Systems and methods for gasifying a feedstock

a technology of feedstock and gasification system, which is applied in the direction of muffler furnaces, furnaces, lighting and heating apparatus, etc., can solve the problems of problems that can also be encountered, and can be encountered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

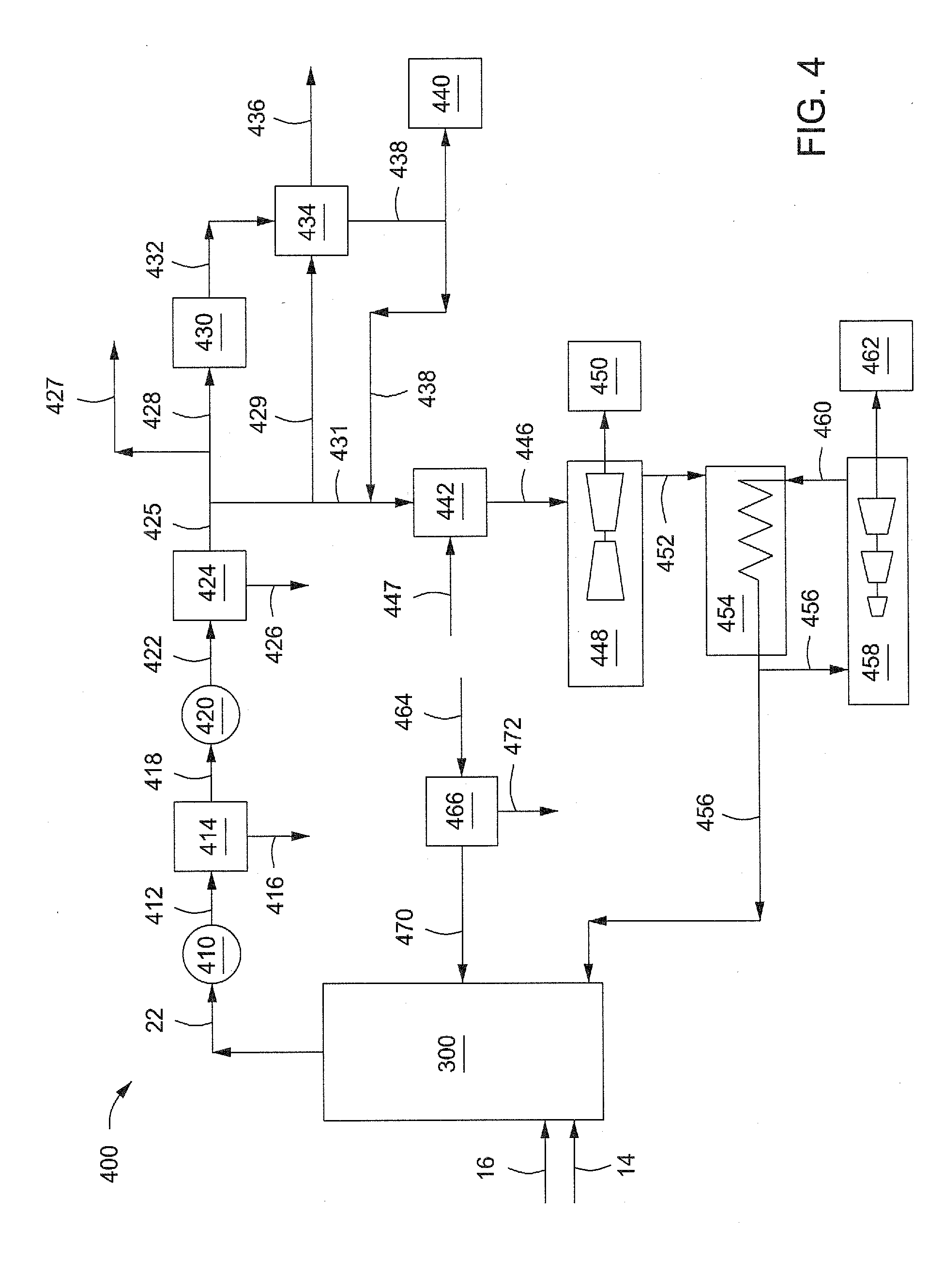

[0011]Systems and methods for gasifying a feedstock are provided. The method can include combining one or more feedstocks and one or more solid components in a treatment zone to provide a treated feedstock. At least a portion of the treated feedstock can be introduced to a reaction zone of a gasifier. The one or more solid components can have an average density and an average cross-sectional size that adjusts at least one of an average density of solids within a solids bed of the gasifier and an average cross-sectional size of the solids within the solids bed of the gasifier.

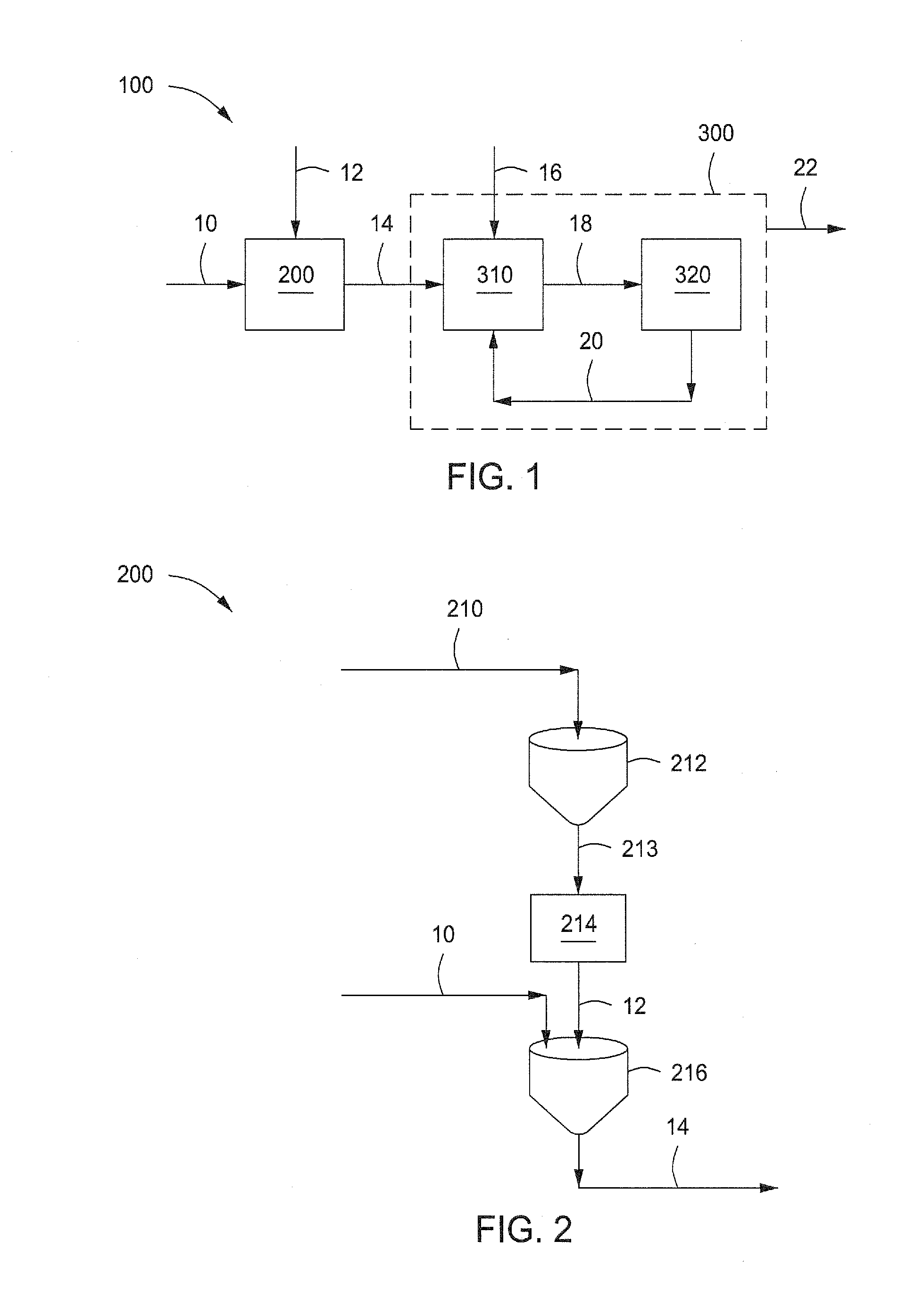

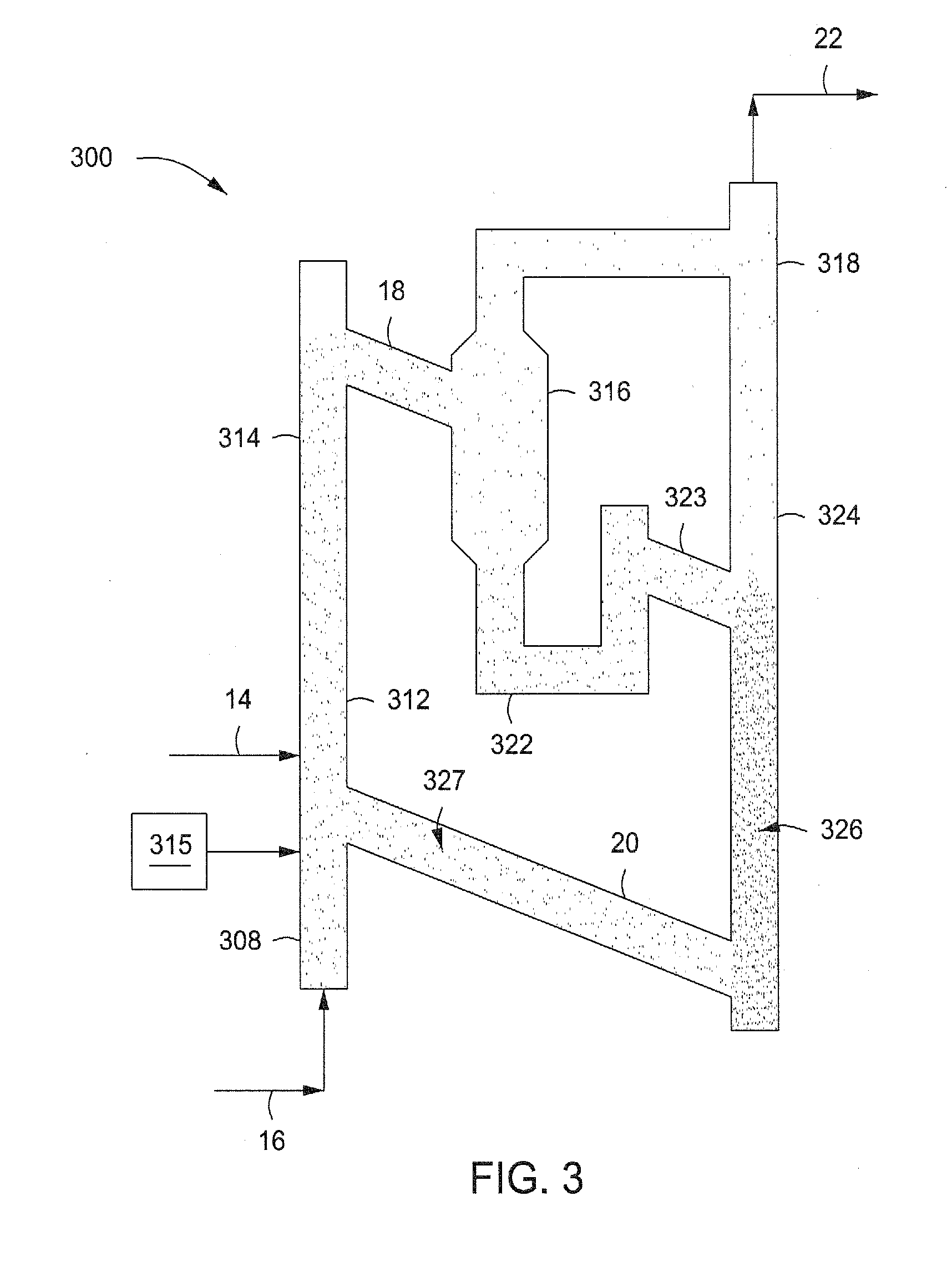

[0012]FIG. 1 depicts an illustrative system 100 for treating and gasifying one or more feedstocks in line 10, according to one or more embodiments. The system 100 can include one or more treatment systems or feedstock treating zones 200 and one or more gasifiers 300. One or more feedstocks via line 10 and one or more solid components via line 12 can be introduced to the treatment system 200 and mixed therein to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| cross-sectional size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com