Measuring method for heat flux density of solid metal

A technology of heat flux density and measurement method, applied in the direction of thermal development of materials, etc., can solve the problems of no measurement of solid metal heat flux density, no written records, etc., and achieve the effects of easy realization of manufacturing process, wide measurement range and high stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

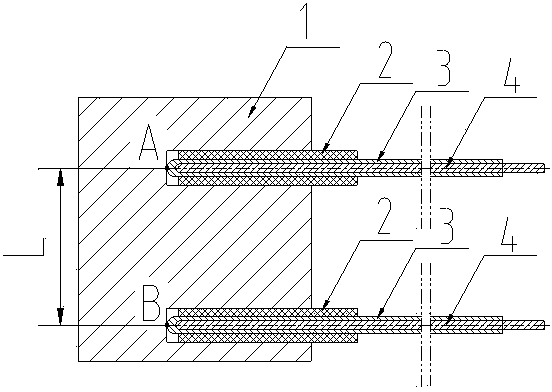

[0025] Such as figure 1 As shown, a method for measuring the heat flux density of a solid metal in the present invention is implemented according to the following steps: (A) Determine the thermal conductivity l (W / m.°C) of the object to be measured. The measuring device works in the air medium, the measured object can be charged or non-charged metal, and the working temperature is from room temperature to 600°C. According to the national standard, the thermal conductivity of the measured object is verified, and the thermal conductivity of the measured object under working conditions is l (W / m.℃);

[0026] (B) For the processing of the measurement hole, on the premise of meeting the measurement accuracy requirements and anti-interference ability, try to choose the solid metal internal temperature measurement device with the smallest outer diameter. The outer diameter of the insulating casing of the temperature measurement device is d, and the value range of d 5??10 -4 ~2??10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com