Preparation method of high-purity organosilicone monomer

A technology for organosilicon and monomers, which is applied in the field of preparation of high-purity organosilicon monomers, and can solve problems such as poor controllability of the processing process, inability to apply industrial production, and inability to guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] Preparation of High Purity Organosilicon Monomer

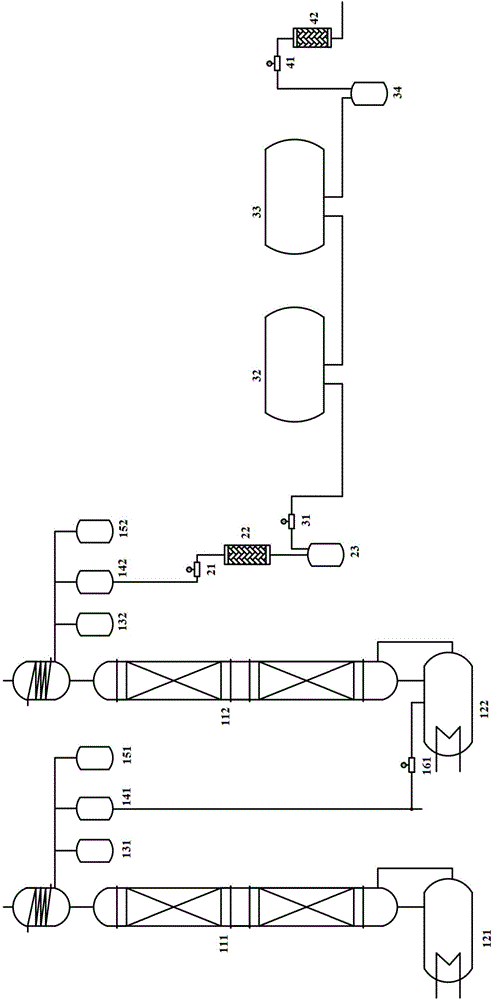

[0060] The present invention provides a kind of preparation method of high-purity organosilicon monomer, and described preparation method comprises the following steps:

[0061] (1) Pass the industrial organosilicon monomer through multiple rectification towers, so as to perform multiple rectification on it to obtain the first purified organosilicon monomer;

[0062] (2) Passing the first purified organosilicon monomer through the first membrane filter to perform coarse filtration to obtain the second purified organosilicon monomer;

[0063] (3) Entering the second purified organosilicon monomer into a multiple sub-boiling still, distilling it, and collecting fractions to obtain a third purified organosilicon monomer;

[0064] (4) Filtering the third purified organosilicon monomer through a second membrane filter to obtain a high-purity organosilicon monomer.

[0065] In another preferred embodiment, the organosilicon...

Embodiment 1

[0098] The preparation of embodiment 1 high-purity octamethylcyclotetrasiloxane

[0099] (1) Distillation

[0100] Under normal pressure, add industrial-grade octamethylcyclotetrasiloxane into the reaction kettle, and then conduct continuous rectification through four sets of rectification columns in series, control the split ratio and column temperature, and collect fractions at 173-175°C.

[0101] (2) Coarse filtration

[0102] Pass the collected fractions through a 0.5 μm membrane filter with a metering pump.

[0103] (3) sub-boiling distillation

[0104] Under the protection of nitrogen, continuously inject samples into the sub-boiling distiller through a metering pump, connect two groups of sub-boiling distillers in series, and raise the heating temperature to 150-155°C to collect fractions.

[0105] (4) Fine filtration

[0106] The collected fractions are passed through a 0.005 μm membrane filter by a metering pump, and then output to direct filling.

[0107] The pr...

Embodiment 2

[0108] The preparation of embodiment 2 high-purity octamethylcyclotetrasiloxane

[0109] (1) Distillation

[0110] Under normal pressure, add industrial-grade octamethylcyclotetrasiloxane into the reaction kettle, and then conduct continuous rectification through five sets of rectification columns in series, control the split ratio and column temperature, and collect fractions at 173-175°C.

[0111] (2) Coarse filtration

[0112] Pass the collected fractions through a 0.1 μm membrane filter with a metering pump.

[0113] (3) sub-boiling distillation

[0114] Under the protection of nitrogen, continuously inject samples into the sub-boiling stills through metering pumps, connect three groups of sub-boiling stills in series, and raise the heating temperature to 140-145°C to collect fractions.

[0115] (4) Fine filtration

[0116] The collected fractions are passed through a 0.005 μm membrane filter by a metering pump, and then output for direct filling.

[0117] The product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com