform 2. Far-infrared 100 micron carbon fiber interlayer 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com