Patents

Literature

51results about "Cooling soap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dimensionally Stable Solid Rinse Aid

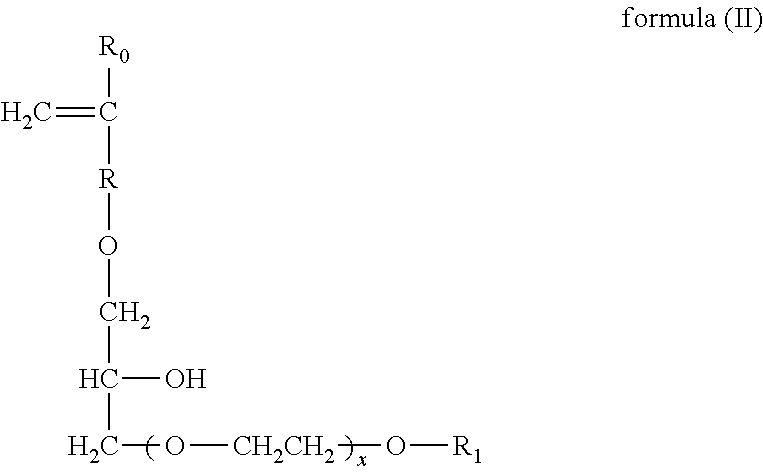

ActiveUS20080293615A1Reduced water solid filming in waterReduce spotting and water solids filmingOrganic detergent compounding agentsDrying soapAlcoholPreservative

The present invention is a solid rinse aid composition and methods of making and using the same. The solid rinse aid composition generally includes sodium sulfate and urea as solidification agents and an effective amount of an alcohol ethoxylate compound sheeting agent component and an effective amount of defoamer component. The solid rinse aid composition may also incorporate a preservative system including sodium bisulfate. The solid rinse aid composition may be phosphate-free, aminocarboxylate-free, and GRAS if desired.

Owner:ECOLAB USA INC

Process of making an article for dissolution upon use to deliver surfactants

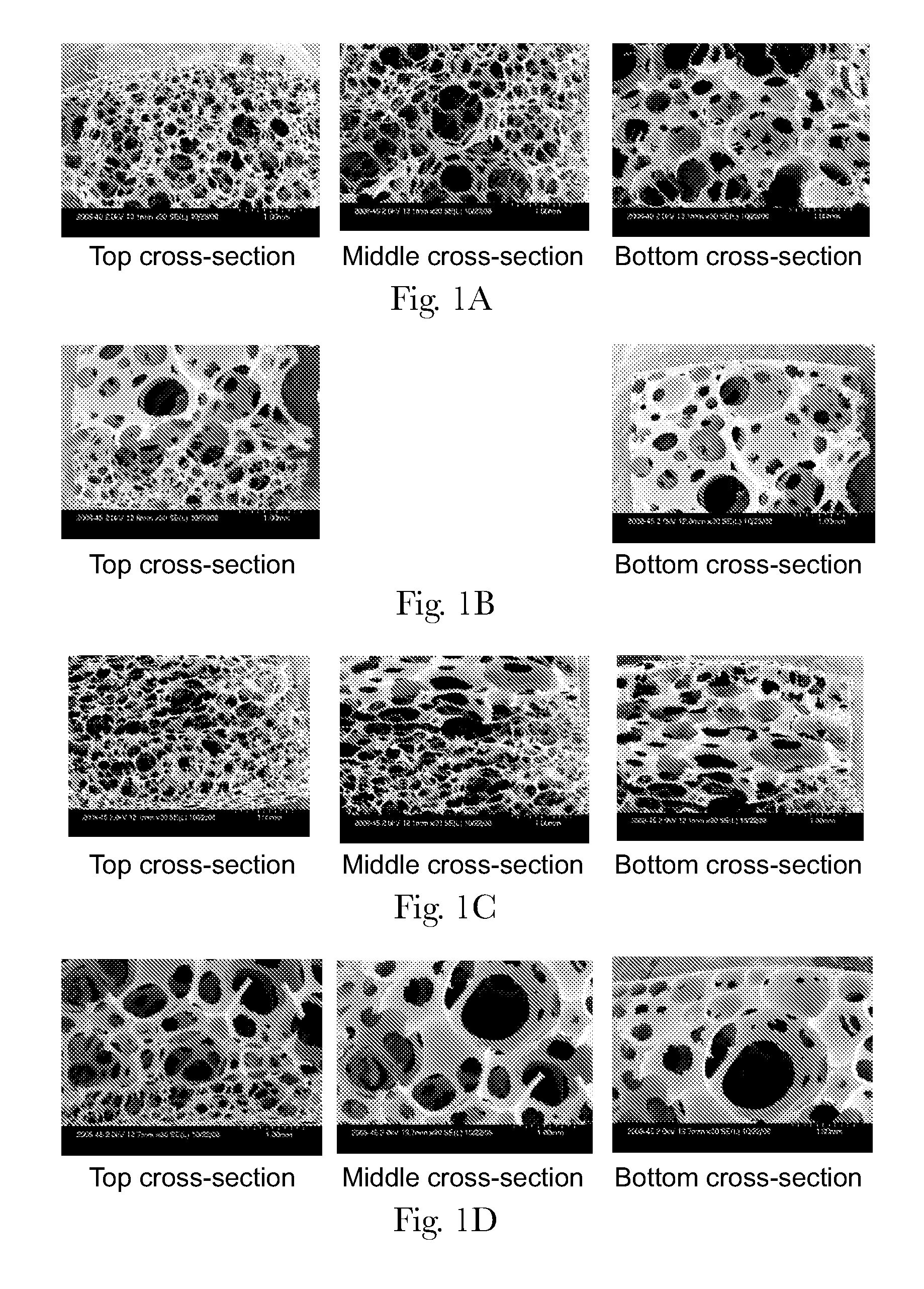

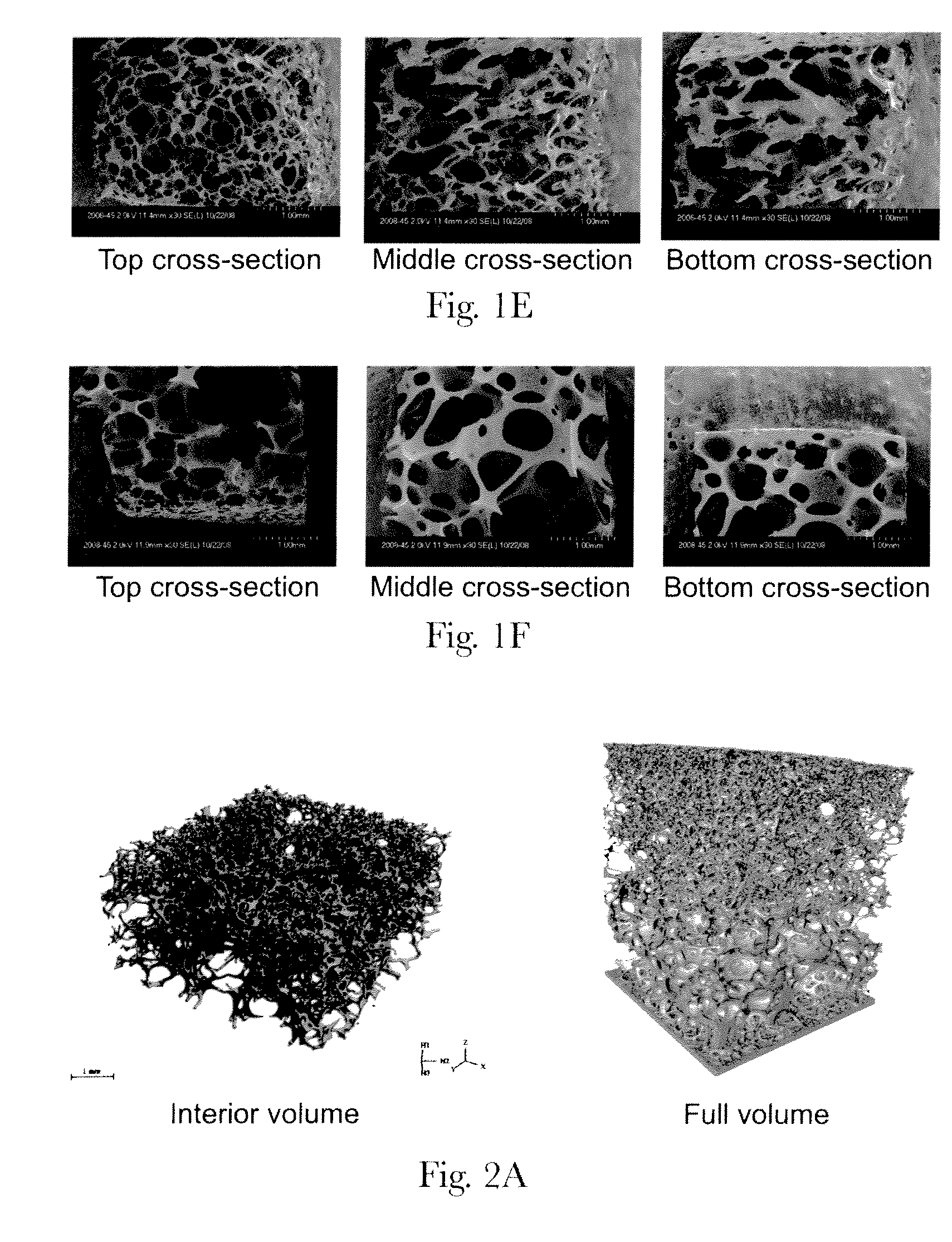

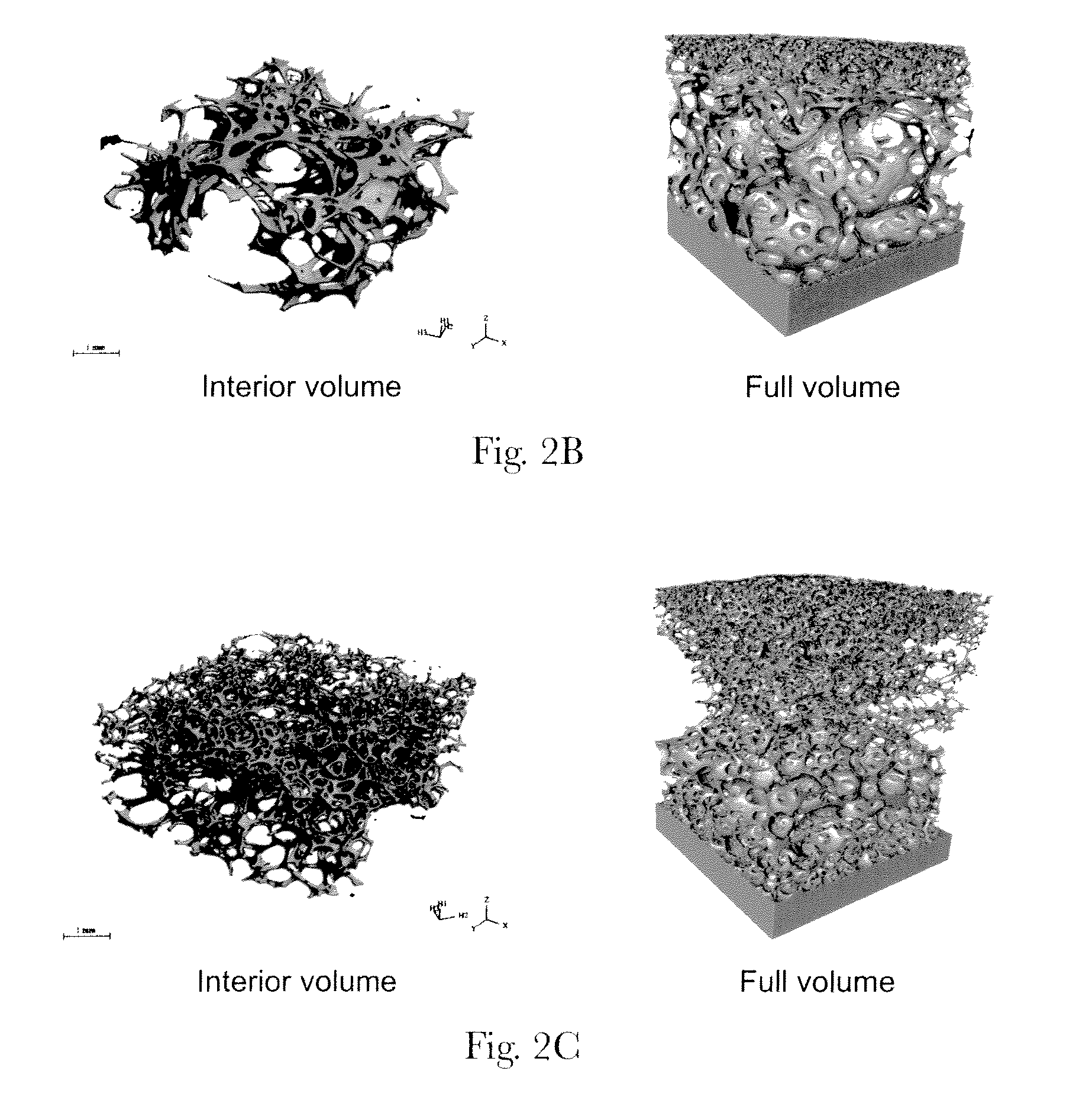

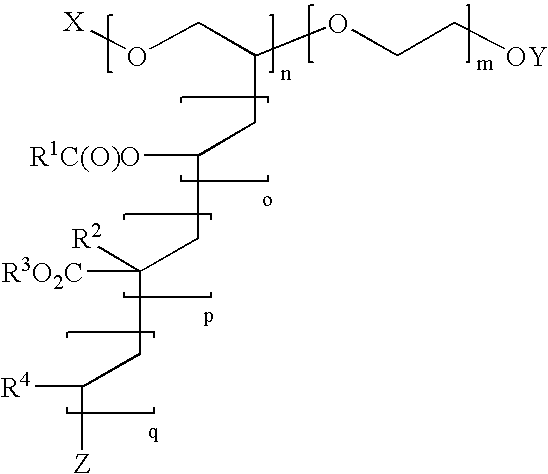

A process that results in a flexible dissolvable porous solid article that can be used as a personal care composition or a fabric care composition.

Owner:THE PROCTER & GAMBLE COMPANY

Detergent product and method for making same

Owner:THE PROCTER & GAMBLE COMPANY

Process of making an article for dissolution upon use to deliver surfactants

Owner:PROCTER & GAMBLE CO

Spray dried powdered detergents with perfume-containing capsules

The present invention relates to a process for the manufacture of a spray dried powder comprising:(a) forming a warm, stirred aqueous slurry comprising: inorganic salts, at least one binding agent and 0.001 to 20% by weight of capsules based on the weight of spray dried powder, said capsules containing benefit agents including at least perfume, and(b) spray drying the resultant slurry to form a spray dried powder, said capsules being such that:1) more than 40% of the benefit agents remain encapsulated 60 minutes after dispersion thereof at 70° C. in the slurry as defined in the “slurry survival test” in a sealed vessel without agitation; and2) more than 30% of the benefit agents added for 15 minutes to an ambient slurry as defined in the “spray dry test” survive spray drying through a laboratory scale spray drier.

Owner:TAKASAGO INTERNATIONAL CORPORATION

Detergent composition

InactiveUS20070281879A1Speed up the processReduce liquid viscosityOrganic detergent compounding agentsDrying soapPendant groupSpray drying

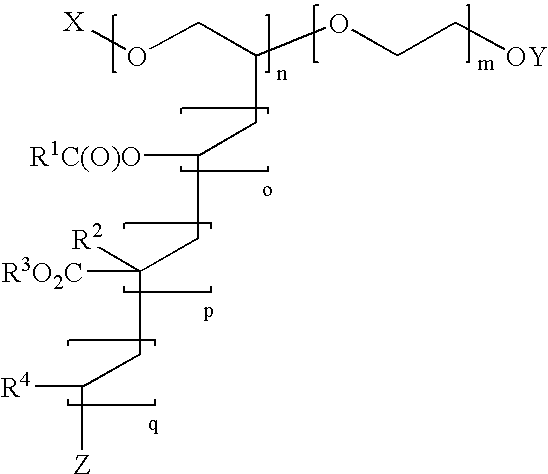

A detergent auxiliary composition comprising from 0.001 wt % to 99 wt % cleaning polymer having a hydrophilic backbone and at least one hydrophobic pendant group, and an adjunct ingredient in which the hydrophilic backbone constitutes less than 50%, preferably less than 45% by weight of the polymer. The detergent auxiliary composition may be, for example a spray-dried particle or an agglomerate. Also described are detergent compositions comprising the detergent auxiliary composition.

Owner:THE PROCTER & GAMBLE COMPANY

Spray drying

InactiveUS20070149423A1Organic detergent compounding agentsDrying soapInorganic saltsLaboratory scale

The present invention relates to a process for the manufacture of a spray dried powder comprising: (a) forming a warm, stirred aqueous slurry comprising: inorganic salts, at least one binding agent and 0.001 to 20% by weight of capsules based on the weight of spray dried powder, said capsules containing benefit agents including at least perfume, and (b) spray drying the resultant slurry to form a spray dried powder, said capsules being such that: 1) more than 40% of the benefit agents remain encapsulated 60 minutes after dispersion thereof at 70° C. in the slurry as defined in the “slurry survival test” in a sealed vessel without agitation; and 2) more than 30% of the benefit agents added for 15 minutes to an ambient slurry as defined in the “spray dry test” survive spray drying through a laboratory scale spray drier.

Owner:TAKASAGO INTERNATIONAL CORPORATION

Dimensionally stable solid rinse aid

ActiveUS20120231992A1Reduced stabilityReduced water solid filming in waterOrganic detergent compounding agentsDrying soapAlcoholPreservative

The present invention is a solid rinse aid composition and methods of making and using the same. The solid rinse aid composition generally includes sodium sulfate and urea as solidification agents and an effective amount of an alcohol ethoxylate compound sheeting agent component and an effective amount of defoamer component. The solid rinse aid composition may also incorporate a preservative system including sodium bisulfate. The solid rinse aid composition may be phosphate-free, aminocarboxylate-free, and GRAS if desired.

Owner:ECOLAB USA INC

Anionic surfactant powder

InactiveUS20050106118A1Improve stabilityImprove powder propertiesCosmetic preparationsOrganic chemistryInorganic saltsSolubility

To provide an anionic surfactant powder comprising a polyoxyalkylene ether sulfate which powder has high stability in hard water, high low-temperature solubility and is improved in powder characteristics such as caking characteristics, and a method of producing the anionic surfactant powder. An anionic surfactant powder comprising polyoxyalkylene alkyl ether sulfates in which the average addition mol number of alkylene oxides is 0.05 to 2, wherein the content of the polyoxyalkylene alkyl ether sulfates provided with alkylene oxides added thereto in an amount of 4 mol or more is 30 % by weight or less based on the total anionic surfactant, an anionic surfactant powder further comprising a water-soluble inorganic salt, a method of producing each of these anionic surfactant powders, and a detergent composition and a cement additive comprising these anionic surfactant powders.

Owner:KAO CORP

Dimensionally stable solid rinse aid

ActiveUS7521412B2Reduced water solid filming in waterReduce spotting and water solids filmingOrganic detergent compounding agentsOrganic chemistryAlcoholPreservative

The present invention is a solid rinse aid composition and methods of making and using the same. The solid rinse aid composition generally includes sodium sulfate and urea as solidification agents and an effective amount of an alcohol ethoxylate compound sheeting agent component and an effective amount of defoamer component. The solid rinse aid composition may also incorporate a preservative system including sodium bisulfate. The solid rinse aid composition may be phosphate-free, aminocarboxylate-free, and GRAS if desired.

Owner:ECOLAB USA INC

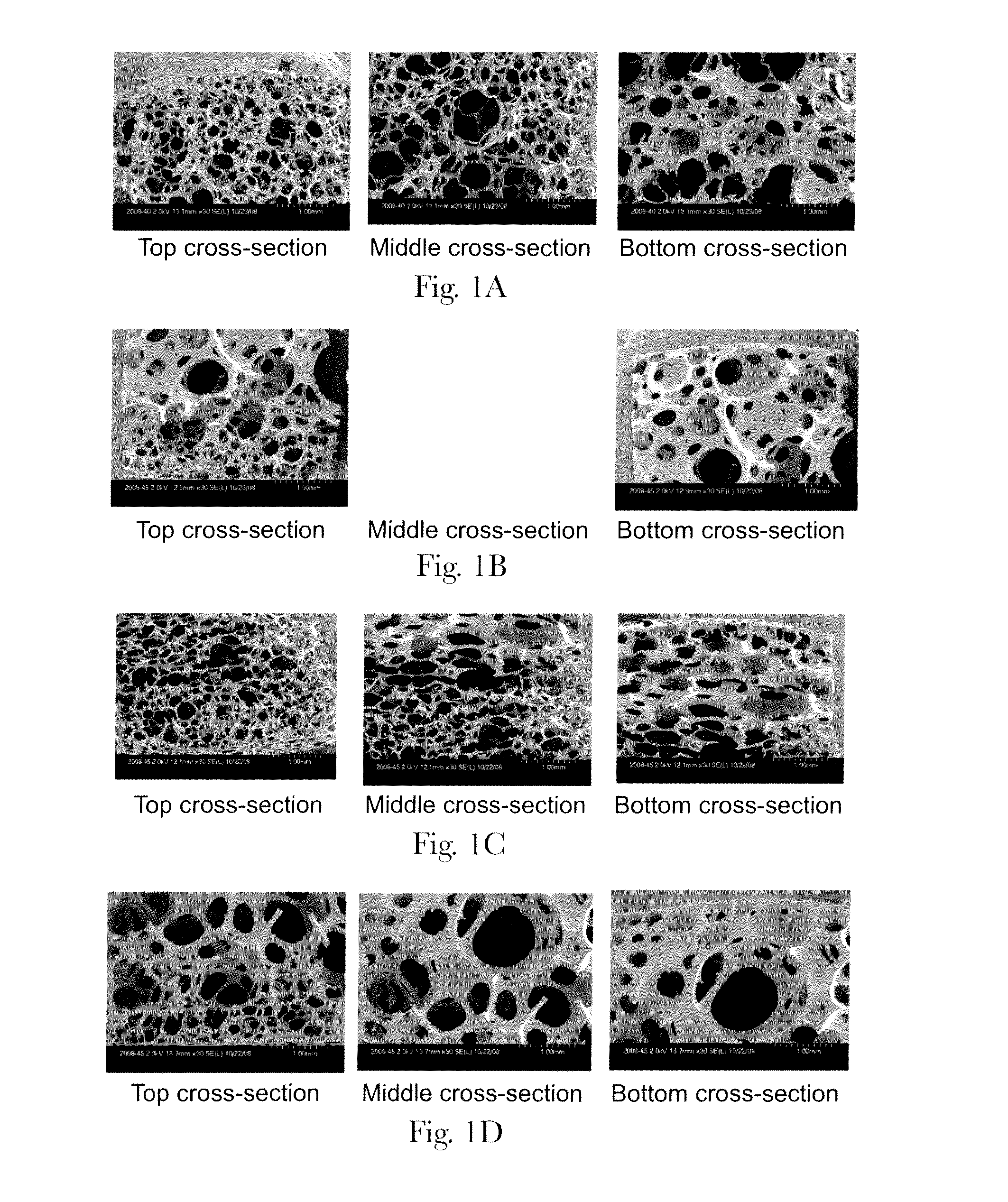

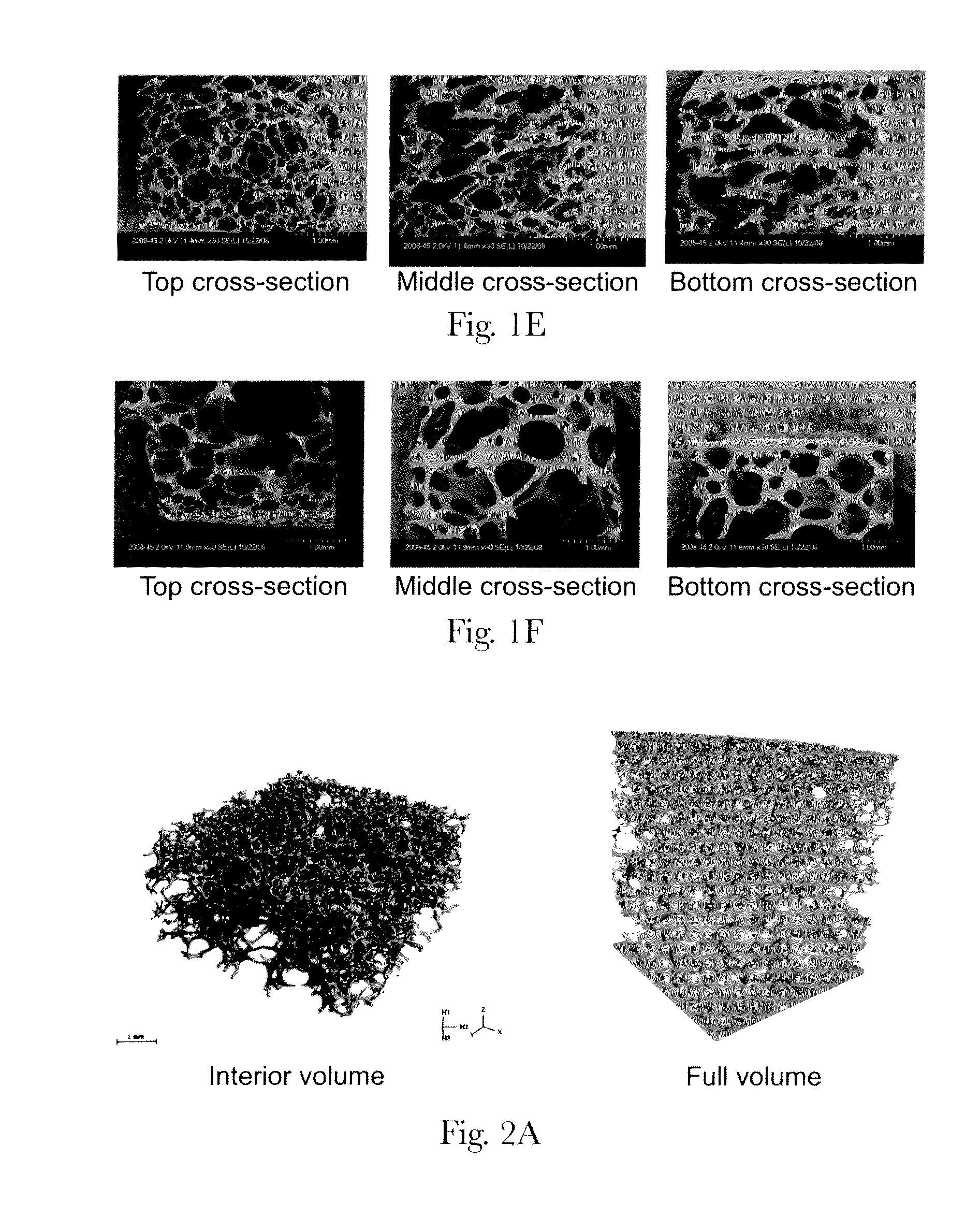

Method for making a nanoporous granular material and a detergent composition

InactiveUS6627597B1Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSolubilityControlled release

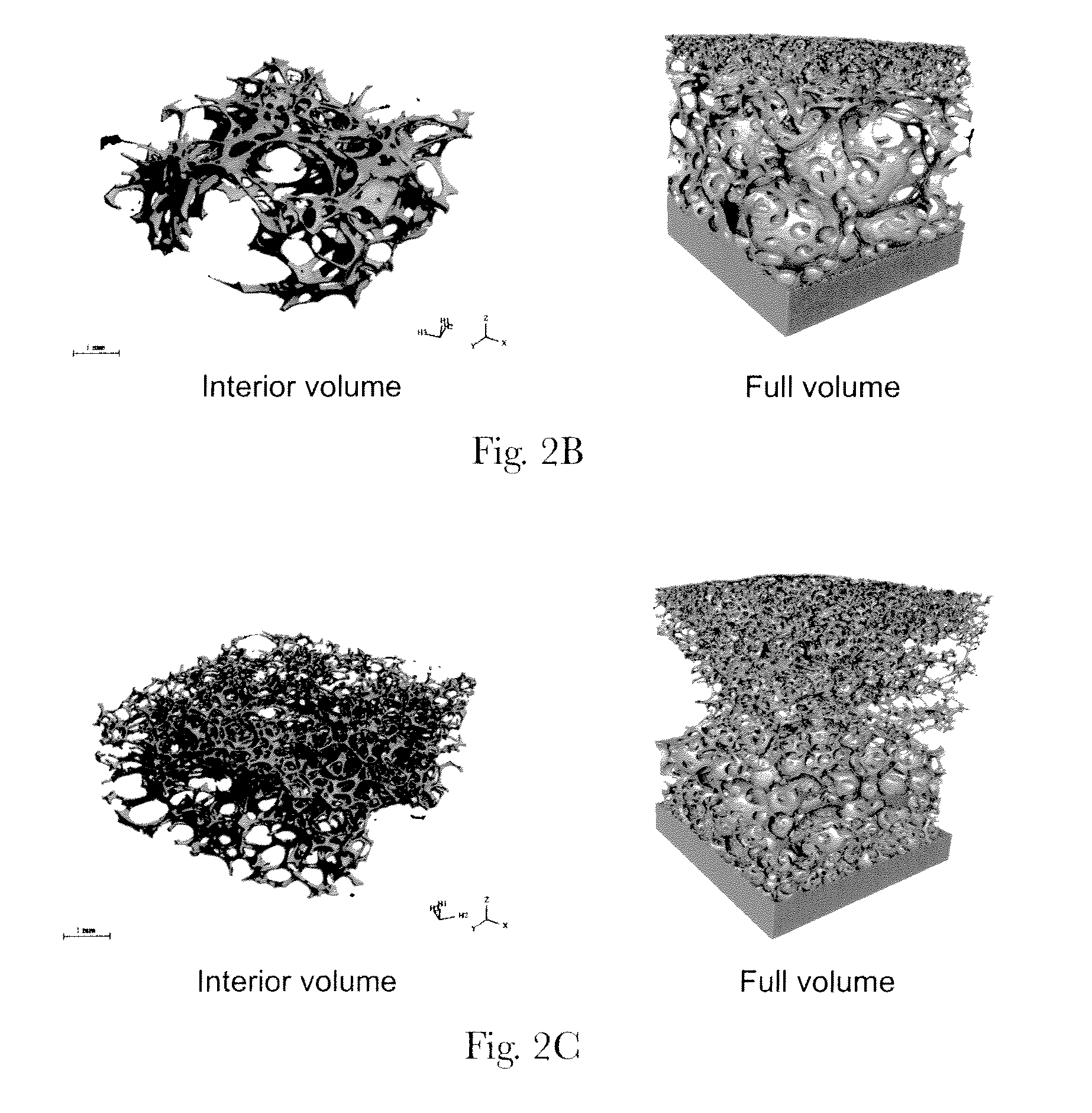

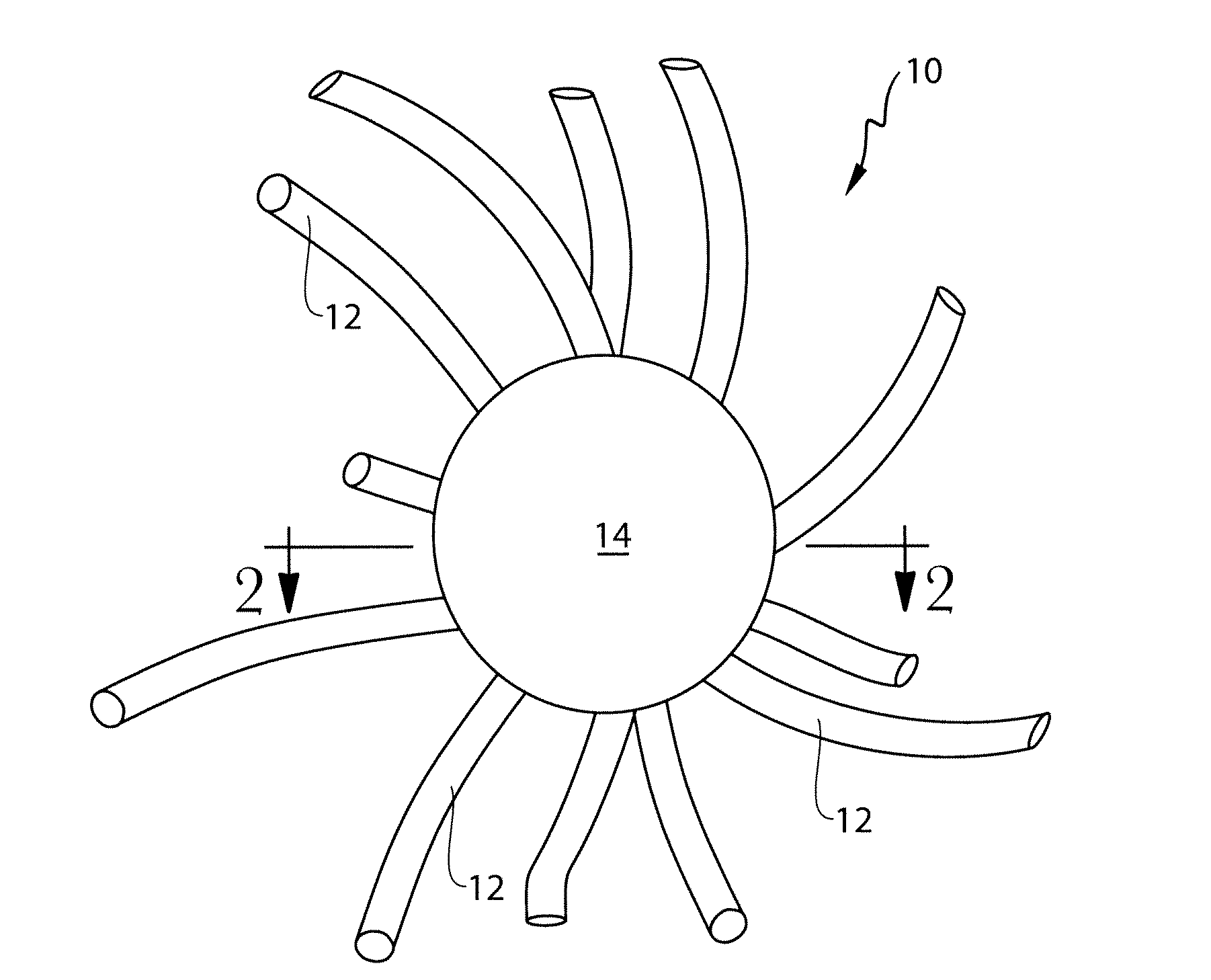

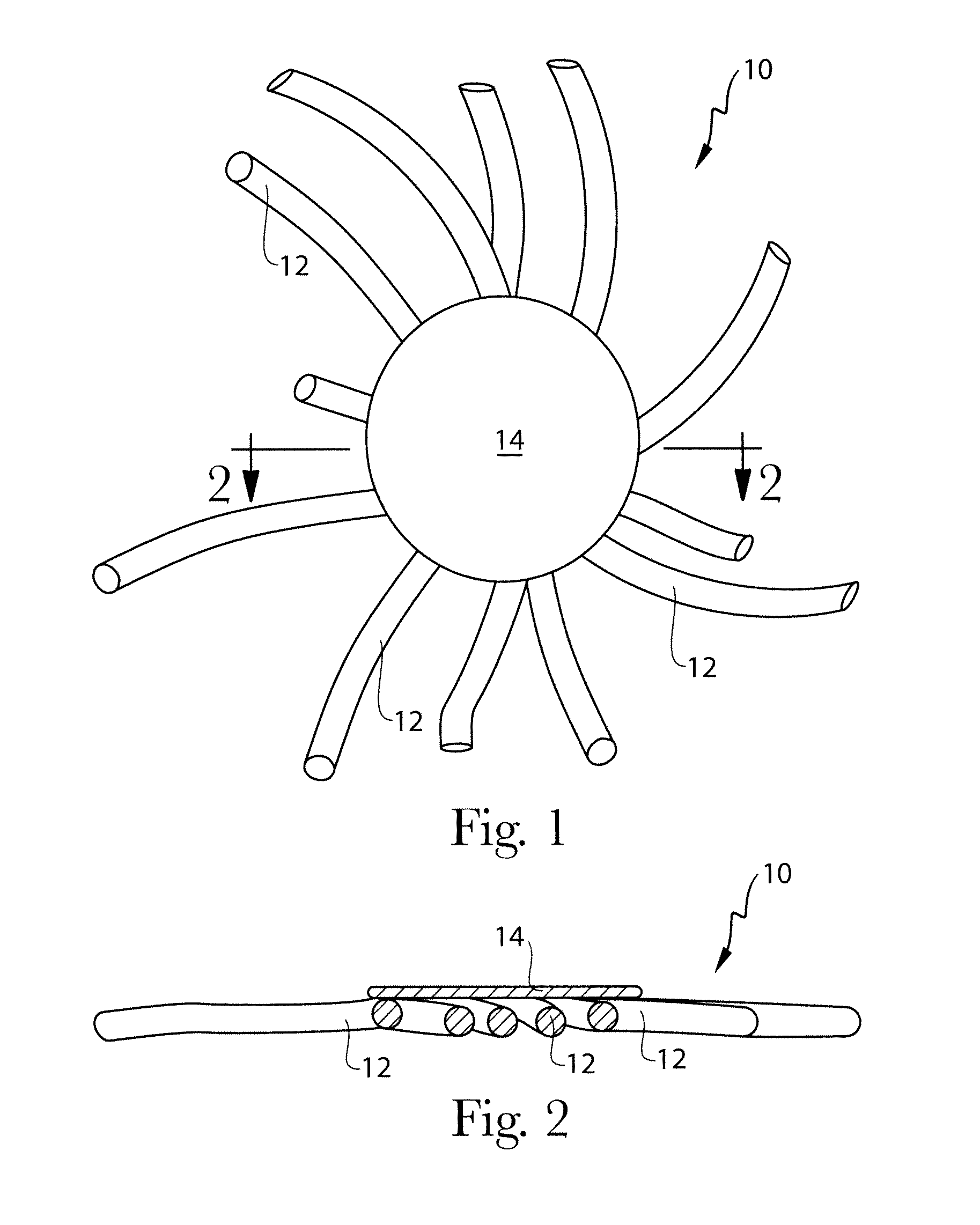

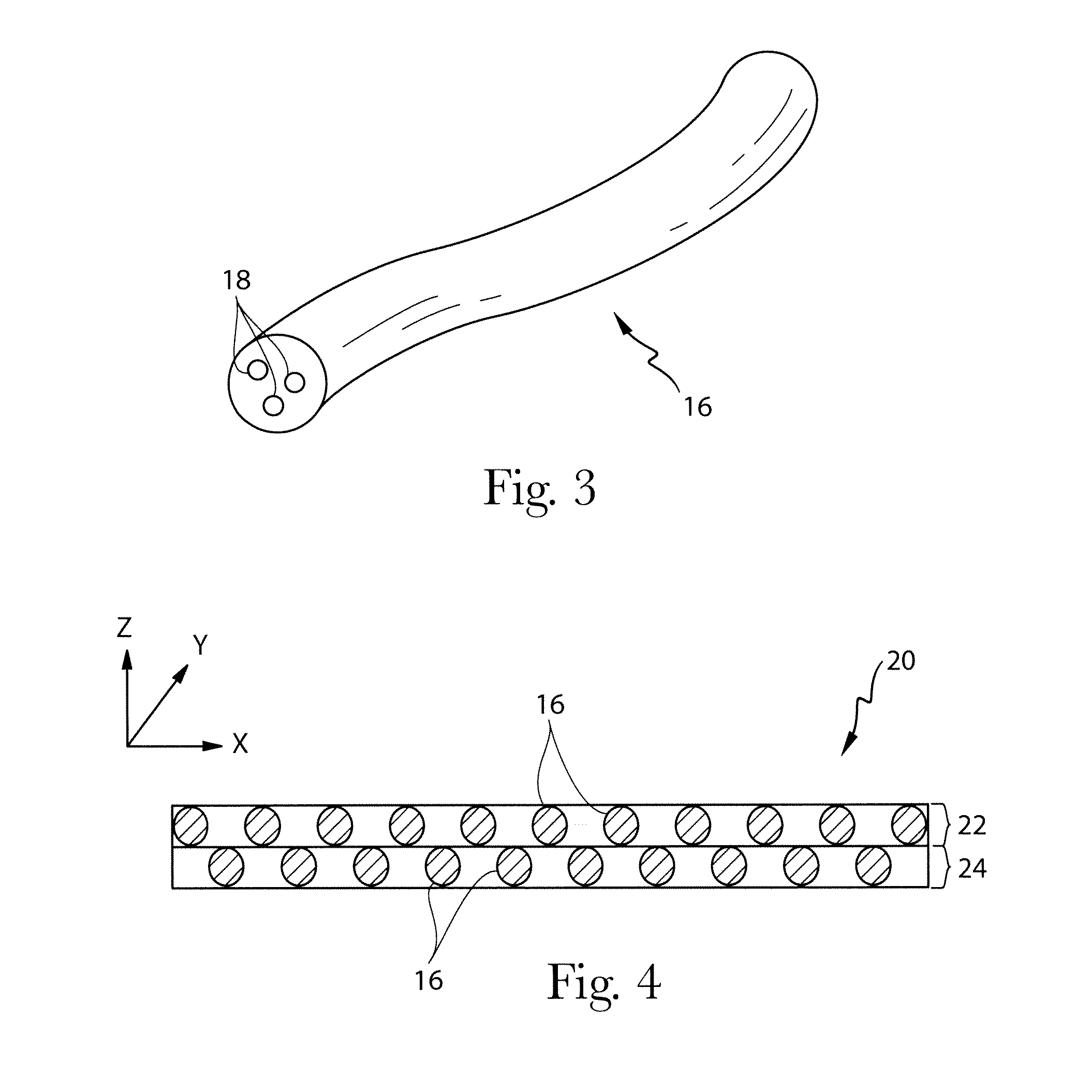

A process for producing a starting material in a granular form and in a nanoporous anhydrous state, a process for improving the water-solubility and controlled release characteristics of a detergent material, and a detergent composition are disclosed. In one aspect, a process for producing a starting material in a granular form and in a nanoporous anhydrous state includes obtaining a starting material in a form of a dispersion or solution in a sublimable solvent or mixtures of sublimable solvents, forming graded droplets by atomization, freezing the graded droplets in a freezing medium at a controlled freezing rate of a least 100° C. per second to form frozen droplets and drying the frozen droplets by vacuum sublimation to obtain freeze-dried granules of the starting material in a nanoporous anhydrous state. The starting material in dispersion or solution form has a viscosity suitable for atomization and formation of graded droplets.

Owner:THE PROCTER & GAMBLE COMPANY

Detergent composition

InactiveUS7465701B2Speed up the processReduce liquid viscosityOrganic detergent compounding agentsDrying soapPendant groupPolymer chemistry

A detergent auxiliary composition comprising from 0.001 wt % to 99 wt % cleaning polymer having a hydrophilic backbone and at least one hydrophobic pendant group, and an adjunct ingredient in which the hydrophilic backbone constitutes less than 50%, preferably less than 45% by weight of the polymer. The detergent auxiliary composition may be, for example a spray-dried particle or an agglomerate. Also described are detergent compositions comprising the detergent auxiliary composition.

Owner:PROCTER & GAMBLE CO

Enhanced melting point rinse aid solid compositions with synergistic preservative

The invention includes a GRAS preservative system including sodium bisulfate and a combination of specific organic acids that act in a synergistic capacity. The preservative further has the benefit of a higher melting point of approximately 110° or higher making it particularly suited for solid wash applications. According to the invention it has surprisingly been found that a combination of sodium bisulfate, sorbic acid, and benzoic acid produced better preservative properties than other organic acid combinations or each acid by itself.

Owner:ECOLAB USA INC

Degerming antiallergic green prickleyash skin care soap and preparing method thereof

ActiveCN105623929APromote growthImprove cleanlinessSoap detergents with organic compounding agentsSoap detergents with inorganic compounding agentsGlycerolEther

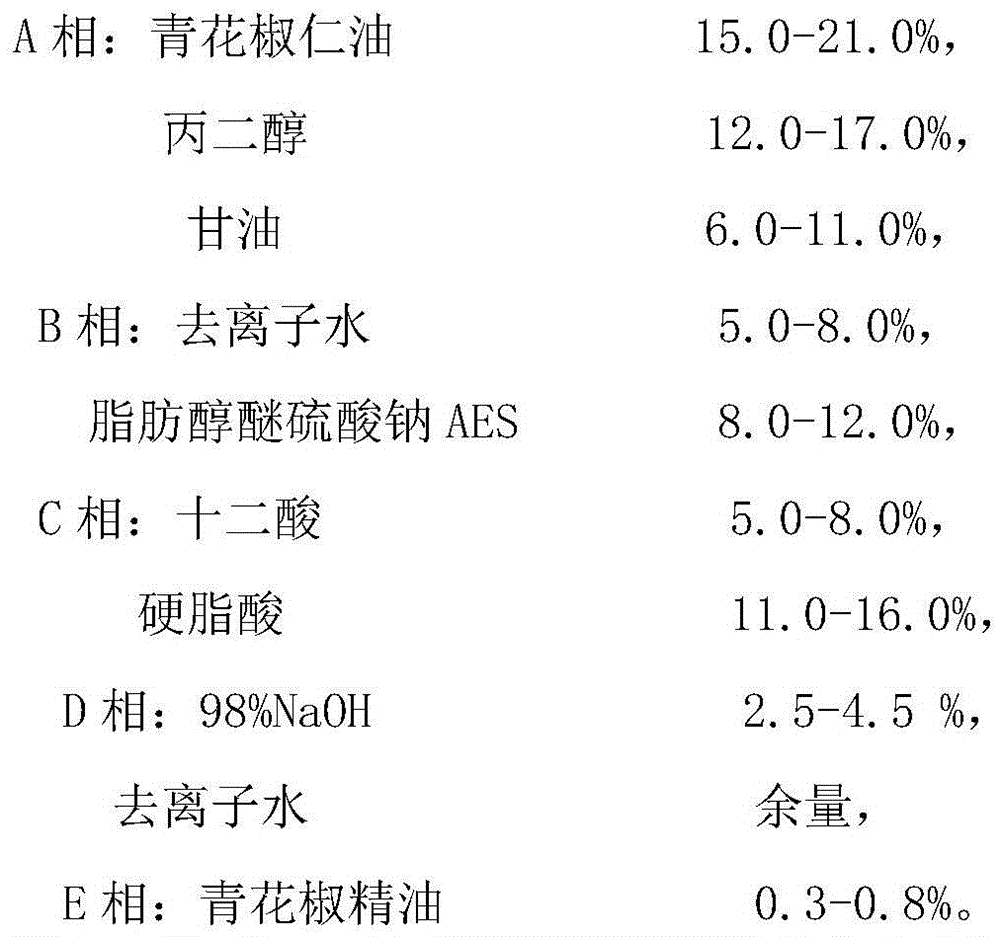

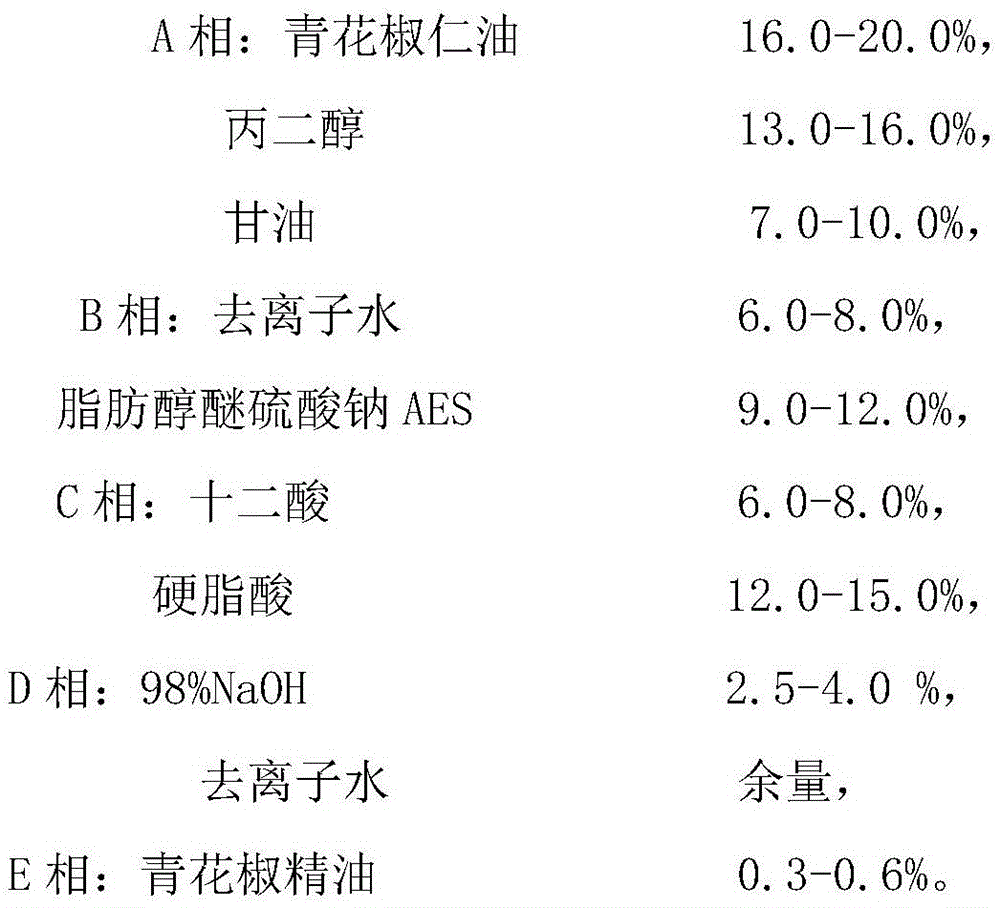

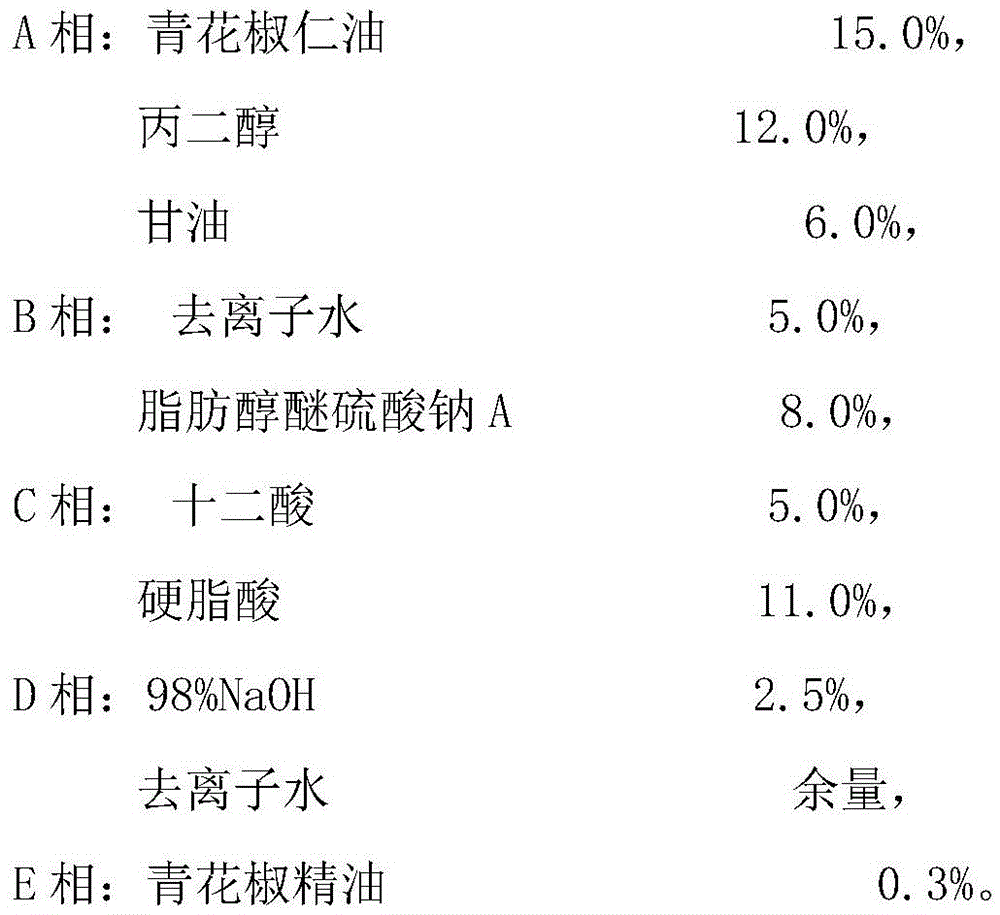

The invention discloses a degerming antiallergic green prickleyash skin care soap and a preparing method thereof. The degerming antiallergic green prickleyash skin care soap is prepared from following components in percent by weight: A phase: 15.0-21.0 percent of green prickleyash kernel oil, 12.0-17.0 percent of propylene glycol, 6.0-11.0 percent of glycerinum, B phase: 5.0-8.0 percent of deionized water, 8.0-12.0 percent of sodium fatty alcohol ether sulphate AES, C phase: 5.0-8.0 percent of lauric acid, 11.0-16.0 percent of stearic acid, D phase: 2.5-4.5 percent of 98 percent of NaOH, the balance of deionized water, and E phase: 0.3-0.8 percent of green prickleyash essential oil. The skin care soap finished product is light yellow, semitransparent, good in stability, aromatic in odor, rich in foam, and capable of nourishing skin and achieving an excellent sterilizing action.

Owner:NANJING WILD PANT COMPREHENSIVE UTILIZATION INST THE ALL CHINA SUPPLY & MARKETING COOPERATIV +1

Production of anionic surfactant granules by in situ neutralisation

InactiveUS6514930B2Reduce the possibilityReduce riskInorganic/elemental detergent compounding agentsDrying soapPolymer scienceLotion

A process for the production of detergent particles comprises feeding an acid precursor of an anionic surfactant, a neutralizing agent and aluminosilicate detergency builder into a horizontal thin-film evaporator / drier. The evaporator / drier comprises a mixing region, a drying region and a cooling region. Neutralization of the acid precursor is effected, together with granulation, drying and cooling, to form the detergent particles. At least some of the aluminosilicate builder is fed into the thin-film evaporator / drier between the drying region and the cooling region and / or into the cooling region. When all of he aluminosilicate builder is fed into the cooling region, the aluminosilicate is in an amount of more than 20% by weight of the particles exiting the cooling region.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

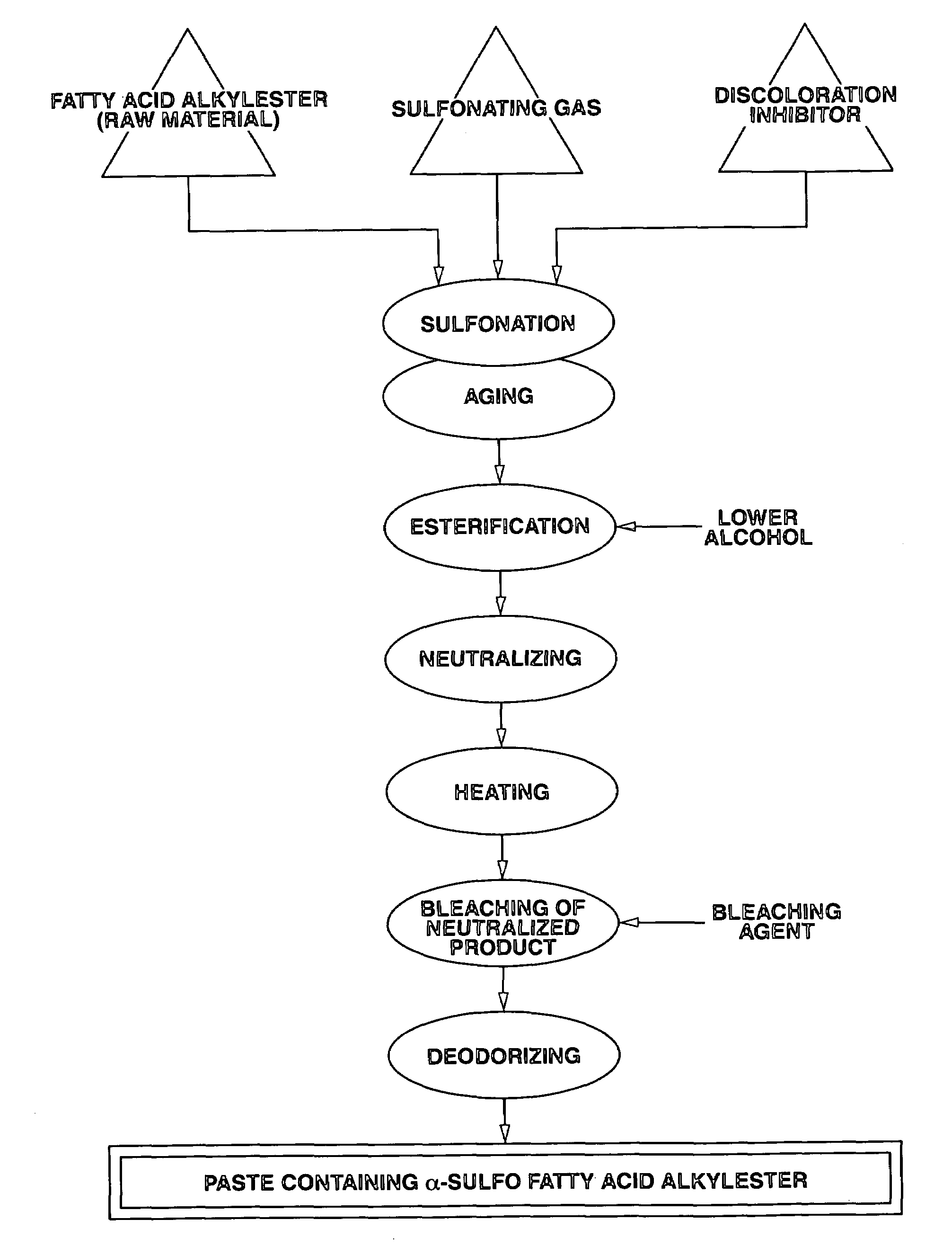

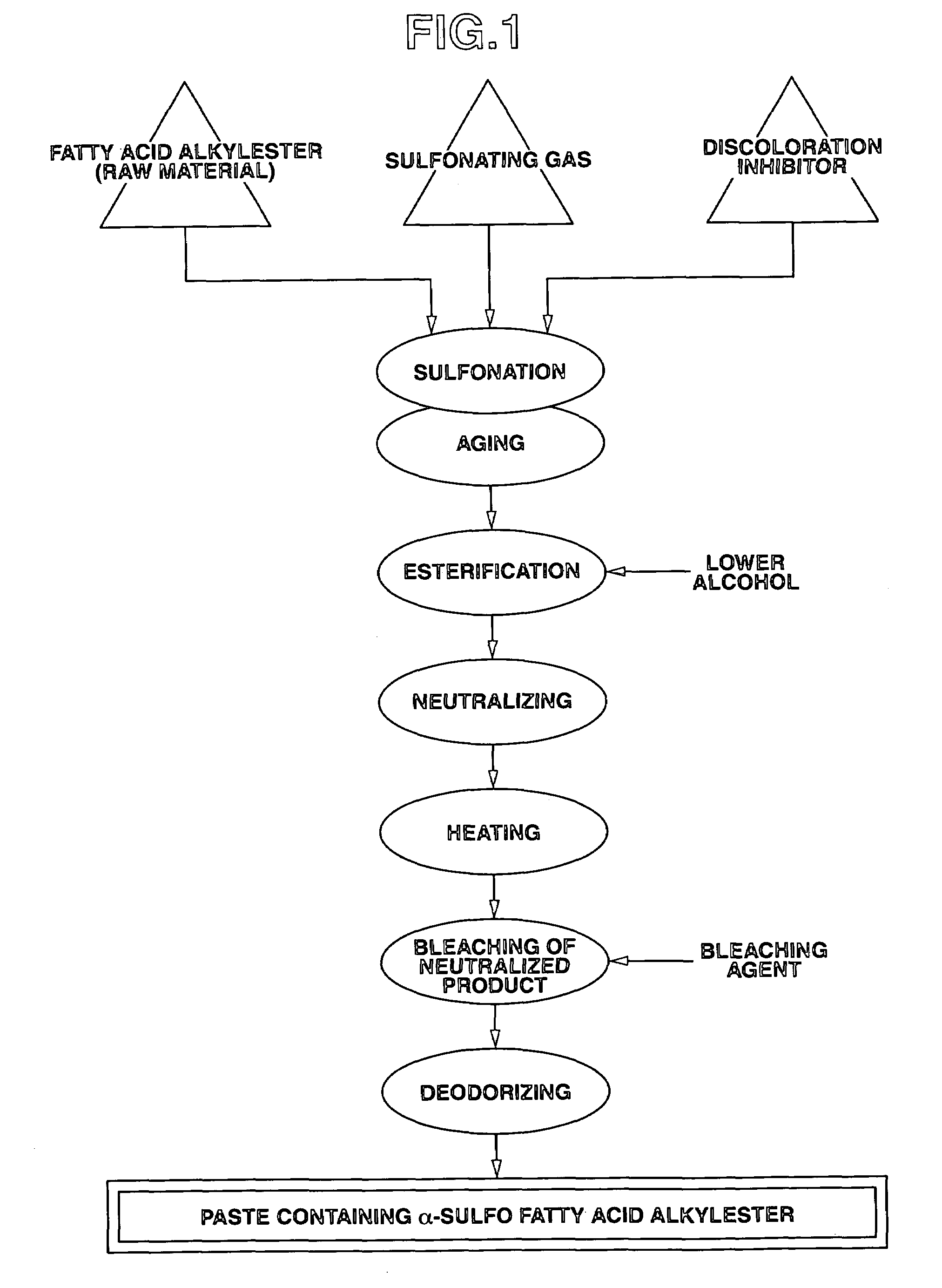

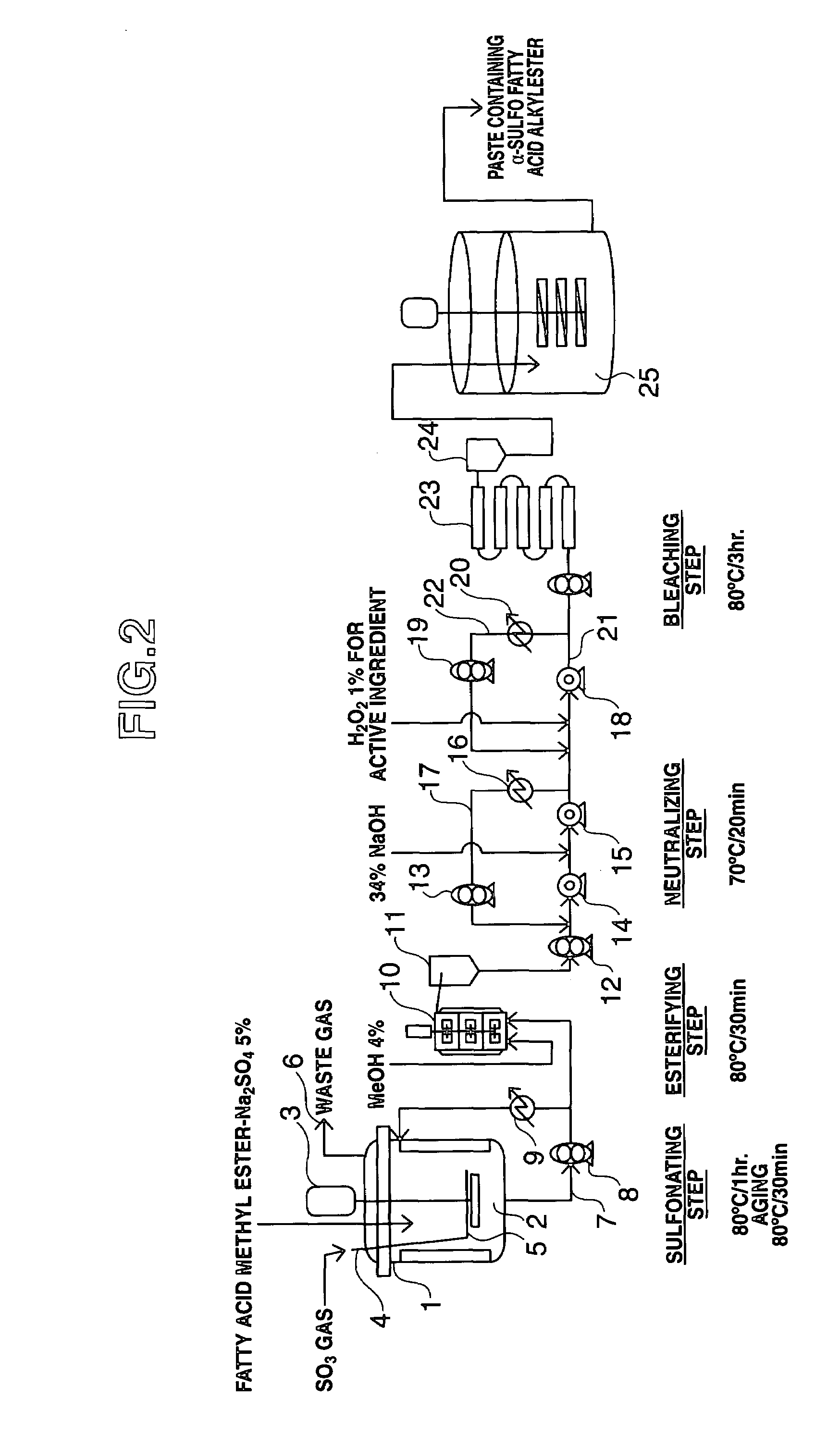

Powders, flakes, or pellets containing salts of a sulfo fatty acid alkyl esters in high concentrations, process for production thereof, granulated detergents, and process for production thereof

ActiveUS7592302B2Maintain good propertiesGood colorNon-ionic surface-active compoundsDrying soapHigh concentrationFatty acid

A process for producing powder, flakes, or pellets containing α-sulfo fatty acid alkylester salt in high concentrations, the process including: (1) a step of preparing a paste containing α-sulfo fatty acid alkylester salt; (2) a step of aging the thus obtained paste; (3) a step of making the aged paste into flakes or pellets containing equal to or less than 10 wt % of water and then optionally crushing the resulting flakes or pellets into a powder having an average particle diameter of 100-1500 μm; and (4) a step of aging The powder, flakes, or pellets.

Owner:LION CORP

Production of anionic surfactant granules by in situ neutralisation

InactiveUS6518234B2Reduce the possibilityReduce riskDrying soapCooling soapSURFACTANT BLENDChemistry

A process for the production of detergent particles, comprises feeding an acid precursor of an anionic surfactant and a neutralising agent into a horizontal thin-film evaporator / drier comprising a mixing region, a drying region and a cooling region. The resultant detergent particles are graded to separate an oversize granule fraction in which at least 70 wt % of the particles have a minimum diameter of 1000 mum. This fraction is fed back into the process.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

Spray-dried detergent powder

The present invention is a spray-dried powder comprising: (i) from 20 to 80 wt % of a first spray-dried particle comprising less than 5 wt % sulphate, anionic detersive surfactant and having a bulk density of from 300 g / l to 450 g / l: and (ii) from 20 to 80 wt % of a second spray-dried particle comprising at least 45 wt % sulphate, 0 wt % to 15 wt % anionic detersive surfactant, and having a bulk density of from 350 g / l to 700 g / l.

Owner:THE PROCTER & GAMBLE COMPANY

Process for the preparation of coated granular sodium percarbonate, and product obtainable by the process

The invention relates to a process for the preparation of coated granular sodium percarbonate having a low TAM value. The preparation is carried out by fluidized-bed spray granulation at a temperature TG in the range from 45 to 75° C., and the coating is effected by the spray application of an aqueous solution containing at least one coating component in a fluidized bed at a temperature TU in the range from 35 to 100° C. According to the invention, a) after the fluidized-bed spray granulation but before the coating, drying is carried out at TNT of greater than TG, or b) the fluidized-bed granulation is carried out in at least two steps at TG1, TG2 . . . TGn, TG2 or TGn being higher than TG1, and drying being unnecessary if ⅔ of the granulate have been formed at TG1, or c) drying takes place not after the granulation but after the coating, at TUNT, TUNT being at least 20° C. higher than TG.

Owner:EVONIK TREIBACHER

Process For Preparing A Detergent

Disclosed is a process for preparing a granular detergent composition or component having a bulk density of at least 500 g / l. The process disclosed herein comprises the steps of (i) providing an aqueous solution of a surfactant (ii) adding one or more water-soluble salts to the aqueous surfactant solution to precipitate the surfactant, (iii) separating the resulting precipitate, and (iv) drying the product.

Owner:J P LAB PVT

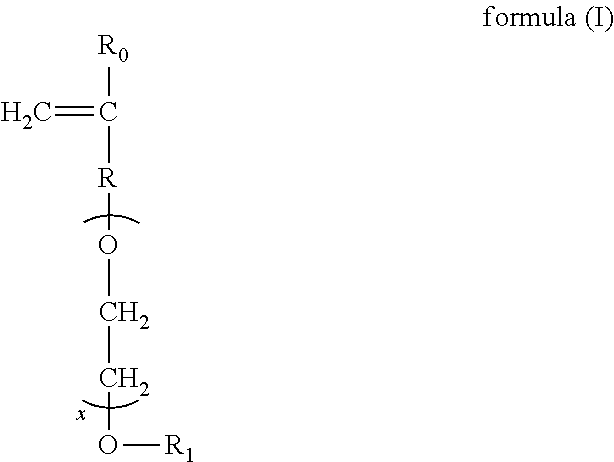

Bactericidal, Fungicidal and Anti-Allergenic Zanthoxylum Schinifolium Skin Care Soap and Method of Preparation

ActiveUS20170191010A1Increase moist feelingImprove stabilitySoap detergents with organic compounding agentsSoap detergents with inorganic compounding agentsGlycerolStearic acid

The present invention discloses a method of preparing a bactericidal, fungicidal and anti-allergenic Zanthoxylum schinifolium skin care soap, wherein the bactericidal, fungicidal and anti-allergenic Zanthoxylum schinifolium skin care soap comprises the following components based on percentage by weight: Component A: Zanthoxylum schinifolium seed oil 15.0-21.0%, propylene glycol 12.0-17.0%, glycerin 6.0-11.0%, Component B: deionized water 5.0-8.0%, sodium alkyl ether sulfate AES 8.0-12.0%, Component C: lauric acid 5.0-8.0%, stearic acid 11.0-16.0%, Component D: 98% NaOH 2.5-4.5%, deionized water balance, Component E: Zanthoxylum schinifolium essential oil 0.3-0.8%. The skin care soap of the present invention is pale yellow and translucent, has good stability, provides great aroma and rich foam, and can nourish the skin and sterilize effectively.

Owner:NANJING WILD PANT COMPREHENSIVE UTILIZATION INST THE ALL CHINA SUPPLY & MARKETING COOPERATIV +1

Dry cleaning soap for removing stubborn stain and preparation method thereof

InactiveCN102080027ASimple componentsNon-toxicCooling soapSoap detergent compositionsFruit juiceSulfite salt

The invention discloses dry cleaning soap for removing stubborn stains and a preparation method thereof. The dry cleaning soap comprises the following components in parts by weight: 1000-2000 parts of surfactant, 500-2000 parts of sodium carbonate, 10-40 parts of sodium sulfite, and an appropriate amount of water. The preparation method is as follows: evenly mixing the compositions by weight; and heating at the temperature of 70-90 DEG C, and then cooling to obtain the dry cleaning soap. The compositions of the dry cleaning soap are simple and is not harmful to a human body, have a good cleaning effect for various stubborn stains such as blood, sweat, ink trace, fruit juice, and ball-point pen trace. The clothes are not subjected to decoloration and damage after being washed by the soap. The soap is applicable to various materials that need washing. The dry cleaning soap is convenient for use, and is smeared on the stains for dry-cleaning, and the clothes is rinsed with fresh water after cleaning. In addition, the dry cleaning soap is no irritant to human bodies, therefore harmless, can be used for washing hair or feet. When being used in washing the hair, it can remove dandruff, and in washing the feed, it prevents the feet from odor and sweating.

Owner:熊善庆

Liquid detergent compositions with low-density particles

Process for reducing the density of solid detergent ingredients by forming said ingredients into hollow-core particles. The density of ingredients such as sodium citrate, sodium carbonate and / or sodium silicate, when formed into such hollow-core particles, allows them to be stably incorporated into non-aqueous liquid laundry detergents.

Owner:THE PROCTER & GAMBLE COMPANY

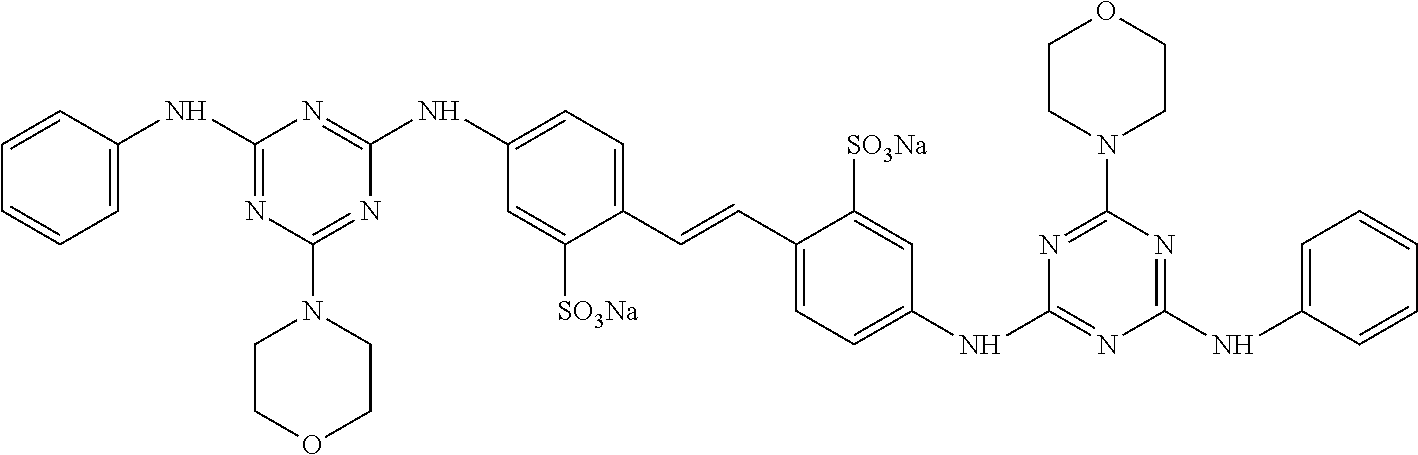

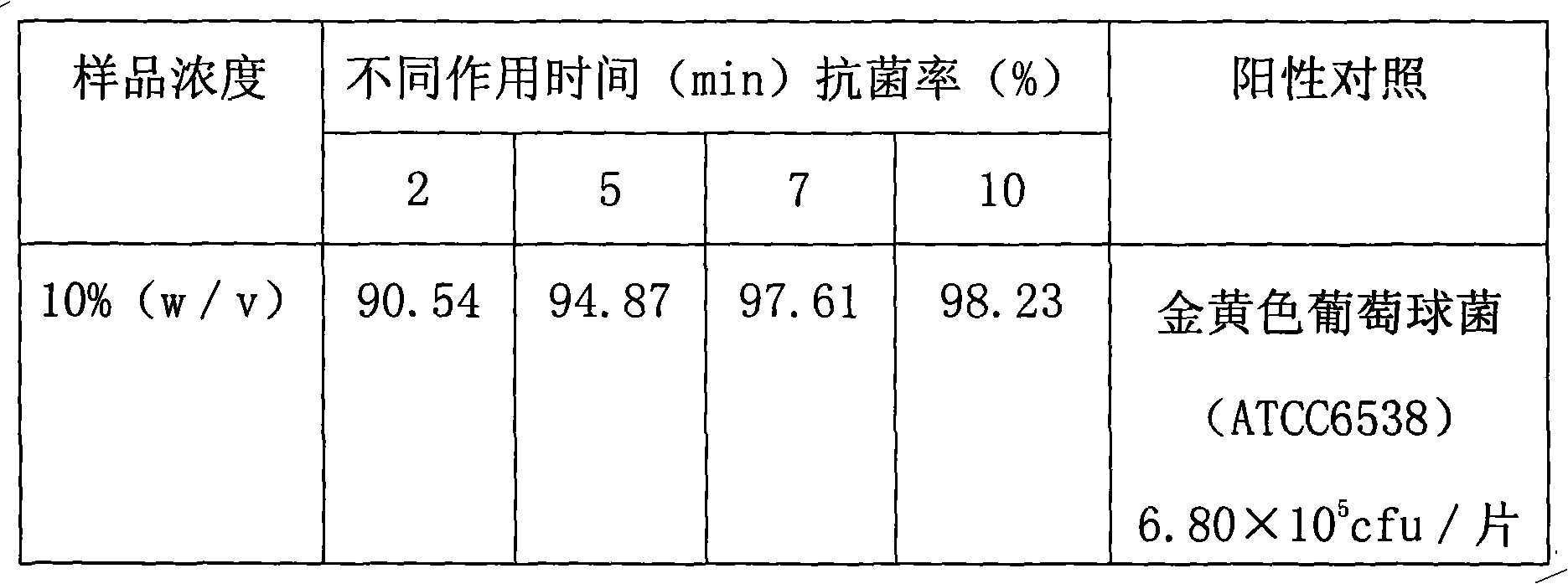

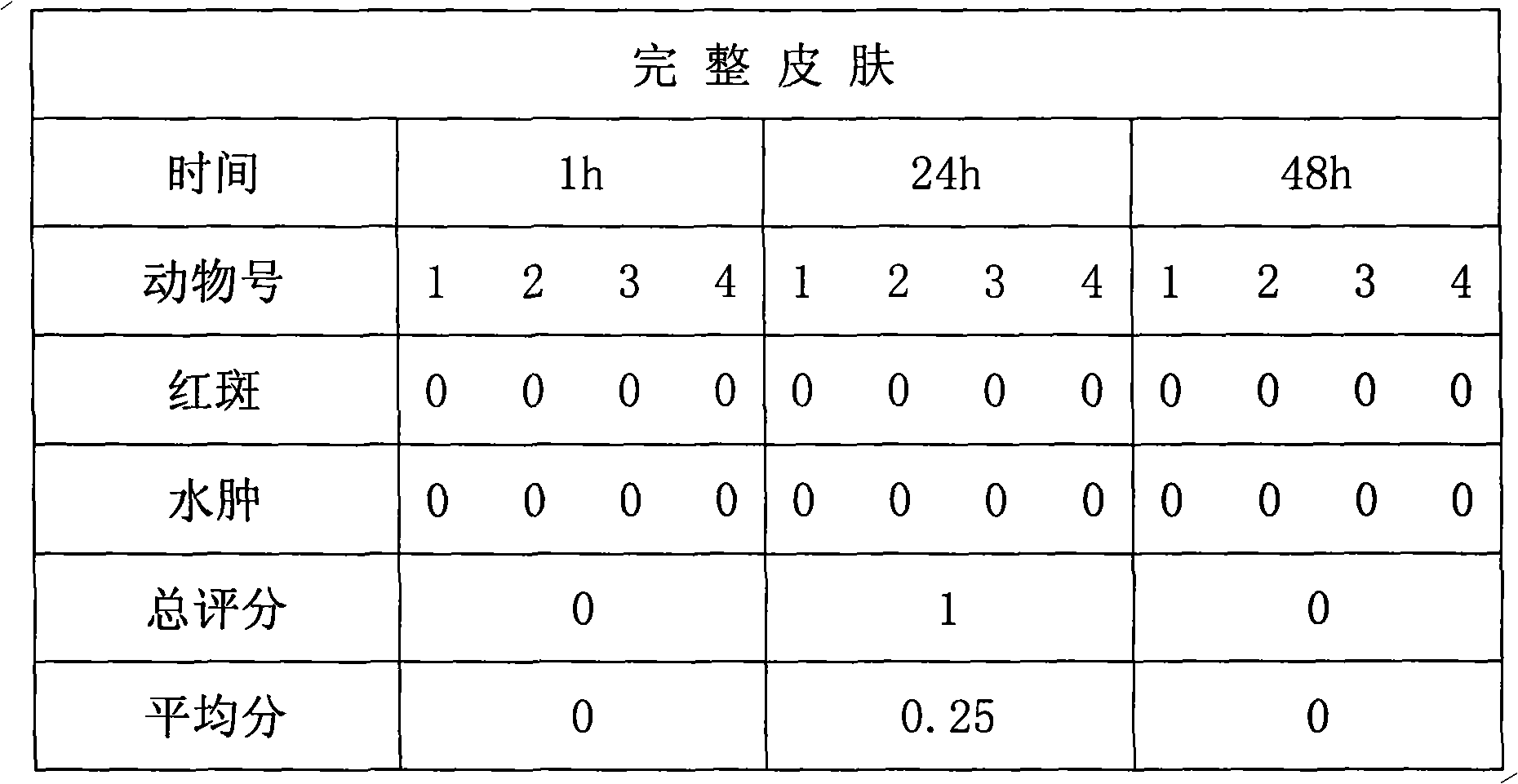

Healthy soap for inhibiting germ reproduction and preventing germ transmission and preparation method thereof

InactiveCN101602986AEfficient decontaminationStrong anti-bacterialSoap detergents with inorganic compounding agentsCooling soapMedicineStaphylococcus aureus

The invention relates to a healthy soap for inhibiting germ reproduction and preventing germ transmission and a preparation method thereof. Germs exist everywhere, and people can contact with germs at any time in the daily life; although most germs have no harm on the health of human beings, germs can result in a bad effect on human beings on specified conditions, namely conditioned pathogen, and even make people ill. The invention is a block healthy soap prepared with the method that corresponding minor ingredients are added into soap base, pancreatic enzyme, KF-88 and essence. The invention has the efficacy of disinfecting, sterilizing, decontaminating, quickly removing epidermis pathogenic bacterium (hepatitis virus, staphylococcus aureus and the like) and various kinds of reproduction, shack and infectious bacteria, effectively inhibiting various germs from reproducing and preventing germs transmission.

Owner:周菊彦

Spray-dried detergtent powder

The present invention is a spray-dried powder comprising: at least 5 wt % of a spray-dried particle comprising at least 40 wt % anionic detersive surfactant, from 15 to 40 wt % carbonate and less than 20 wt % sulphate and having a bulk density of from 300 g / l to 450 g / l.

Owner:THE PROCTER & GAMBLE COMPANY

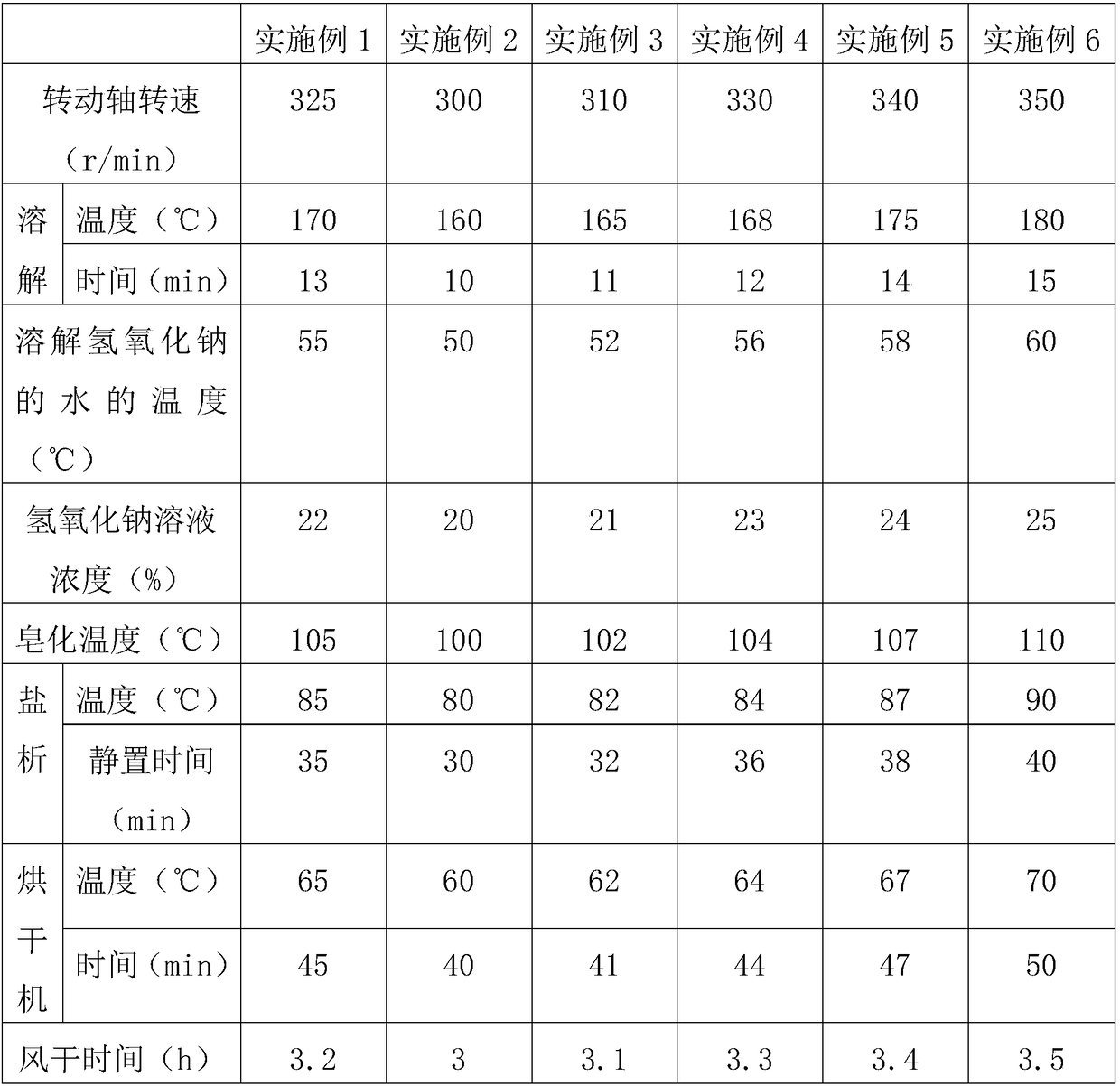

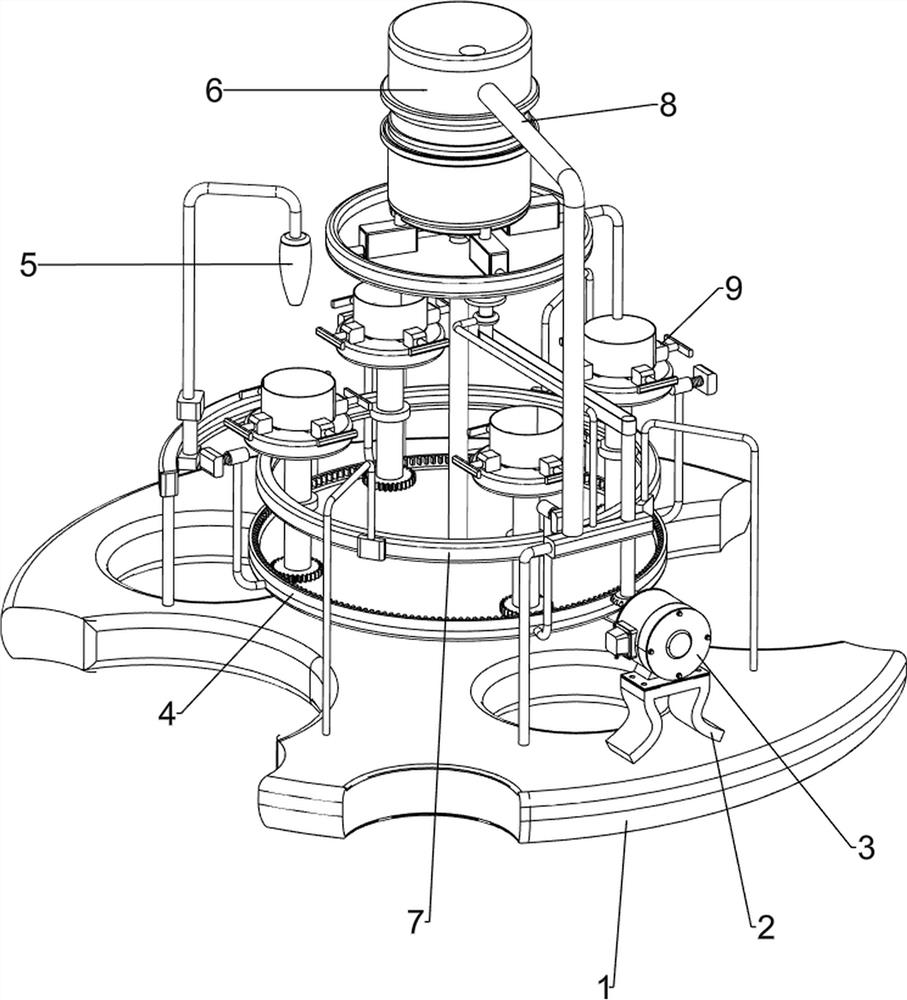

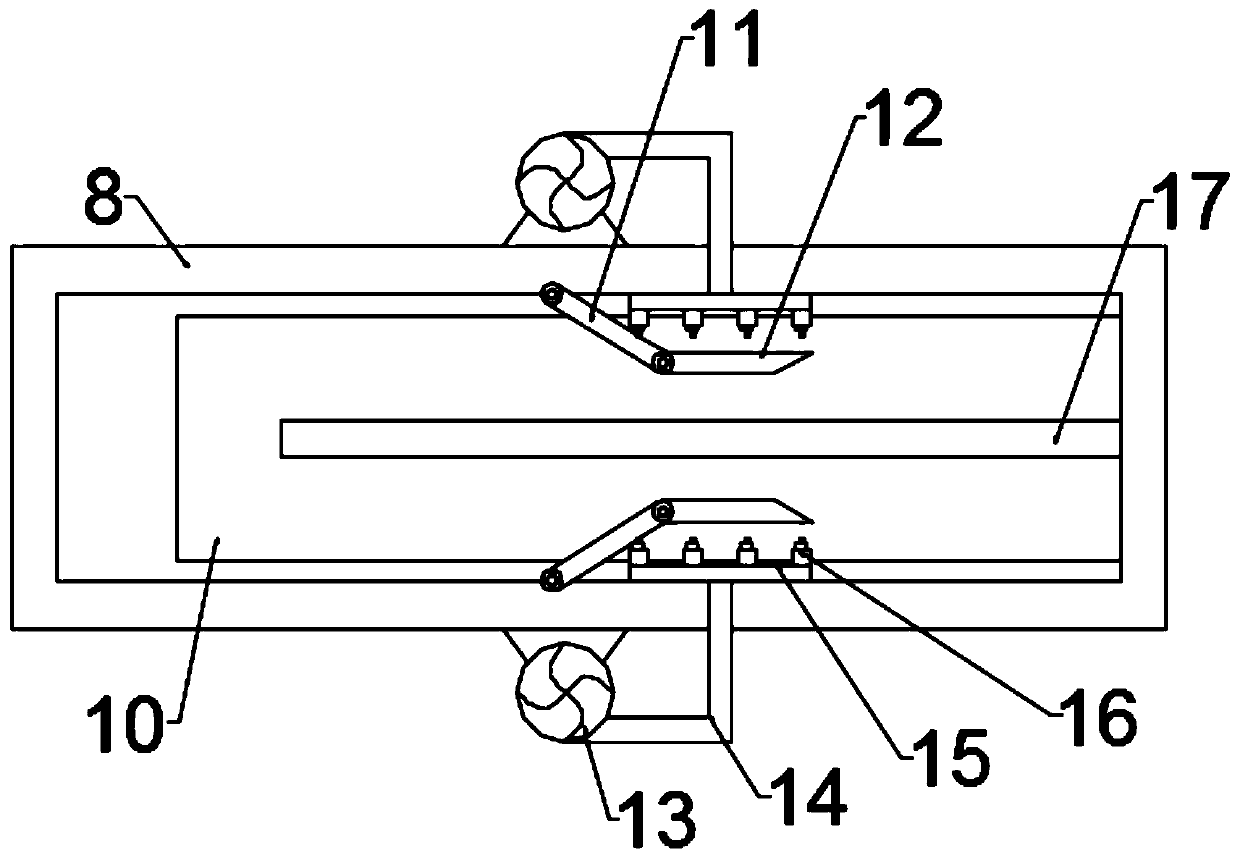

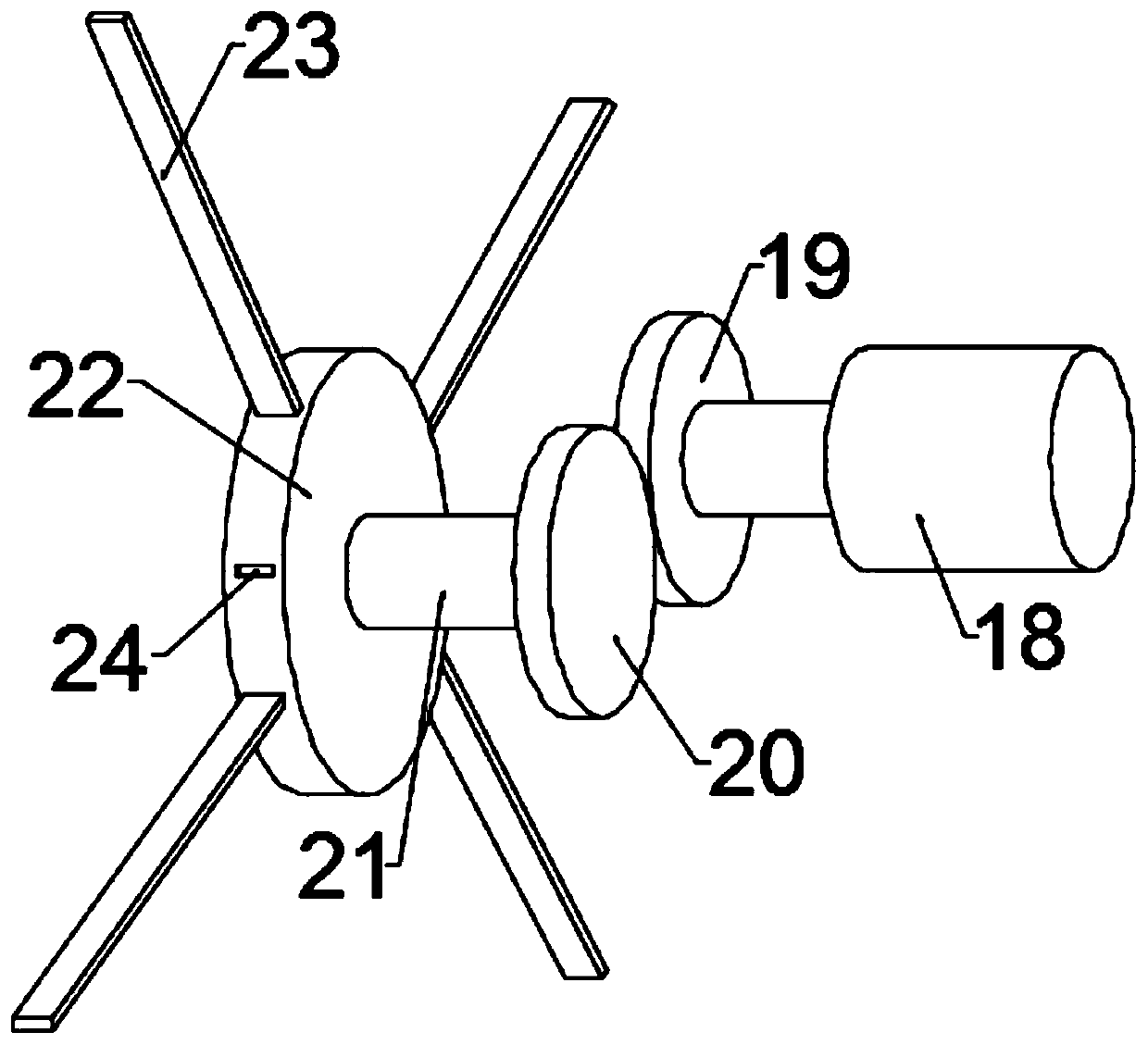

Processing method of soaps

ActiveCN108148694AReduce outflowRealize current limitingDrying soapCooling soapSalting outEngineering

Owner:XUZHOU XUANKE AGRI MASCH CO LTD

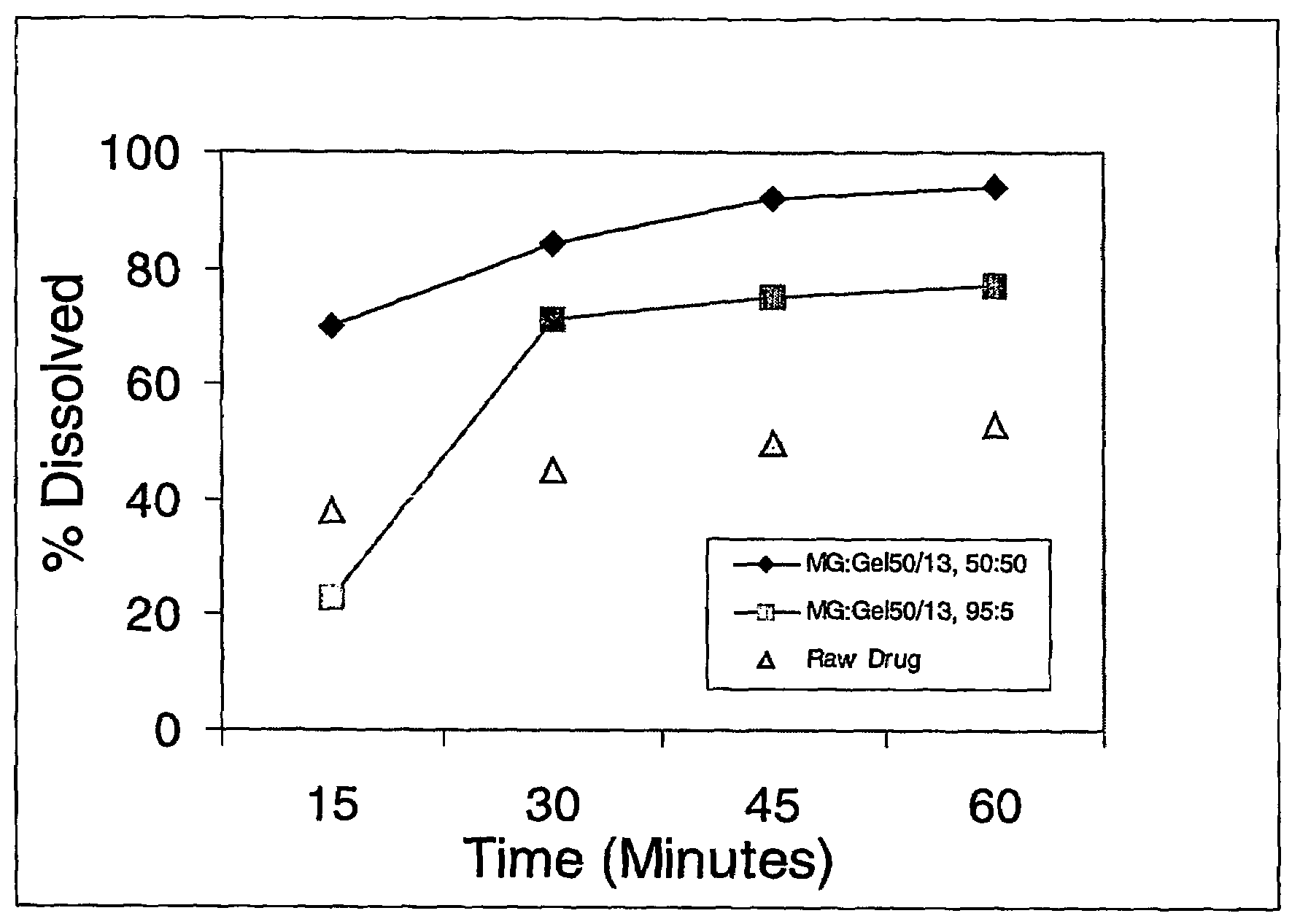

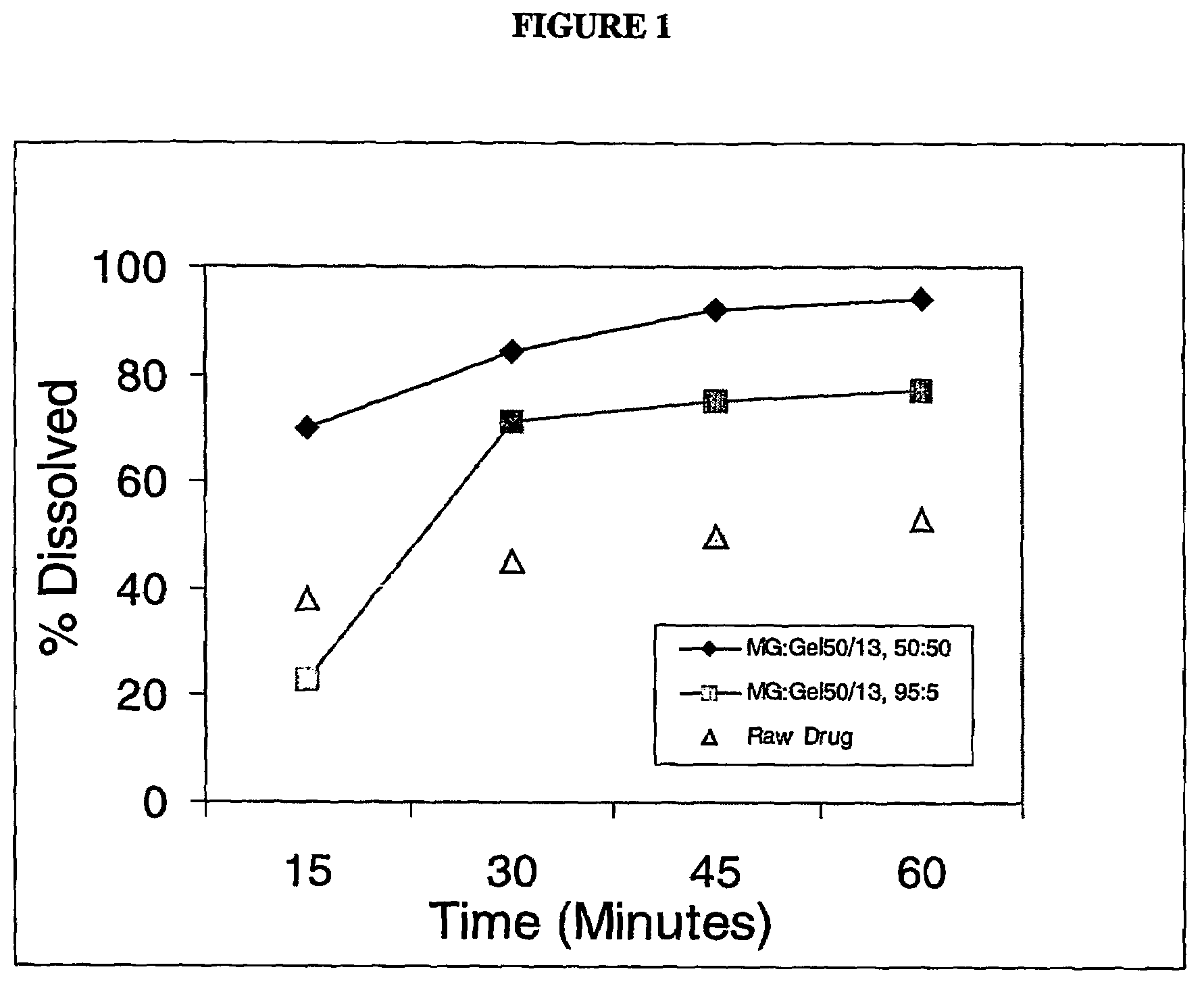

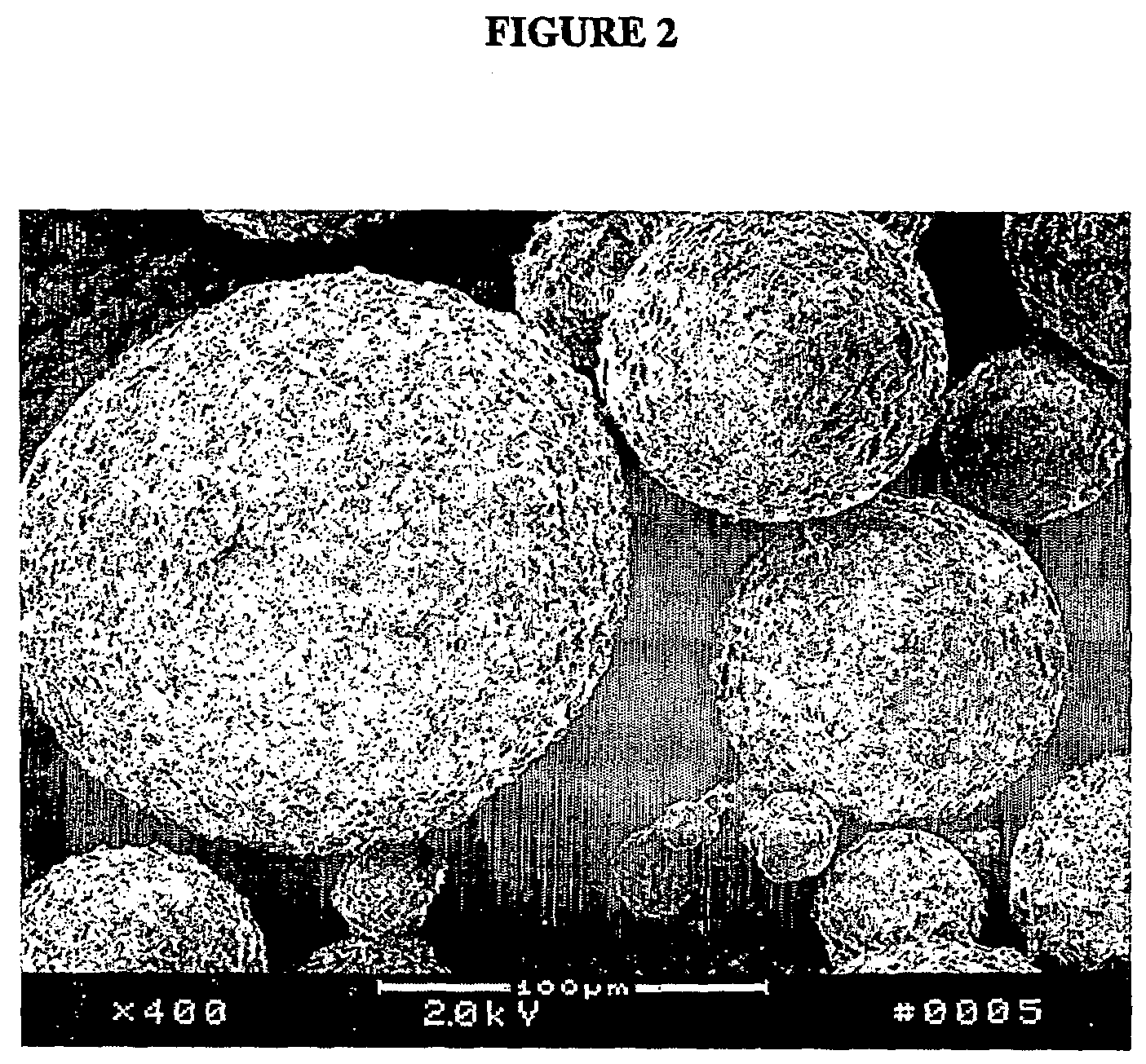

Solid dispersion compositions

Disclosed is a water-dispersible solid composition of a sparingly water-soluble compound in a particulatable lipidic carrier, methods for the preparation and use of the same. The compositions of this intention provide improved solubility and dissolution characteristics and enhanced bioavailability of the sparingly soluble compound.

Owner:GLAXO SMITHKLINE LLC

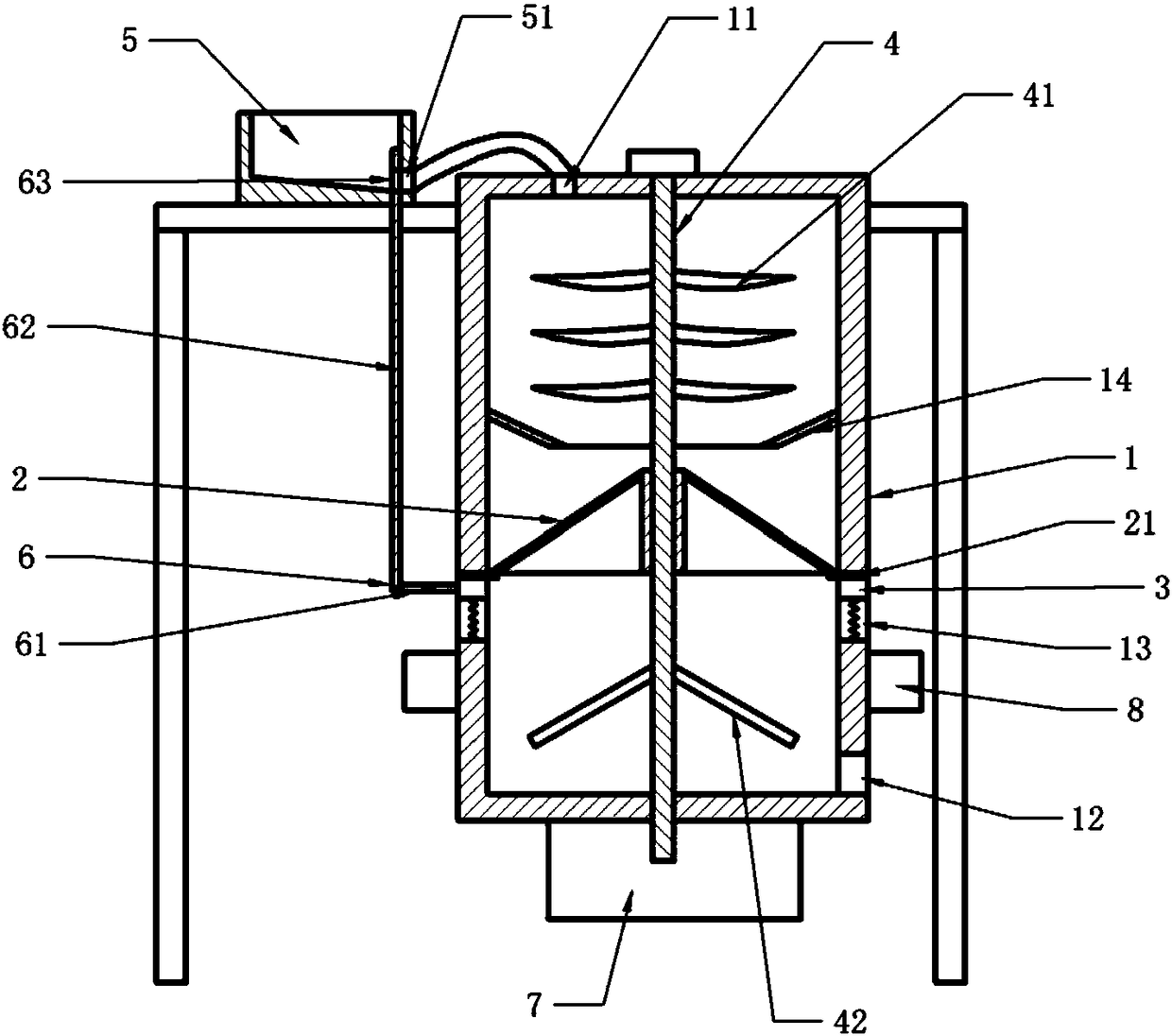

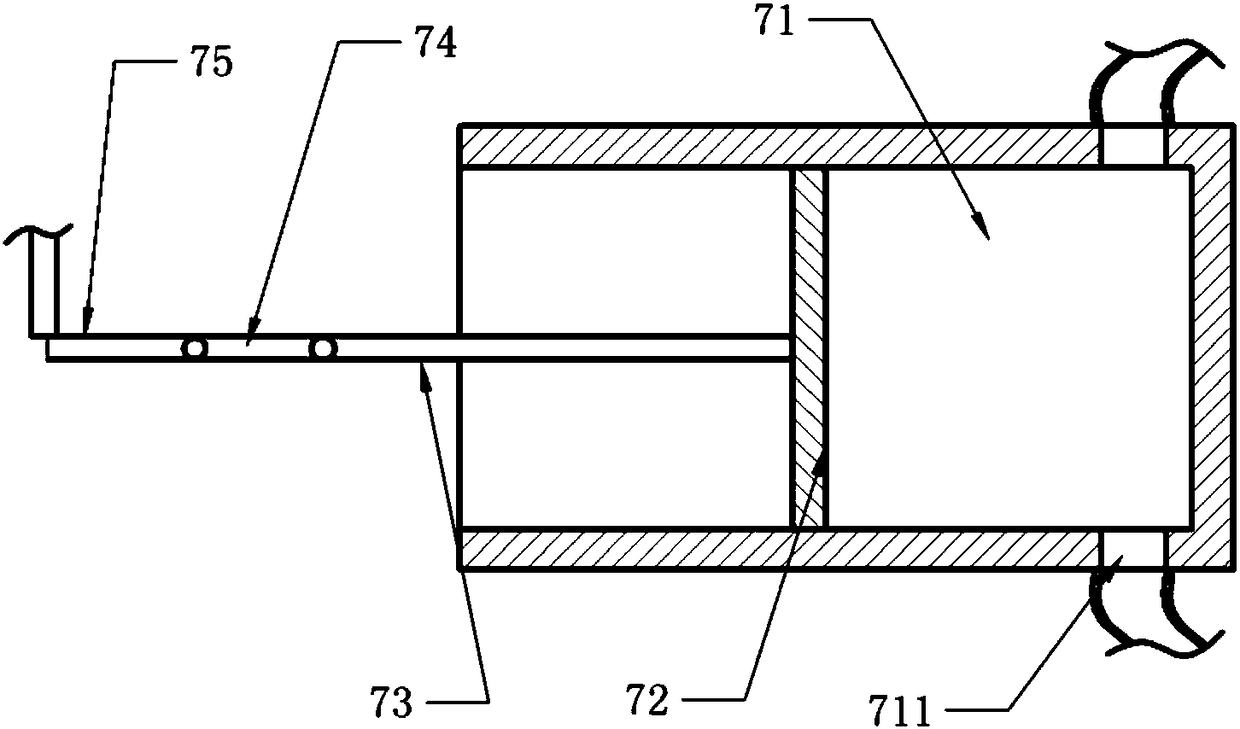

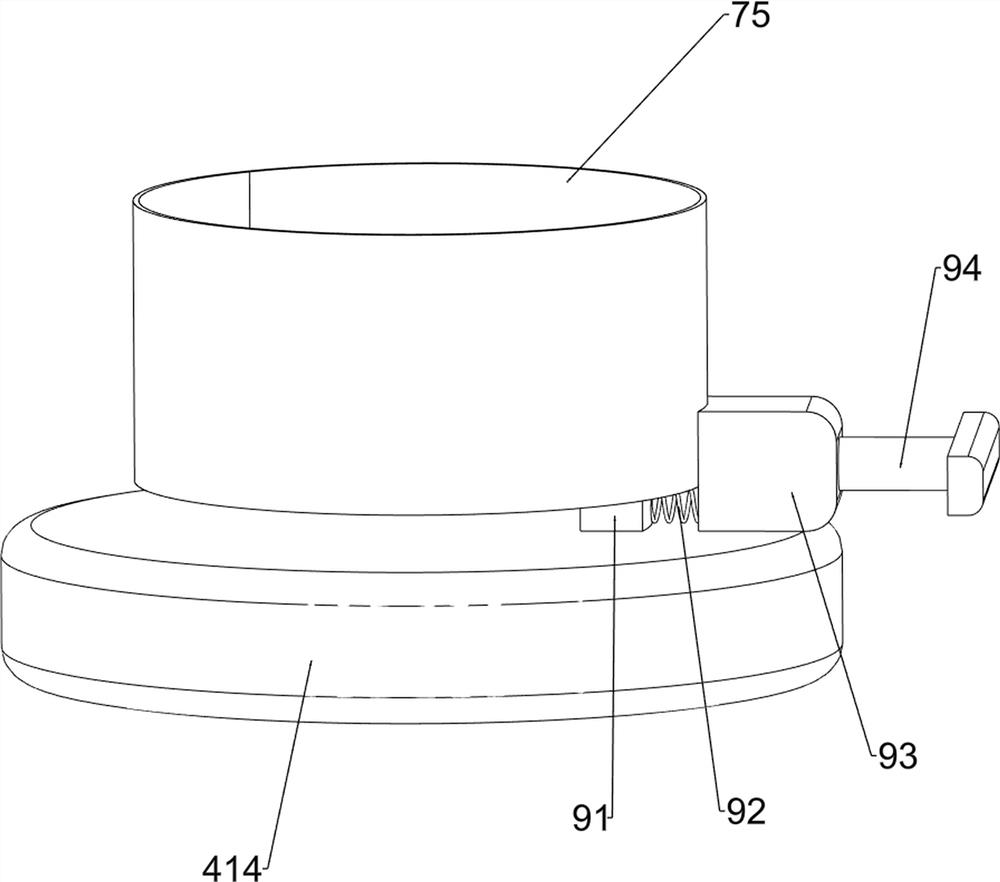

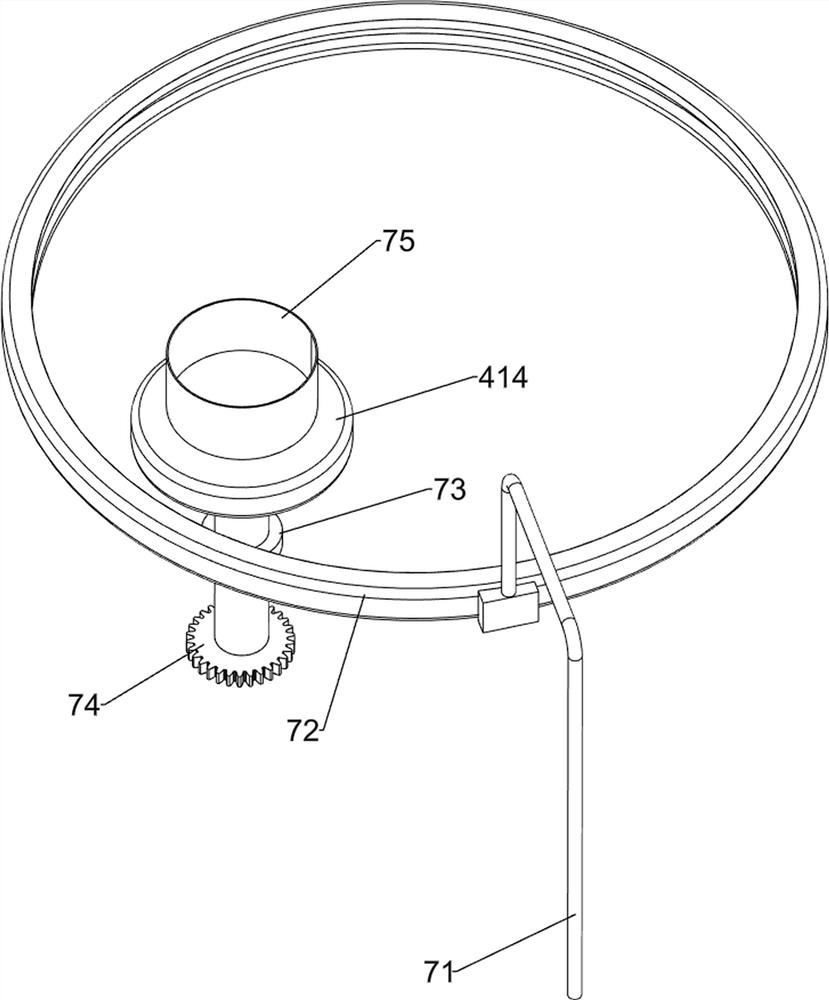

Automatic quick-freezing forming equipment for soapy water

InactiveCN112899090AImprove molding efficiencyImprove production efficiencyCooling soapShaping soapCold airElectric machine

The invention relates to forming equipment, in particular to automatic quick-freezing forming equipment for soapy water. The automatic quick-freezing forming equipment forsoapy water is high in soapy water cooling efficiency and capable of achieving automatic discharging. The automatic quick-freezing forming equipment for soapy water comprises a bottom plate and a first supporting column, wherein the first supporting column is arranged on the bottom plate; a motor mounted on the first supporting column; a conveying mechanism arranged on the bottom plate, wherein the conveying mechanism is connected with an output shaft of the motor; and a cooling mechanism arranged on the bottom plate, wherein the cooling mechanism is connected with the conveying mechanism. The equipment achieves the effect of improving the soapy water forming efficiency; and through cooperation of the conveying mechanism and the cooling mechanism, soapy water can be solidified and formed through cold air, and the soapy water forming process is accelerated; and through cooperation of the feeding mechanism and the stirring mechanism, the automatic discharging effect is achieved.

Owner:郭小光

Production of anionic surfactant granules by in situ neutralisation

InactiveUS20020065207A1Reduce the possibilityReduce riskDrying soapCooling soapSURFACTANT BLENDChemistry

A process for the production of detergent particles, comprises feeding an acid precursor of an anionic surfactant and a neutralising agent into a horizontal thin-film evaporator / drier comprising a mixing region, a drying region and a cooling region. The resultant detergent particles are graded to separate an oversize granule fraction in which at least 70 wt % of the particles have a minimum diameter of 1000 mum. This fraction is fed back into the process.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

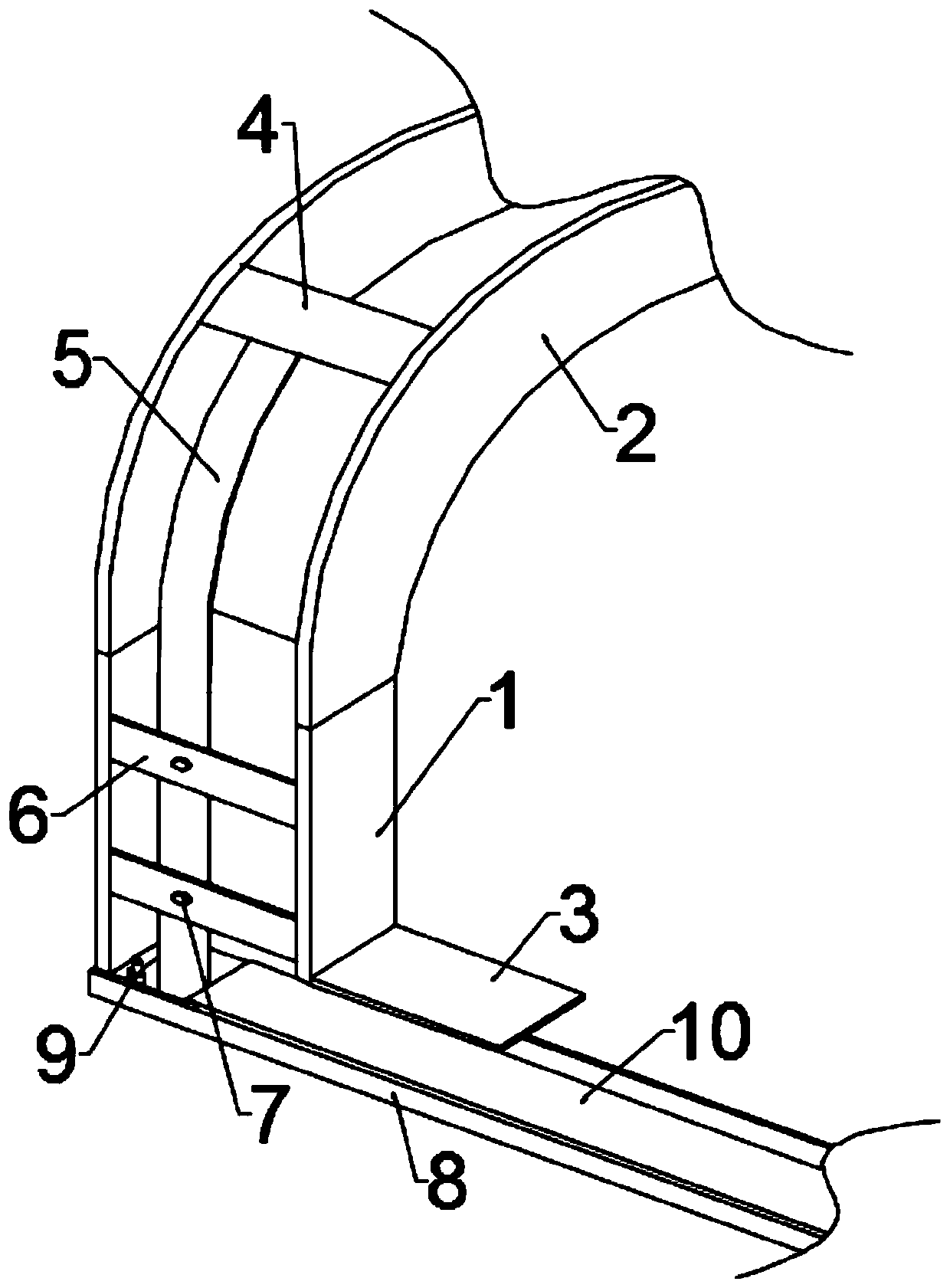

Feeding and conveying device of soap packaging machine

InactiveCN110902018AEasy to packControl distanceCooling soapShaping soapProcess engineeringWaste material

The invention relates to the technical field of soap processing, and particularly discloses a feeding and conveying device of a soap packaging machine. The feeding and conveying device comprises a soap collecting mechanism and a soap conveying mechanism, wherein the soap conveying mechanism is located right below the soap collecting mechanism, the soap collecting mechanism comprises a square groove and an arc groove which are connected, a clamping assembly is arranged on the square groove, the soap conveying mechanism comprises a conveying groove and a conveying belt installed in the conveyinggroove, a position clamping assembly is arranged in the conveying belt, and a cutting assembly and a waste collecting mechanism are arranged on two sides of the conveying groove. Different from an existing conveying device with a single function, the feeding and conveying device is particularly provided with the cutting assembly so that redundant soap can be cut, the soap with consistent size specification can be obtained, the soap connected together can be separated through the position clamping assembly to facilitate packaging, then, the waste collecting mechanism is used for collecting waste chips cut in the cutting process, and cleaning and sanitation of the feeding and conveying device are guaranteed.

Owner:安徽华谊日新科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com