Multi-pore instant soap

A porous and soapy technology, applied in the direction of dry soap, detergent materials, chemical instruments and methods, etc., can solve the inconvenience of use and the surrounding environment, the environment is dirty, the soap cannot be cleaned, foaming, moisturizing, and fragrance heavy work And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The soap liquid drying of embodiment 1-put interstitial thing

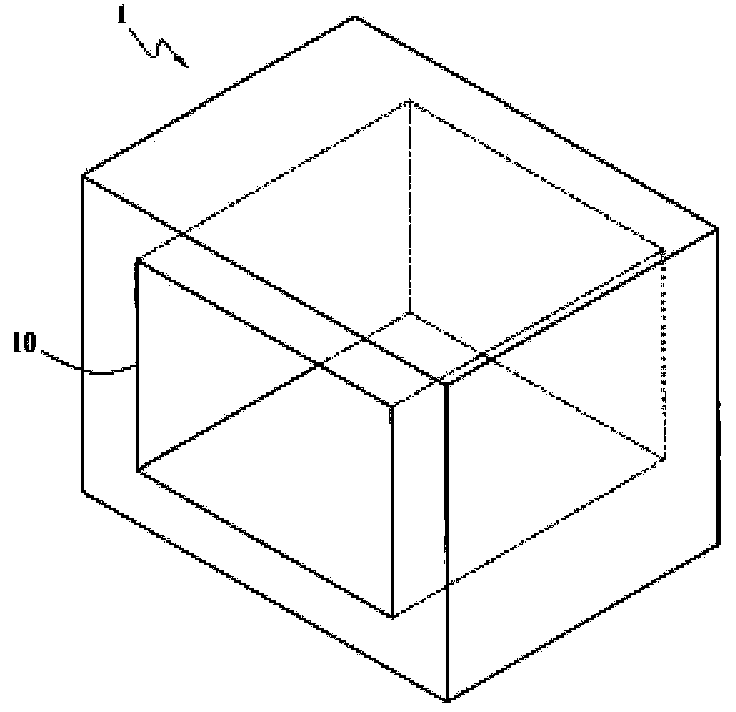

[0052] 1-1 Prepare a square mold, which contains 10 square cubes of 5mm*5mm*5mm, and then fill the semi-finished soap liquid inside.

[0053] 1-2 Then place 10 spacers of 3mm*3mm*3mm square rods in the square three-dimensional grid respectively.

[0054]1-3 After 20 days of natural air drying, 10 porous instant soaps with an appearance of 0.125cm3 and a porosity of 38% can be obtained.

Embodiment 2

[0055] The soap liquid drying of embodiment 2-introduce gas drying

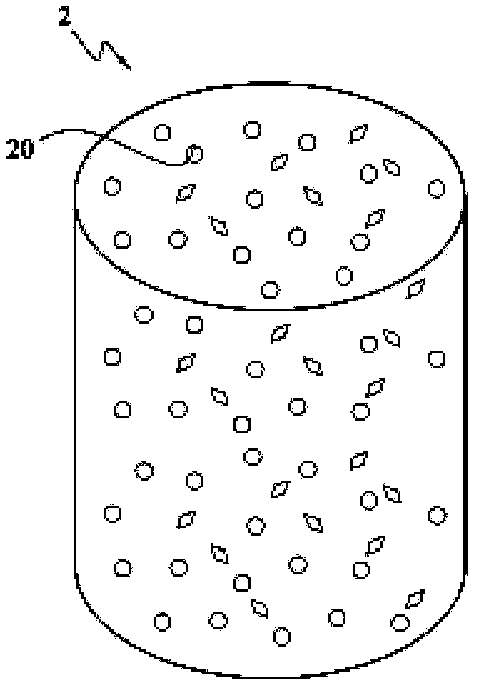

[0056] 2-1 Prepare a square mold with a size of 4cm*4cm*4cm. Then fill the semi-finished soap liquid inside.

[0057] 2-2 Use the gas pump to inject 10L / min of gas until the soap liquid is fully mixed with the gas to achieve a foaming state.

[0058] 2-3 Place the foamed soap body in a dry environment of 70 degrees to dry and solidify to obtain a porous instant soap with an appearance of 64cm3 and a porosity of 51%.

[0059] 2-4 The porous soap is then externally cut to a size of 0.125 to 15.6 cm3.

Embodiment 3

[0060] The soap liquid drying of embodiment 3-vacuum freeze-drying

[0061] 3-1 Prepare a square mold, which contains 100 triangular three-dimensional squares of 7mm*7mm*3mm, and then fill the semi-finished soap liquid inside.

[0062] 3-2 Place the square mold inside a vacuum cavity with temperature control function.

[0063] 3-3 Set the temperature inside the cavity to -28°C, so that the soap can be completely frozen and solidified.

[0064] 3-4 After freezing and solidifying, use a vacuum pump to pump the cavity pressure to a vacuum pressure of 18*10-3 Torr, so that the crystal water inside the frozen soap body can be sublimated and removed.

[0065] 3-5 After the water of crystallization is removed, take it out to obtain 100 porous instant soaps with an appearance of 0.147cm3 and a porosity of 71%.

[0066] Table 1

[0067]

Example 1

Example 2

Example 3

Grease 1(g)

coconut oil / 10

coconut oil / 10

coconut oil / 10

Grease 2(g) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com