Processing method of soaps

A processing method and soap technology, which are applied in the manufacture of soap solution, chemical instruments and methods, molding soap, etc., can solve the problems of longer soap processing time, longer crushing time, poor crushing effect of raw materials, etc. Time, improve efficiency, shorten the effect of processing time

Active Publication Date: 2018-06-12

XUZHOU XUANKE AGRI MASCH CO LTD

View PDF4 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] The present invention intends to provide a soap processing method to solve the problem in the prior art that the raw materials adhere to the

Method used

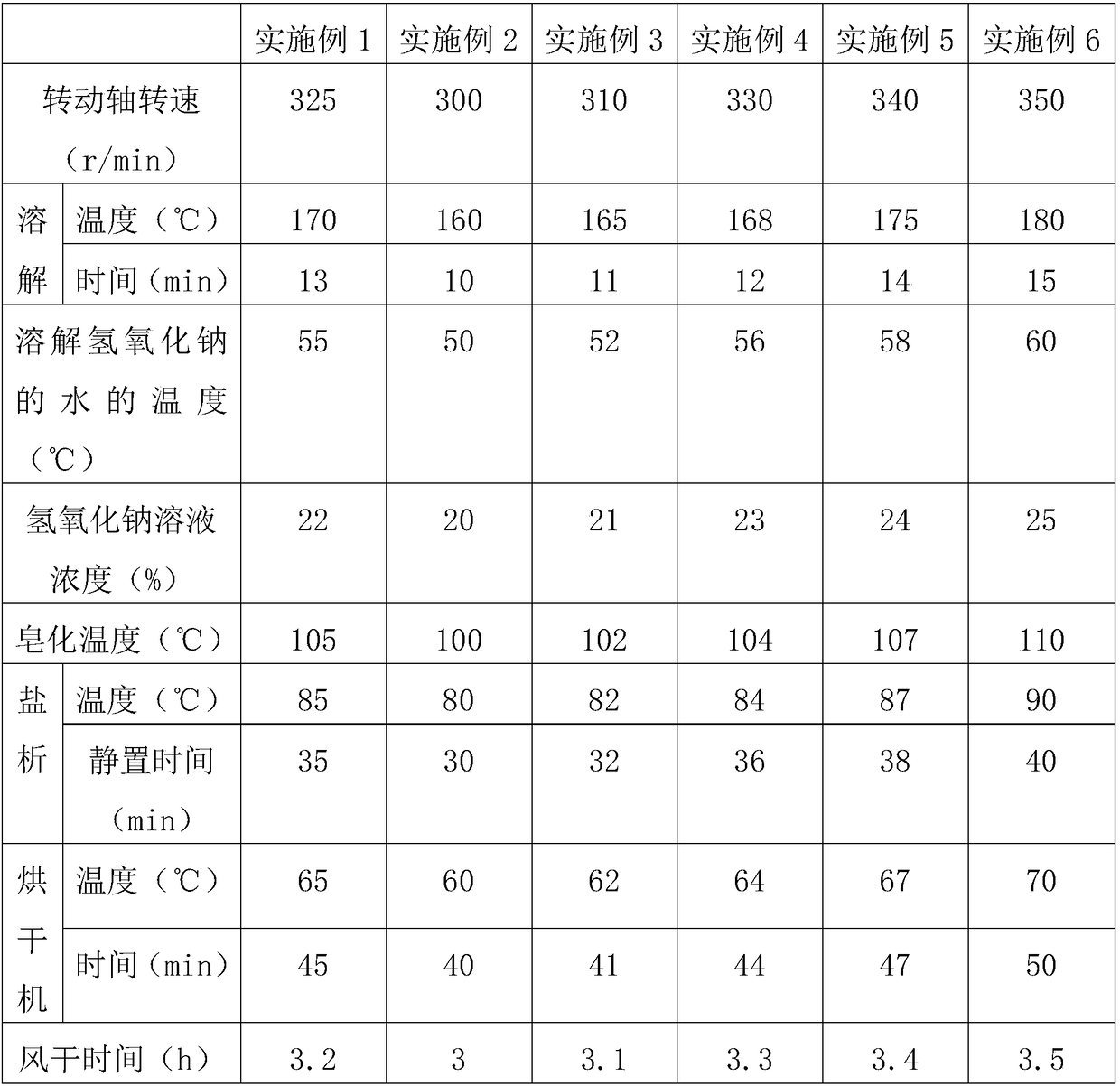

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

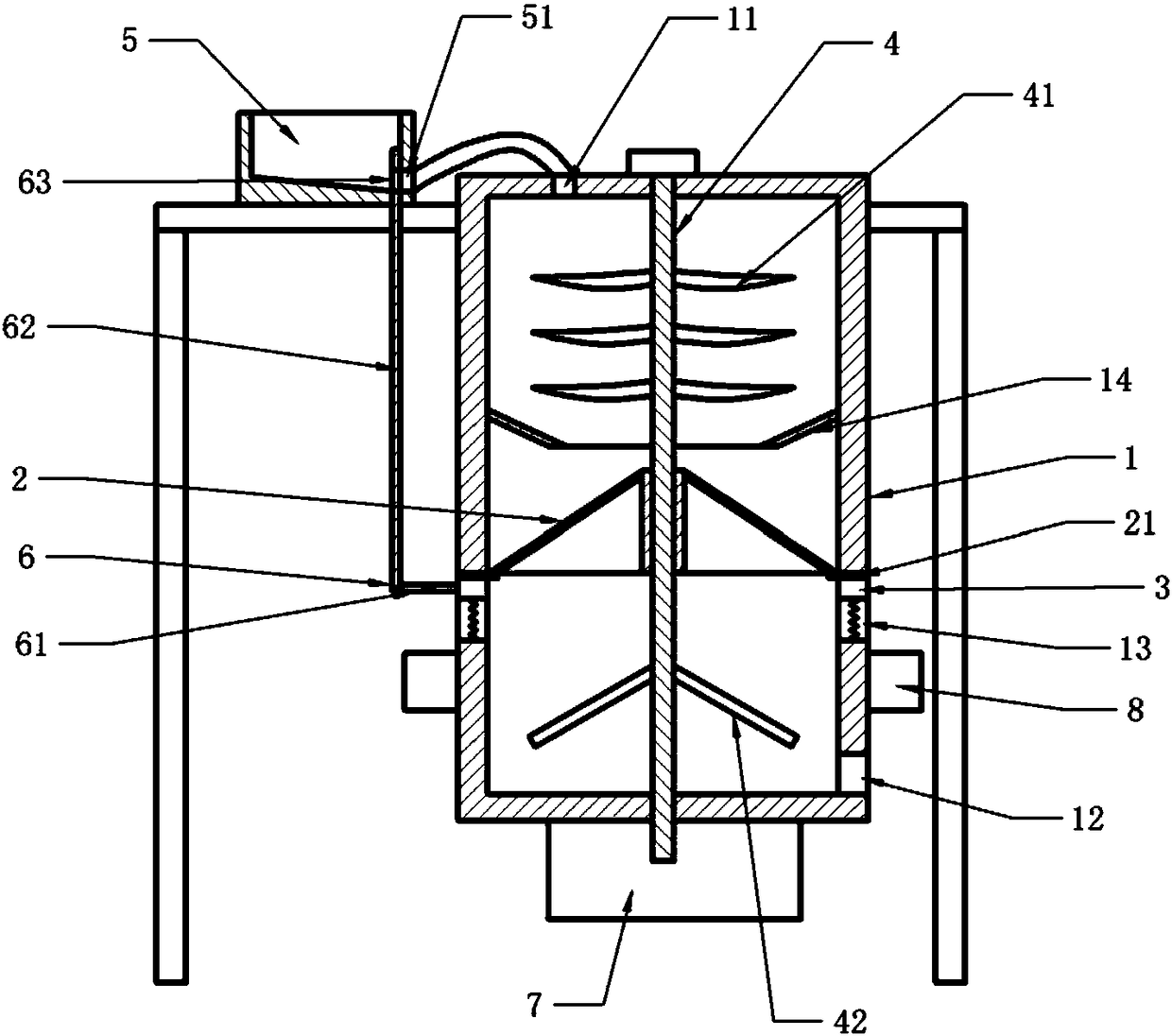

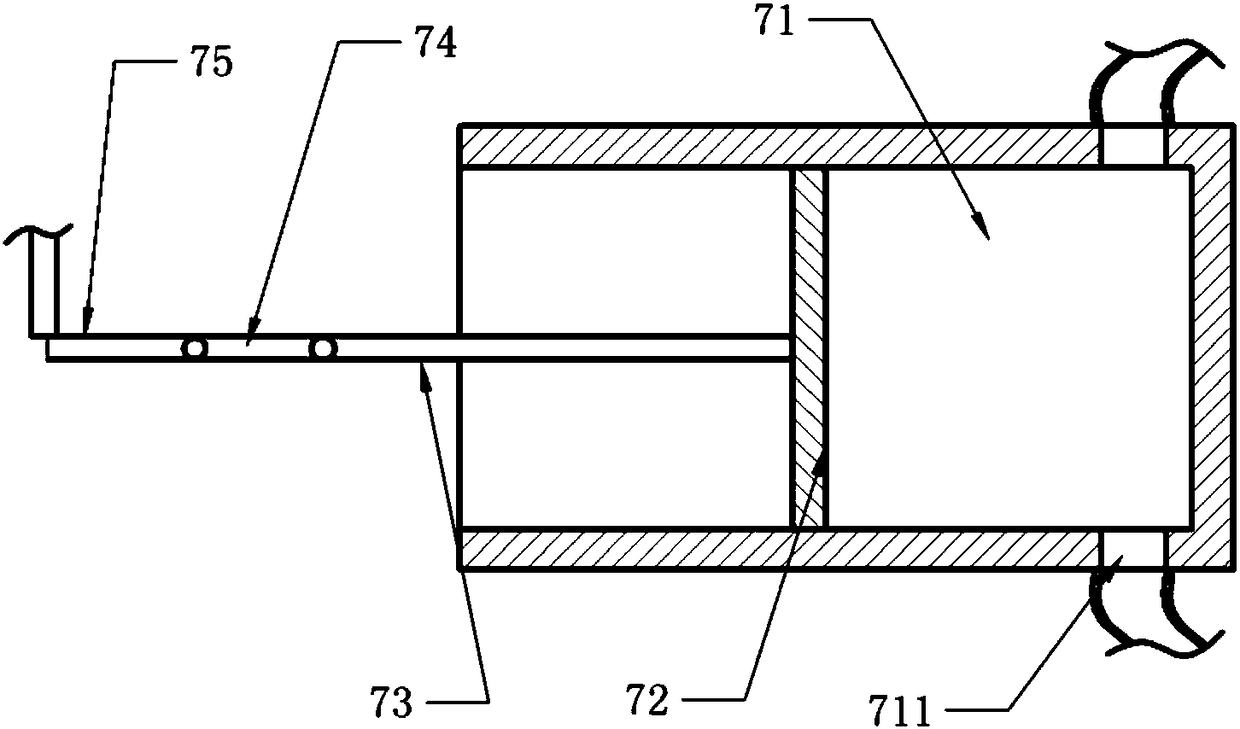

The invention belongs to the technical field of processing of articles for daily life and discloses a processing method of soaps. The processing method comprises the steps of: building equipment, crushing raw materials, dissolving, saponifying, salting out, drying and forming. A crushing device is adopted for crushing and comprises a crushing barrel, wherein the crushing barrel is provided with arotary shaft and a motor for driving the rotary shaft to rotate; the lower end of the rotary shaft penetrates through the crushing barrel and is positioned in the crushing barrel; a plurality of crushing blades are uniformly distributed at the lower end of the rotary shaft; a feeding port is arranged in the top part of the crushing barrel and a discharging port is arranged in the bottom part of the side wall of the crushing barrel; the top part of the crushing barrel is connected with a storage box; a blanking port is arranged on the storage box; a feeding pipe is connected between the blanking port and the feeding port. The processing method disclosed by the invention has the advantage that the problems that the raw materials are adhered on the crushing blades, then the crushing effect ofthe raw materials is poor and the crushing time is prolonged so as to cause long soap-processing time in the prior art are solved.

Description

technical field [0001] The invention belongs to the field of daily necessities processing, and in particular relates to a soap processing method. Background technique [0002] Soap is a general term for metal salts of fatty acids. It is a product made of fatty acid sodium and other surfactants as the main raw materials, adding quality improvers and appearance improvers, and processed and shaped. Because it is soluble in water and has the effect of washing and decontaminating, it is often used for washing clothes. [0003] The main raw materials of soap processing are crushing, mixing, dissolving, saponification, salting out, and drying and forming processes. Among them, the crushing of raw materials is the most basic process of soap processing. Its function is to crush the raw materials so that the dissolution is faster; the current soap processing method Often use a pulverizer for pulverization. [0004] The current pulverizer mainly includes a crushing barrel, a rotating...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C11D13/00C11D13/12C11D13/16C11D13/26

CPCC11D13/00C11D13/12C11D13/16C11D13/26

Inventor 王如君

Owner XUZHOU XUANKE AGRI MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com