Preparation process for improving density of solid electrolyte

A solid electrolyte and dense technology, applied in electrolytes, circuits, electrical components, etc., to achieve the effect of improving ionic conductivity, cheap raw materials, and simple and easy methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: The preparation process of lithium aluminum silicate is as follows: accurately weigh alumina, silicon dioxide, and lithium carbonate according to the stoichiometric ratio, add ethylene glycol and mill at 300 rpm for 20 hours, dry at 65°C, and then roast to obtain lithium aluminum silicate .

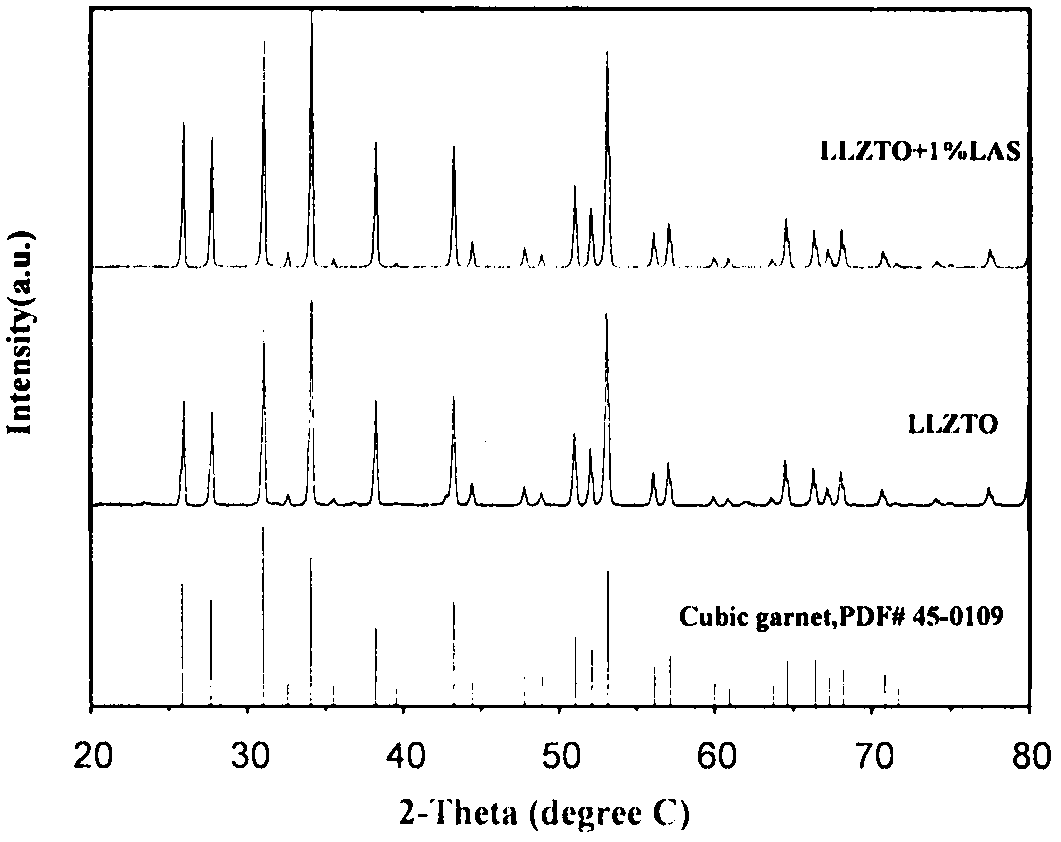

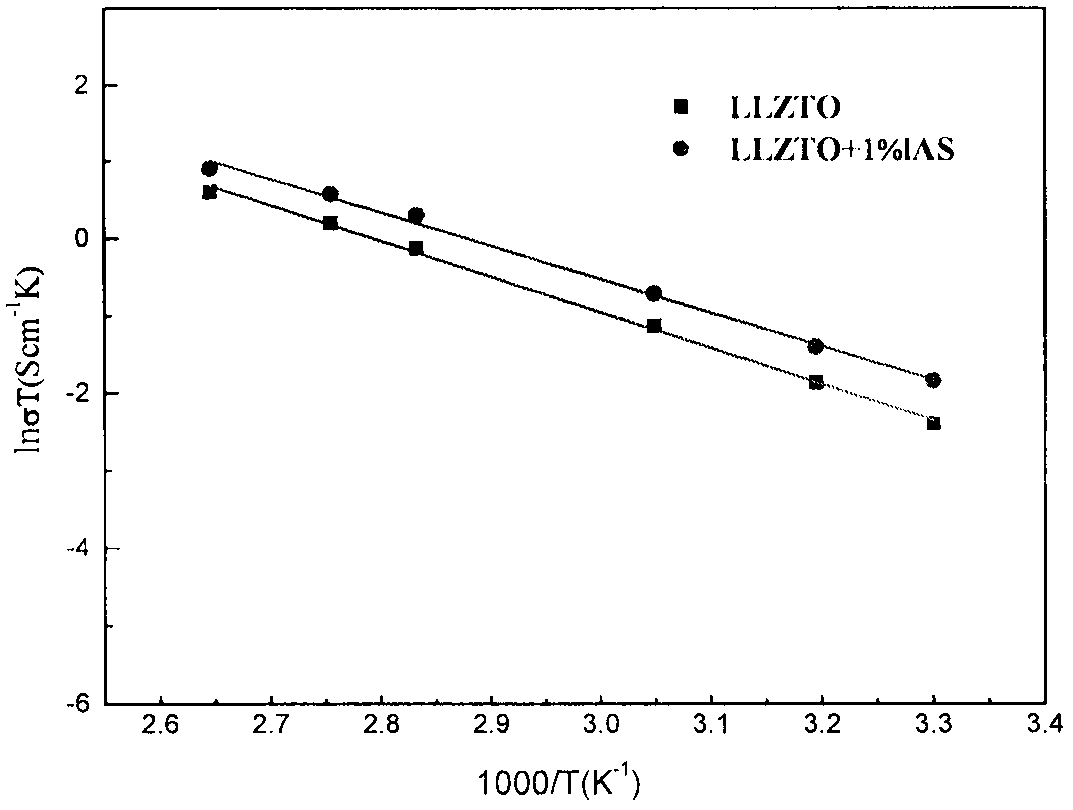

[0027] Preparation of lithium aluminum silicate adding tantalum doped lithium lanthanum zirconium oxygen electrolyte sheet: add lithium carbonate, tantalum pentoxide, zirconia, lanthanum oxide accurately weighed according to the stoichiometric ratio, add ethylene glycol and ball mill at 300rpm for 10h, 65℃ After drying, roast at 900°C for 10h, add 0.5%wt. lithium aluminum silicate ball mill to the obtained powder, ball mill for 20h, revolution speed 300rpm, add binder 2.7%PVB ball mill after drying at 65°C, 30Mpa after drying The tablet was pressed down for 2 minutes to obtain an electrolyte precursor sheet with a diameter of 12.7 mm. It was fired at 650°C for 8 hours to...

Embodiment 2

[0029] Example 2: The preparation process of lithium aluminum silicate is as follows: Accurately weigh alumina, silicon dioxide, and lithium carbonate according to the stoichiometric ratio, add ethylene glycol and ball mill at a revolution speed of 300 rpm for 20 hours, dry at 65°C and then roast to obtain silicic acid Aluminum Lithium.

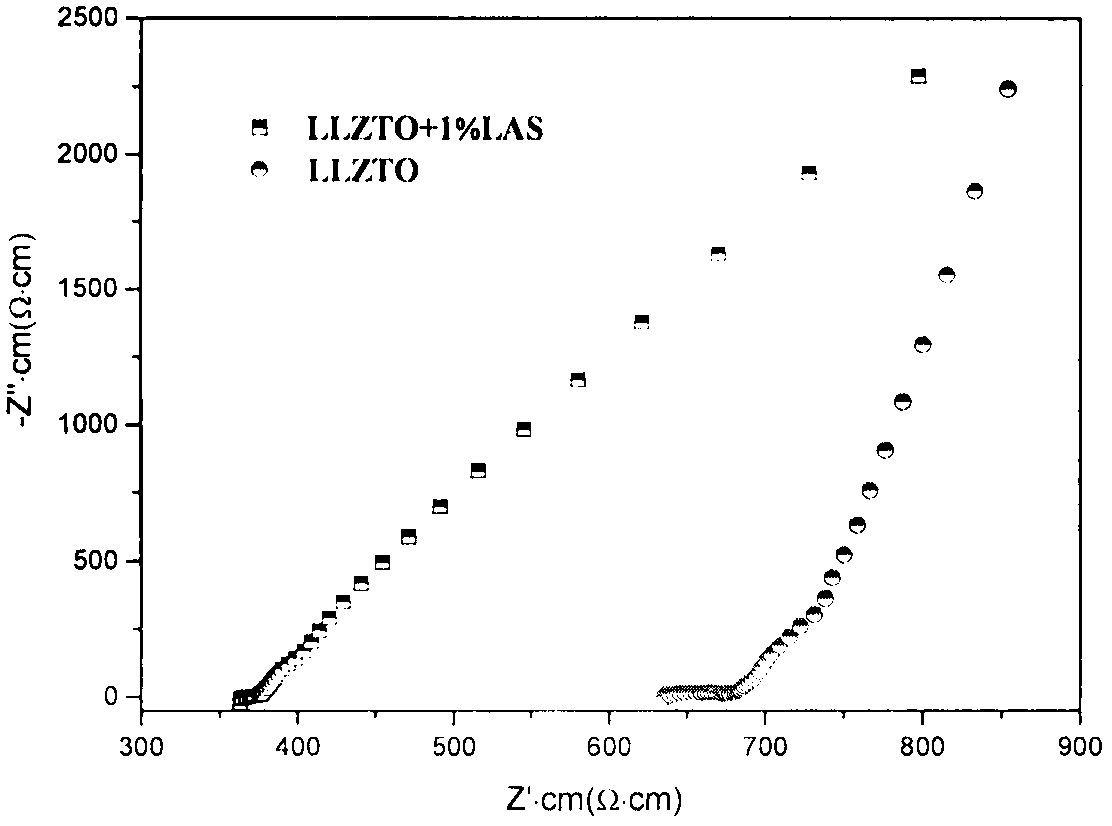

[0030] Preparation of lithium aluminum silicate adding tantalum doped lithium lanthanum zirconium oxygen electrolyte sheet: add lithium carbonate, tantalum pentoxide, zirconia, lanthanum oxide accurately weighed according to the stoichiometric ratio, add ethylene glycol and ball mill at 300rpm for 10h, 65℃ After drying, roast at 900°C for 10 hours, add 1%wt. lithium aluminum silicate ball mill to the obtained powder, ball mill for 20h, revolution speed 300rpm, add binder 2.7%PVB ball mill after drying at 65°C, 30Mpa after drying The tablet was pressed down for 2 minutes to obtain an electrolyte precursor sheet with a diameter of 12.7 mm. It w...

Embodiment 3

[0032] Example 3: The preparation process of lithium aluminum silicate is as follows: accurately weigh alumina, silicon dioxide, and lithium carbonate according to the stoichiometric ratio, add ethylene glycol and mill at 300 rpm for 20 hours, dry at 65°C and then roast to obtain lithium aluminum silicate .

[0033] Preparation of aluminum silicate adding tantalum-doped lithium-lanthanum-zirconium-oxygen electrolyte sheet: adding tantalum carbonate, tantalum pentoxide, zirconia, and lanthanum oxide accurately weighed according to the stoichiometric ratio, adding ethylene glycol and ball milling at 300rpm for 10h, 65°C After drying, roast at 900°C for 10 hours, add 4% wt. lithium aluminum silicate ball mill to the obtained powder, ball mill for 20 hours, revolution speed 300rpm, add binder 2.7% PVB ball mill after drying at 65°C, 30Mpa after drying The tablet was pressed down for 2 minutes to obtain an electrolyte precursor sheet with a diameter of 12.7 mm. It was fired at 650°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com