Automatic quick-freezing forming equipment for soapy water

A molding equipment and soapy water technology, which is applied in the field of soapy water automatic quick-freezing molding equipment, can solve the problems of low cooling efficiency of soapy water and the inability to automatically unload materials, etc., and achieve the effects of improving production efficiency, beautiful appearance, and improving molding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

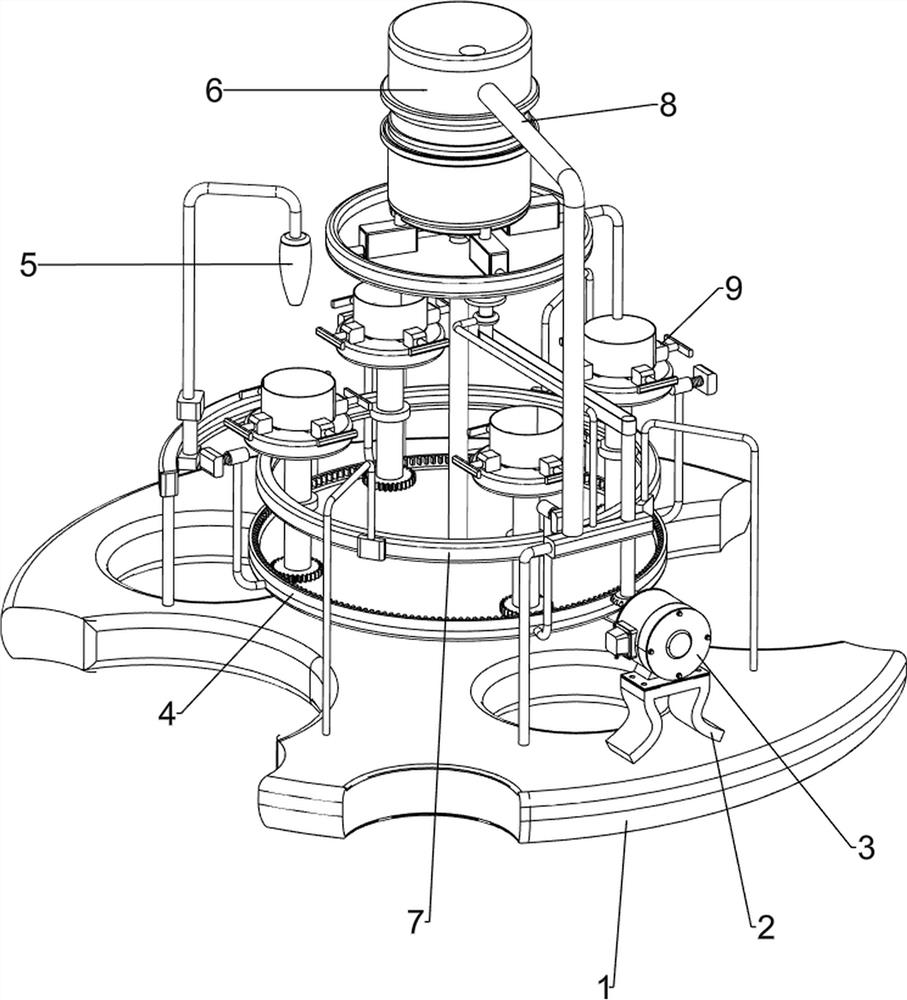

[0081] A kind of soapy water automatic quick-freezing molding equipment, such as figure 1 As shown, it includes a base plate 1, a first support column 2, a motor 3, a transmission mechanism 4, and a cooling mechanism 5. The upper front portion of the base plate 1 is provided with a first support column 2, and a motor 3 is installed on the top of the first support column 2. The base plate 1 is provided with a transmission mechanism 4 in the upper middle, and the transmission mechanism 4 is connected with the output shaft of the motor 3;

[0082] When people make soap, the cooling of soap takes a long time and the production efficiency is low. The present invention helps people improve the molding efficiency of soap. First, the model filled with soapy water is placed on the transmission mechanism 4, and the motor 3 and the cooling mechanism are started. After 5, the motor 3 drives the transmission mechanism 4 to run, and the transmission mechanism 4 drives the soapy water to rot...

Embodiment 2

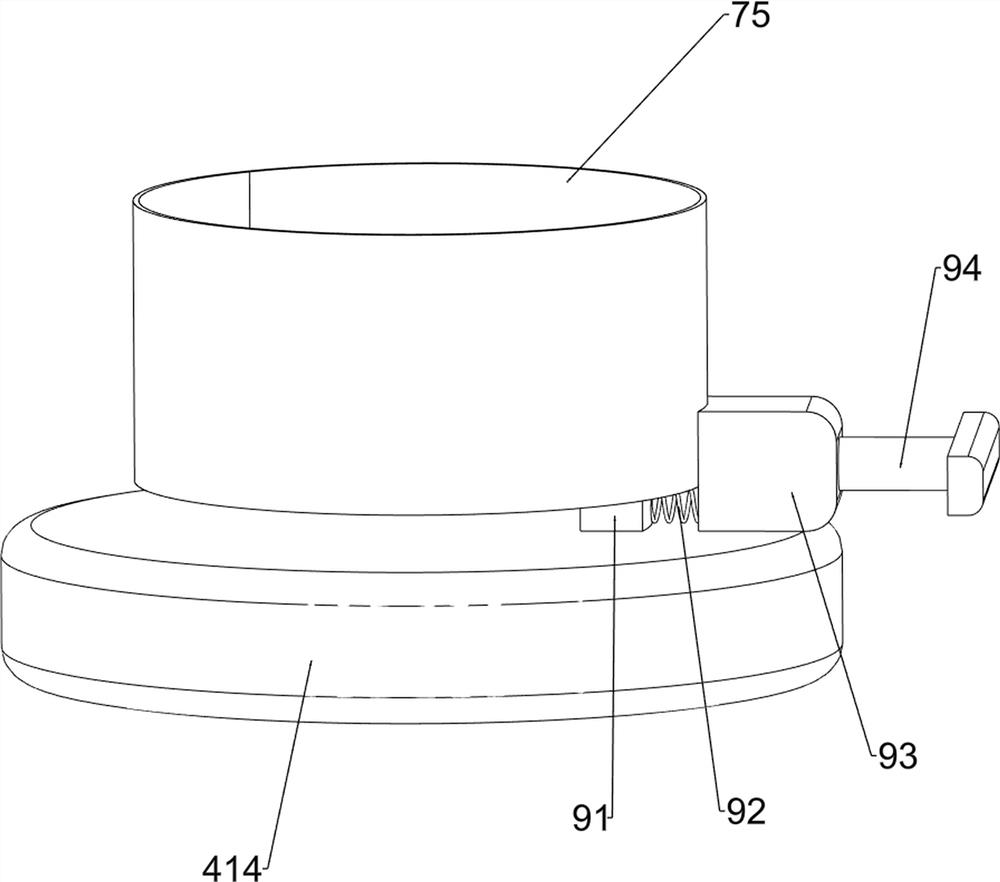

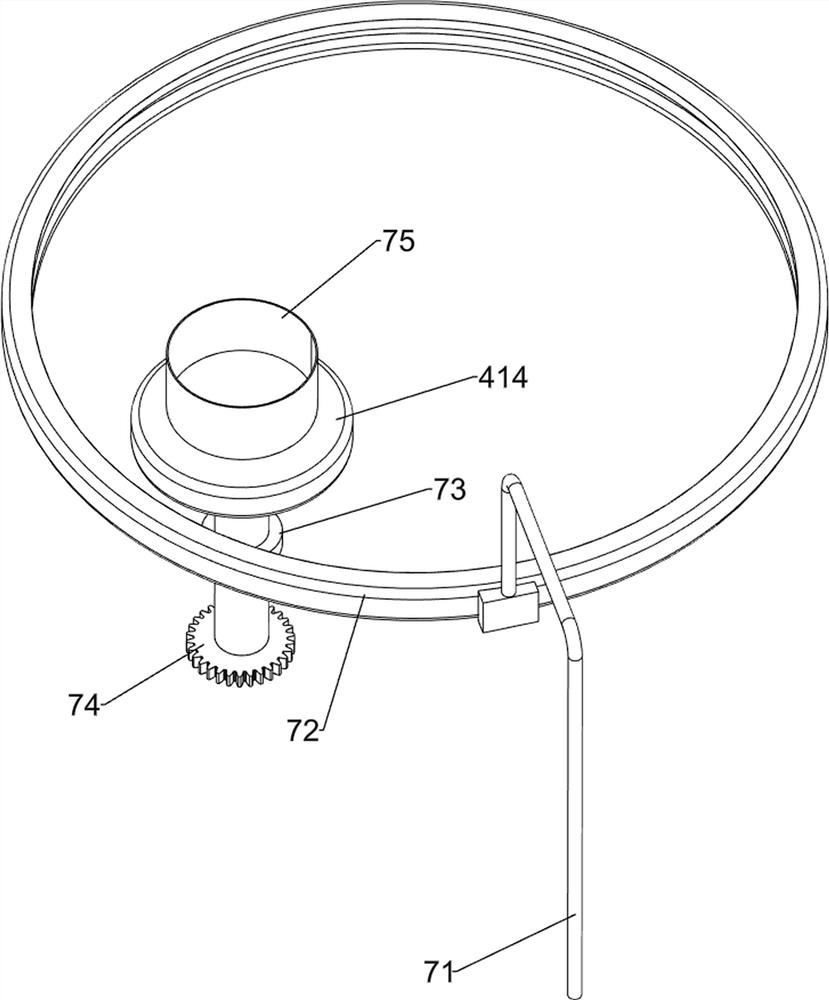

[0084] On the basis of Example 1, such as figure 2 and image 3 As shown, the transmission mechanism 4 includes a second support column 41, a support plate 42, a third support column 43, a first rotating shaft 44, a fourth supporting column 45, a second rotating shaft 46, a third rotating shaft 47, a bevel gear set 48, The first transmission assembly 49, the fourth rotating shaft 410, the first straight gear 411, the missing gear 412, the ring gear 413 and the turret 414, the upper front part of the bottom plate 1 is provided with the second support column 41, and the upper middle part of the bottom plate 1 is provided with a support plate 42. A third support column 43 is provided on the rear side of the upper part of the first support column 2. The upper part of the third support column 43 is rotatably provided with a first rotating shaft 44. The first rotating shaft 44 is connected to the output shaft of the motor 3. The top of the second supporting column 41 The fourth su...

Embodiment 3

[0089] On the basis of Example 2, such as figure 1 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, it also includes a feeding mechanism 6, the conveying mechanism 4 is provided with a feeding mechanism 6, the feeding mechanism 6 is connected with the bottom plate 1, and the feeding mechanism 6 includes a tray 61, a sixth support column 62, and a feeding box 63 , baffle plate 631, sliding sleeve 632, second connecting rod 64, material storage box 65 and discharge pipe 66, bottom plate 1 upper rear part is provided with tray 61, tray 61 is connected with the fourth rotating shaft 410 rotationally, the second support column The top of 41 is provided with a sixth support column 62, the top of the fourth rotating shaft 410 is rotatably provided with a loading box 63, and a sliding sleeve 632 is slidably connected between the loading box 63 and the sixth supporting column 62, and the top of the fourth rotating shaft 410 is provided with There are four second connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com