Patents

Literature

45results about "Drying soap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dimensionally Stable Solid Rinse Aid

ActiveUS20080293615A1Reduced water solid filming in waterReduce spotting and water solids filmingOrganic detergent compounding agentsDrying soapAlcoholPreservative

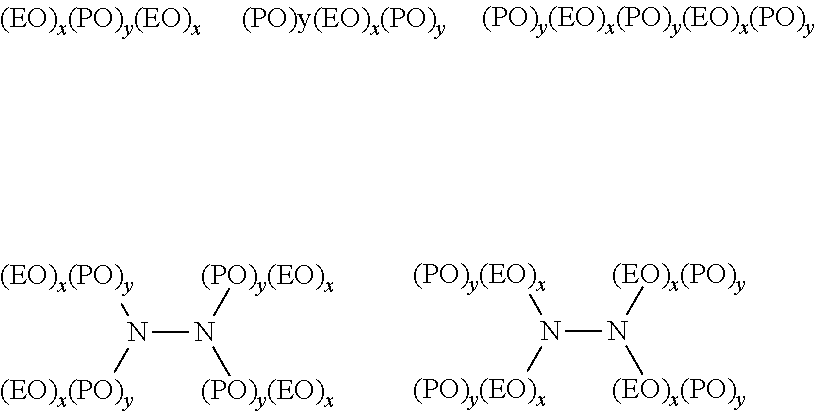

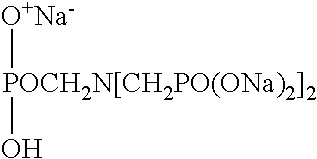

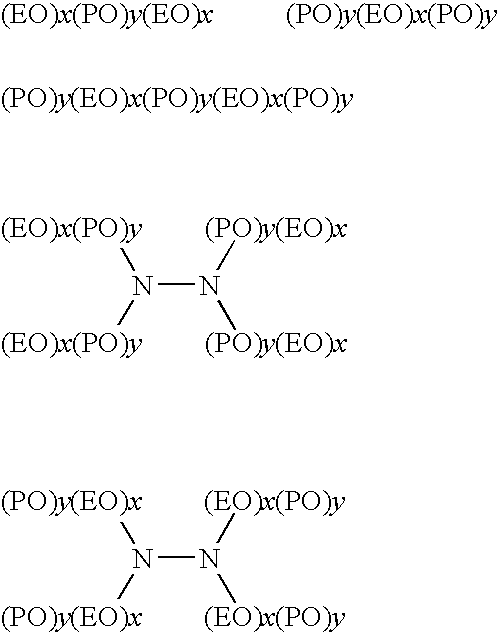

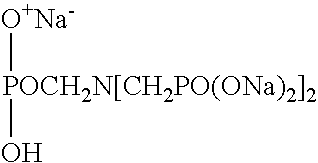

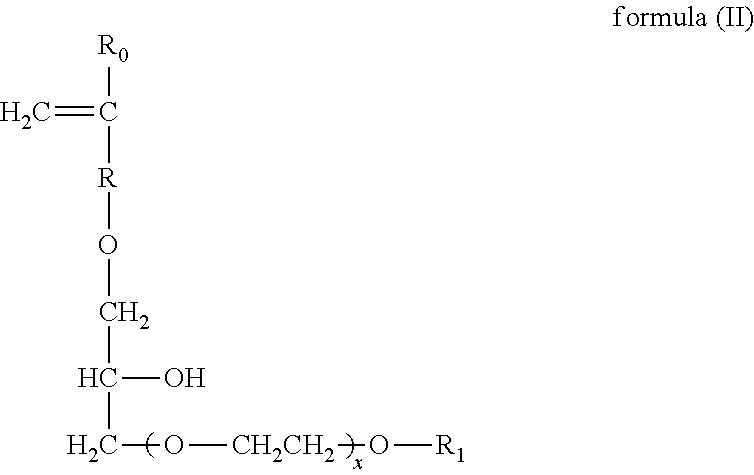

The present invention is a solid rinse aid composition and methods of making and using the same. The solid rinse aid composition generally includes sodium sulfate and urea as solidification agents and an effective amount of an alcohol ethoxylate compound sheeting agent component and an effective amount of defoamer component. The solid rinse aid composition may also incorporate a preservative system including sodium bisulfate. The solid rinse aid composition may be phosphate-free, aminocarboxylate-free, and GRAS if desired.

Owner:ECOLAB USA INC

Process of making an article for dissolution upon use to deliver surfactants

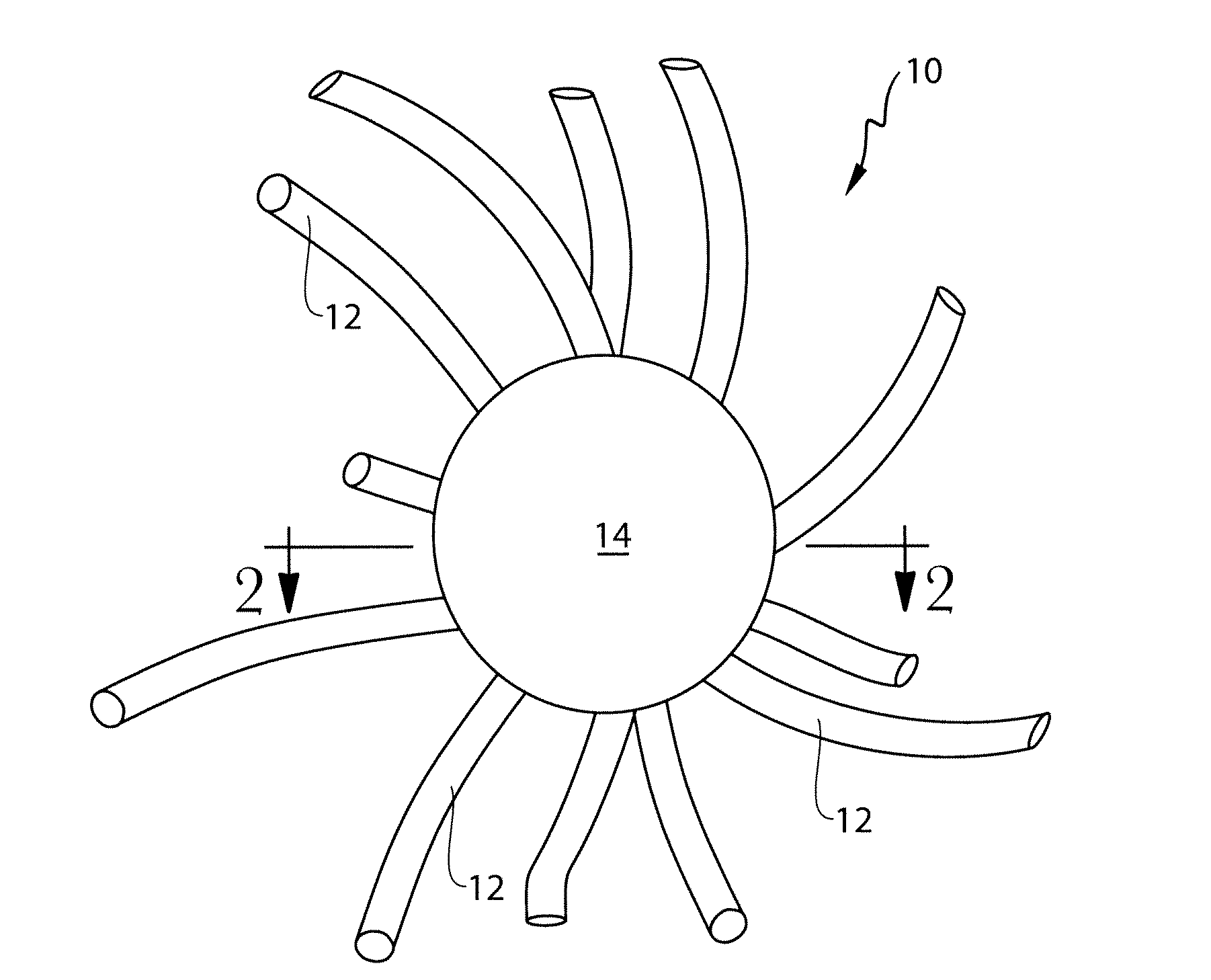

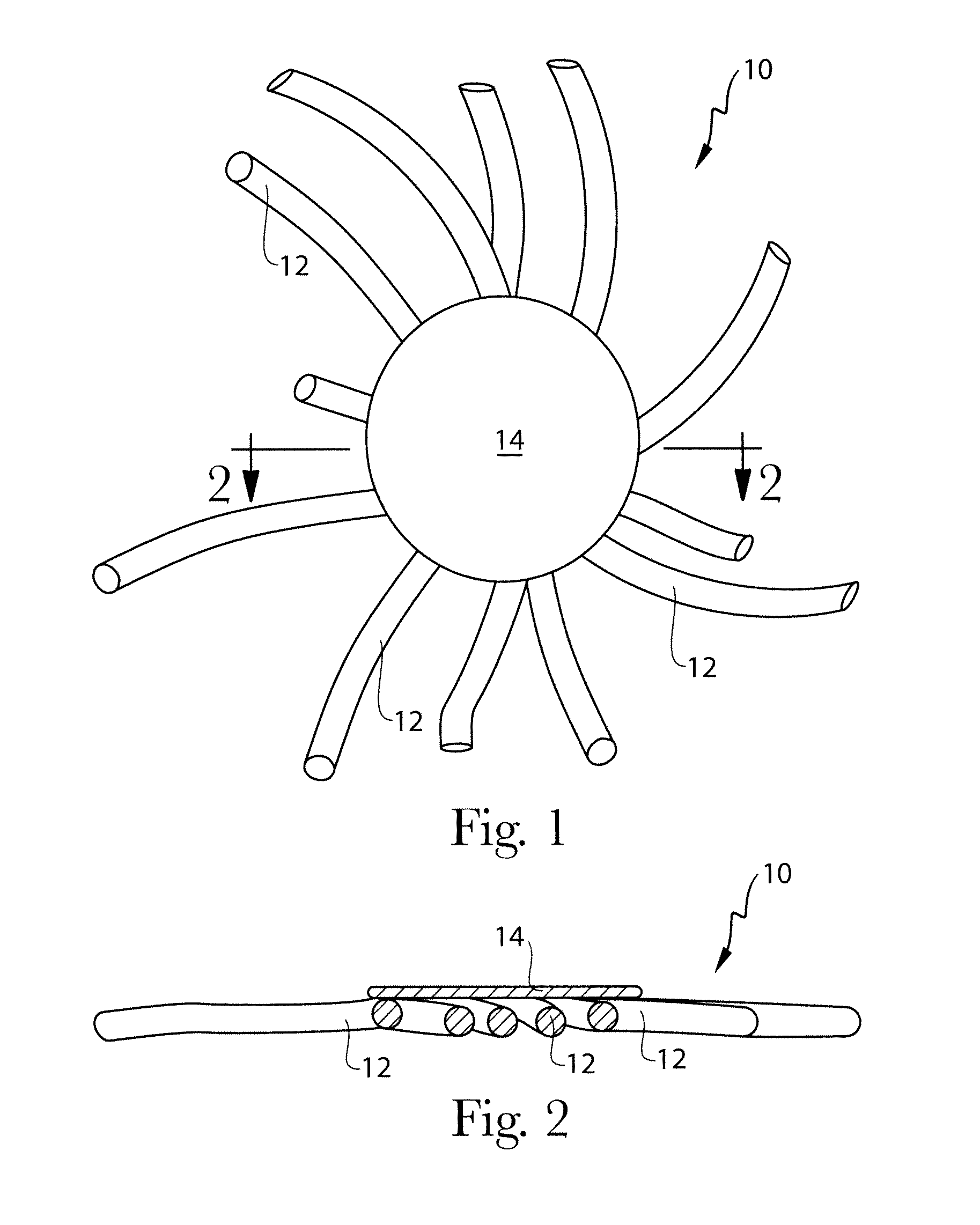

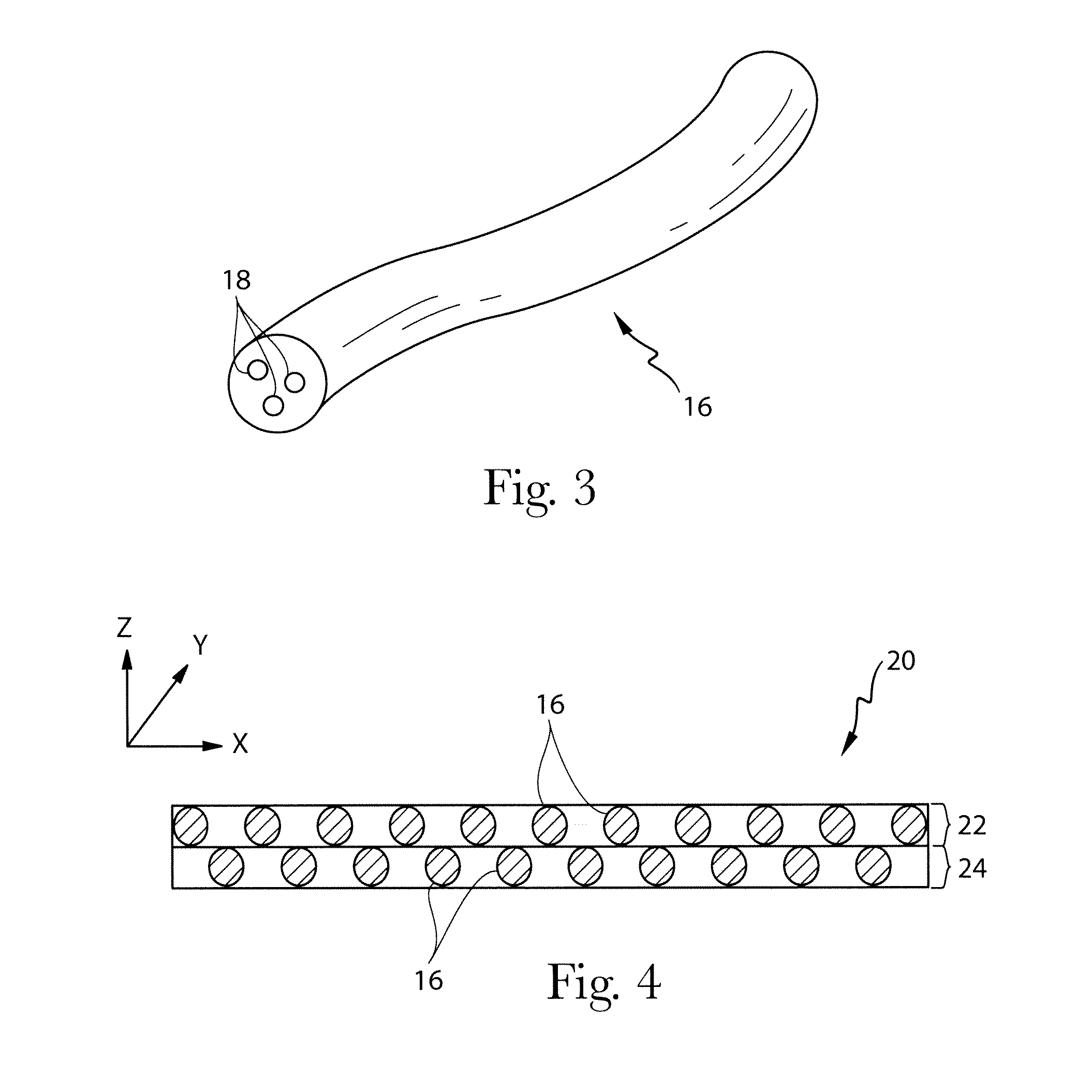

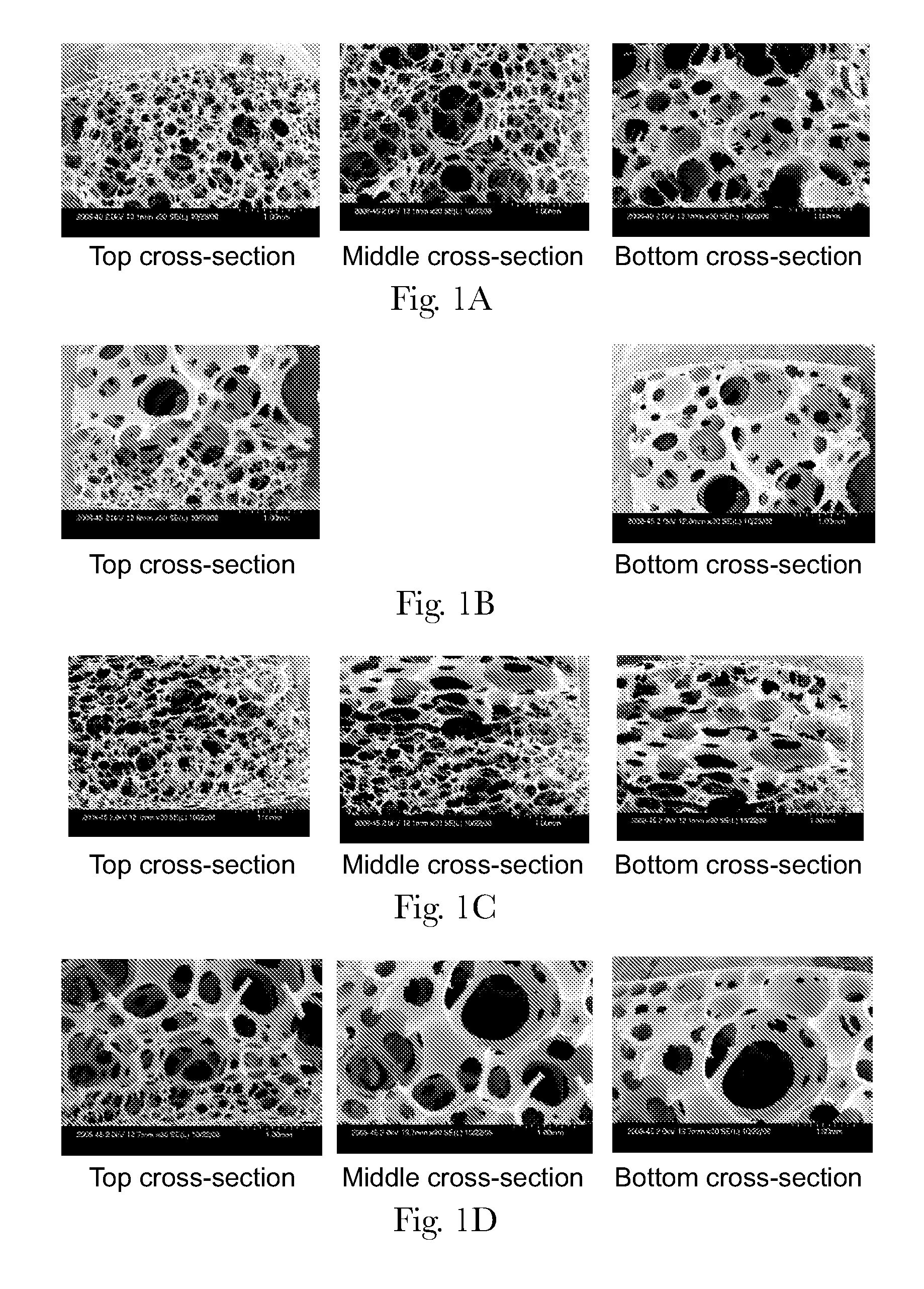

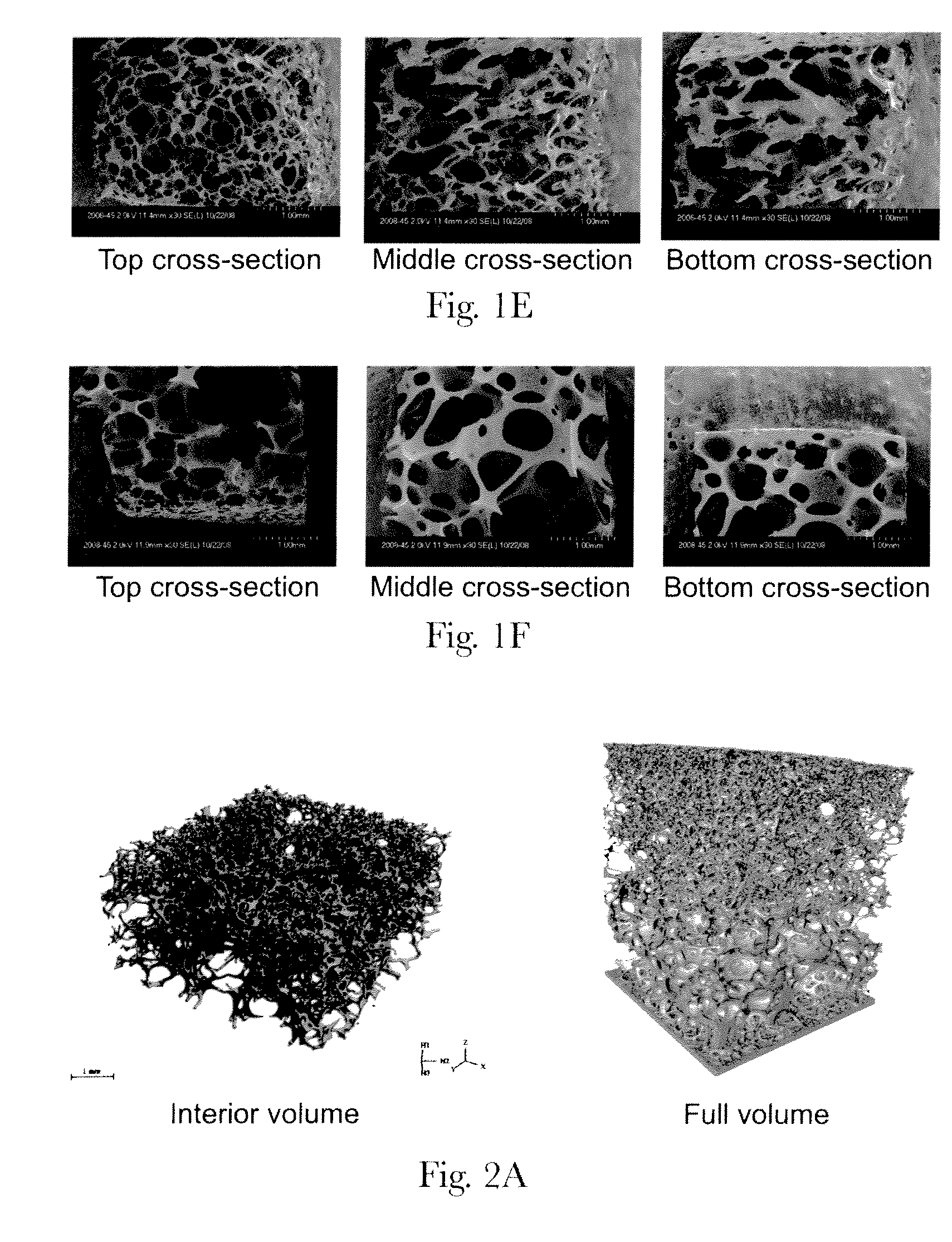

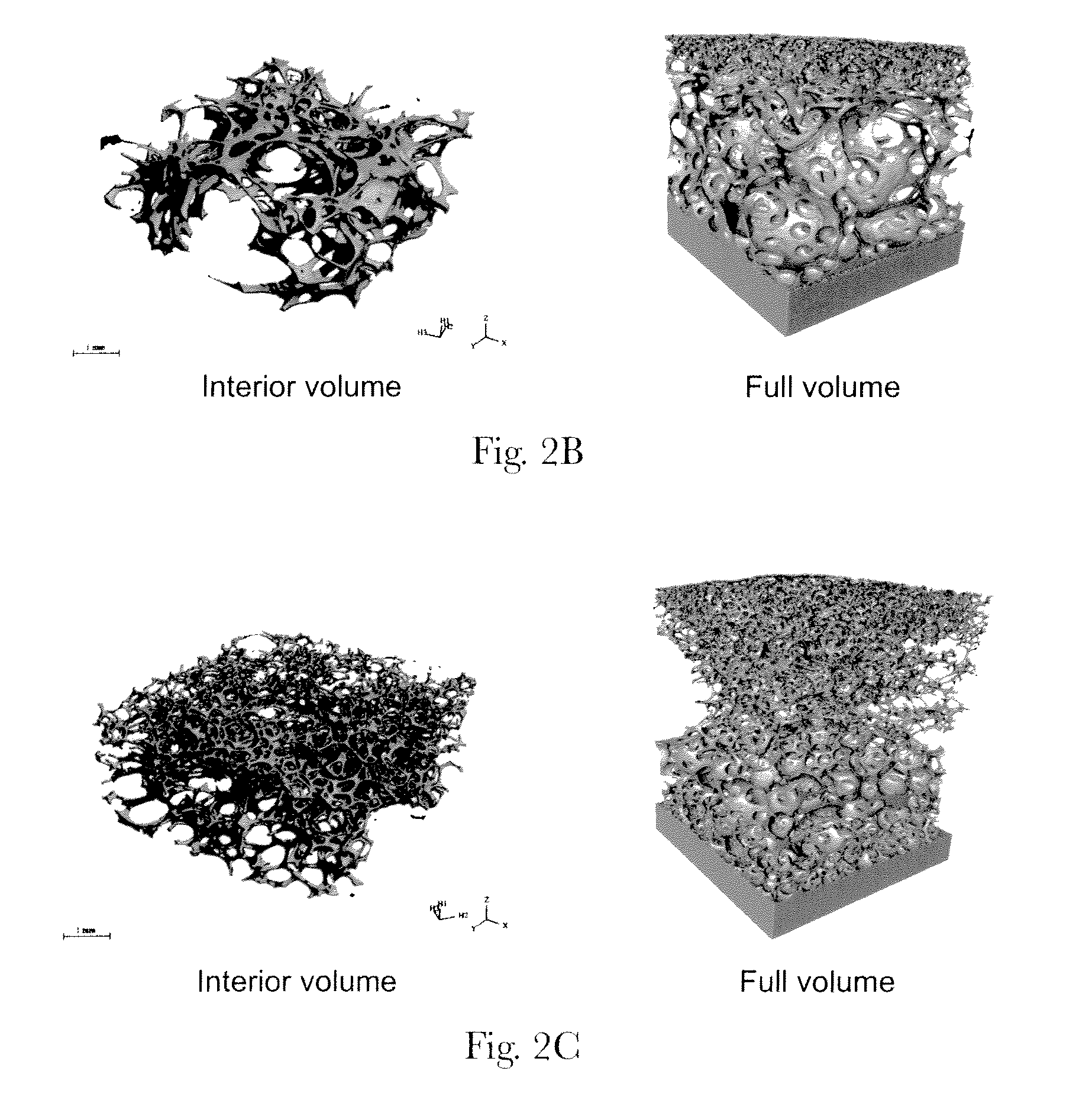

A process that results in a flexible dissolvable porous solid article that can be used as a personal care composition or a fabric care composition.

Owner:THE PROCTER & GAMBLE COMPANY

Detergent product and method for making same

Owner:THE PROCTER & GAMBLE COMPANY

Process of making an article for dissolution upon use to deliver surfactants

Owner:PROCTER & GAMBLE CO

Spray dried powdered detergents with perfume-containing capsules

The present invention relates to a process for the manufacture of a spray dried powder comprising:(a) forming a warm, stirred aqueous slurry comprising: inorganic salts, at least one binding agent and 0.001 to 20% by weight of capsules based on the weight of spray dried powder, said capsules containing benefit agents including at least perfume, and(b) spray drying the resultant slurry to form a spray dried powder, said capsules being such that:1) more than 40% of the benefit agents remain encapsulated 60 minutes after dispersion thereof at 70° C. in the slurry as defined in the “slurry survival test” in a sealed vessel without agitation; and2) more than 30% of the benefit agents added for 15 minutes to an ambient slurry as defined in the “spray dry test” survive spray drying through a laboratory scale spray drier.

Owner:TAKASAGO INTERNATIONAL CORPORATION

Detergent composition

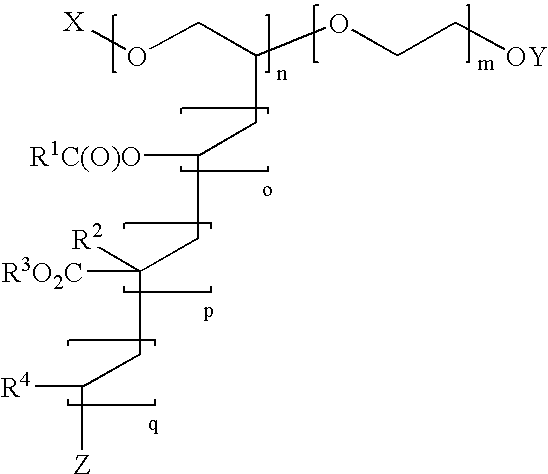

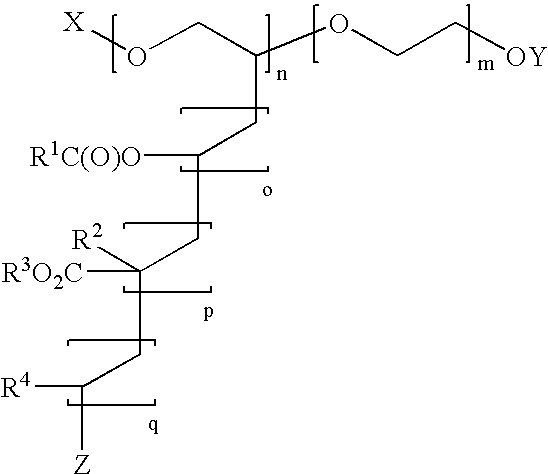

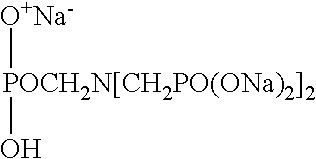

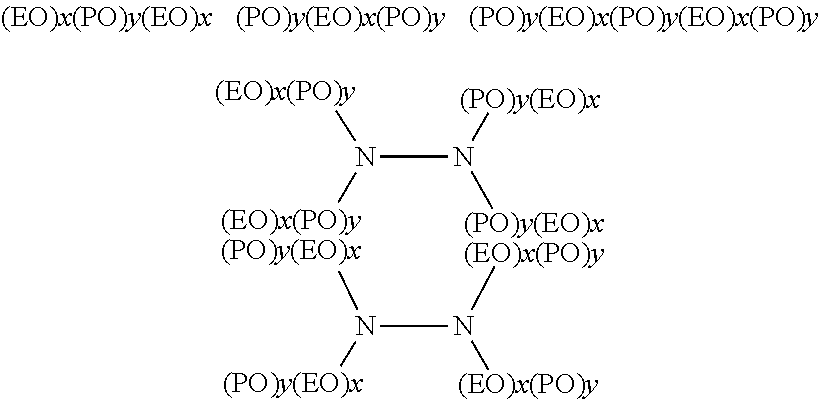

InactiveUS20070281879A1Speed up the processReduce liquid viscosityOrganic detergent compounding agentsDrying soapPendant groupSpray drying

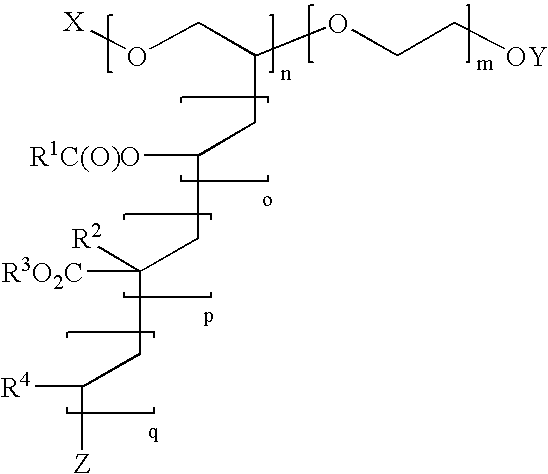

A detergent auxiliary composition comprising from 0.001 wt % to 99 wt % cleaning polymer having a hydrophilic backbone and at least one hydrophobic pendant group, and an adjunct ingredient in which the hydrophilic backbone constitutes less than 50%, preferably less than 45% by weight of the polymer. The detergent auxiliary composition may be, for example a spray-dried particle or an agglomerate. Also described are detergent compositions comprising the detergent auxiliary composition.

Owner:THE PROCTER & GAMBLE COMPANY

Spray drying

InactiveUS20070149423A1Organic detergent compounding agentsDrying soapInorganic saltsLaboratory scale

The present invention relates to a process for the manufacture of a spray dried powder comprising: (a) forming a warm, stirred aqueous slurry comprising: inorganic salts, at least one binding agent and 0.001 to 20% by weight of capsules based on the weight of spray dried powder, said capsules containing benefit agents including at least perfume, and (b) spray drying the resultant slurry to form a spray dried powder, said capsules being such that: 1) more than 40% of the benefit agents remain encapsulated 60 minutes after dispersion thereof at 70° C. in the slurry as defined in the “slurry survival test” in a sealed vessel without agitation; and 2) more than 30% of the benefit agents added for 15 minutes to an ambient slurry as defined in the “spray dry test” survive spray drying through a laboratory scale spray drier.

Owner:TAKASAGO INTERNATIONAL CORPORATION

Dimensionally stable solid rinse aid

ActiveUS20120231992A1Reduced stabilityReduced water solid filming in waterOrganic detergent compounding agentsDrying soapAlcoholPreservative

The present invention is a solid rinse aid composition and methods of making and using the same. The solid rinse aid composition generally includes sodium sulfate and urea as solidification agents and an effective amount of an alcohol ethoxylate compound sheeting agent component and an effective amount of defoamer component. The solid rinse aid composition may also incorporate a preservative system including sodium bisulfate. The solid rinse aid composition may be phosphate-free, aminocarboxylate-free, and GRAS if desired.

Owner:ECOLAB USA INC

Anionic surfactant powder

InactiveUS20050106118A1Improve stabilityImprove powder propertiesCosmetic preparationsOrganic chemistryInorganic saltsSolubility

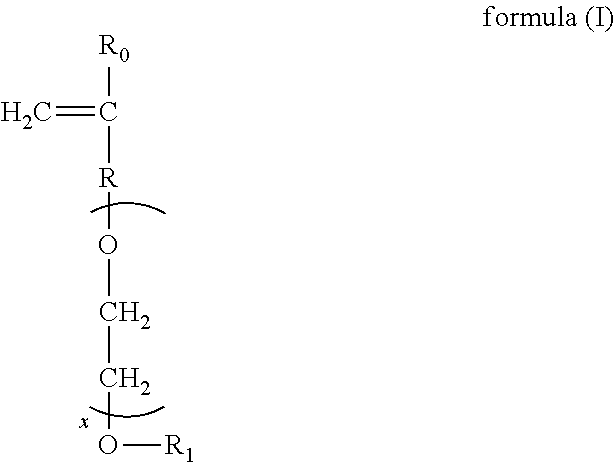

To provide an anionic surfactant powder comprising a polyoxyalkylene ether sulfate which powder has high stability in hard water, high low-temperature solubility and is improved in powder characteristics such as caking characteristics, and a method of producing the anionic surfactant powder. An anionic surfactant powder comprising polyoxyalkylene alkyl ether sulfates in which the average addition mol number of alkylene oxides is 0.05 to 2, wherein the content of the polyoxyalkylene alkyl ether sulfates provided with alkylene oxides added thereto in an amount of 4 mol or more is 30 % by weight or less based on the total anionic surfactant, an anionic surfactant powder further comprising a water-soluble inorganic salt, a method of producing each of these anionic surfactant powders, and a detergent composition and a cement additive comprising these anionic surfactant powders.

Owner:KAO CORP

Dimensionally stable solid rinse aid

ActiveUS7521412B2Reduced water solid filming in waterReduce spotting and water solids filmingOrganic detergent compounding agentsOrganic chemistryAlcoholPreservative

The present invention is a solid rinse aid composition and methods of making and using the same. The solid rinse aid composition generally includes sodium sulfate and urea as solidification agents and an effective amount of an alcohol ethoxylate compound sheeting agent component and an effective amount of defoamer component. The solid rinse aid composition may also incorporate a preservative system including sodium bisulfate. The solid rinse aid composition may be phosphate-free, aminocarboxylate-free, and GRAS if desired.

Owner:ECOLAB USA INC

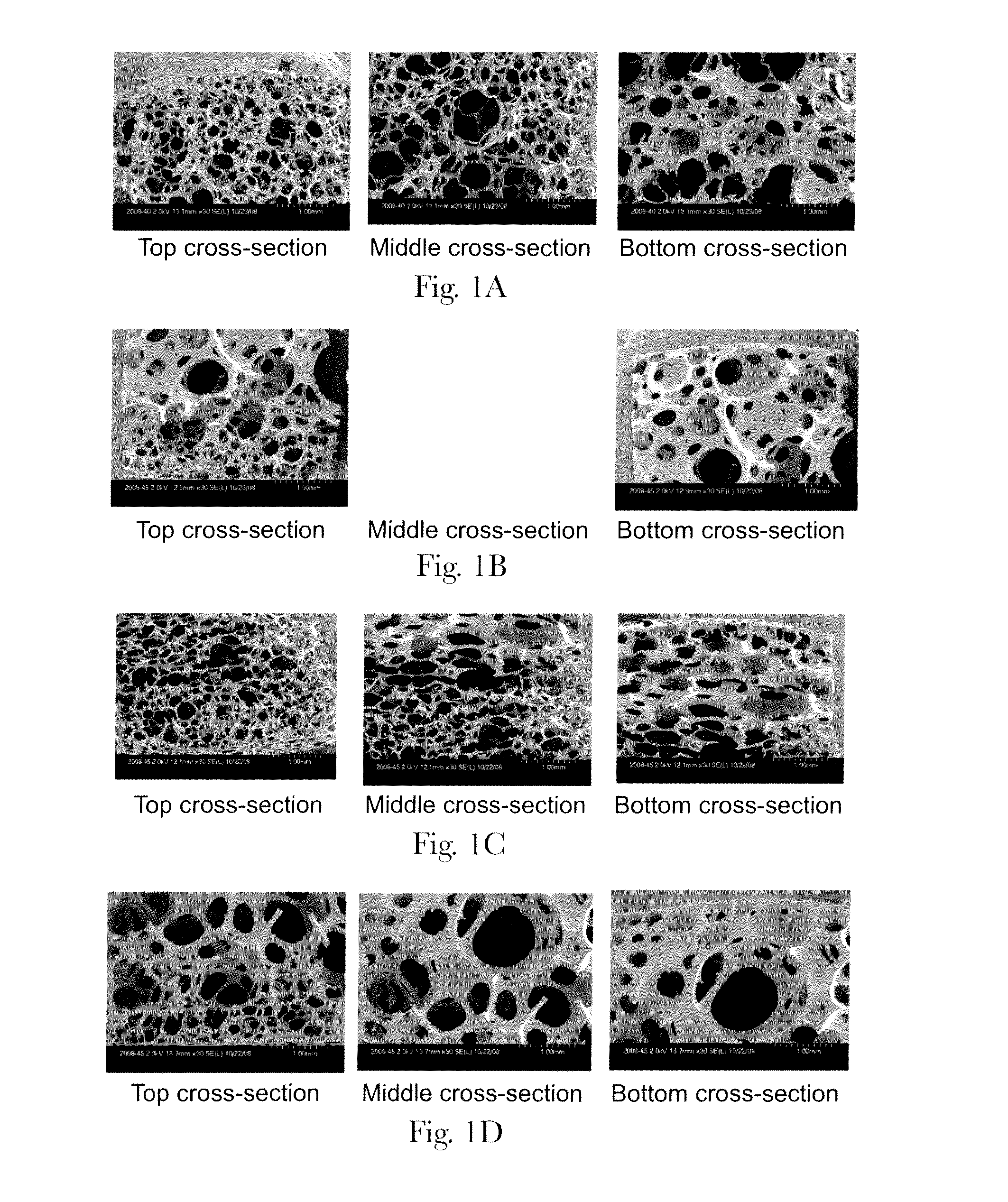

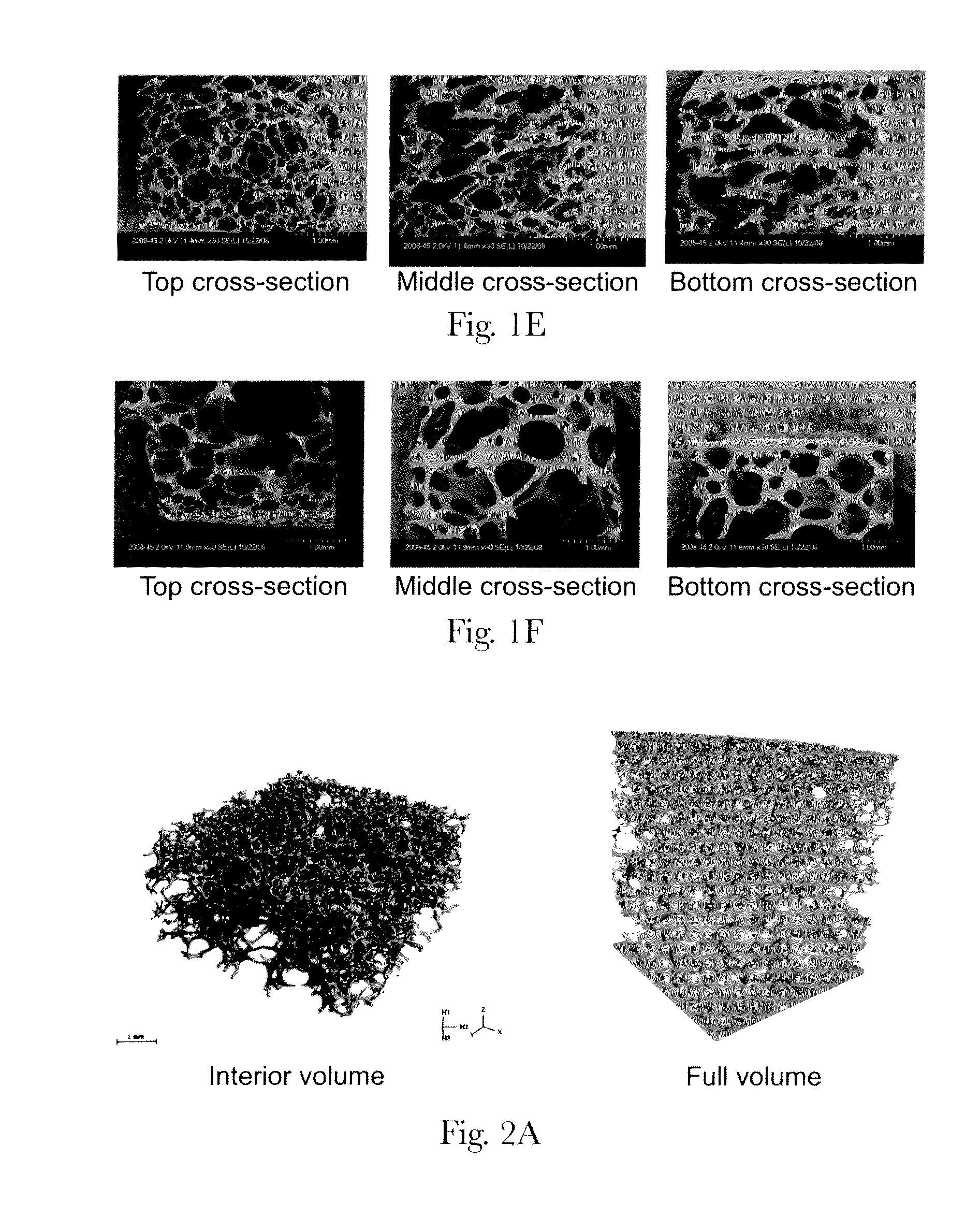

Method for making a nanoporous granular material and a detergent composition

InactiveUS6627597B1Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSolubilityControlled release

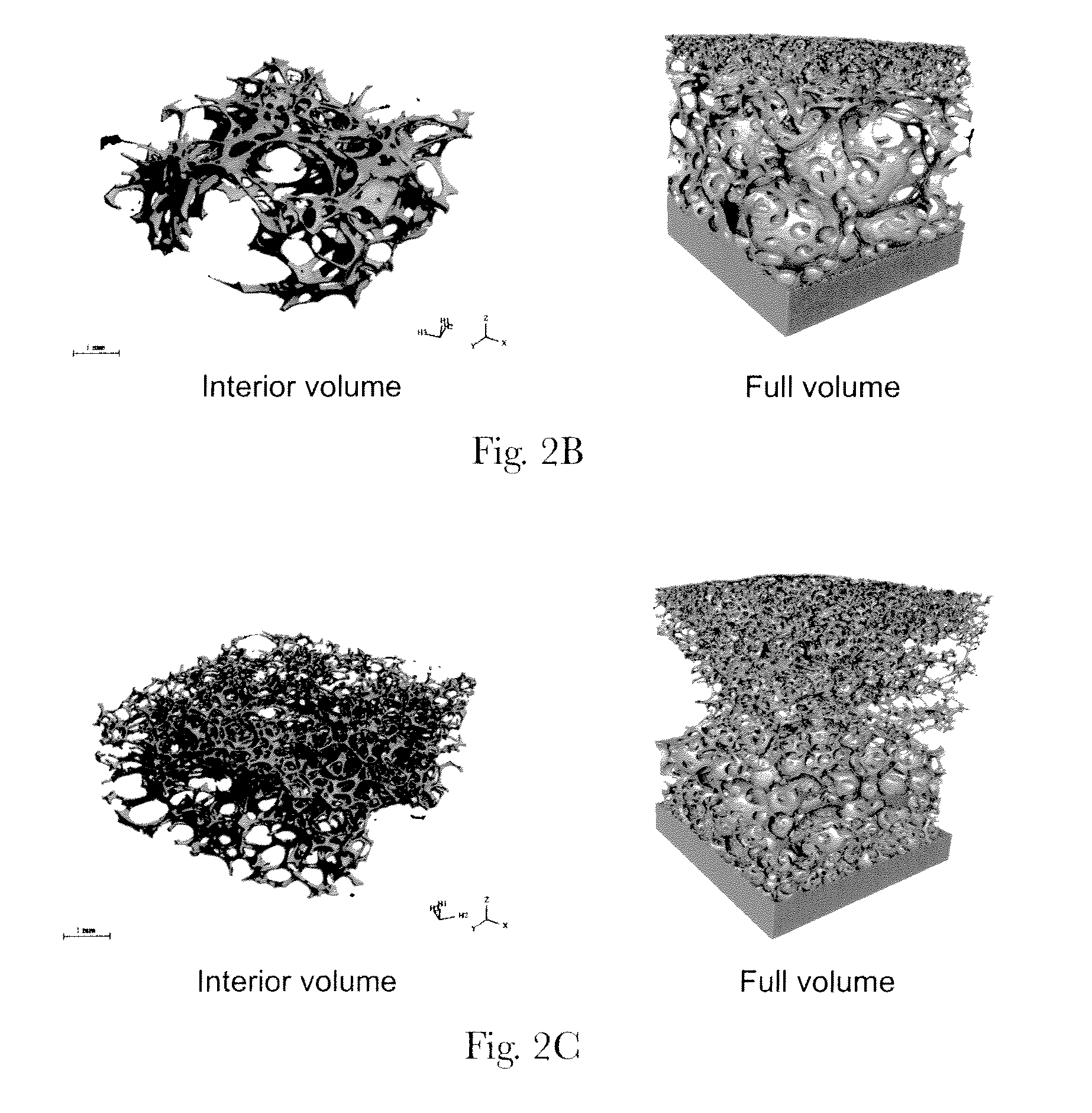

A process for producing a starting material in a granular form and in a nanoporous anhydrous state, a process for improving the water-solubility and controlled release characteristics of a detergent material, and a detergent composition are disclosed. In one aspect, a process for producing a starting material in a granular form and in a nanoporous anhydrous state includes obtaining a starting material in a form of a dispersion or solution in a sublimable solvent or mixtures of sublimable solvents, forming graded droplets by atomization, freezing the graded droplets in a freezing medium at a controlled freezing rate of a least 100° C. per second to form frozen droplets and drying the frozen droplets by vacuum sublimation to obtain freeze-dried granules of the starting material in a nanoporous anhydrous state. The starting material in dispersion or solution form has a viscosity suitable for atomization and formation of graded droplets.

Owner:THE PROCTER & GAMBLE COMPANY

Detergent composition

InactiveUS7465701B2Speed up the processReduce liquid viscosityOrganic detergent compounding agentsDrying soapPendant groupPolymer chemistry

A detergent auxiliary composition comprising from 0.001 wt % to 99 wt % cleaning polymer having a hydrophilic backbone and at least one hydrophobic pendant group, and an adjunct ingredient in which the hydrophilic backbone constitutes less than 50%, preferably less than 45% by weight of the polymer. The detergent auxiliary composition may be, for example a spray-dried particle or an agglomerate. Also described are detergent compositions comprising the detergent auxiliary composition.

Owner:PROCTER & GAMBLE CO

Enhanced melting point rinse aid solid compositions with synergistic preservative

The invention includes a GRAS preservative system including sodium bisulfate and a combination of specific organic acids that act in a synergistic capacity. The preservative further has the benefit of a higher melting point of approximately 110° or higher making it particularly suited for solid wash applications. According to the invention it has surprisingly been found that a combination of sodium bisulfate, sorbic acid, and benzoic acid produced better preservative properties than other organic acid combinations or each acid by itself.

Owner:ECOLAB USA INC

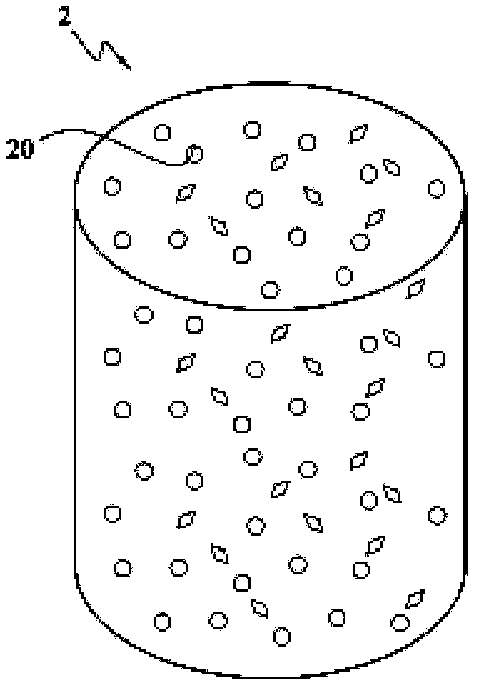

Multi-pore instant soap

The invention discloses a multi-pore instant soap and manufacturing method thereof, and aims to solve potential problems in use of conventional bar-shaped, piece-shaped, liquid and powder soaps on the market. The multi-pore instant soap is composed of a fatty acid salt soap body comprising more than one oil, more than one alkali and more than one additive; the soap body is in a multi-pore structure, the size of the soup is 0.125-15.6 cm<3>, and the porosity of the soup is between 15% andss 90%. The multi-pore instant soap has a quick dissolution property, the final products of the multi-pore instant soap can be in a solid, liquid, gas or glue state, such that the multi-pore instant soap can be used through attaching, seeping, dispersing and filling.

Owner:林 昆仪

Production of anionic surfactant granules by in situ neutralisation

InactiveUS6514930B2Reduce the possibilityReduce riskInorganic/elemental detergent compounding agentsDrying soapPolymer scienceLotion

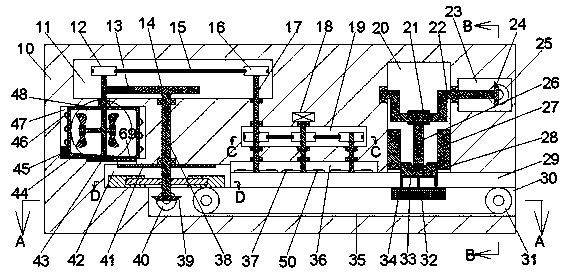

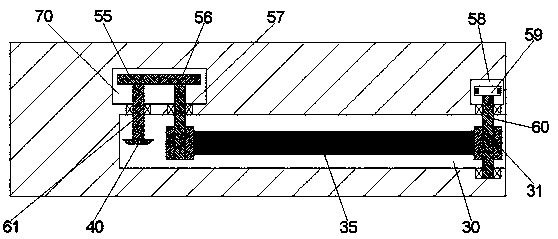

A process for the production of detergent particles comprises feeding an acid precursor of an anionic surfactant, a neutralizing agent and aluminosilicate detergency builder into a horizontal thin-film evaporator / drier. The evaporator / drier comprises a mixing region, a drying region and a cooling region. Neutralization of the acid precursor is effected, together with granulation, drying and cooling, to form the detergent particles. At least some of the aluminosilicate builder is fed into the thin-film evaporator / drier between the drying region and the cooling region and / or into the cooling region. When all of he aluminosilicate builder is fed into the cooling region, the aluminosilicate is in an amount of more than 20% by weight of the particles exiting the cooling region.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

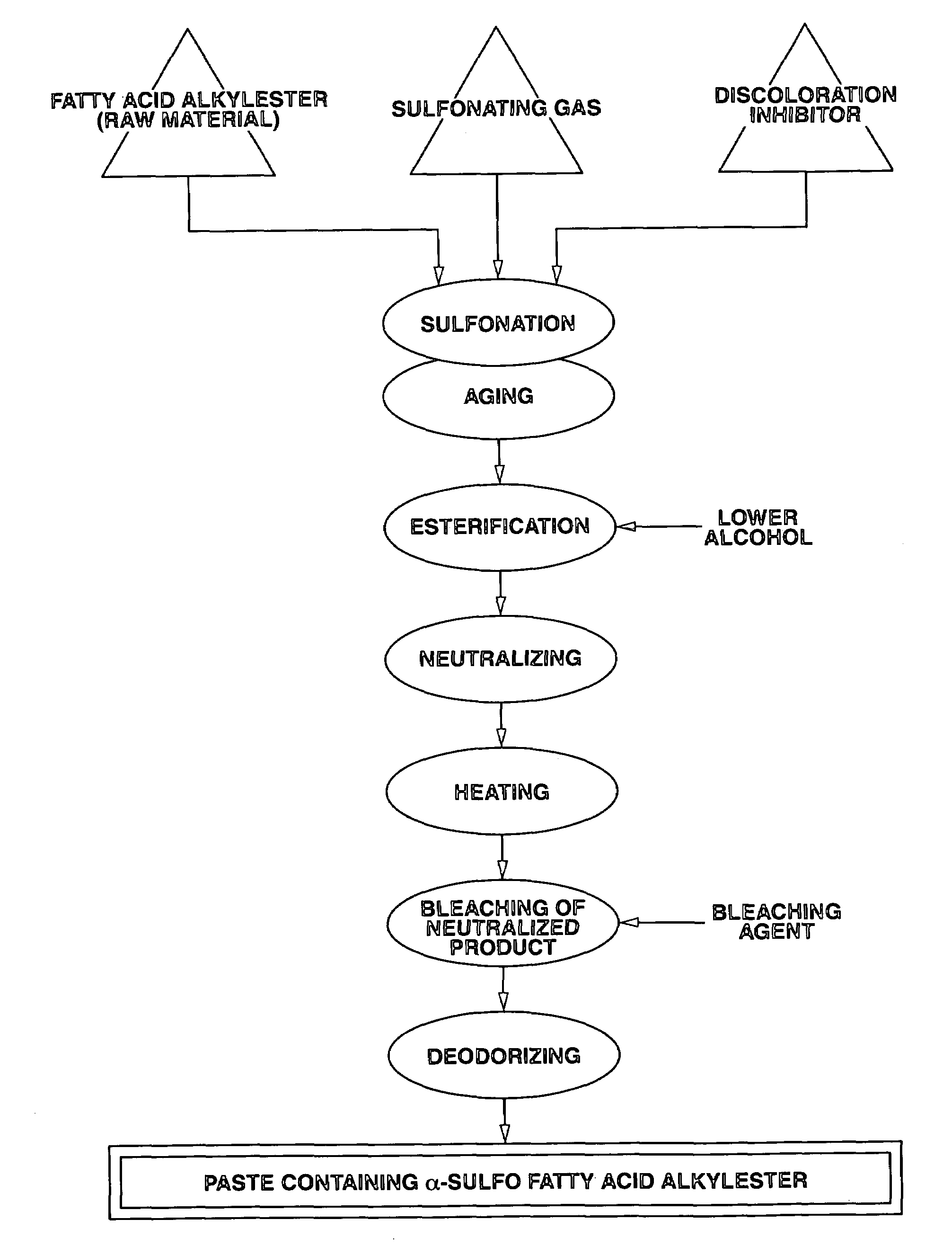

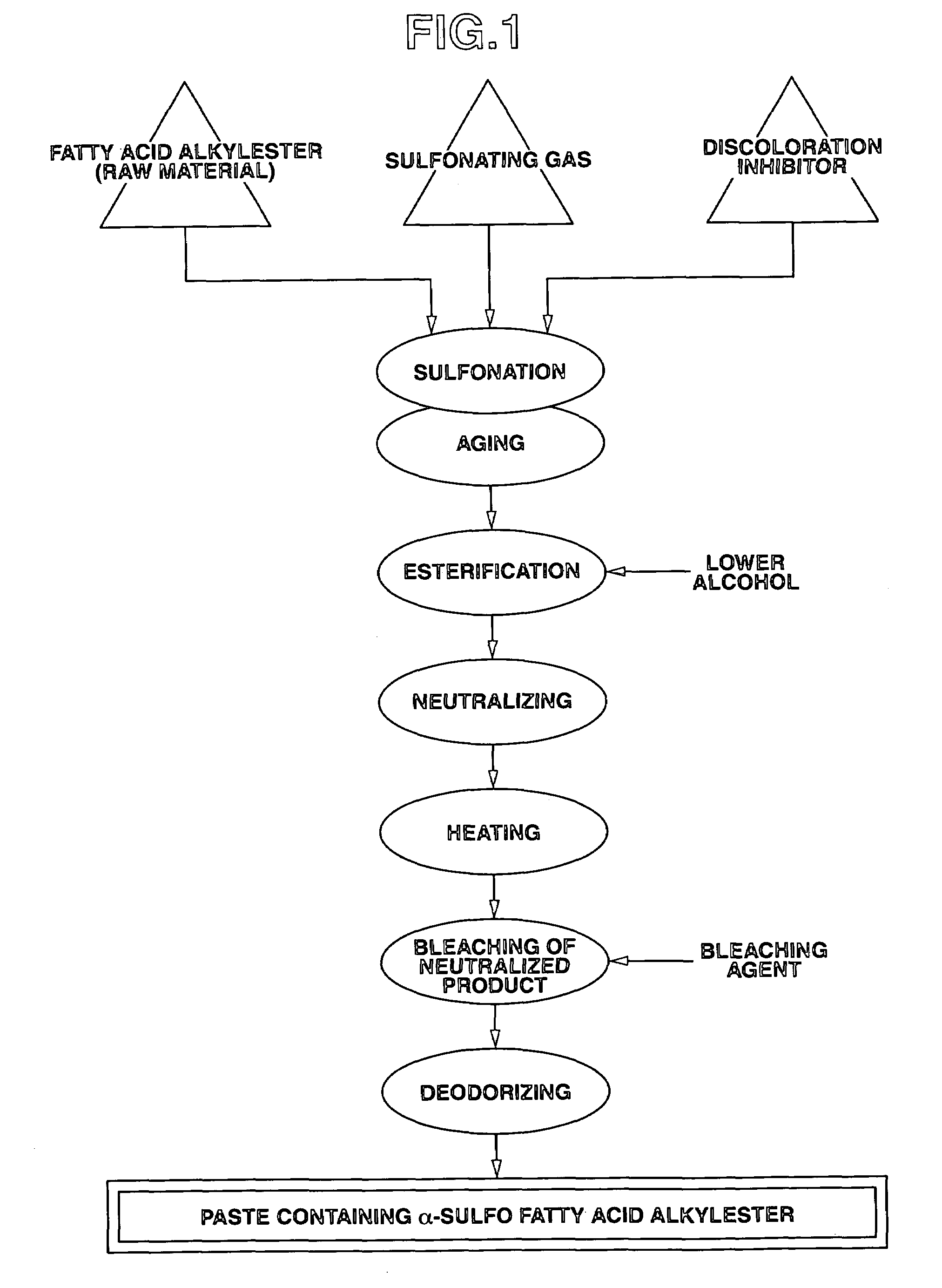

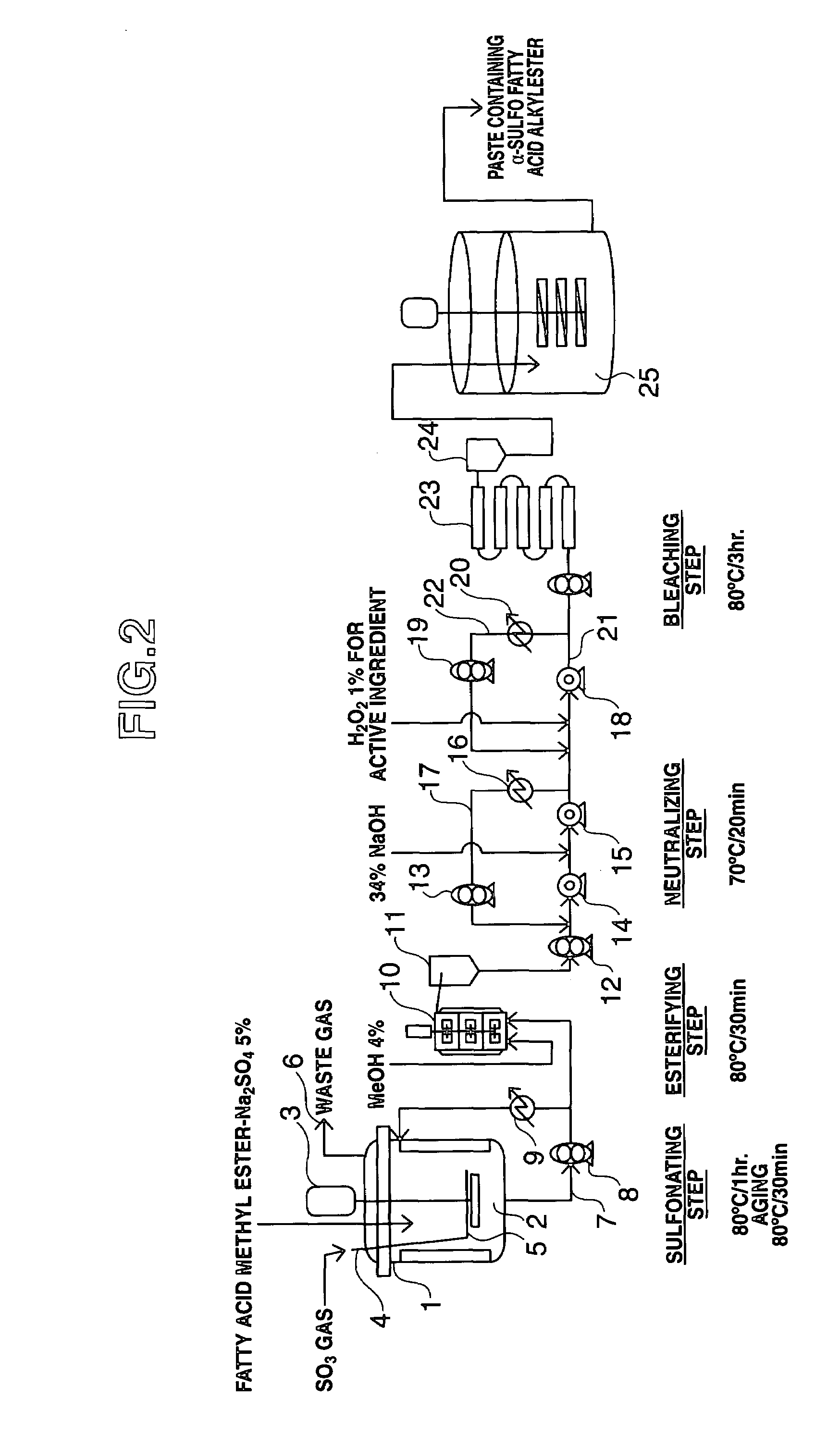

Powders, flakes, or pellets containing salts of a sulfo fatty acid alkyl esters in high concentrations, process for production thereof, granulated detergents, and process for production thereof

ActiveUS7592302B2Maintain good propertiesGood colorNon-ionic surface-active compoundsDrying soapHigh concentrationFatty acid

A process for producing powder, flakes, or pellets containing α-sulfo fatty acid alkylester salt in high concentrations, the process including: (1) a step of preparing a paste containing α-sulfo fatty acid alkylester salt; (2) a step of aging the thus obtained paste; (3) a step of making the aged paste into flakes or pellets containing equal to or less than 10 wt % of water and then optionally crushing the resulting flakes or pellets into a powder having an average particle diameter of 100-1500 μm; and (4) a step of aging The powder, flakes, or pellets.

Owner:LION CORP

Production of anionic surfactant granules by in situ neutralisation

InactiveUS6518234B2Reduce the possibilityReduce riskDrying soapCooling soapSURFACTANT BLENDChemistry

A process for the production of detergent particles, comprises feeding an acid precursor of an anionic surfactant and a neutralising agent into a horizontal thin-film evaporator / drier comprising a mixing region, a drying region and a cooling region. The resultant detergent particles are graded to separate an oversize granule fraction in which at least 70 wt % of the particles have a minimum diameter of 1000 mum. This fraction is fed back into the process.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

Spray-dried detergent powder

The present invention is a spray-dried powder comprising: (i) from 20 to 80 wt % of a first spray-dried particle comprising less than 5 wt % sulphate, anionic detersive surfactant and having a bulk density of from 300 g / l to 450 g / l: and (ii) from 20 to 80 wt % of a second spray-dried particle comprising at least 45 wt % sulphate, 0 wt % to 15 wt % anionic detersive surfactant, and having a bulk density of from 350 g / l to 700 g / l.

Owner:THE PROCTER & GAMBLE COMPANY

Process for the preparation of coated granular sodium percarbonate, and product obtainable by the process

The invention relates to a process for the preparation of coated granular sodium percarbonate having a low TAM value. The preparation is carried out by fluidized-bed spray granulation at a temperature TG in the range from 45 to 75° C., and the coating is effected by the spray application of an aqueous solution containing at least one coating component in a fluidized bed at a temperature TU in the range from 35 to 100° C. According to the invention, a) after the fluidized-bed spray granulation but before the coating, drying is carried out at TNT of greater than TG, or b) the fluidized-bed granulation is carried out in at least two steps at TG1, TG2 . . . TGn, TG2 or TGn being higher than TG1, and drying being unnecessary if ⅔ of the granulate have been formed at TG1, or c) drying takes place not after the granulation but after the coating, at TUNT, TUNT being at least 20° C. higher than TG.

Owner:EVONIK TREIBACHER

Process For Preparing A Detergent

Disclosed is a process for preparing a granular detergent composition or component having a bulk density of at least 500 g / l. The process disclosed herein comprises the steps of (i) providing an aqueous solution of a surfactant (ii) adding one or more water-soluble salts to the aqueous surfactant solution to precipitate the surfactant, (iii) separating the resulting precipitate, and (iv) drying the product.

Owner:J P LAB PVT

Liquid detergent compositions with low-density particles

Process for reducing the density of solid detergent ingredients by forming said ingredients into hollow-core particles. The density of ingredients such as sodium citrate, sodium carbonate and / or sodium silicate, when formed into such hollow-core particles, allows them to be stably incorporated into non-aqueous liquid laundry detergents.

Owner:THE PROCTER & GAMBLE COMPANY

Spray-dried detergtent powder

The present invention is a spray-dried powder comprising: at least 5 wt % of a spray-dried particle comprising at least 40 wt % anionic detersive surfactant, from 15 to 40 wt % carbonate and less than 20 wt % sulphate and having a bulk density of from 300 g / l to 450 g / l.

Owner:THE PROCTER & GAMBLE COMPANY

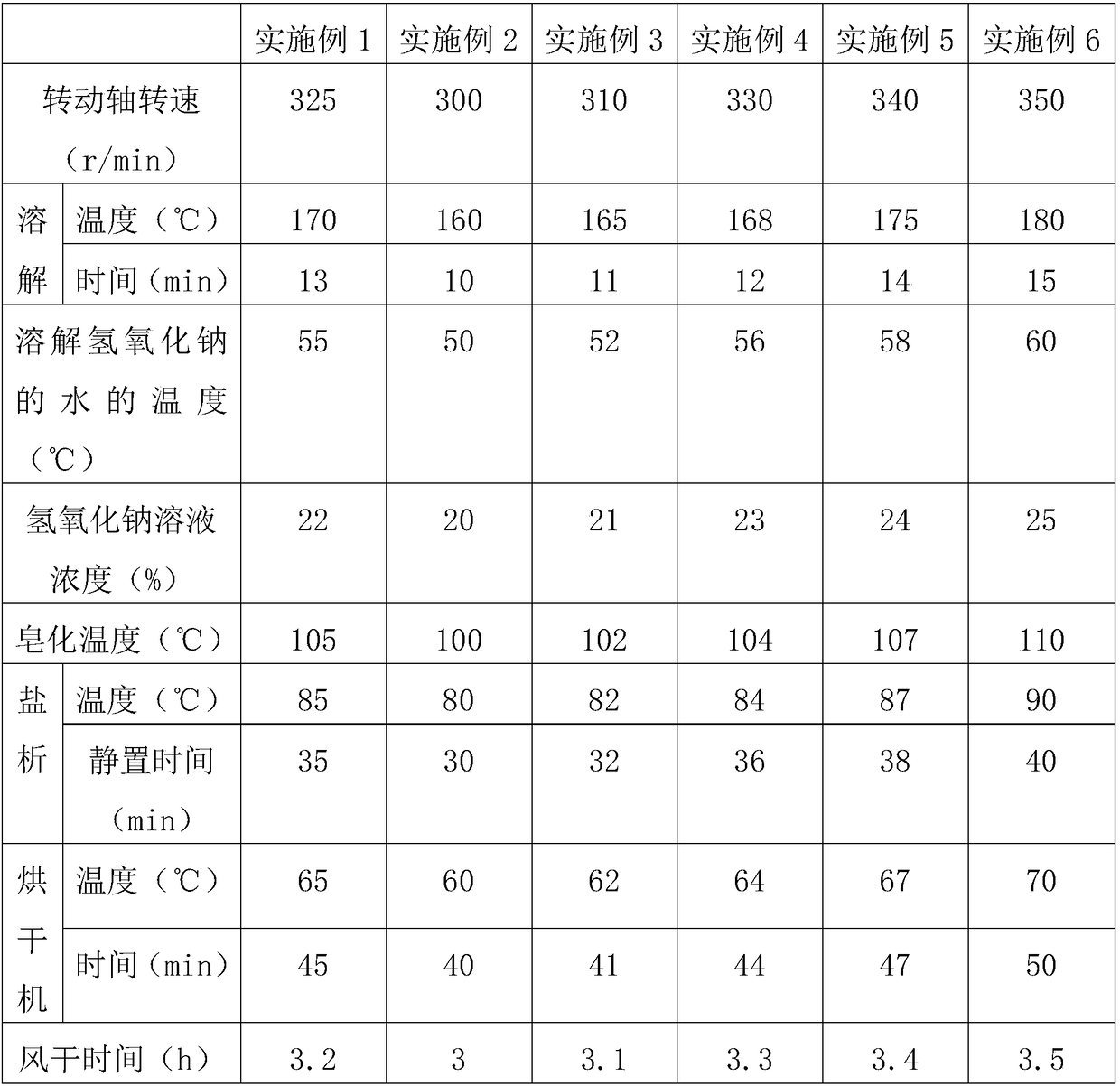

Production process of handmade soap

InactiveCN104327983AComfortable and healthyImprove pass rateDrying soapBLENDER/MIXERProcess engineering

The invention discloses a production process of handmade soap. The process comprises the following steps: preheating grease and an alkali respectively, mixing together, then fully stirring by a stirring machine for 1.5-2h, controlling the stirring speed to 340-600r / min, pouring a mixture obtained from the former step into a mold, further putting the mixture into a vacuum drying machine for drying, then cooling, cutting, and further air-drying in a cool and ventilated place to obtain the mature handmade soap. According to the production process disclosed by the invention, by finely controlling process parameters and strictly controlling process steps, the quality of the product can be strictly controlled, the qualification rate of the product is improved and the comfort and health of the soap during the use can be ensured.

Owner:绵阳原香农业科技有限公司

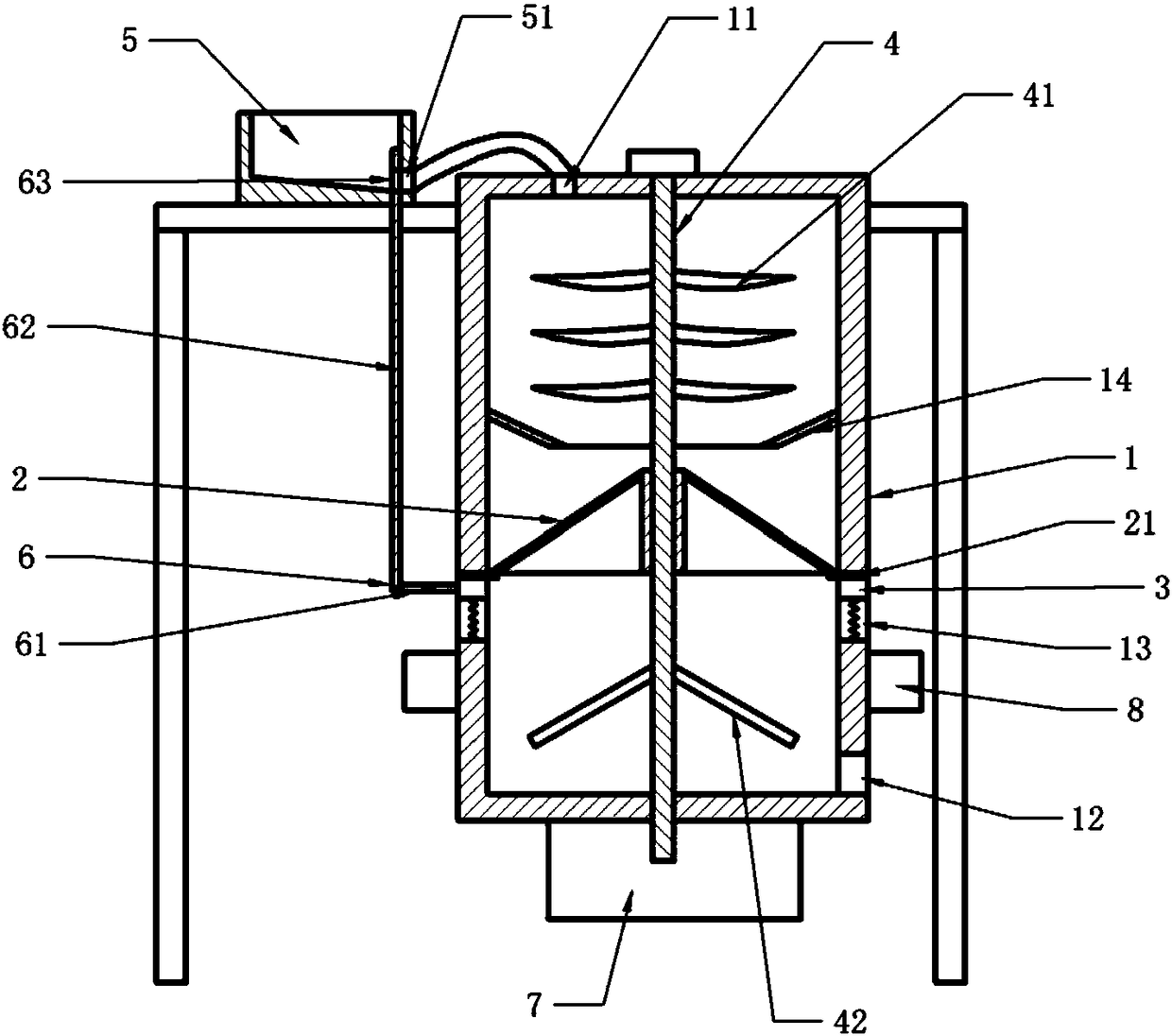

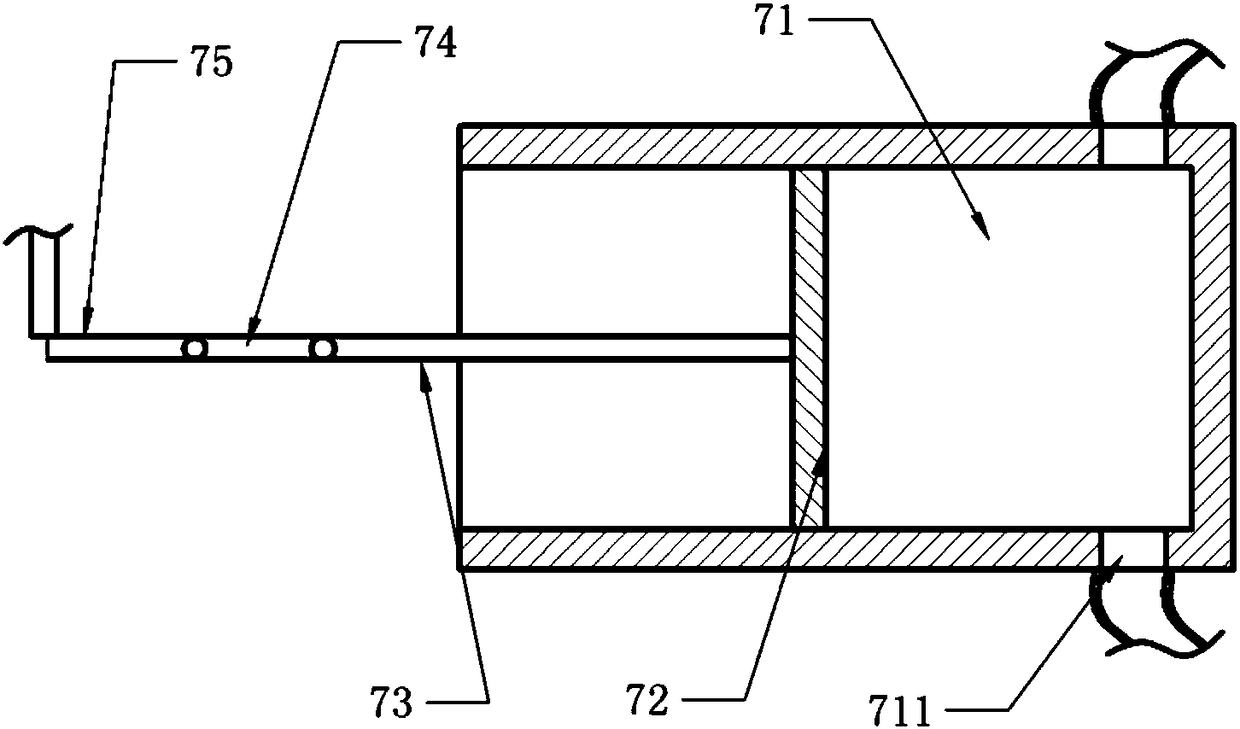

Processing method of soaps

ActiveCN108148694AReduce outflowRealize current limitingDrying soapCooling soapSalting outEngineering

Owner:XUZHOU XUANKE AGRI MASCH CO LTD

Production of anionic surfactant granules by in situ neutralisation

InactiveUS20020065207A1Reduce the possibilityReduce riskDrying soapCooling soapSURFACTANT BLENDChemistry

A process for the production of detergent particles, comprises feeding an acid precursor of an anionic surfactant and a neutralising agent into a horizontal thin-film evaporator / drier comprising a mixing region, a drying region and a cooling region. The resultant detergent particles are graded to separate an oversize granule fraction in which at least 70 wt % of the particles have a minimum diameter of 1000 mum. This fraction is fed back into the process.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

Soap containing yak milk components and preparation method thereof

InactiveCN106281801ASignificant cleanlinessSignificant skin care effectCutting soapDrying soapFlavorPreservative

The invention discloses a soap containing yak milk components and a preparation method thereof. The preparation method comprises the following steps: mixing Tibetan yak butter, sea-buckthorn seed oil, coconut oil, palm oil and olive oil, heating the mixture in water, keeping the temperature of the oil mixture in the range of 30-45 DEG C; mixing sodium hydroxide with water, stirring the mixture until the sodium hydroxide is completely dissolved, maintaining the alkali liquor temperature between 30 DEG C and 45 DEG C; slowly pouring the oil mixture into the alkali liquor, mixing and stirring the mixture until the soap liquid is in a thick paste state, and when the saponification reaction is complete, adding a perfume and a preservative into the mixture, then slowly adding yak milk, continuously stirring, and finally pouring the soap liquid into a mould to be formed. The preparation method disclosed by the invention has the beneficial effects that (1) the preparation method is simple and practical, and the production cost is low; the physiological activity of the yak milk is greatly protected, and the preparation method is suitable for popularization and application; (2) the content of the yak milk in the soap is 5%-45% and the physiological activity is strong, the soap has the effects of cleaning, whitening, freckle-removing, skin nourishing, anti-aging and the like.

Owner:西宁琉璃王生物科技有限公司

Spray-dried detergent powder

InactiveUS8906842B2Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSulfateSpray dried

The present invention is a spray-dried powder comprising: (i) from 20 to 80 wt % of a first spray-dried particle comprising less than 5 wt % sulphate, anionic detersive surfactant and having a bulk density of from 300 g / l to 450 g / l: and (ii) from 20 to 80 wt % of a second spray-dried particle comprising at least 45 wt % sulphate, 0 wt % to 15 wt % anionic detersive surfactant, and having a bulk density of from 350 g / l to 700 g / l.

Owner:PROCTER & GAMBLE CO

Anionic surfactant powder

InactiveUS7833518B2Improve stabilityImprove powder propertiesCosmetic preparationsDrying soapSolubilityInorganic salts

Owner:KAO CORP

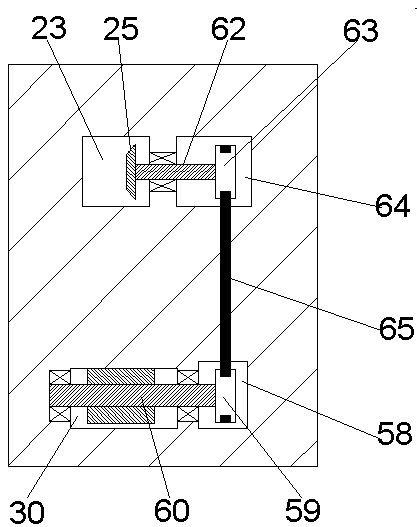

Soap shaping and dicing device

InactiveCN111117818AMix well and evenlySimple structureCutting soapDrying soapEngineeringWater circulation

The invention discloses a soap shaping and dicing device. A stirring mechanism is arranged in a machine body; the stirring mechanism comprises a cooling cavity positioned at the left end in the machine body; fixing blocks are fixed to the upper end wall and the lower end wall in the cooling cavity; a water cooling pipe is wound outside the fixed blocks; a water circulation cooling device which isfixed on the lower end wall of the cooling cavity and is communicated with the water cooling pipe is arranged at the left ends of the fixed blocks; a stirring cavity of which the lower end wall is aninclined surface is formed in the fixed blocks; the rear end of the stirring cavity is provided with a channel, and the channel is communicated with the outside of the machine body and allows materials to enter; air drying is divided into three small parts, the middle part is responsible for absorbing heat, the parts at the two ends are responsible for air drying, and thus the solidification speedis increased; finally, a mold is cut through a cutter, marks are embossed while cutting is conducted, a soap is shaped and transported away, time is saved, and production efficiency is improved.

Owner:FUZHOU GULOU DISTRICT XIARONG TRADING CO LTD

Easily wettable polycarboxylic thickeners

InactiveUS7560423B2Readily dispersibleGood dispersionOrganic detergent compounding agentsDrying soapCarboxylic acidEthylene Homopolymers

Mixtures of acrylic acid homopolymers, acrylic acid copolymers with other olefinically unsaturated carboxylic acids and / or other vinyl monomers, with electrolytes and surfactants, obtained in the form of powders easily wettable in water and with low viscosity of the aqueous dispersions before neutralisation of the free carboxyl groups.

Owner:3V SIGMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com