Uniform phase distribution device in liquid contained multiphase fluidized system

A technology of uniform distribution and multiphase flow, applied in the fields of crystallization, extraction and extraction equipment, heat exchange, and reaction, it can solve the problems of difficulty in realization and complex structure, and achieve easy industrial scale-up, improve economic benefits, and improve utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing, the present invention will be further described.

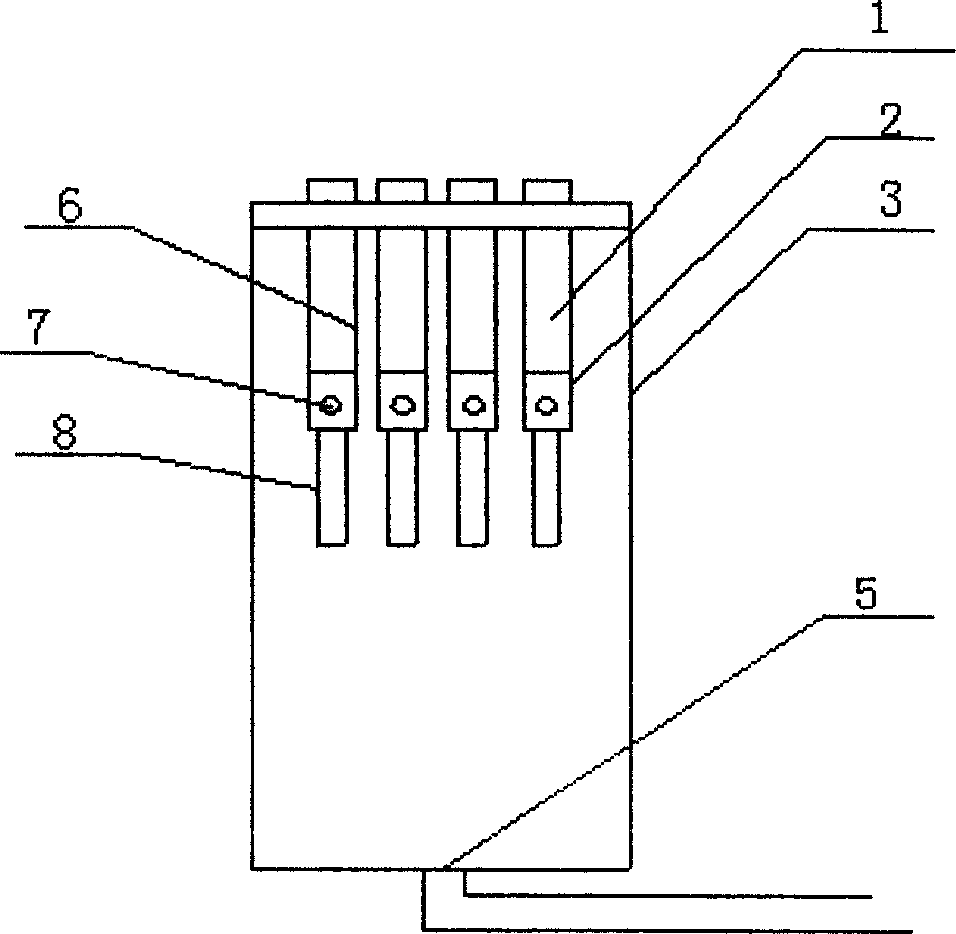

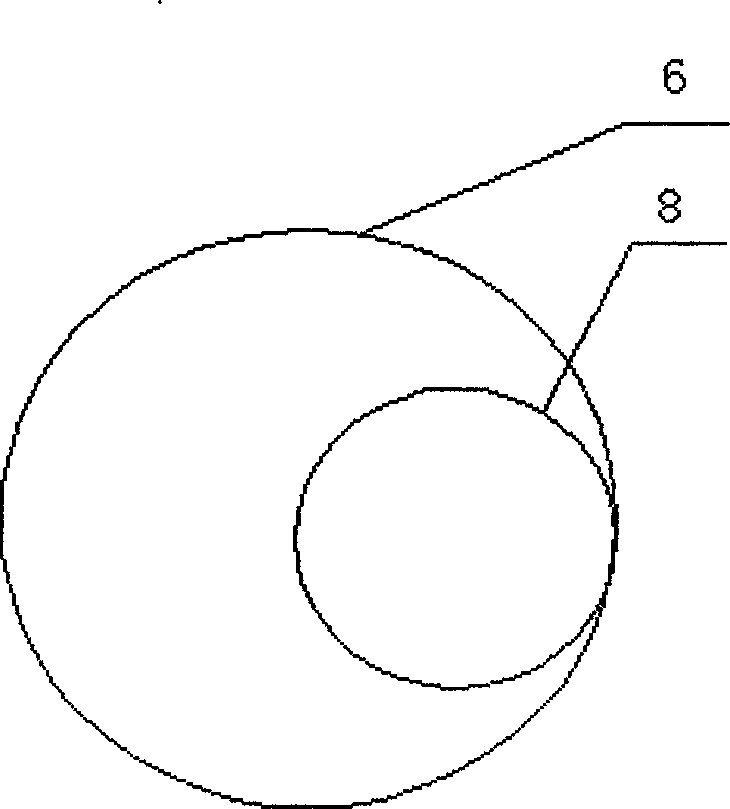

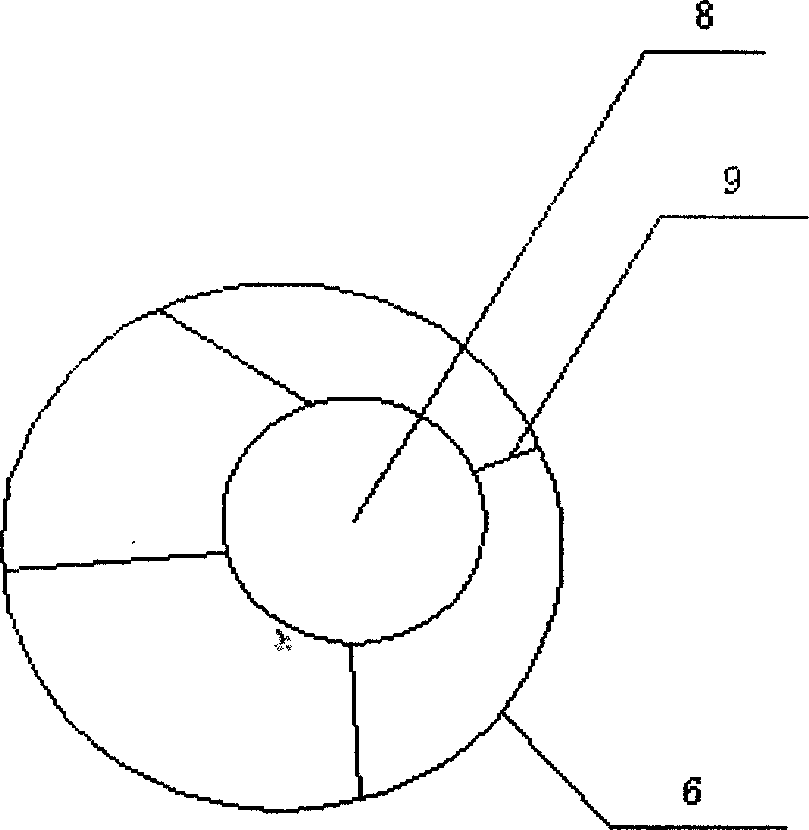

[0036] A device for evenly distributing each phase in a liquid-containing multiphase fluidization system. A material inlet 5 is arranged at the bottom of the lower tube box 3, and a casing structure 1 is arranged on the upper part of the lower tube box. The casing structure is composed of at least two nested tubes , the tubes are provided with a positioning device or the inner wall of the outer tube 6 and the outer wall of the inner tube 8 are fixedly connected, the relative positional relationship between the tubes is concentric or eccentric, and the outer tube may be a heat exchange tube, a reaction tube, or a crystallization tube One of the extraction and extraction tubes or the lower end of one of the heat exchange tubes, reaction tubes, crystallization tubes, extraction and extraction tubes is combined with the connecting tube 2, and the lower nozzle of the inner tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com