Patents

Literature

32results about How to "Reduce misregistration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

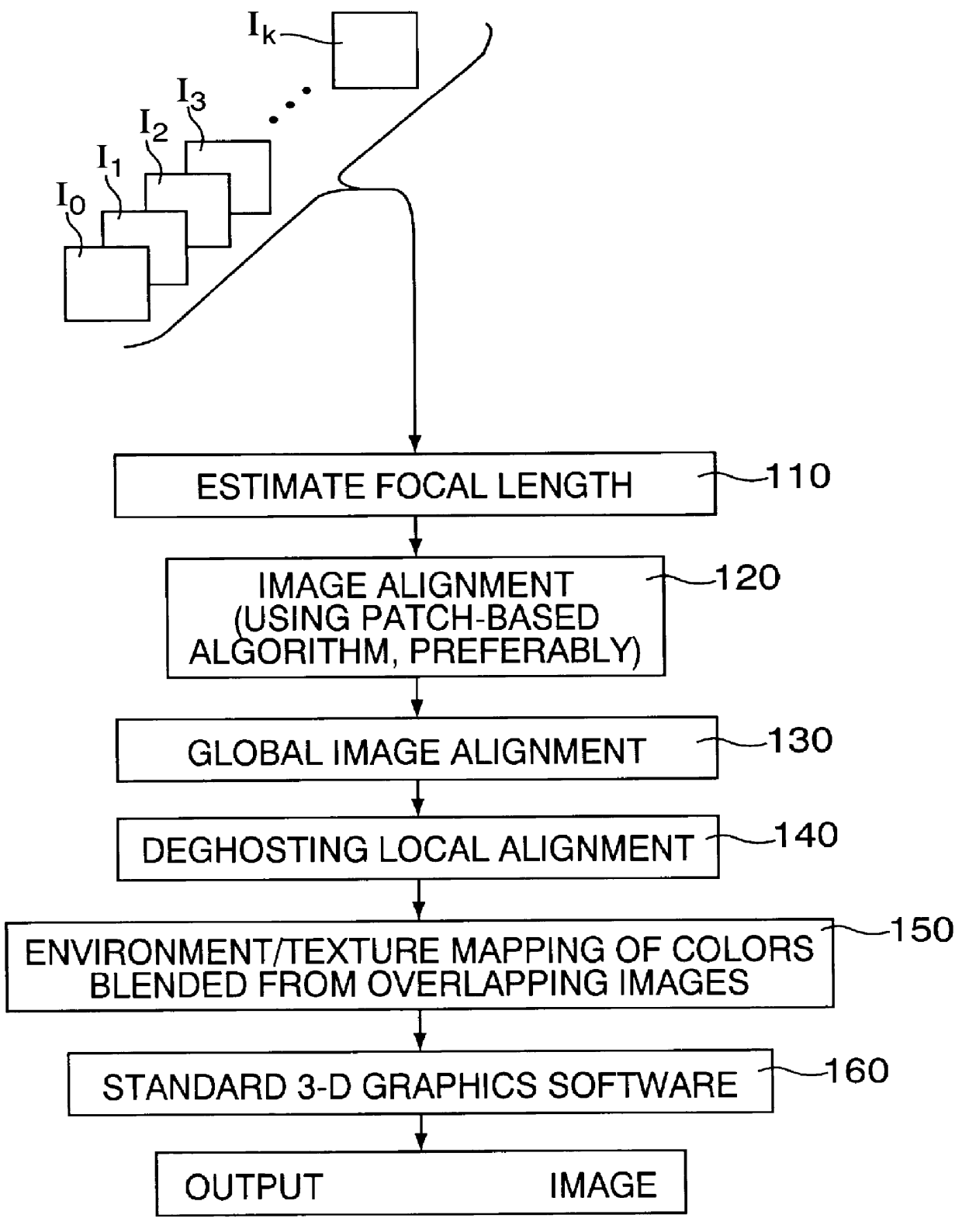

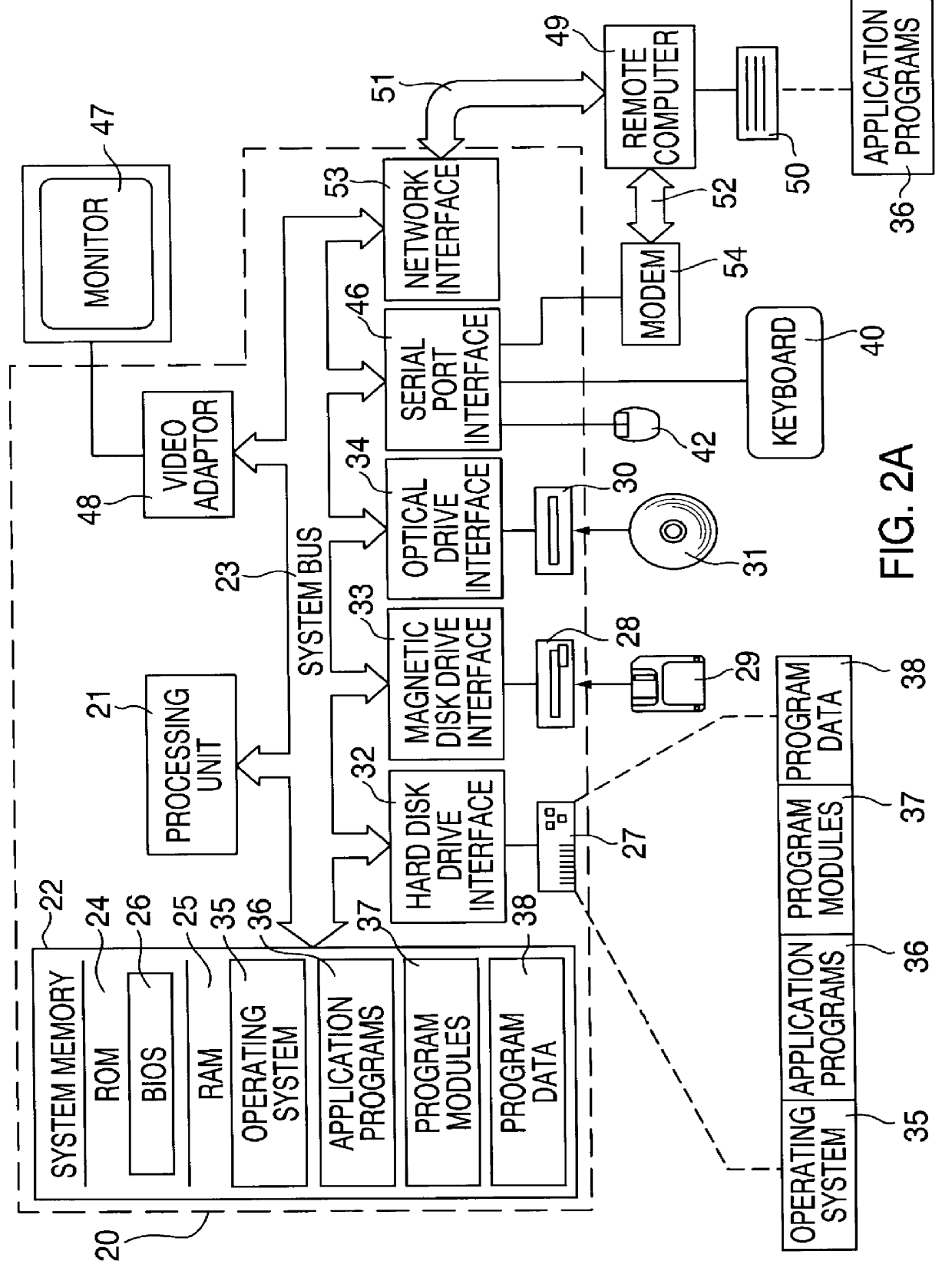

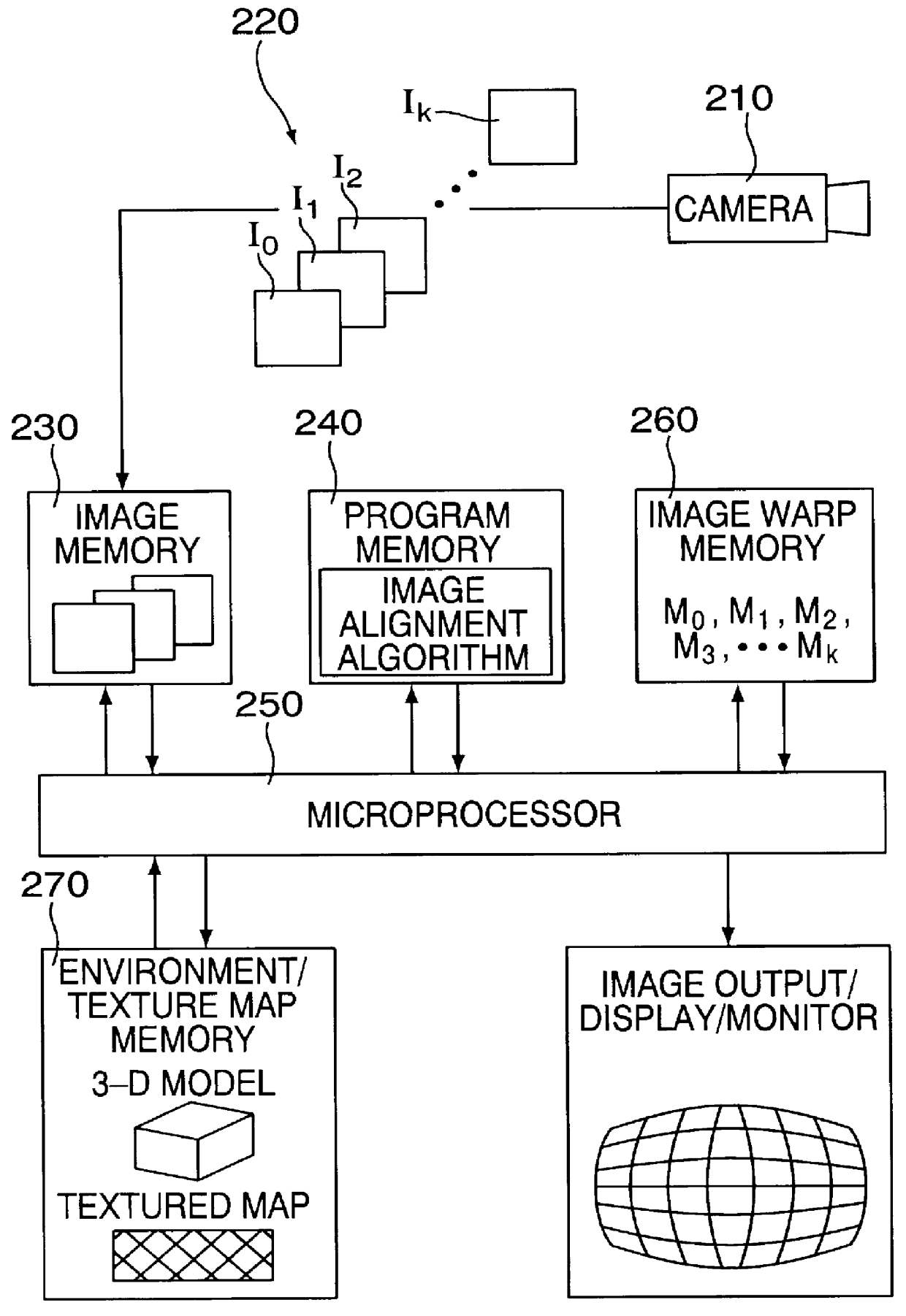

Focal length estimation method and apparatus for construction of panoramic mosaic images

InactiveUS6044181AReduce misregistrationEasy to integrateImage analysisGeometric image transformationEstimation methodsPerspective transformation

The focal length estimation method and apparatus claimed in this application aligns plural overlapping images with one another for constructing an image mosaic. This is accomplished by computing a planar perspective transformation between each overlapping pair of the images, computing from the planar perspective transformation a focal length of each image of the pair, computing from the focal length of each image a focal length transformation, computing a rotational transformation for each of the pair of images whereby a combination of the rotational transformation and the focal length transformation relates the respective image to a three-dimensional coordinate system. Registration errors between the pair of images are reduced by incrementally deforming the rotational transformation of one of the pair of images. The planar perspective transform is a matrix of warp elements, and the focal length is computed as a function of the warp elements, the function being derivable by constraining a first two rows or the first two columns of the matrix to have the same norm and to be orthogonal. The focal length of one image of a pair of images is found by applying the constraint on the matrix columns, while the focal length of the other image of the pair is found by applying the constraint on the matrix rows

Owner:MICROSOFT TECH LICENSING LLC

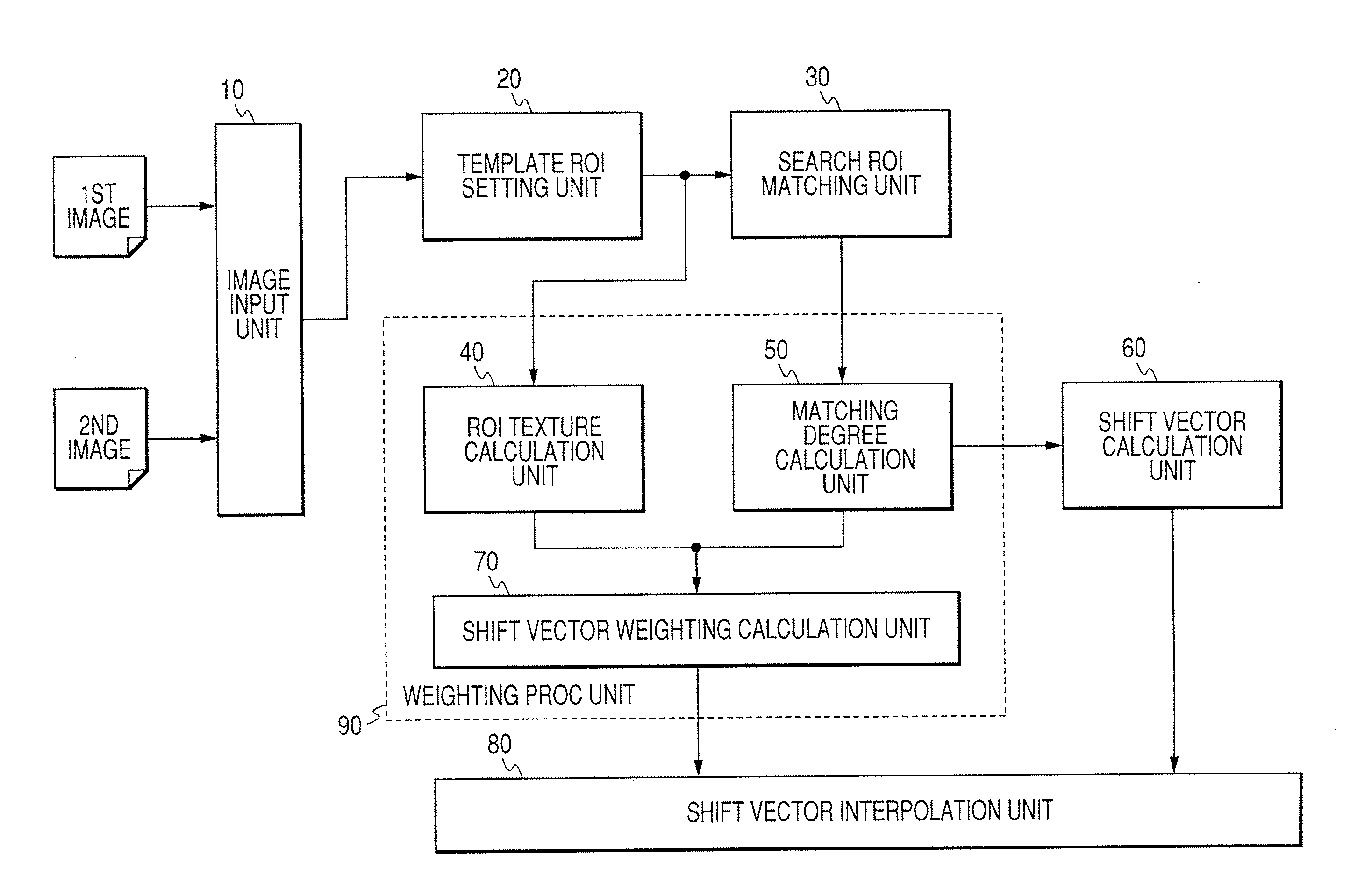

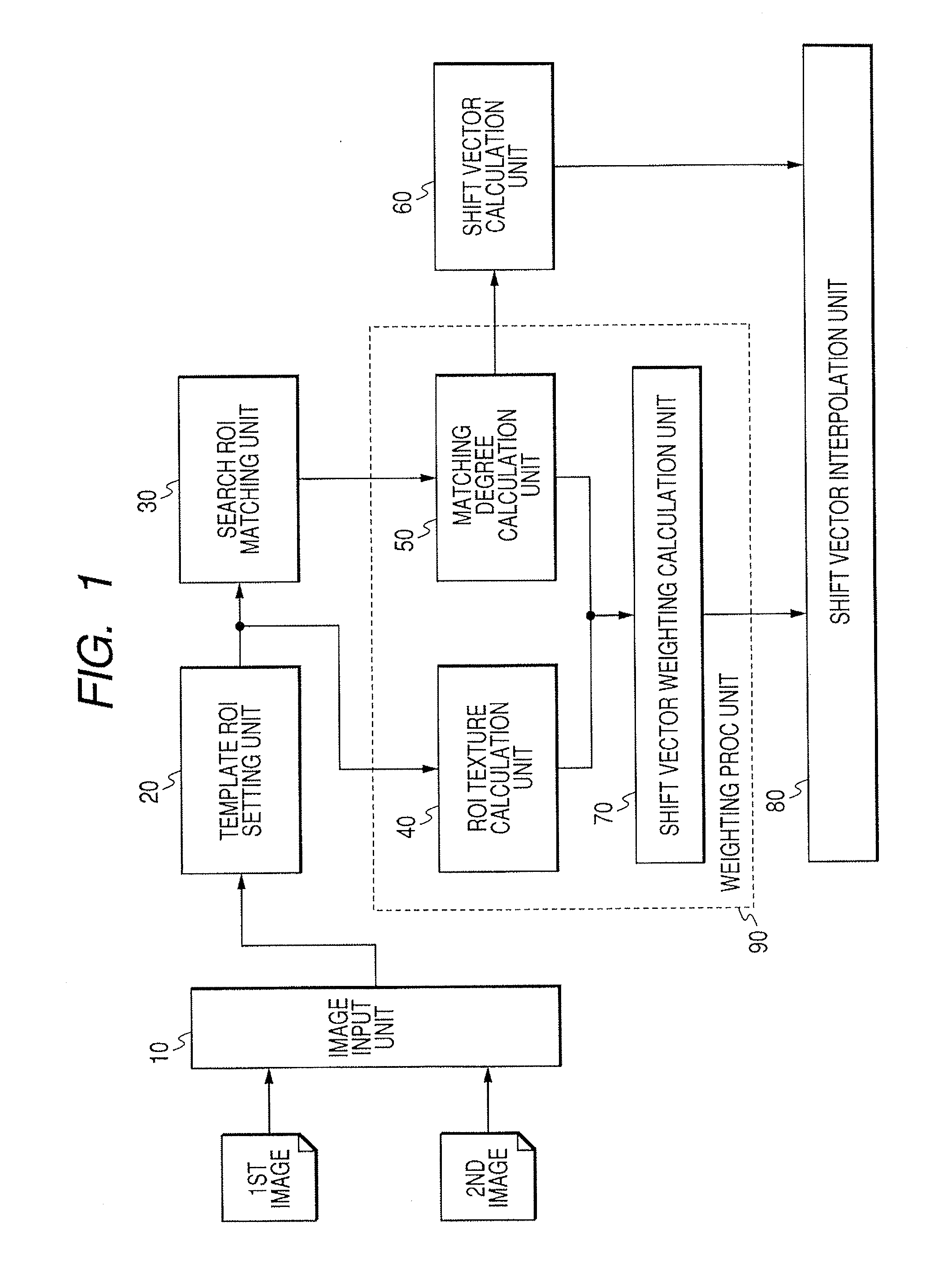

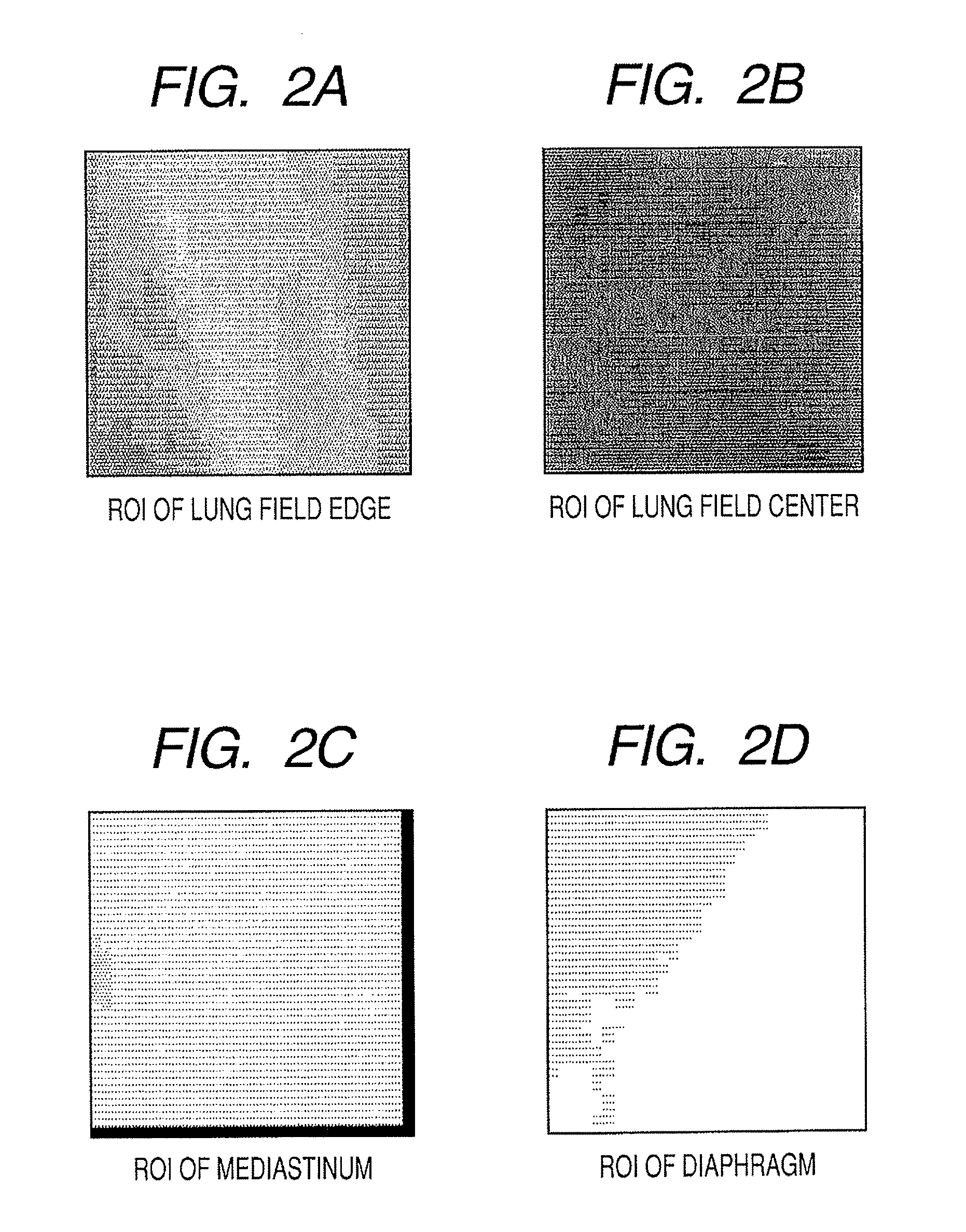

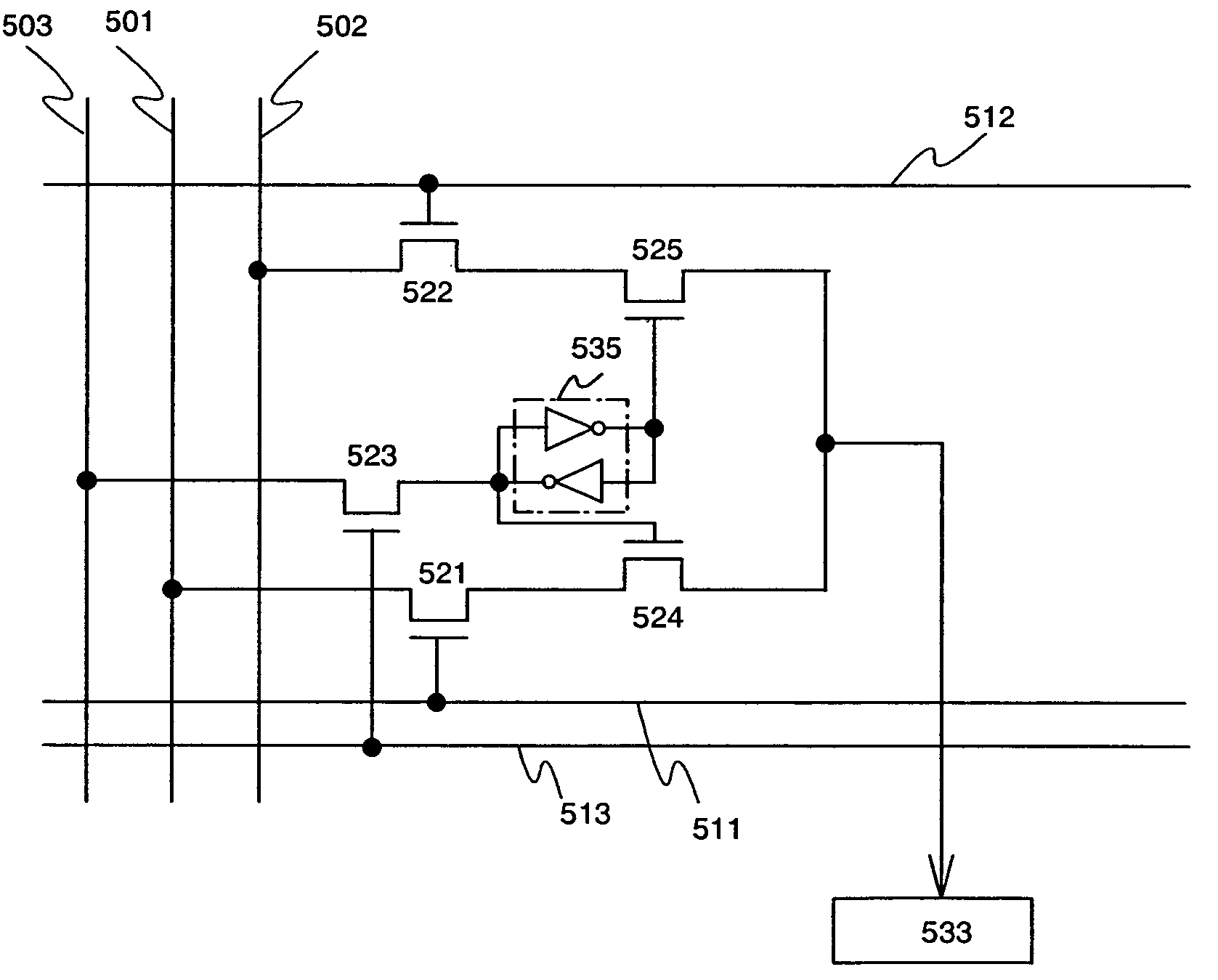

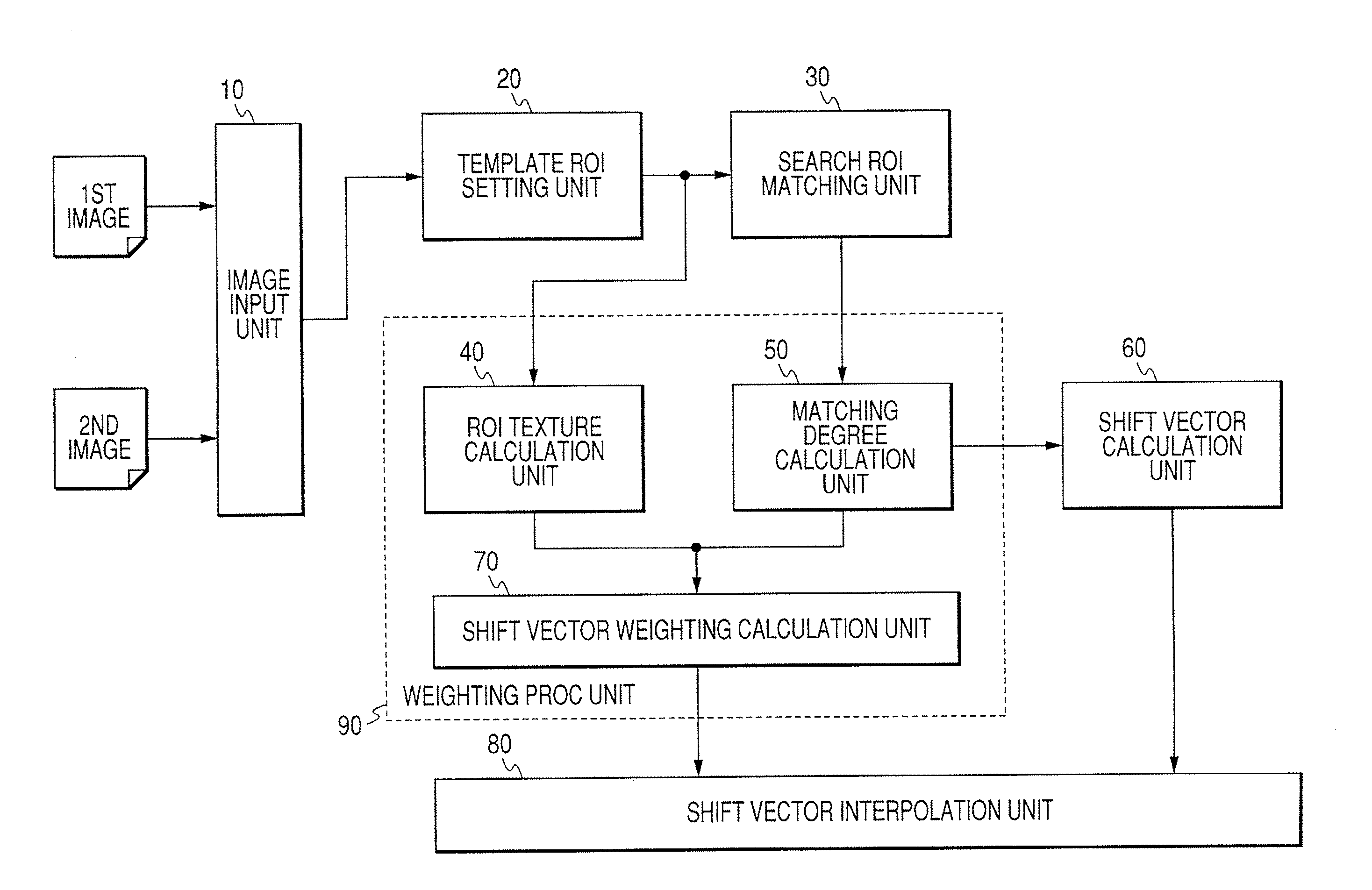

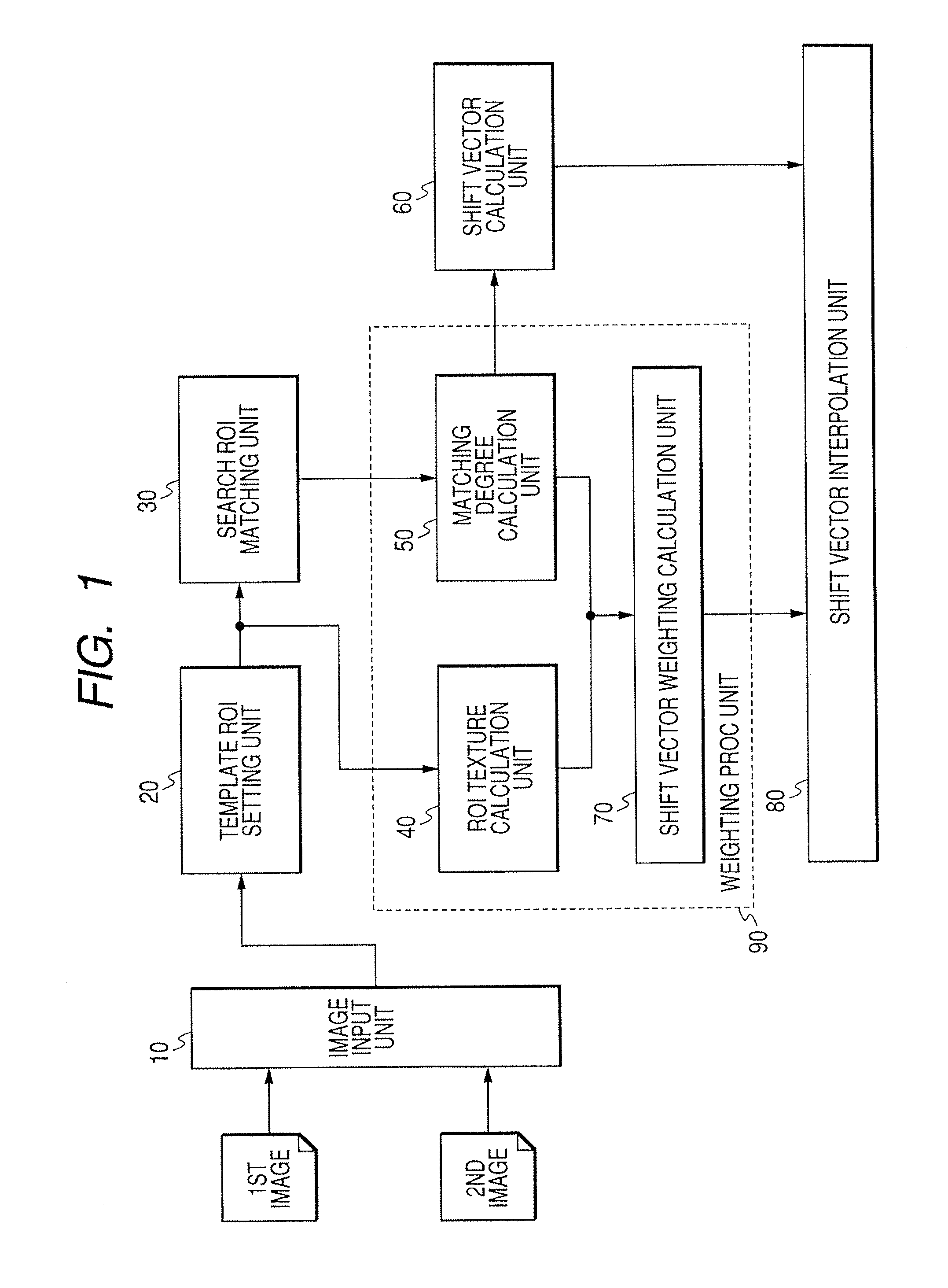

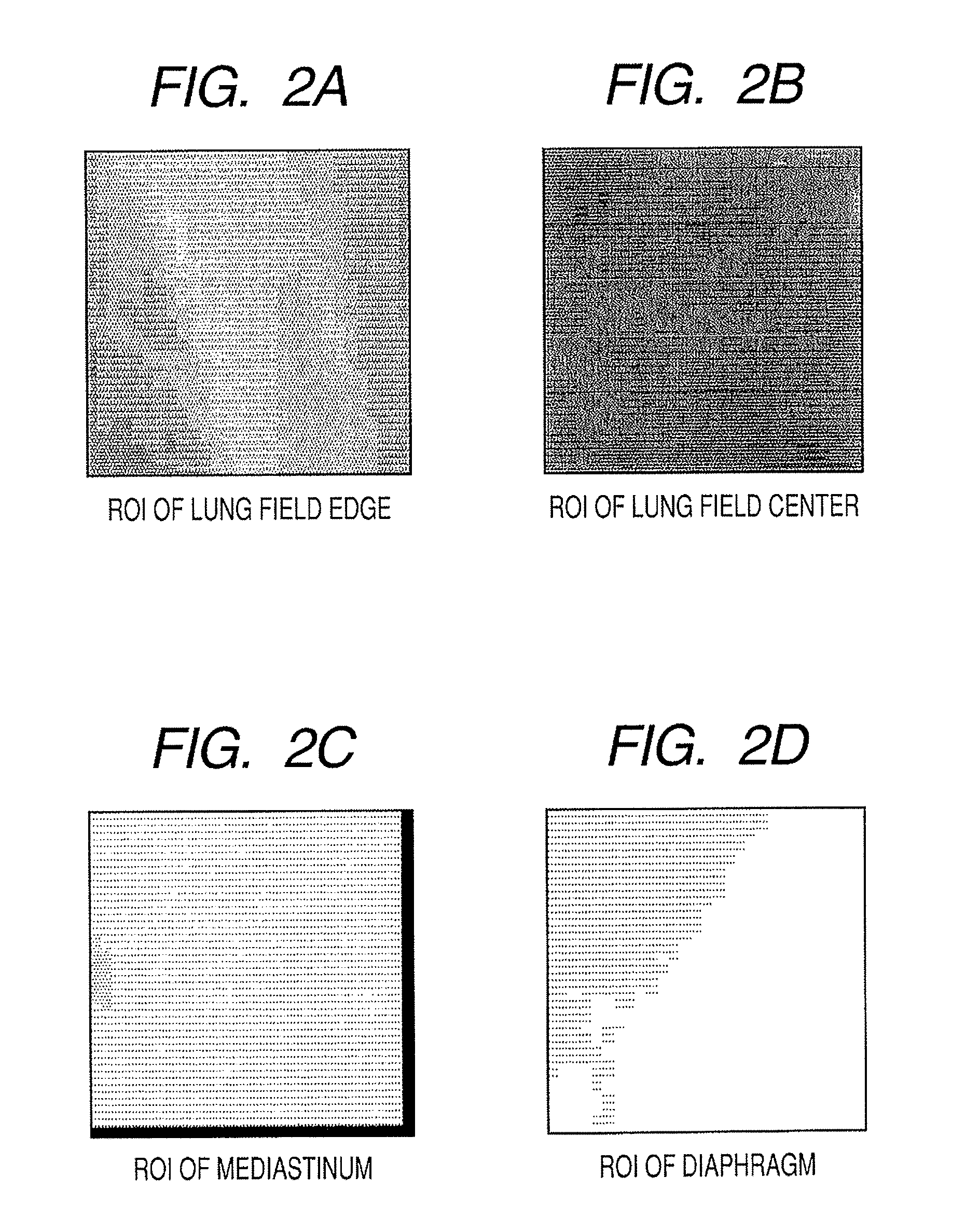

Image Processing Device And Method Which Use Two Images

ActiveUS20070260137A1Increase speedReduce misregistrationImage enhancementTelevision system detailsImaging processingShift vector

The present invention aims to provide image processing device and method capable of generating a difference image at high speed without occurring misregistration. To achieve this, in the image processing device and method, plural regions of interest are set respectively to input first and second images, a shift vector indicating a misregistration amount between the first and second images is calculated with respect to each of the regions of interest, a filter process is executed to the shift vector, the filter-processed shift vector is interpolated, the first and second images are registered based on the interpolated shift vector, and a subtraction operation is executed between corresponding pixels on the respective registered images to acquire the difference image.

Owner:CANON KK

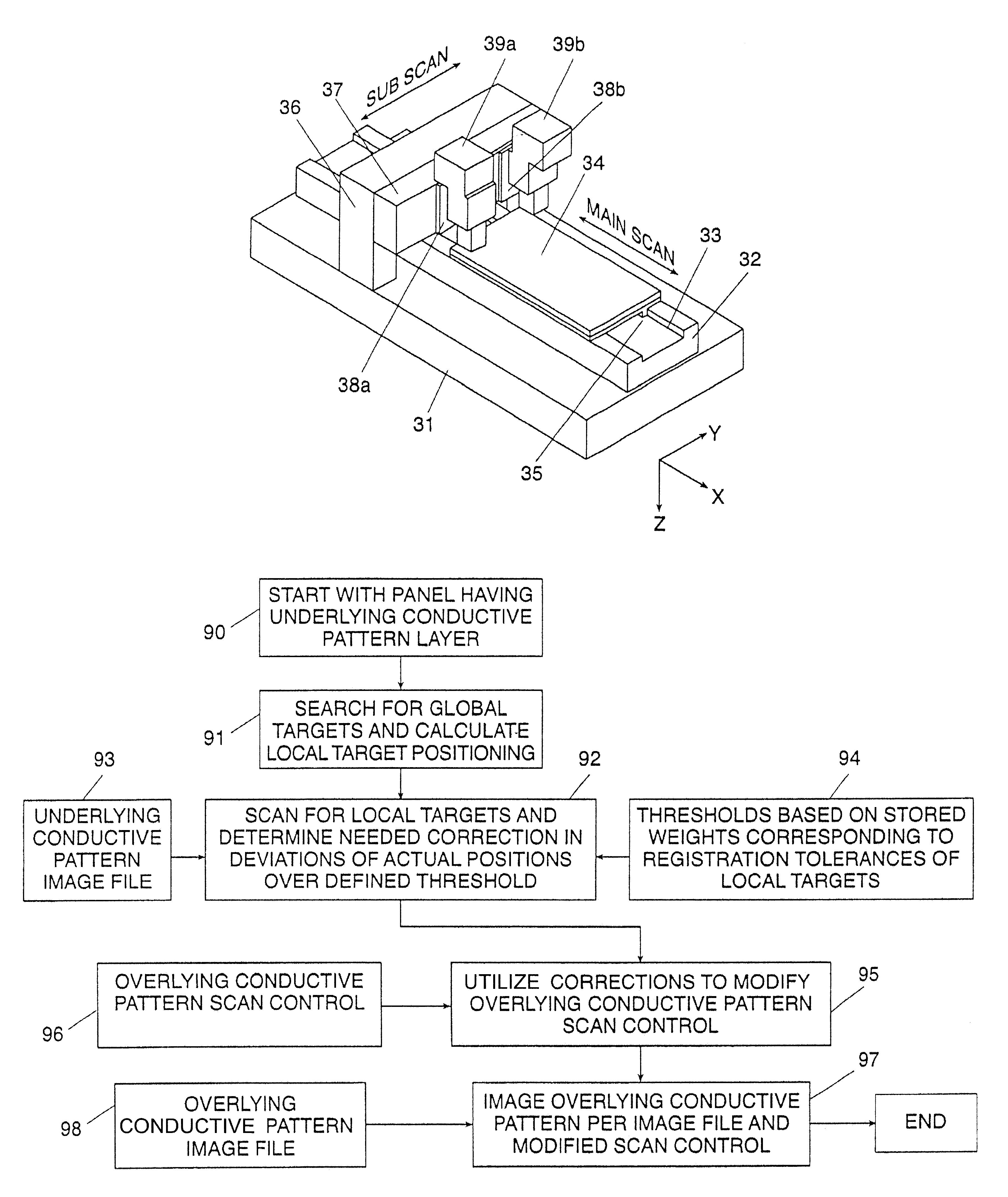

Method and apparatus for registration control in production by imaging

InactiveUS6493064B2Reduce misregistrationPrinted circuit aspectsCircuit board tools positioningControl dataEngineering

A method and apparatus for imaging an overlying conductive pattern over an underlying conductive pattern on a substrate, by determining deviations between the actual locations and the nominal locations of predetermined reference targets in the underlying conductive pattern on the substrate; and utilizing the determined deviations for modifying the scanning control data used for imaging the image data of the overlying conductive pattern in order to reduce misregistration thereof with respect to the underlying conductive pattern. Preferably, the reference targets are predetermined connection sites in the underlying conductive pattern to be precisely located with respect to connection sites in the overlying conductive pattern. The reference features may be assigned different weights according to their registration importance, and the deviations may be determined according to a threshold which varies with the weight assigned to the respective reference feature.

Owner:KODAK IL

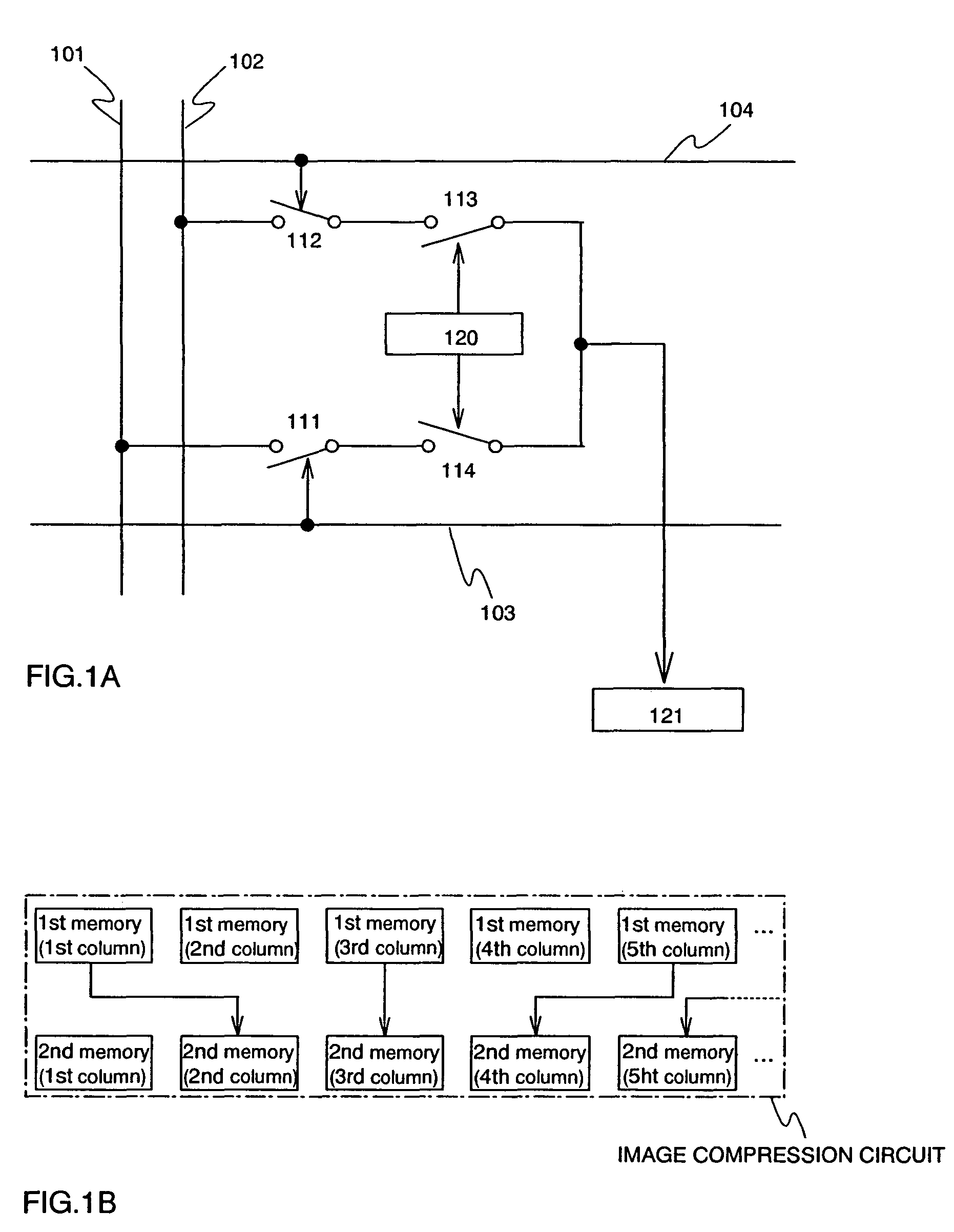

Display device and method of driving the same

InactiveUS7696952B2Reduce malfunctionReduce misregistrationCathode-ray tube indicatorsDisplay deviceComputer science

In a multi-window display device, the following has been merely performed: before data for plural screens is inputted to a display, video signals themselves are subjected to signal processing, and the processed video signals are inputted to the display, whereby display is performed. Therefore, a circuit for performing signal processing, for example, an IC has a complicated structure since video signals for plural screens are stored in a memory. There is provided a pixel structure in which: signal lines for plural screens are arranged; and one of the signal lines is selected to supply a video signal to a display element. For example, in the case of performing display of two screens, there is provided a pixel structure in which: two signal lines, which are inputted with respective video signals for a first screen and a second screen, are arranged; and one of the signal lines is selected to supply a video signal from the selected signal line to a display element.

Owner:SEMICON ENERGY LAB CO LTD

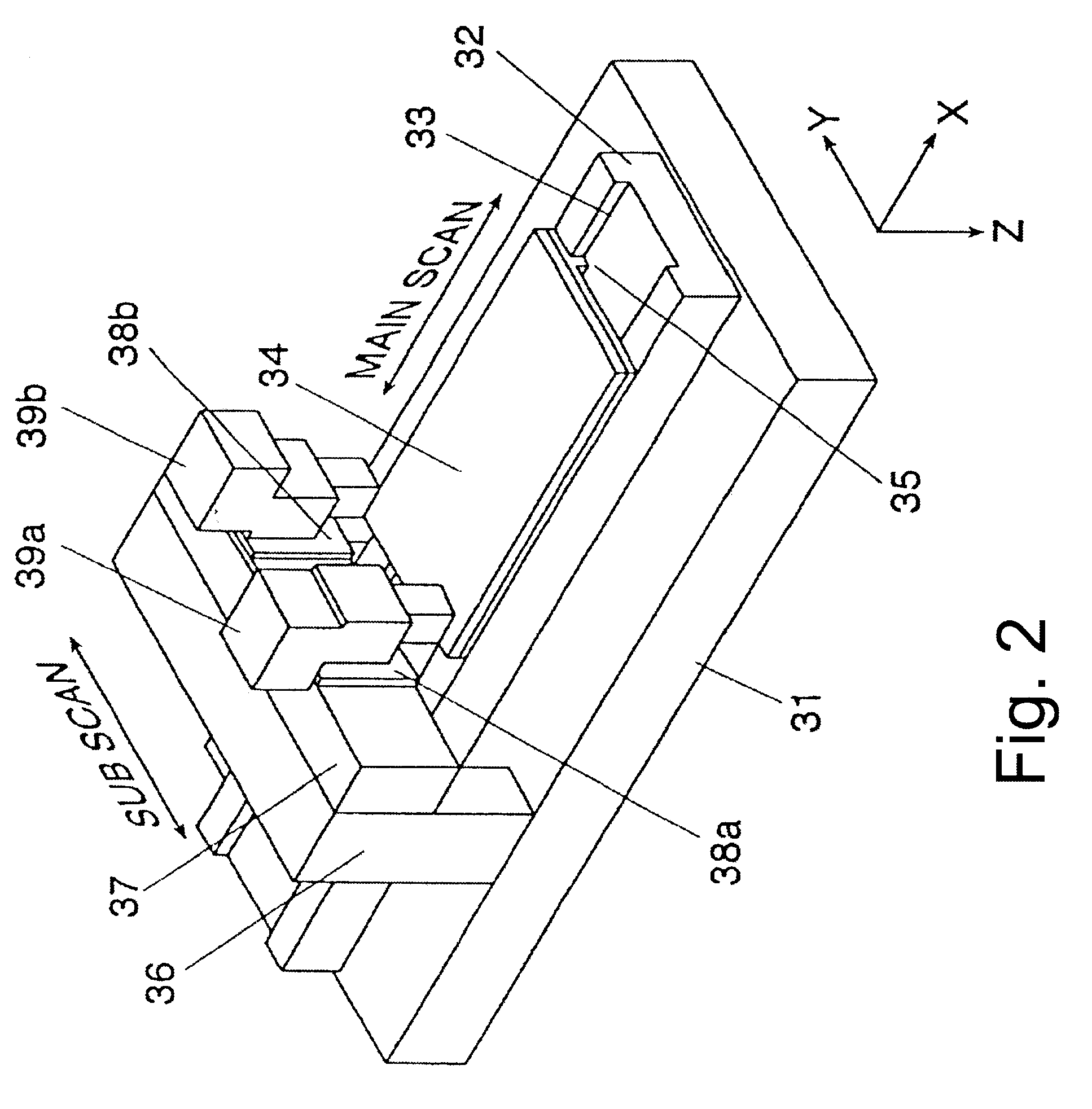

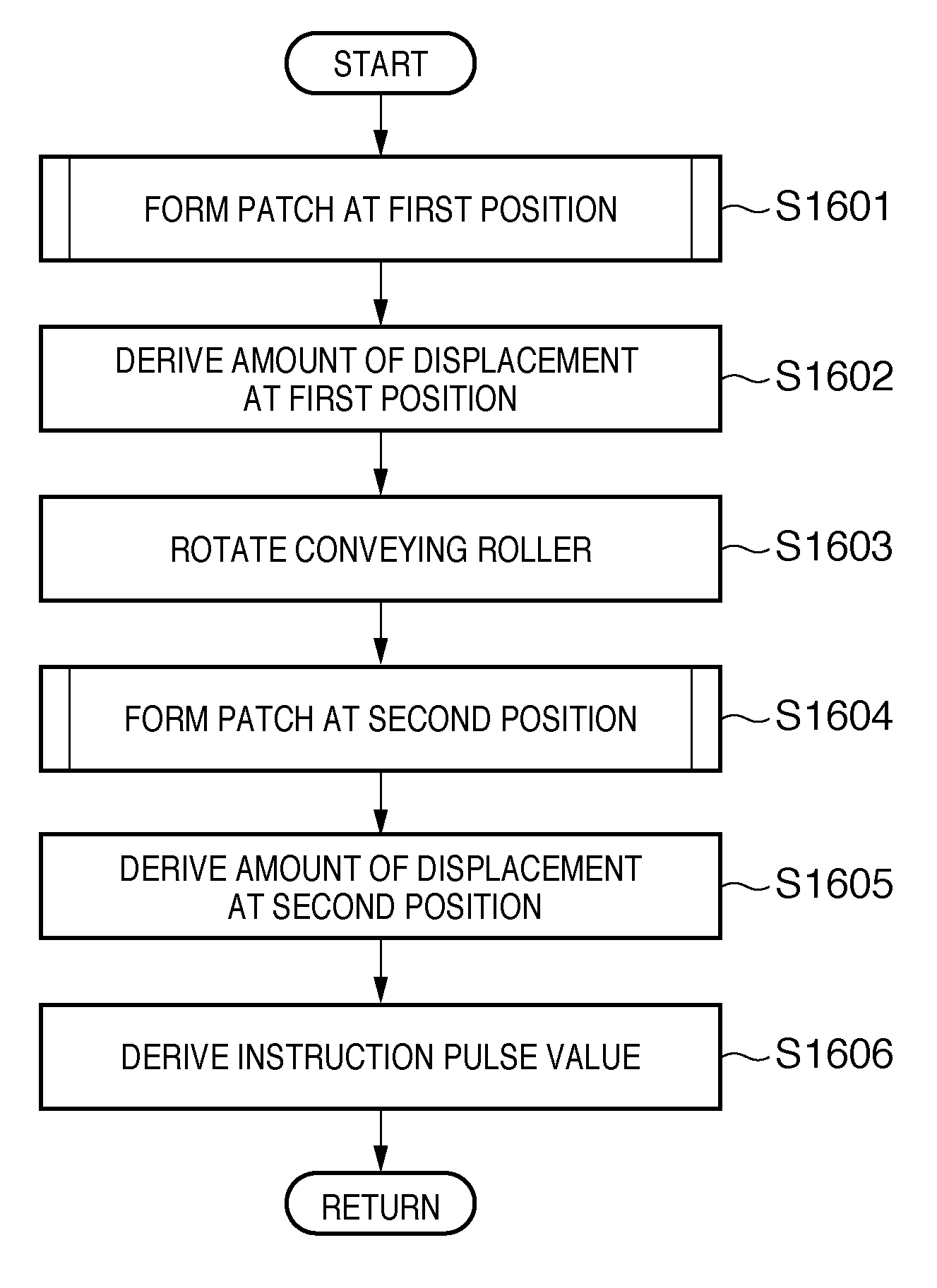

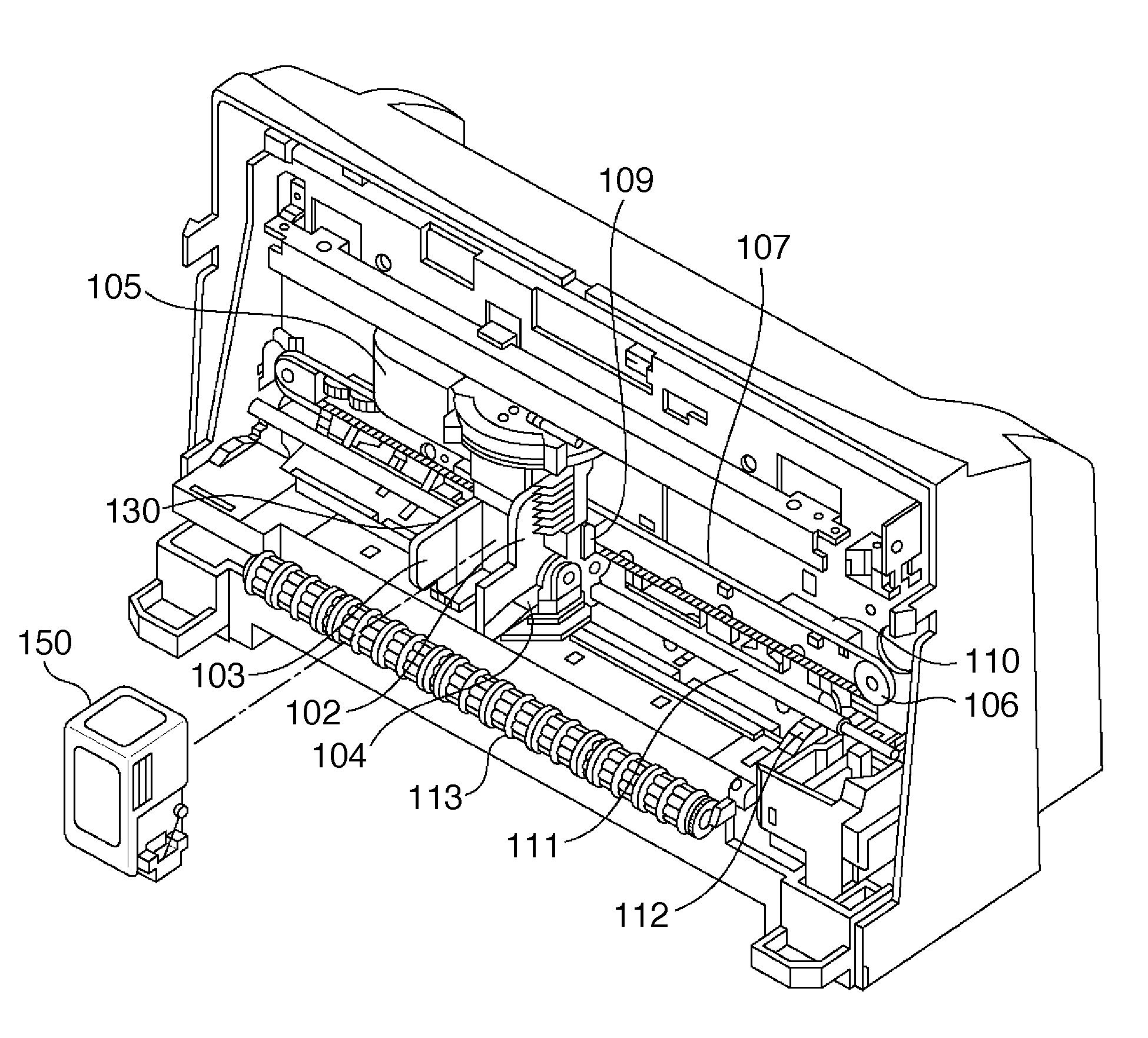

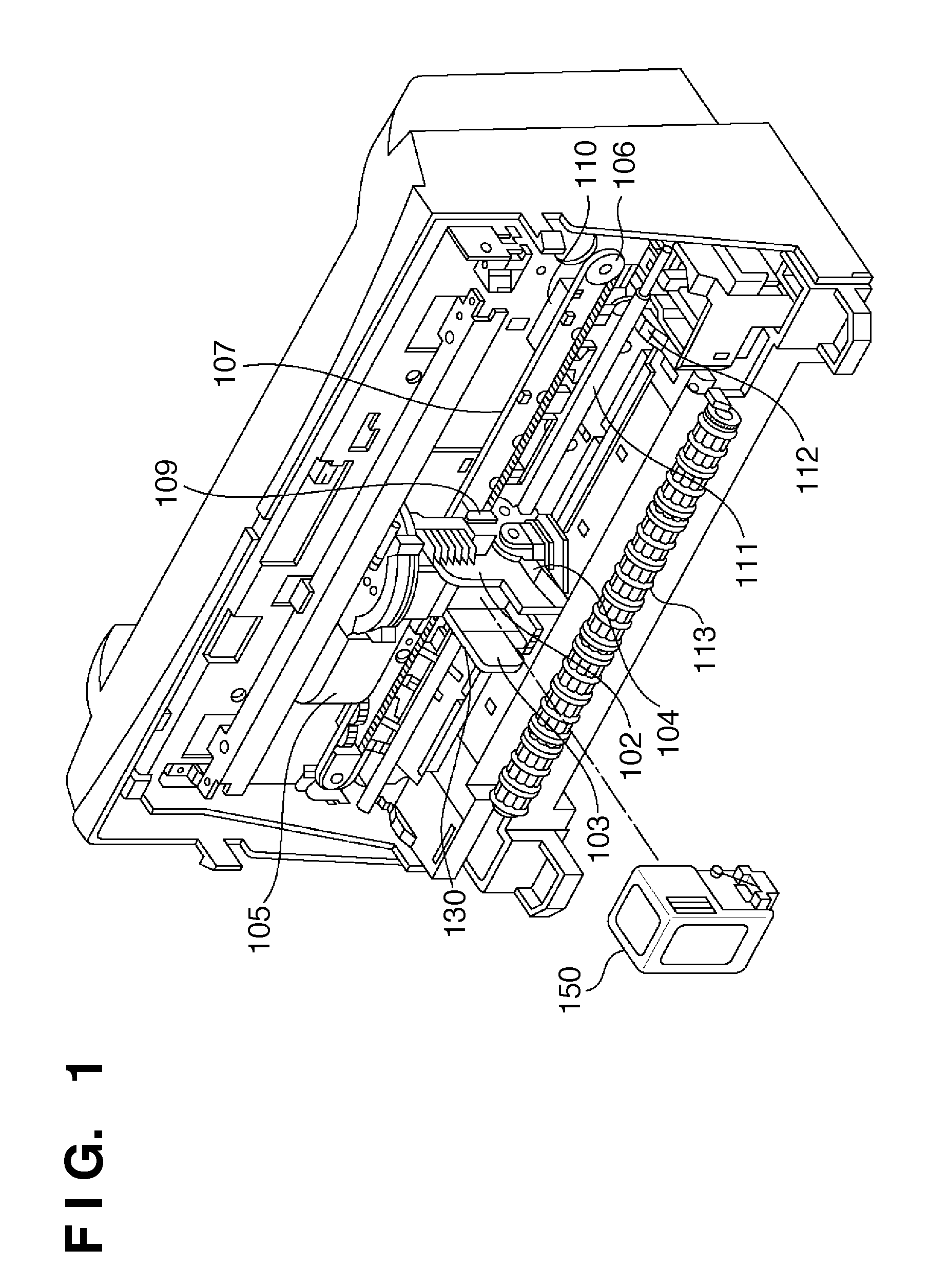

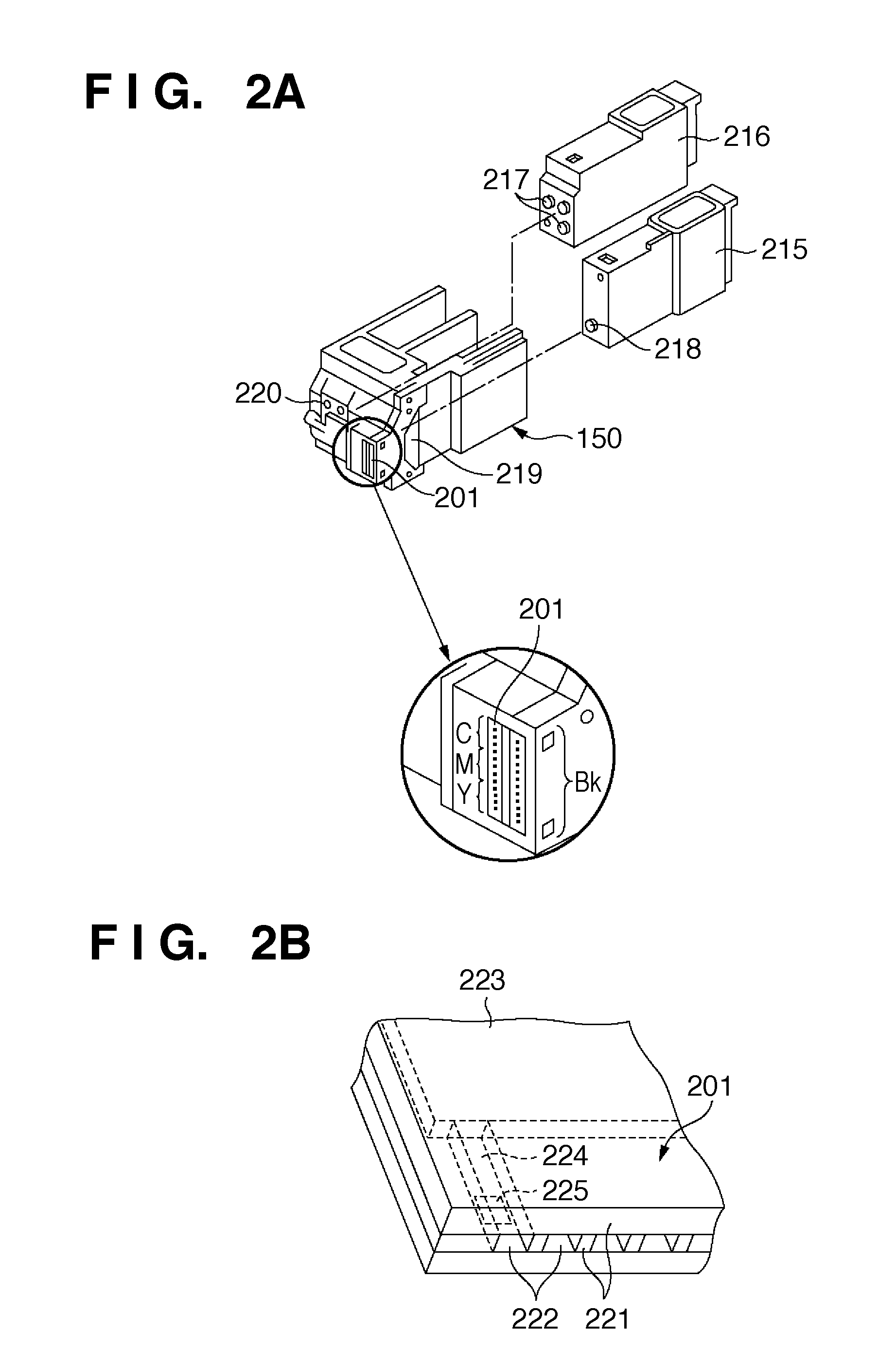

Printing apparatus and printing method

InactiveUS20090237437A1Reduce misregistrationOther printing apparatusEngineeringElectrical and Electronics engineering

Owner:CANON KK

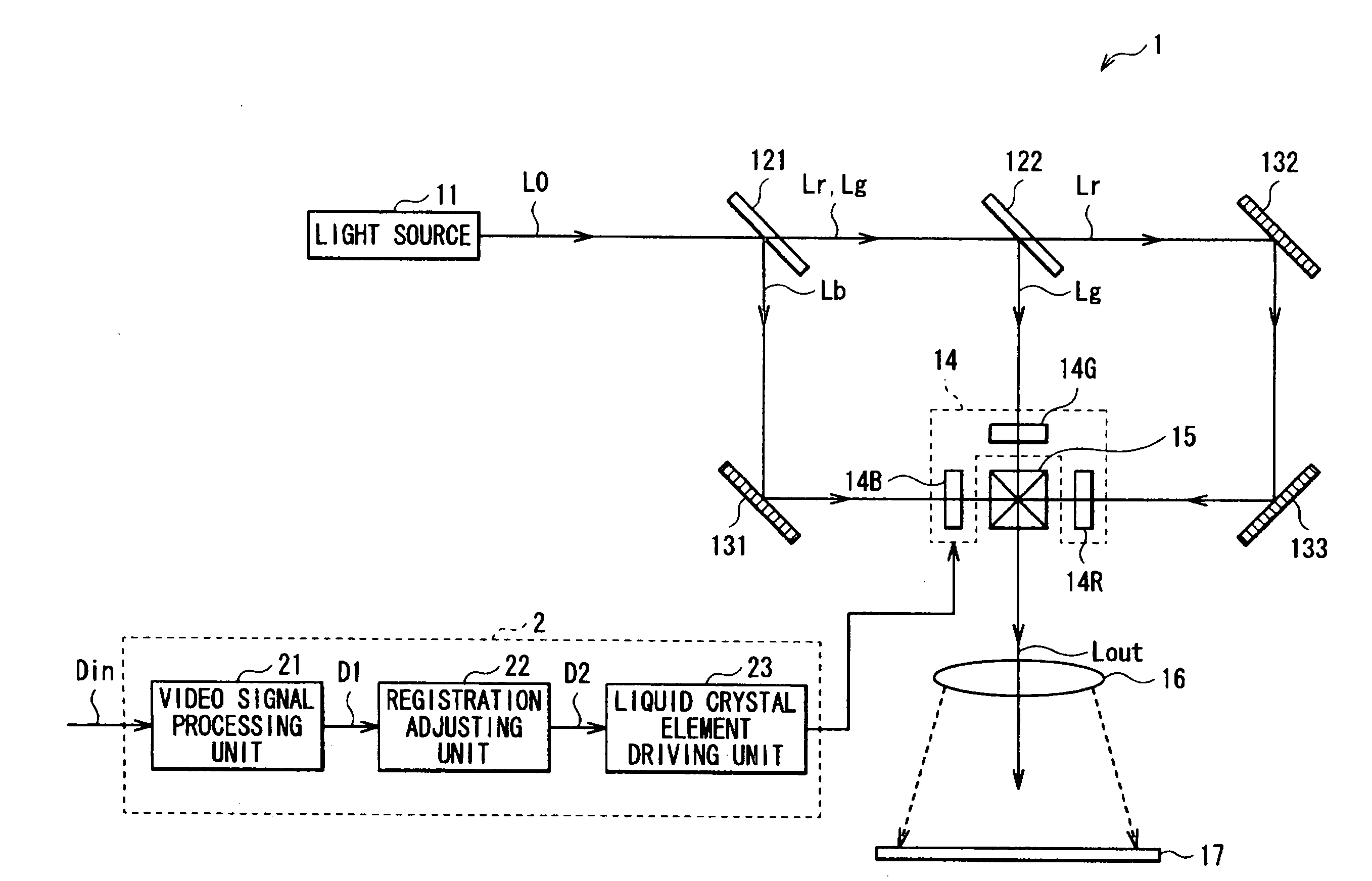

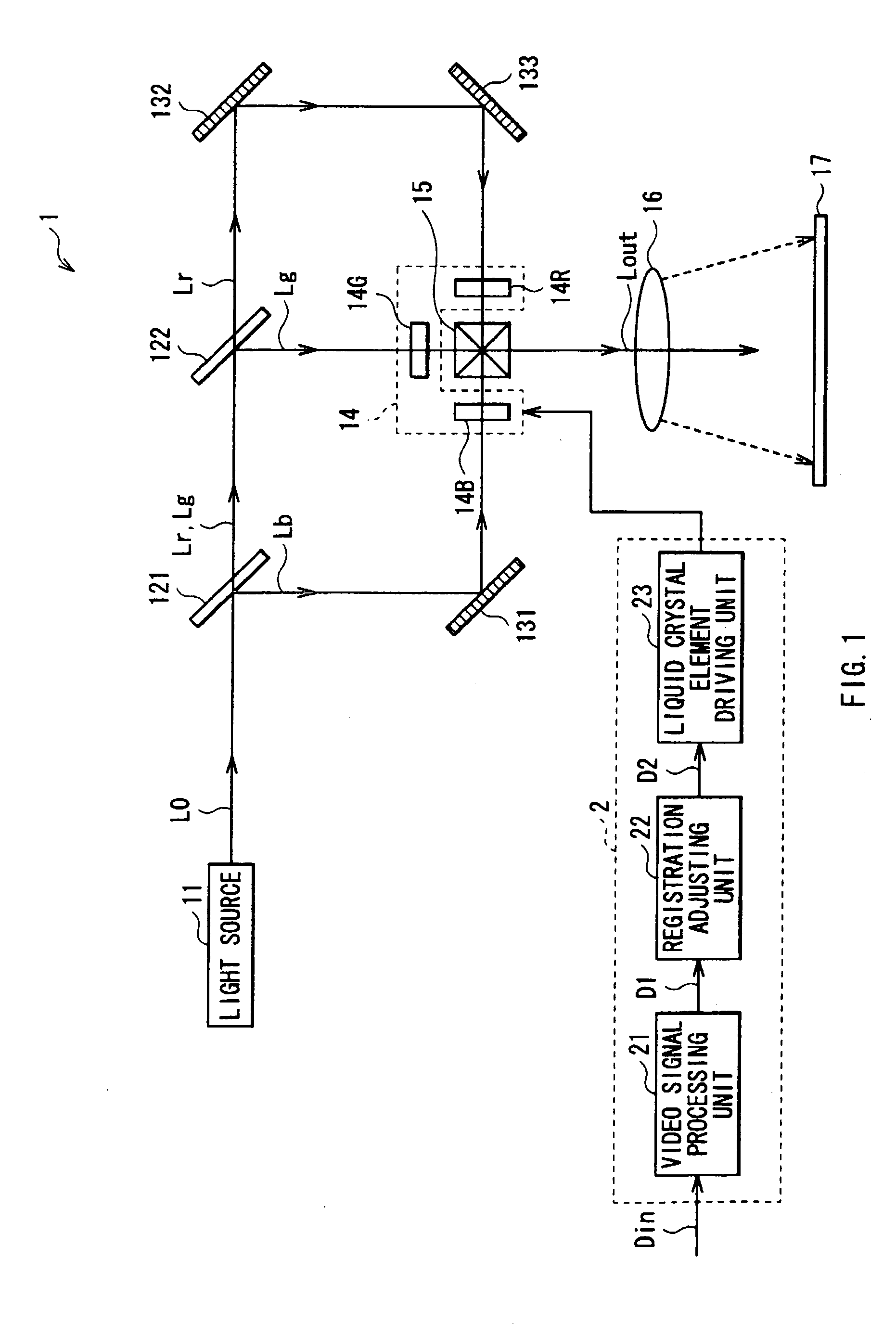

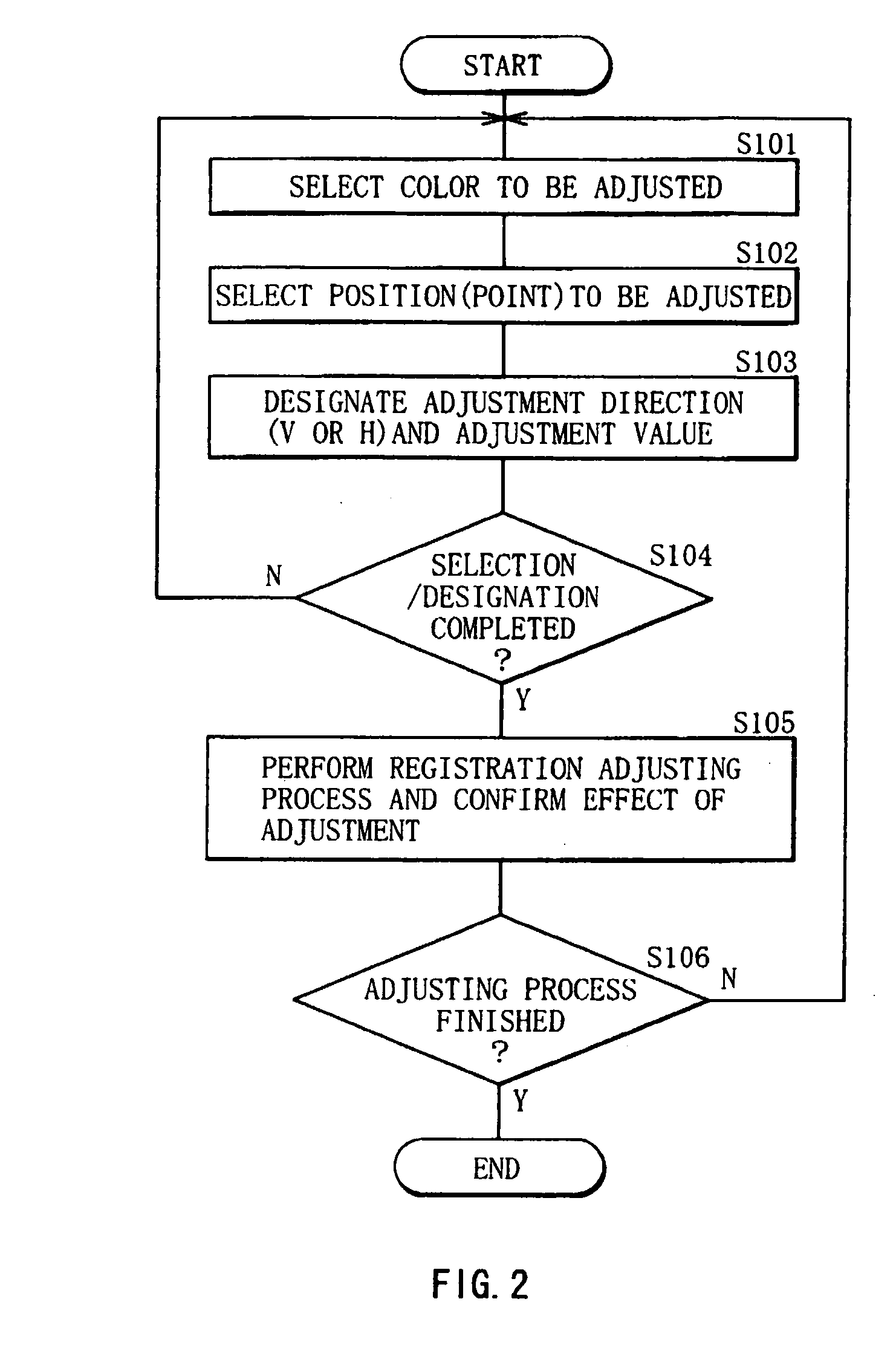

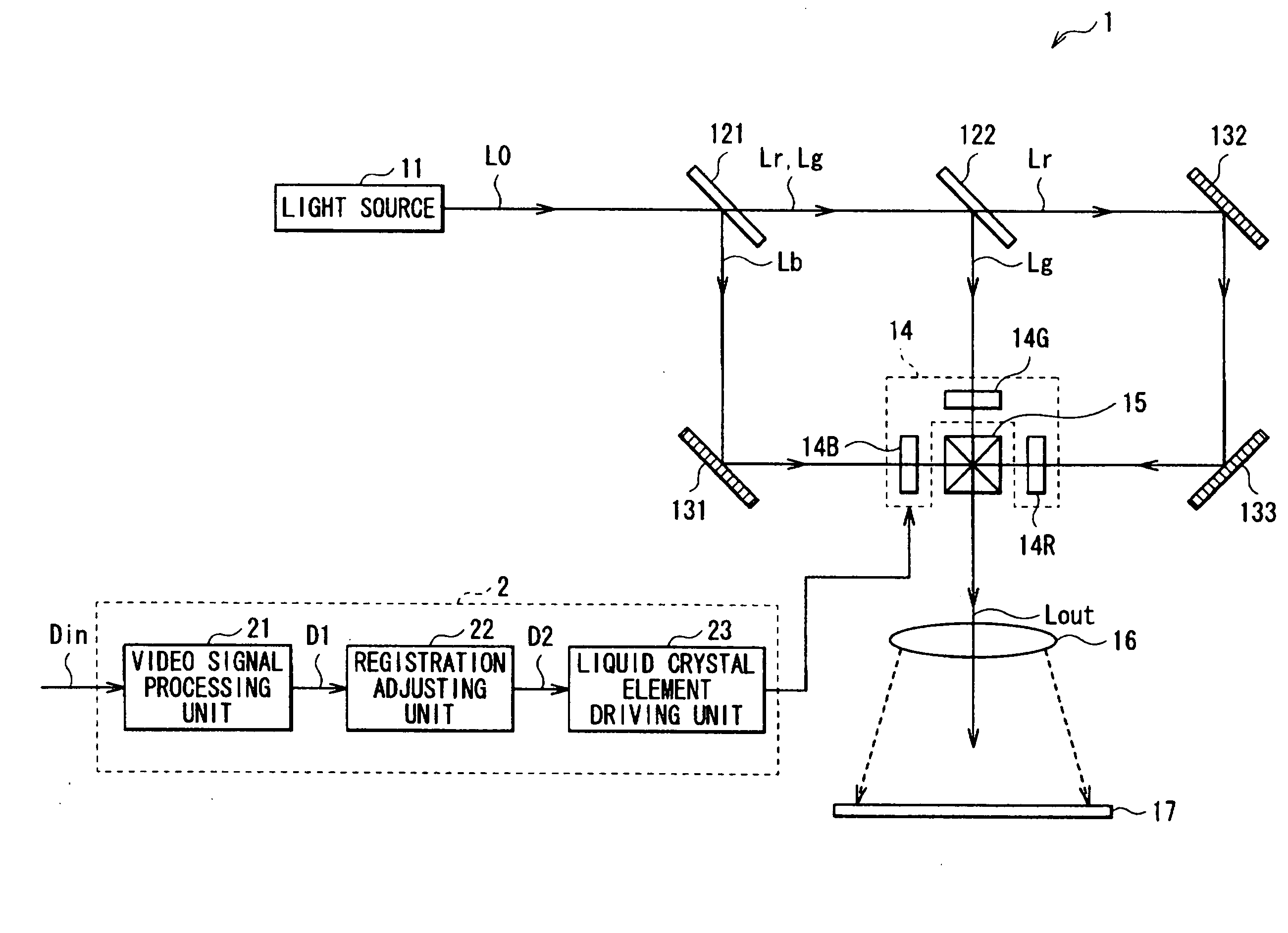

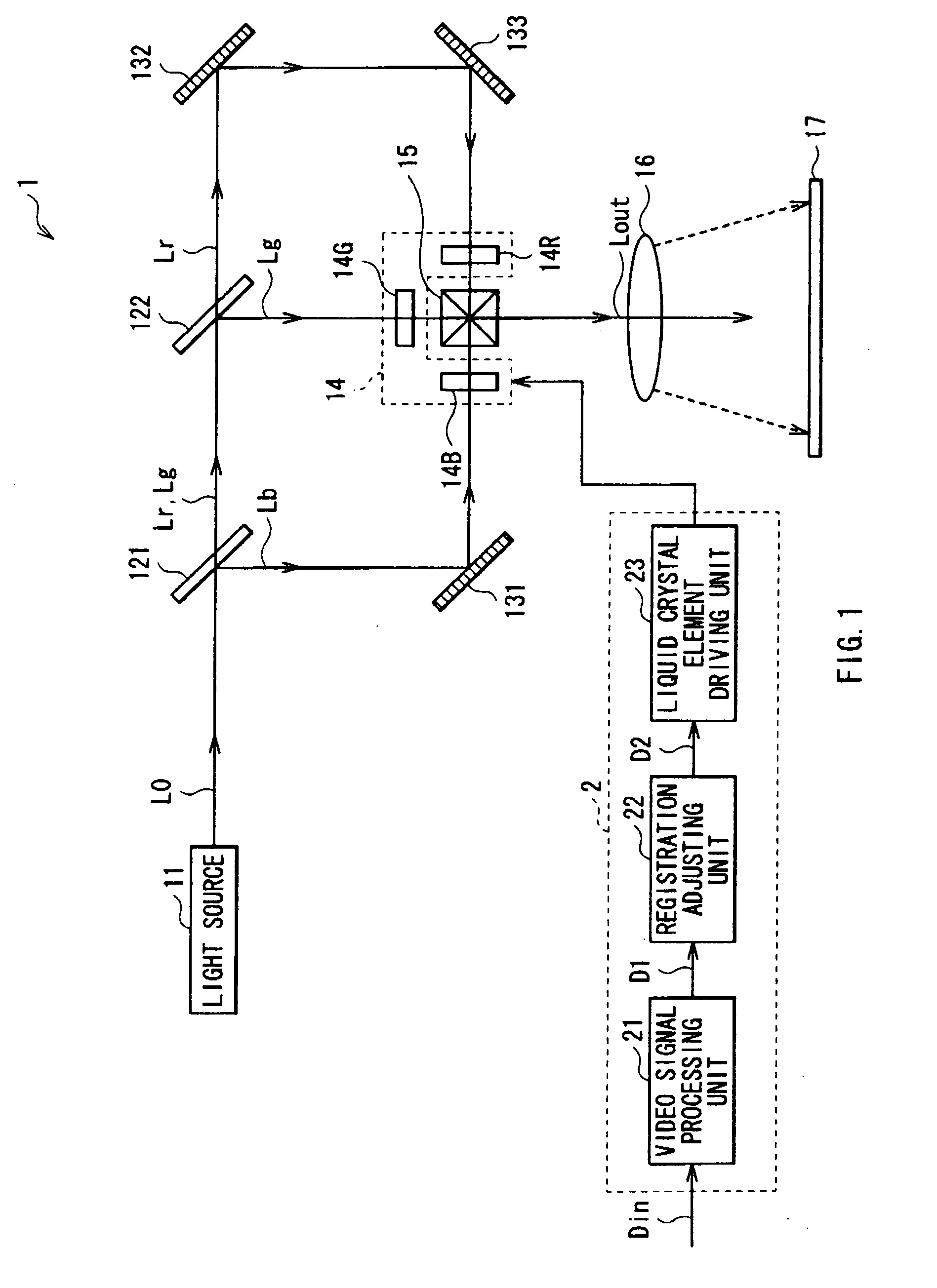

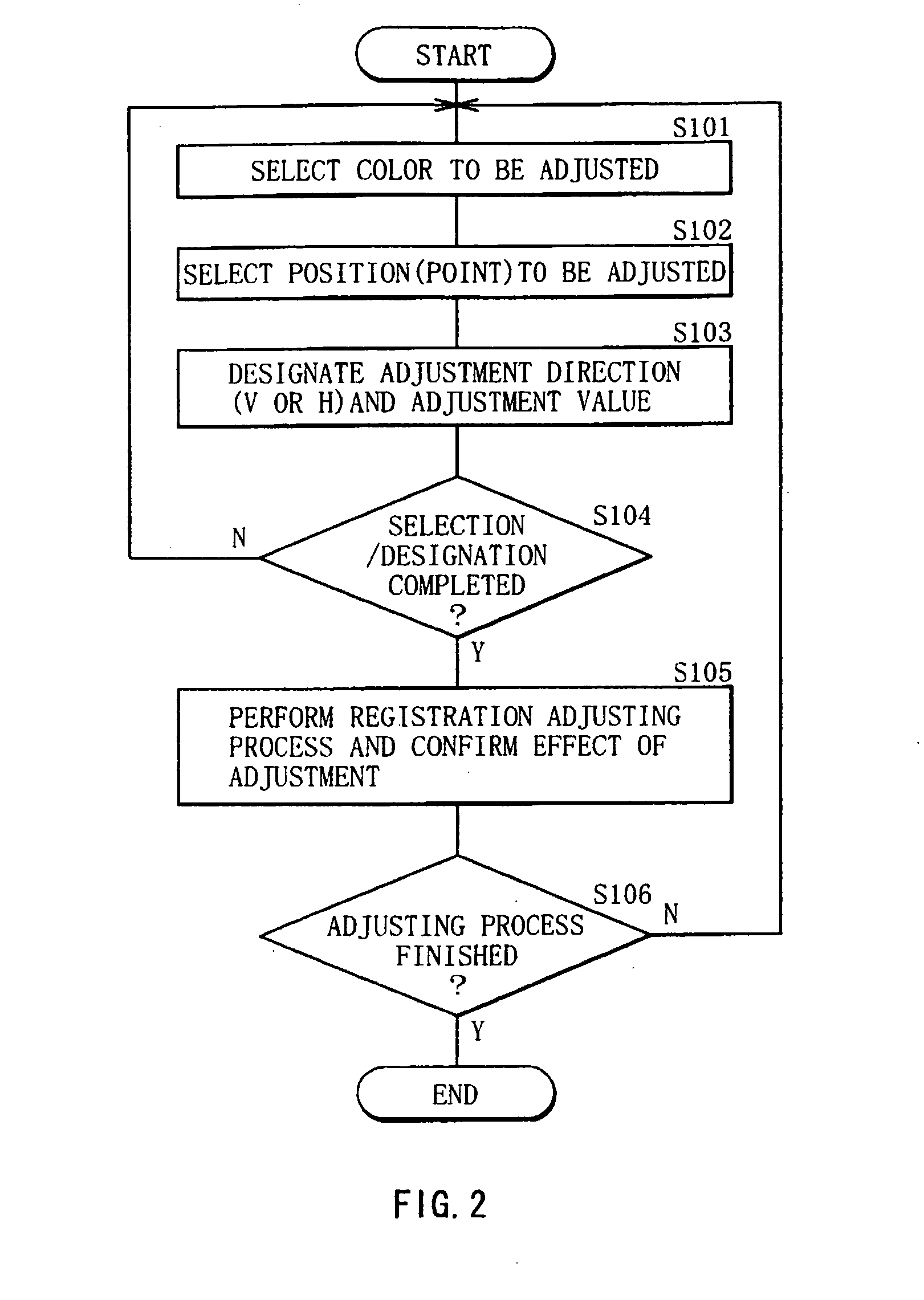

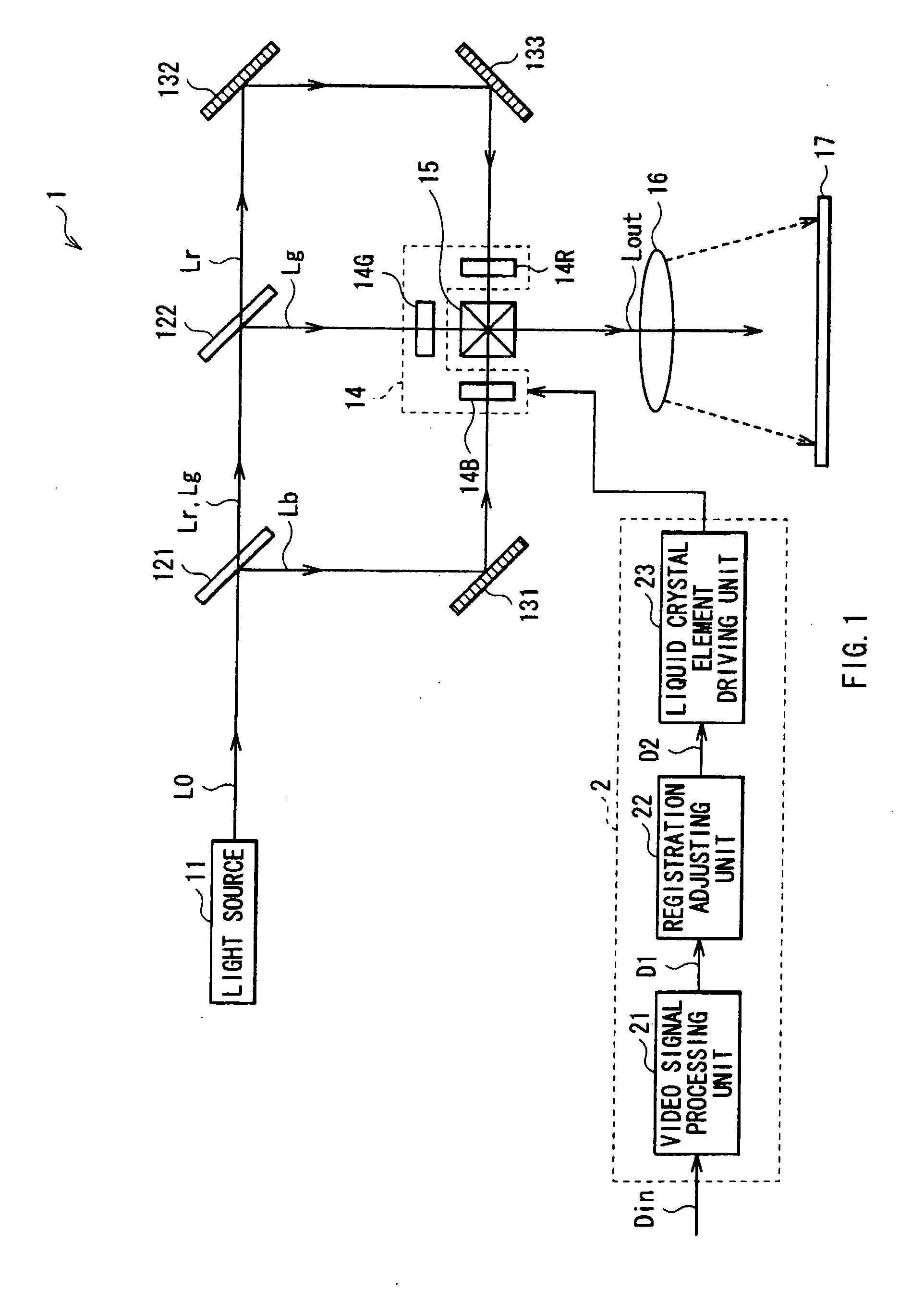

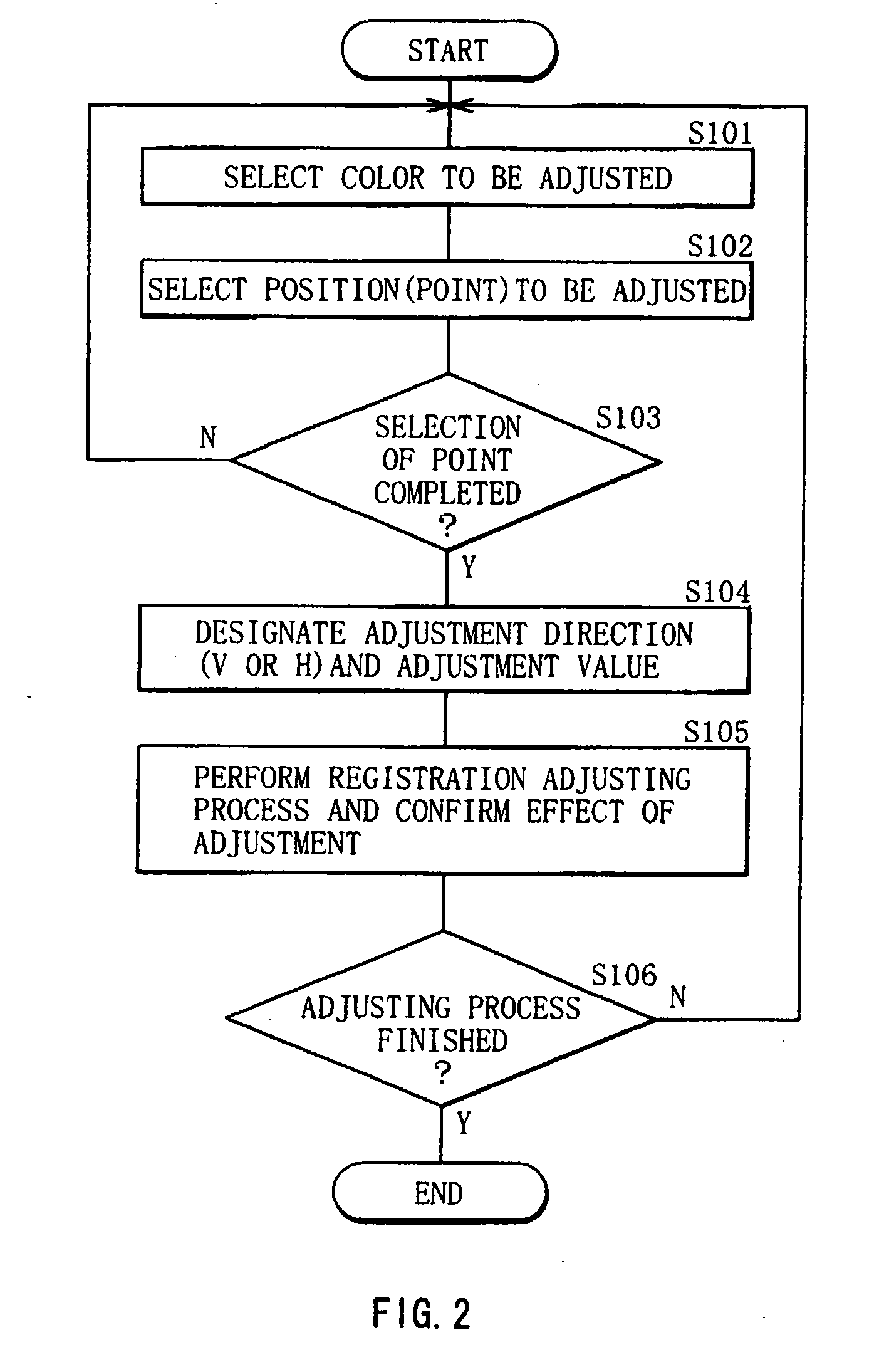

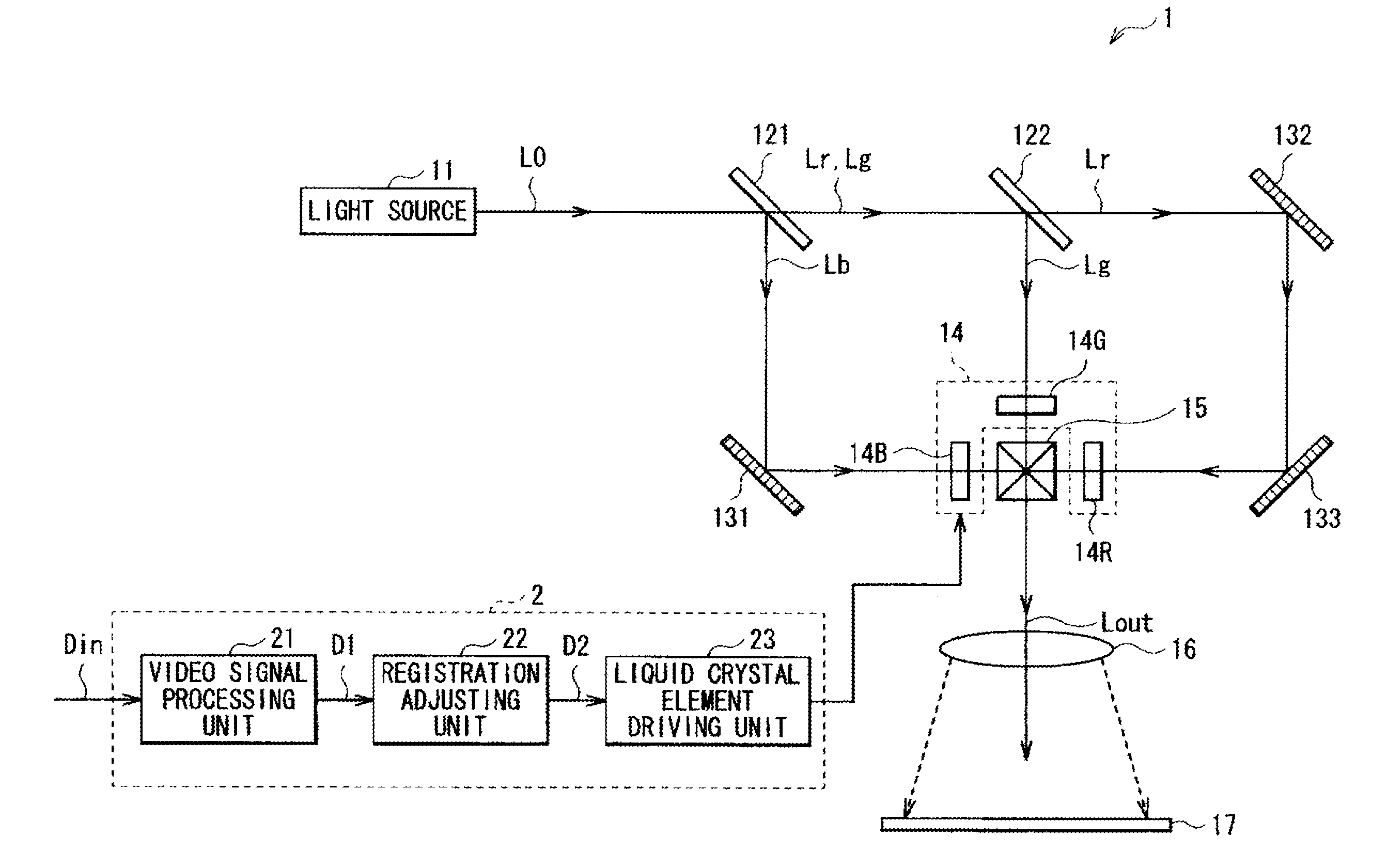

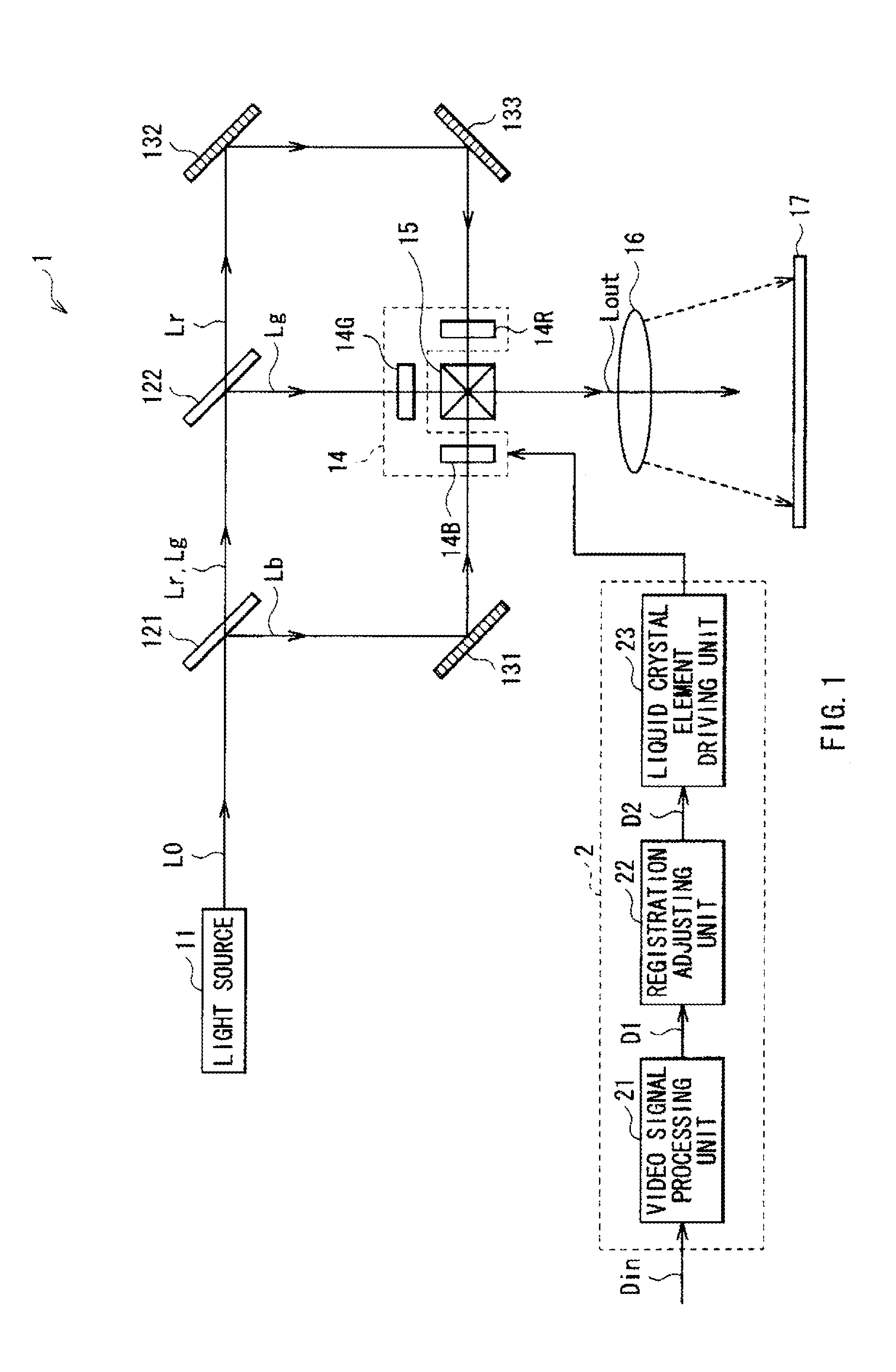

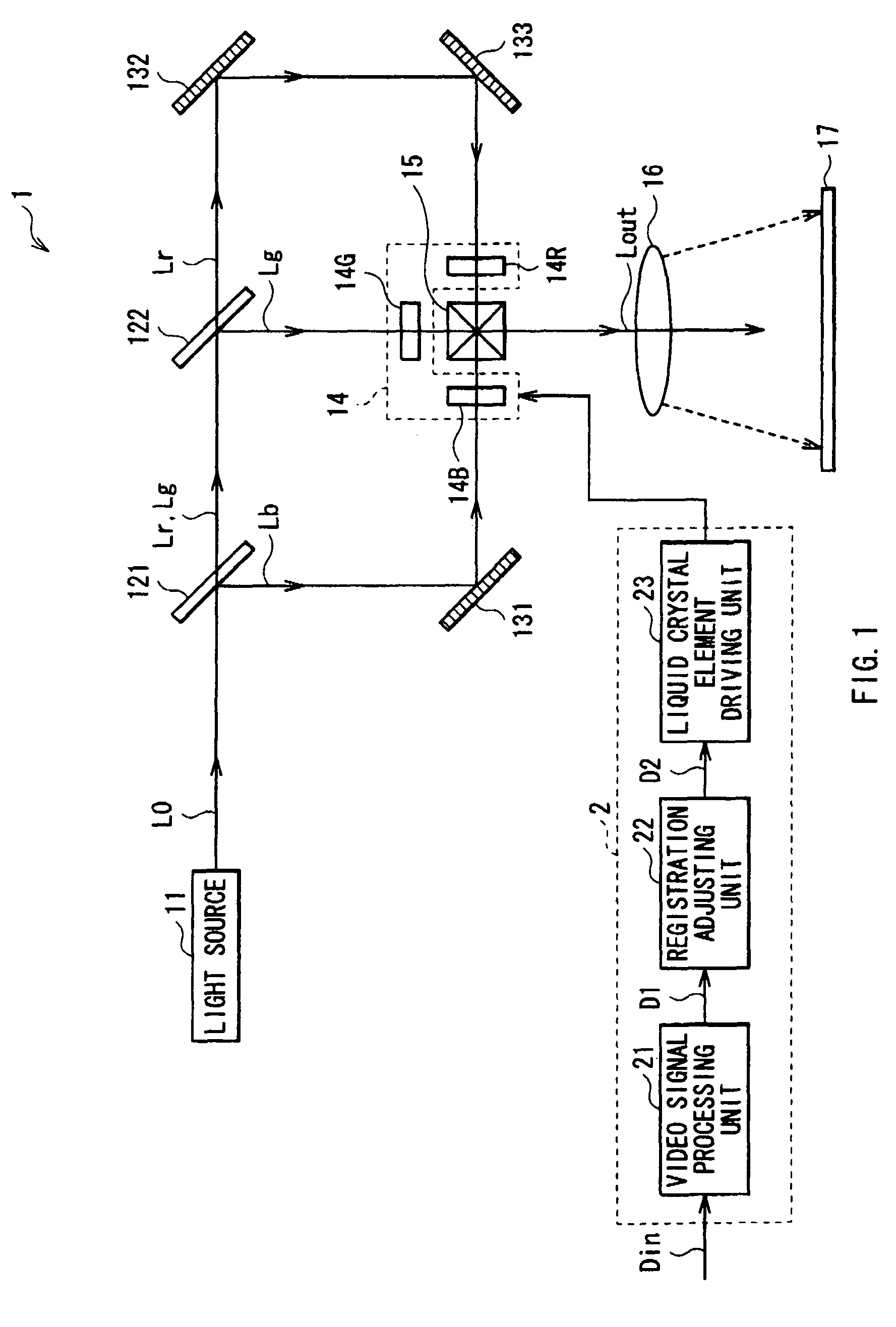

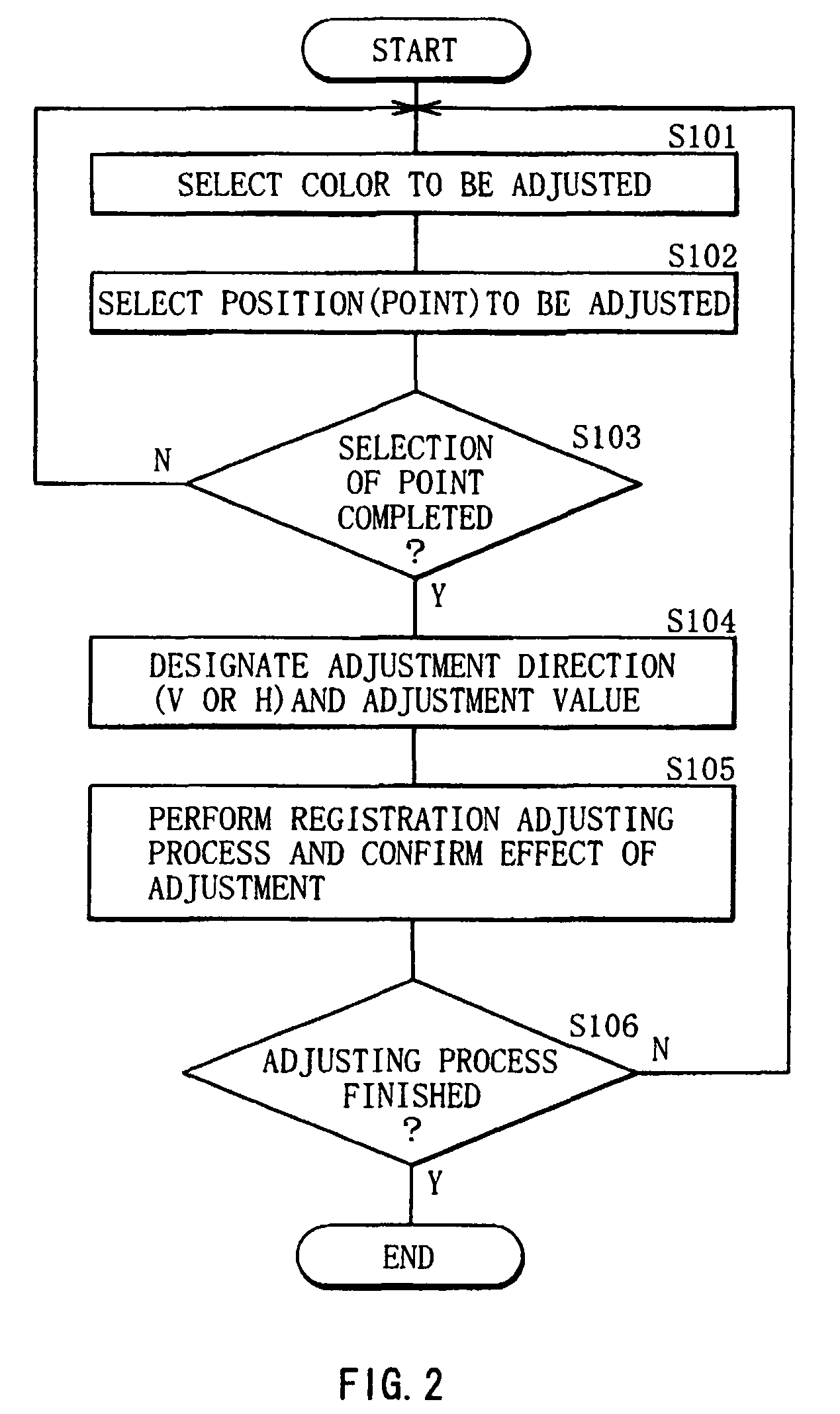

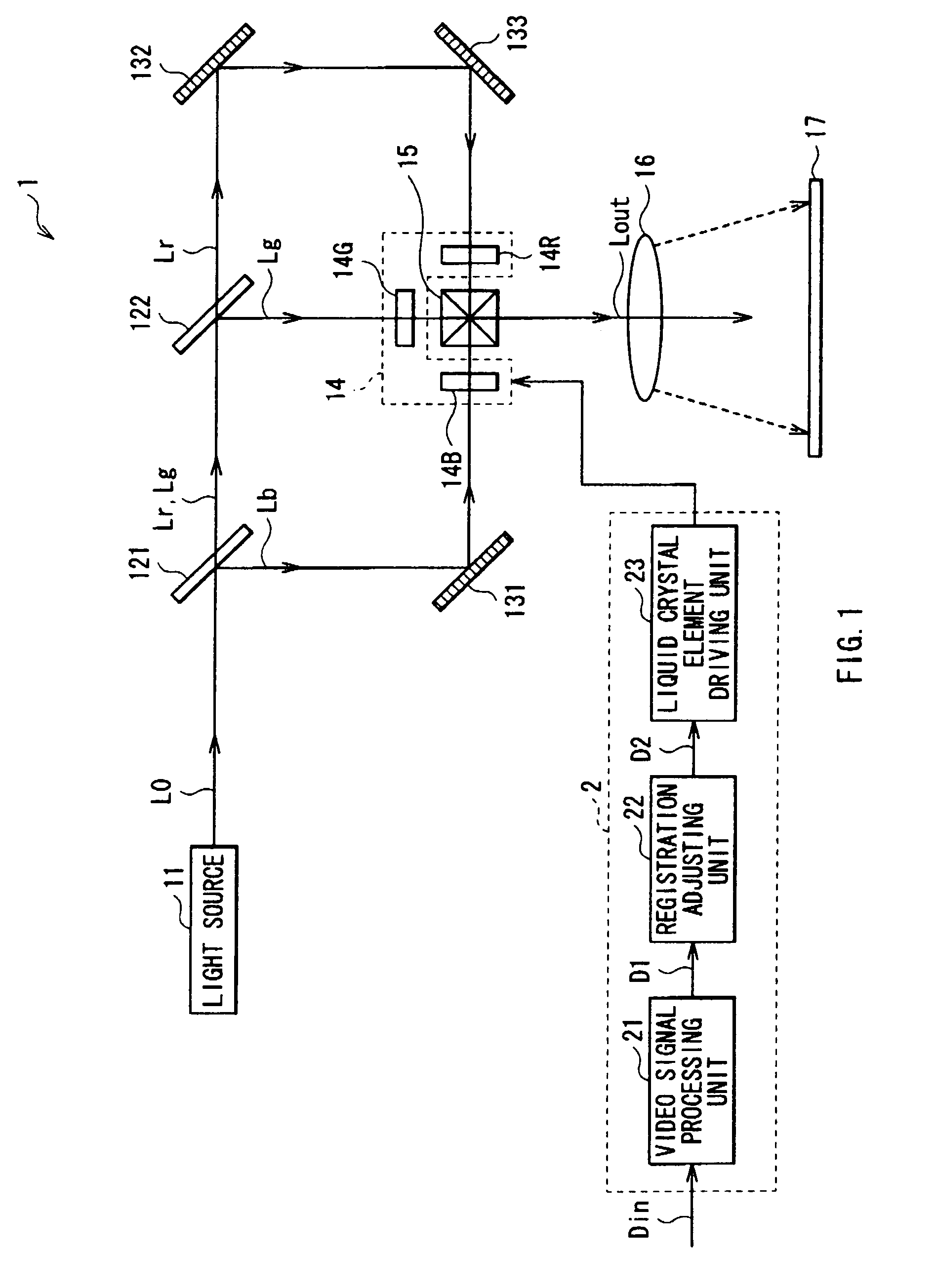

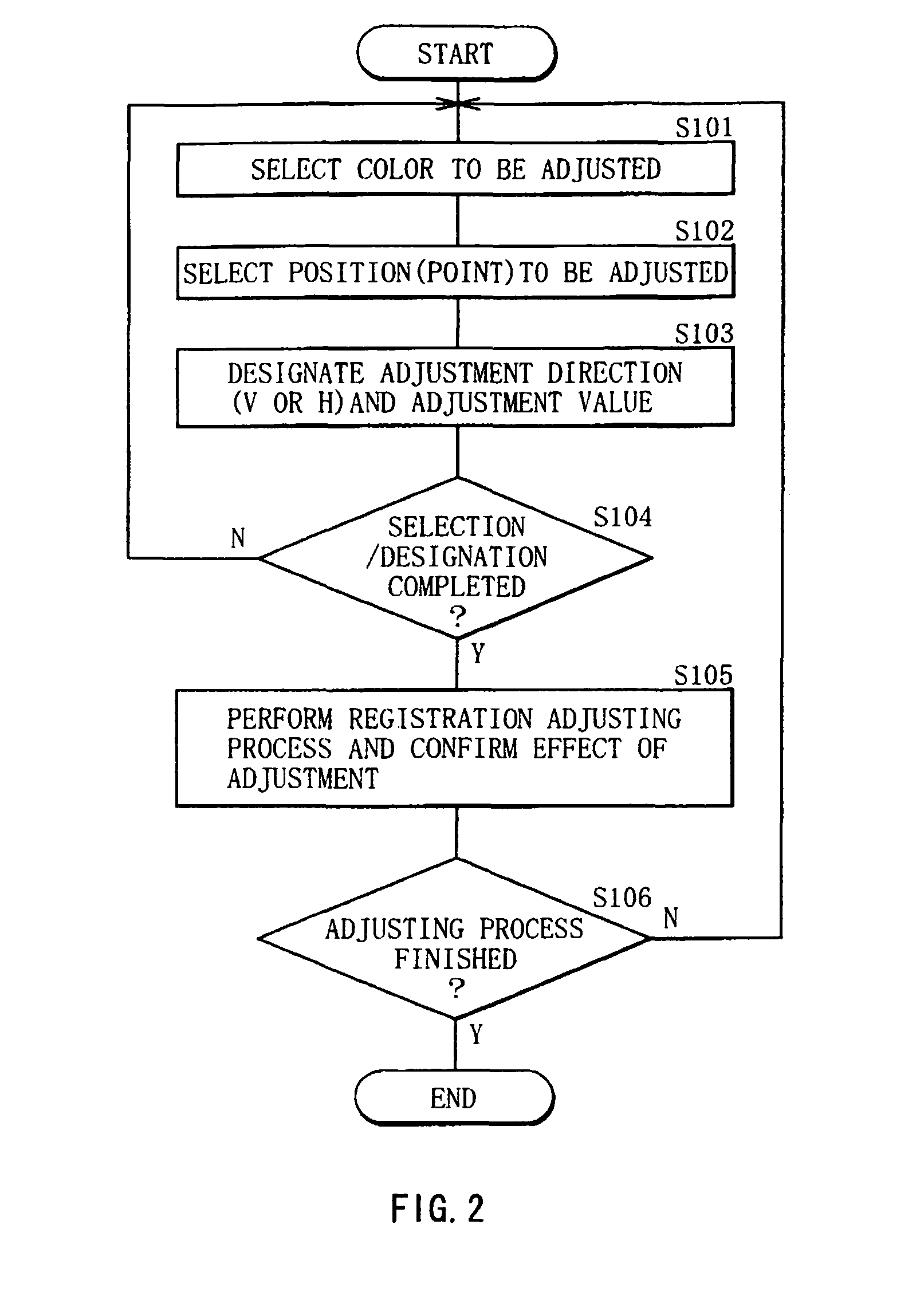

Projection display apparatus

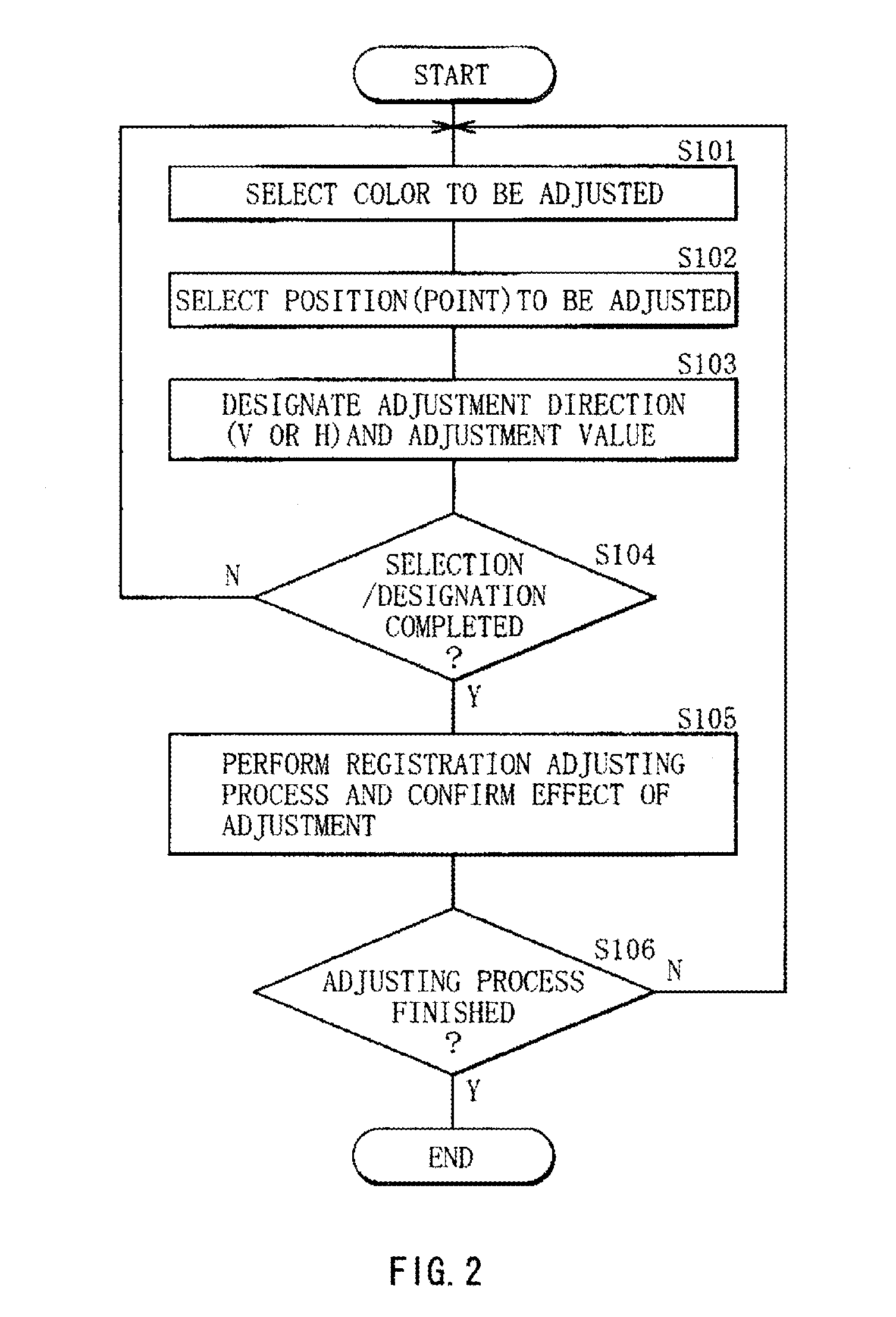

ActiveUS20090027569A1Reduce misregistrationImprove display qualityTelevision system detailsTelevision system scanning detailsComputer graphics (images)Projection display

The present invention provides a projection display apparatus realizing improved operability at the time of registration adjustment irrespective of a use situation of the apparatus. In the case where misregistration occurs between primary color lights, video signals for three colors are corrected (registration adjustment is performed) so as to reduce the misregistration in accordance with an input adjustment value. An image inverting process is performed on an input video signal so that the image is inverted in a display screen. By a configuration by the user, the image is properly inverted in the display screen. When the image inverting process is performed, an adjustment value, with a sign different from that in the misregistration direction in a coordinate system where the image is not inverted, is input by an operation on the display screen.

Owner:SONY CORP

Method for carrying out digitalized spray printing through water-free type three-spraying integrated process

InactiveCN104512139AAvoid damageReduce misregistrationDuplicating/marking methodsFibre treatmentSprayerWastewater

The present invention discloses a method for carrying out digitalized spray printing through a water-free type three-spraying integrated process. According to the method, three groups of sprayers are controlled to carry out superimposed spray printing of different spray printing components on a fabric so as to achieve the three-spraying integrated spray printing of the fabric. The technical scheme of the present invention are that: a pre-treatment liquid, an ink, a post-finishing liquid and other spray printing components are respectively filled in the three groups of the sprayers, and the three spray printing components are subjected to superimposed spray printing on the fabric according to a certain sequence. According to the present invention, each spray printing component is subjected to spray printing according to the requirement, only the pattern area is treated so as to effectively reduce the waste of the pre-treatment liquid and the post-finishing liquid, the positions excluding the pattern area are not affected by the pre-treatment liquid and the post-finishing liquid so as to reduce the influence of the multiply treatments on hand feeling, gas permeability and other performances of the fabric, and the three-spraying integrated spray printing integrates the three tedious processes such as the pre-treatment, the inkjet printing and the post-finishing into the one-step spray printing process so as to eliminate the multiply treatment processes adopting water as the medium, effectively shorten the fabric treatment process, and reduce the wastewater discharge.

Owner:SHANGHAI SUNRUI INNOVATION INVESTMENT

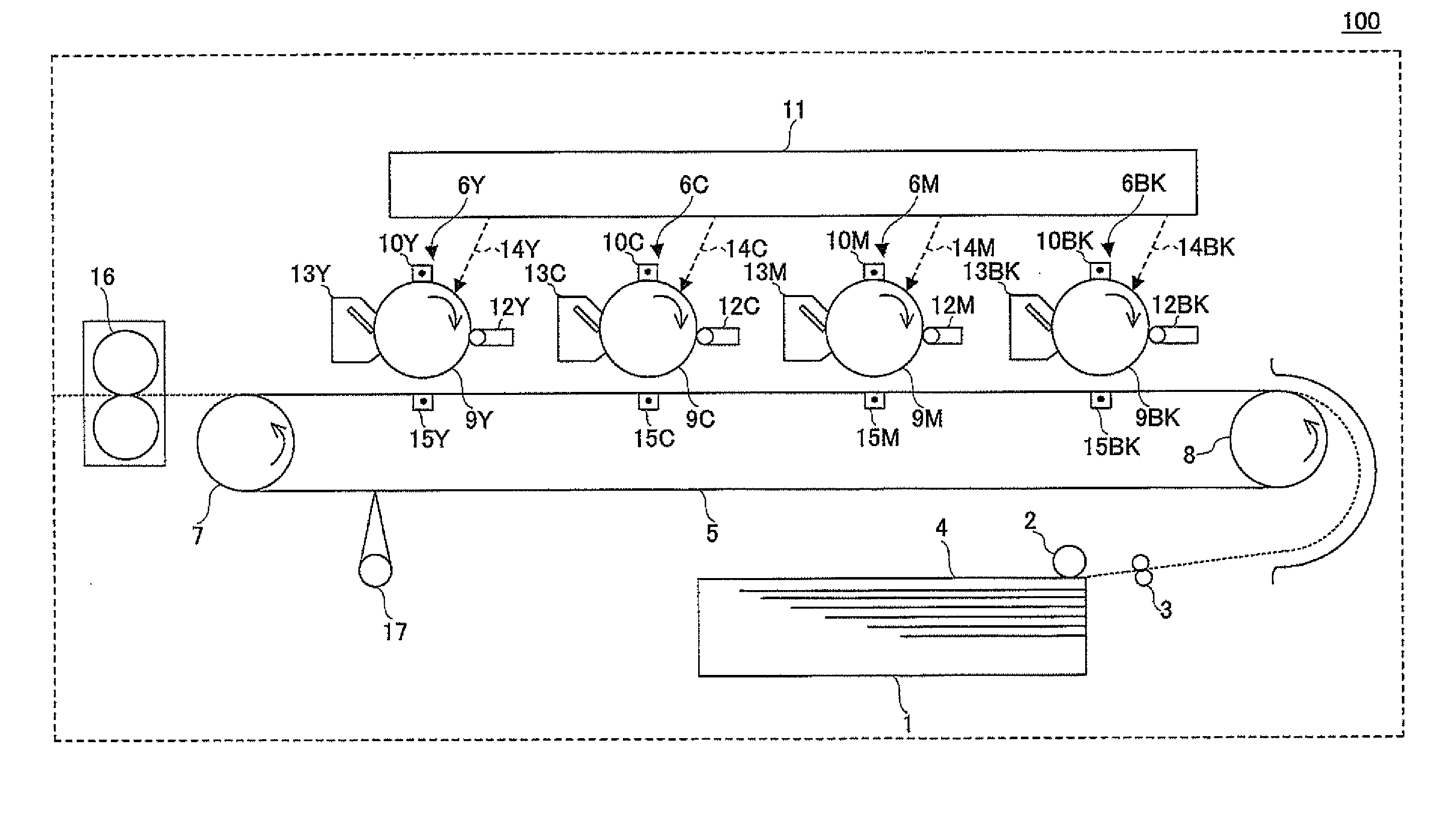

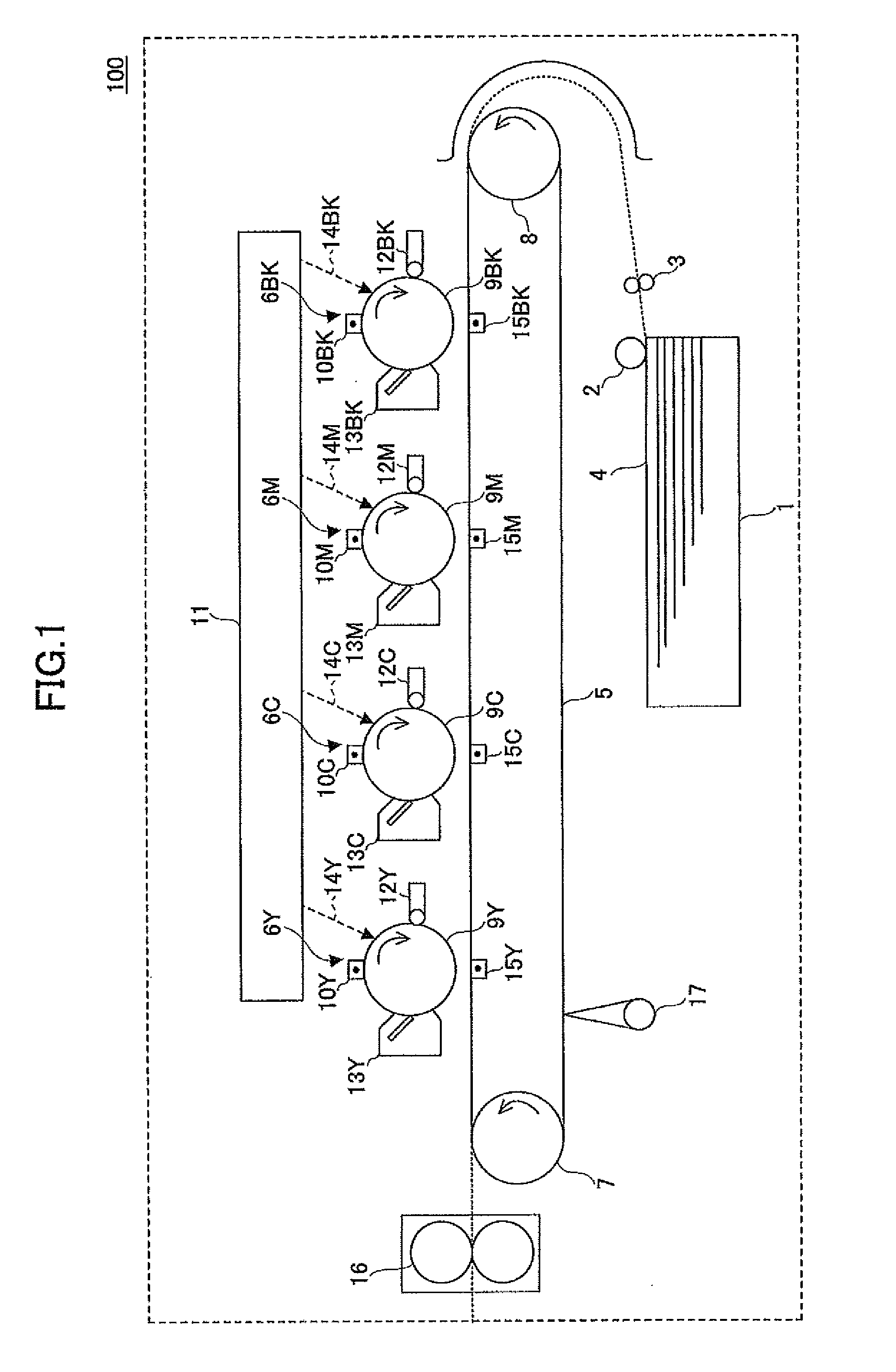

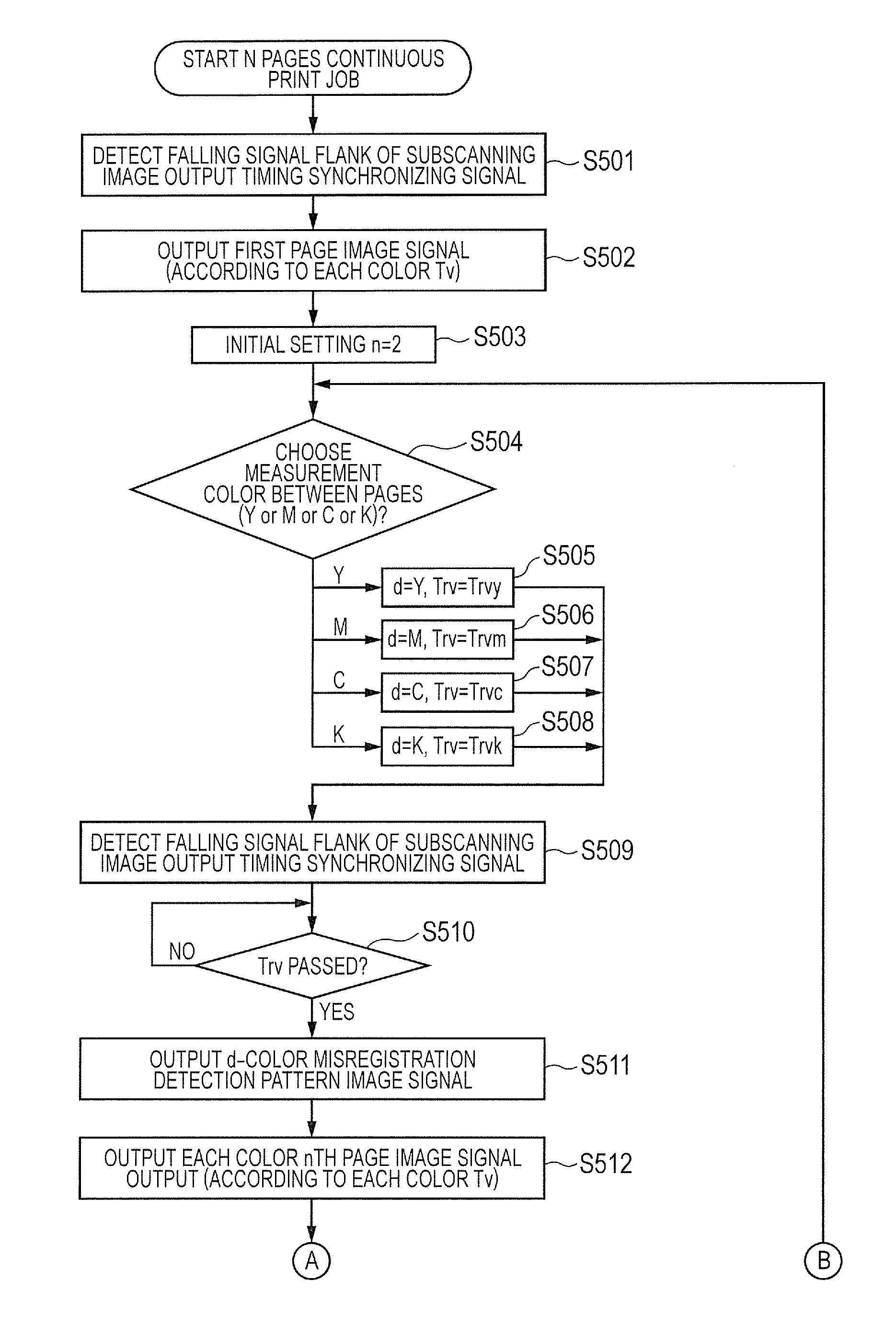

Image forming apparatus, misregistration correction control method and computer-readable information recording medium

InactiveUS20090213399A1Reduce consumption timeReduce down timeDigitally marking record carriersDigital computer detailsLocation detectionImage formation

Owner:RICOH KK

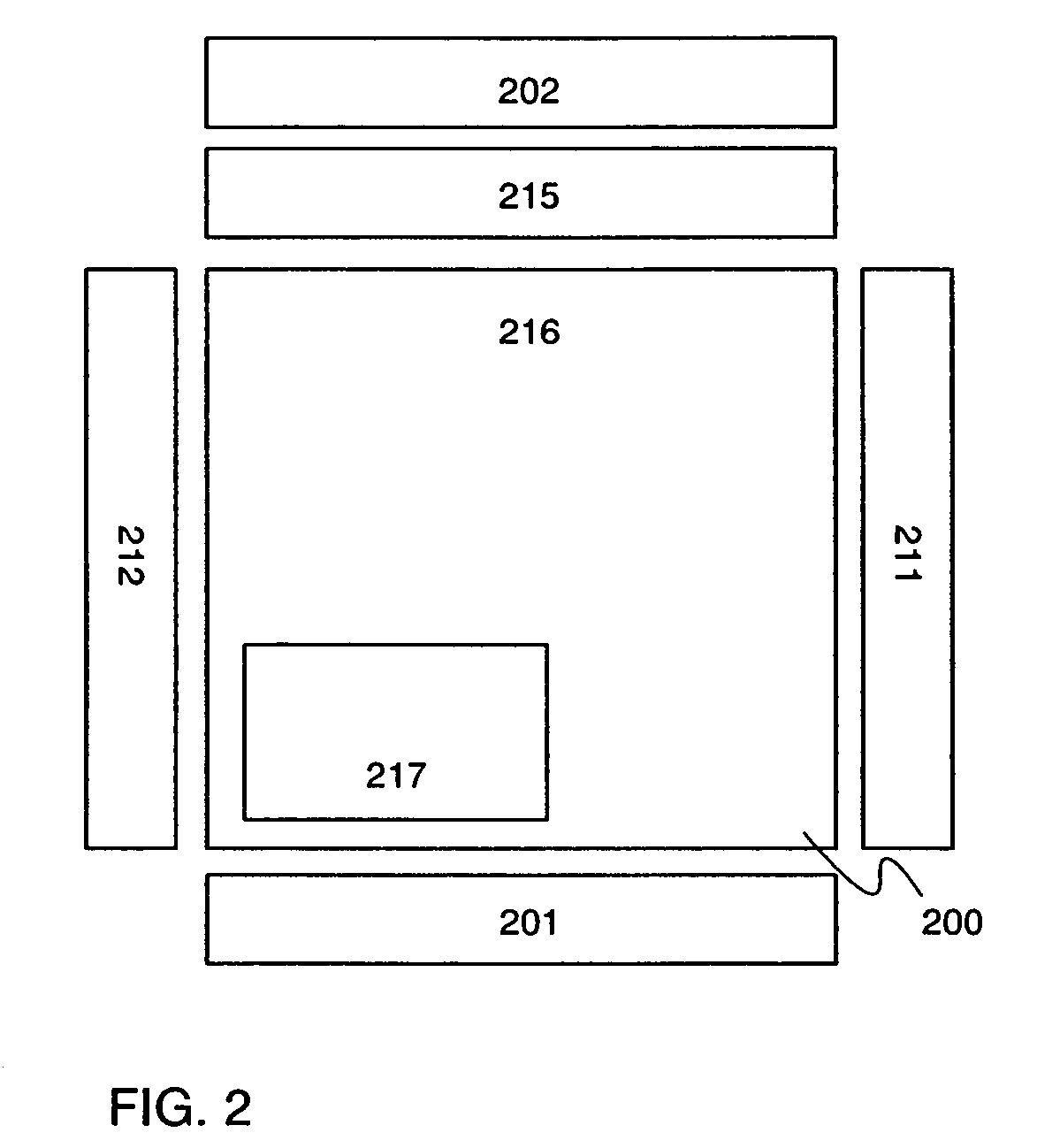

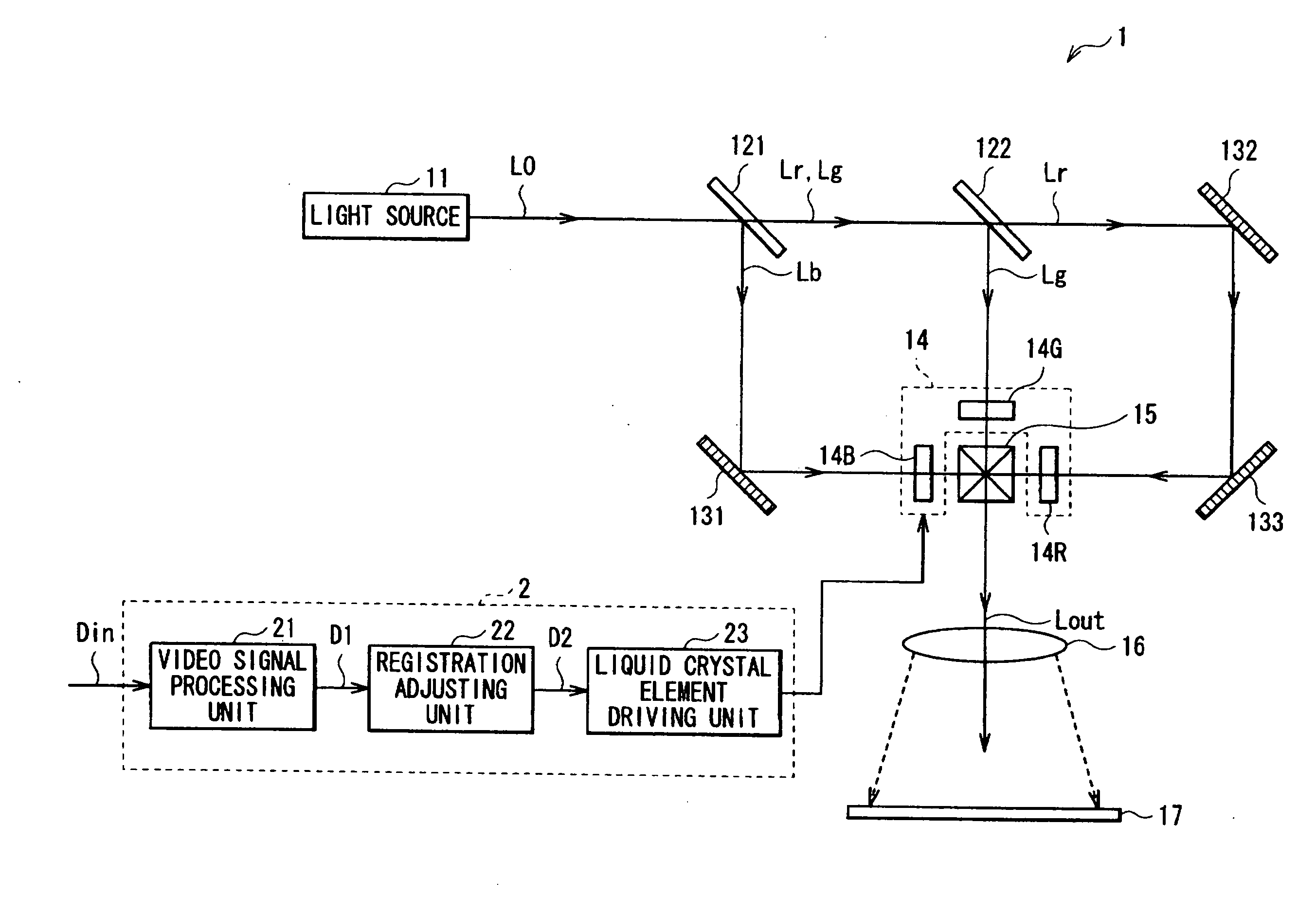

Projection display apparatus

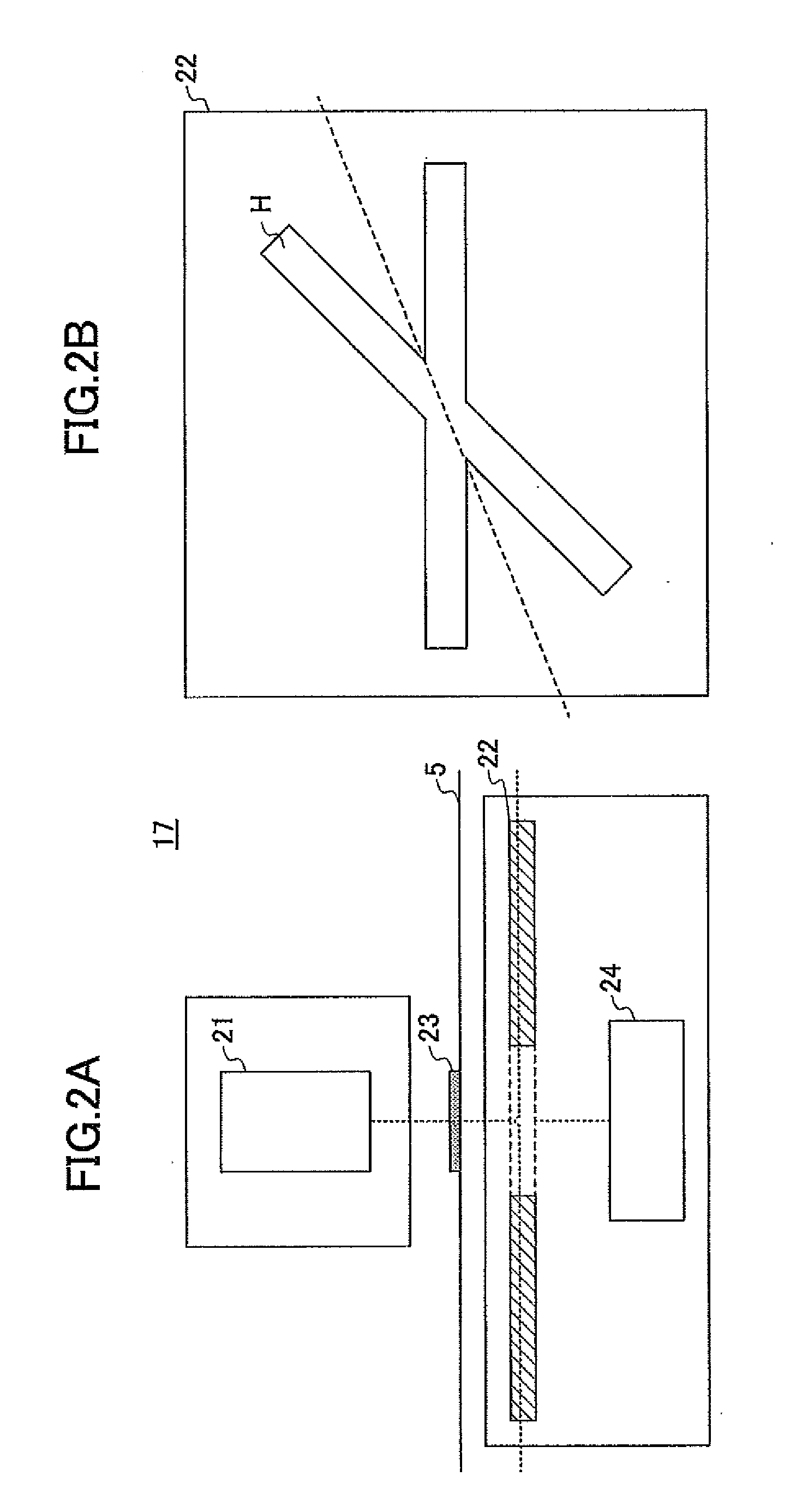

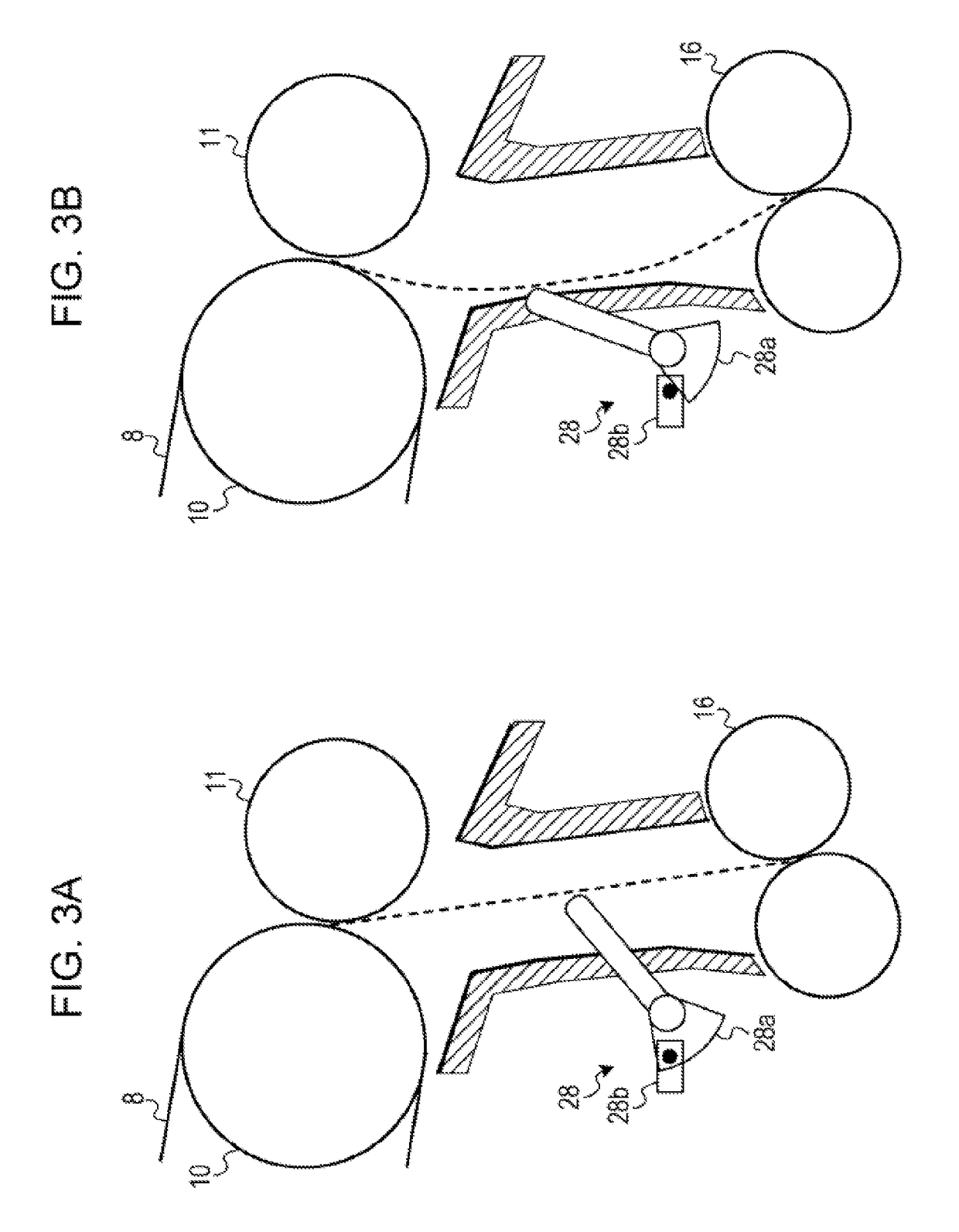

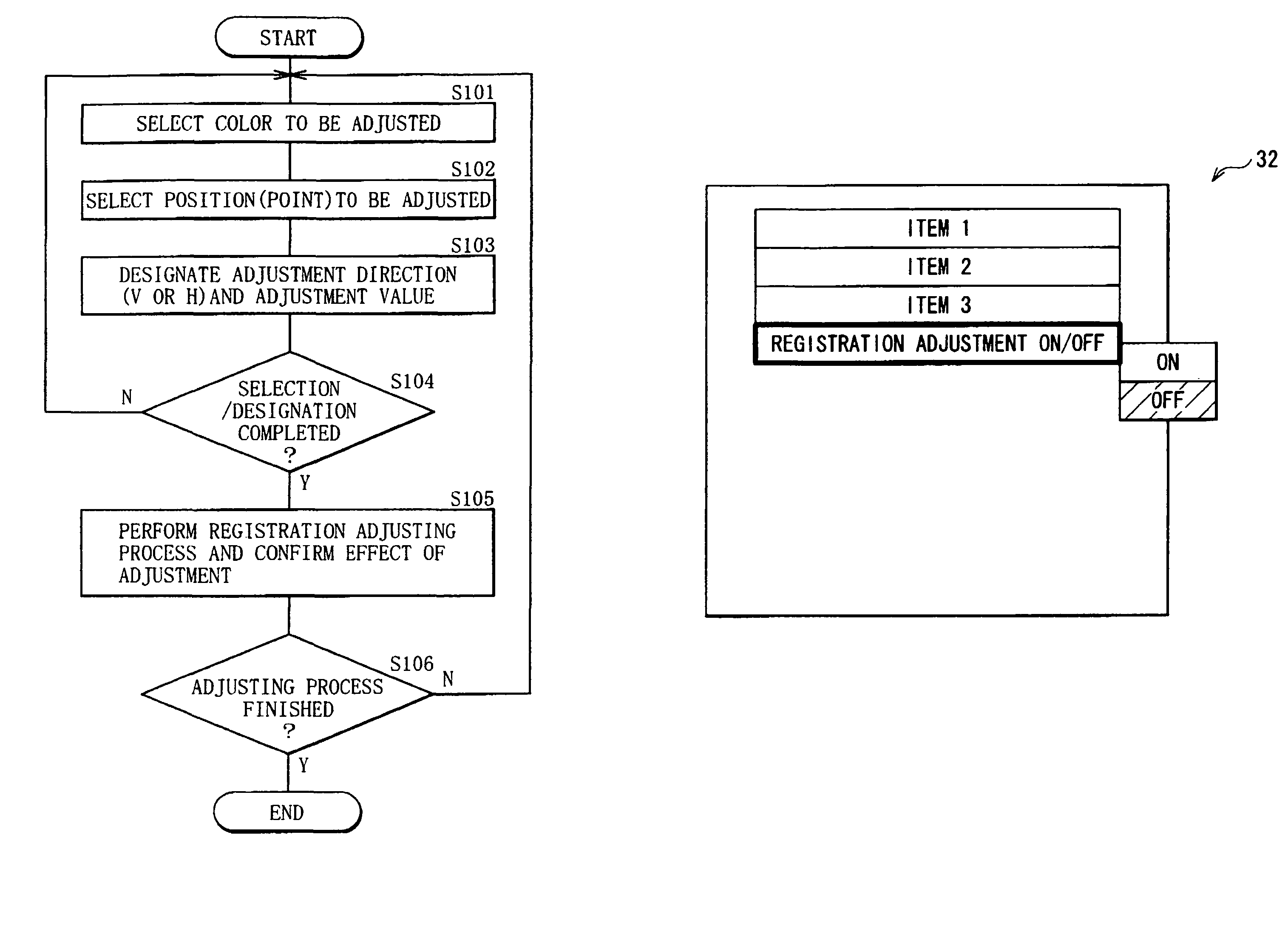

ActiveUS20090027567A1Reduce misregistrationImprove display qualityTelevision system detailsTelevision system scanning detailsProjection displayPrimary color

The present invention provides a projection display apparatus realizing easy recognition of the effect of registration adjustment. The projection display apparatus includes: a light source; a spatial light modulation device modulating, on the basis of a video signal, each of primary color lights for color display emitted from the light source; projecting means for projecting, onto a screen, each of the primary color lights modulated by the spatial light modulation device; and correcting means for correcting, based on a given correction value, the video signal for each of the primary color lights so as to reduce misregistration between the primary color lights projected on the screen, and supplying the corrected video signal to the spatial light modulation device. Validation / invalidation of correction on the video signal by the correcting means is switched in accordance with an operation from the user.

Owner:SONY CORP

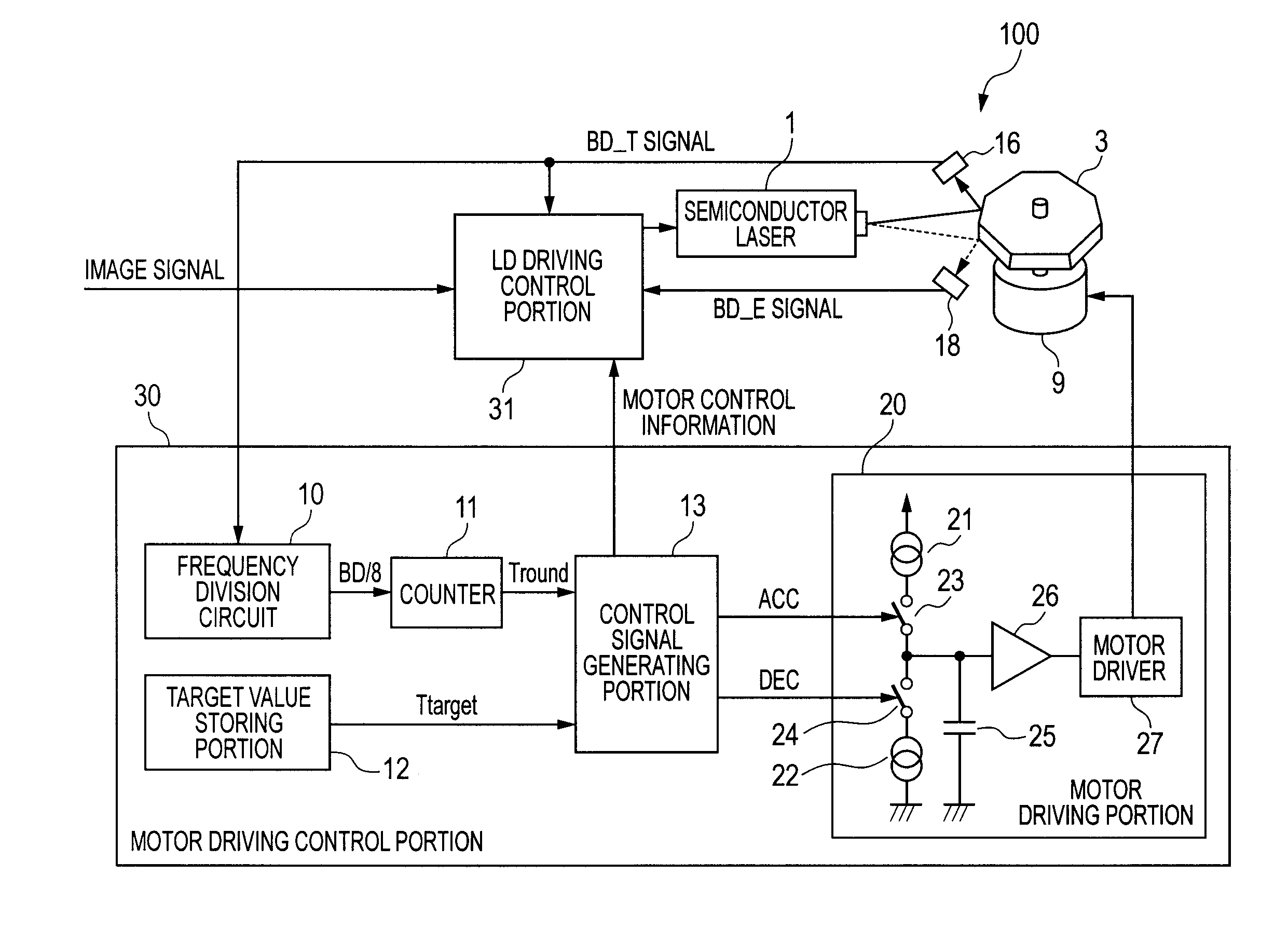

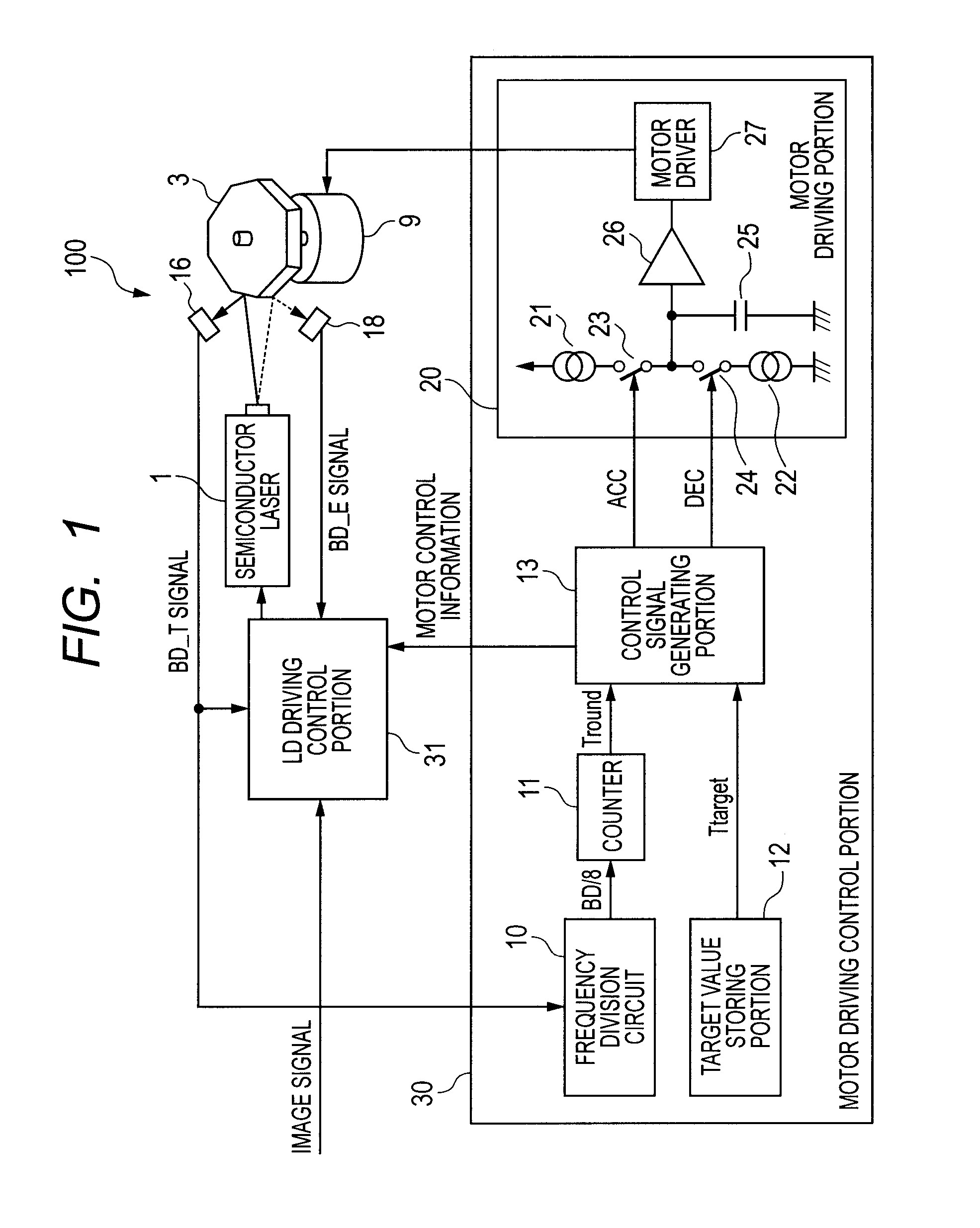

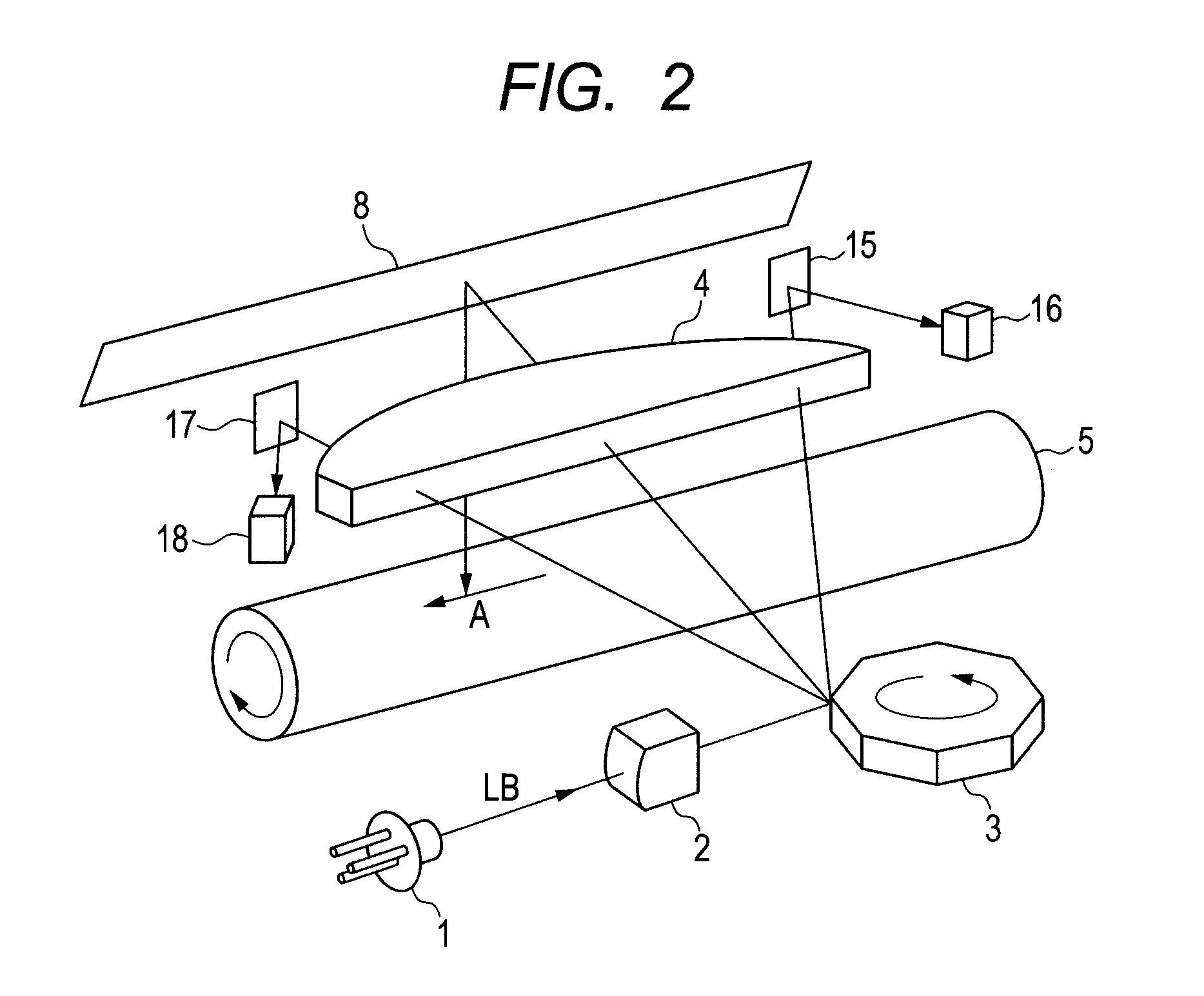

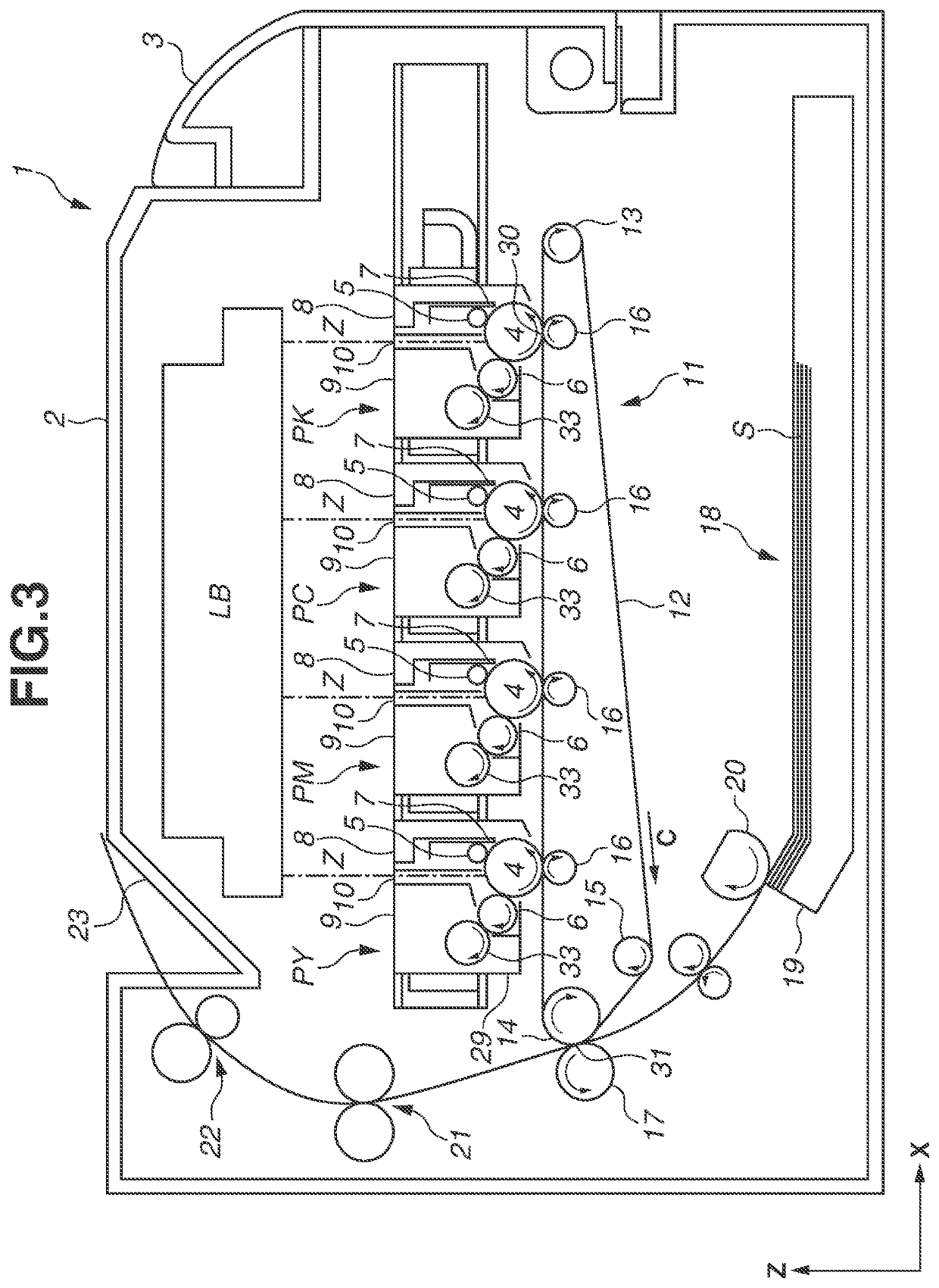

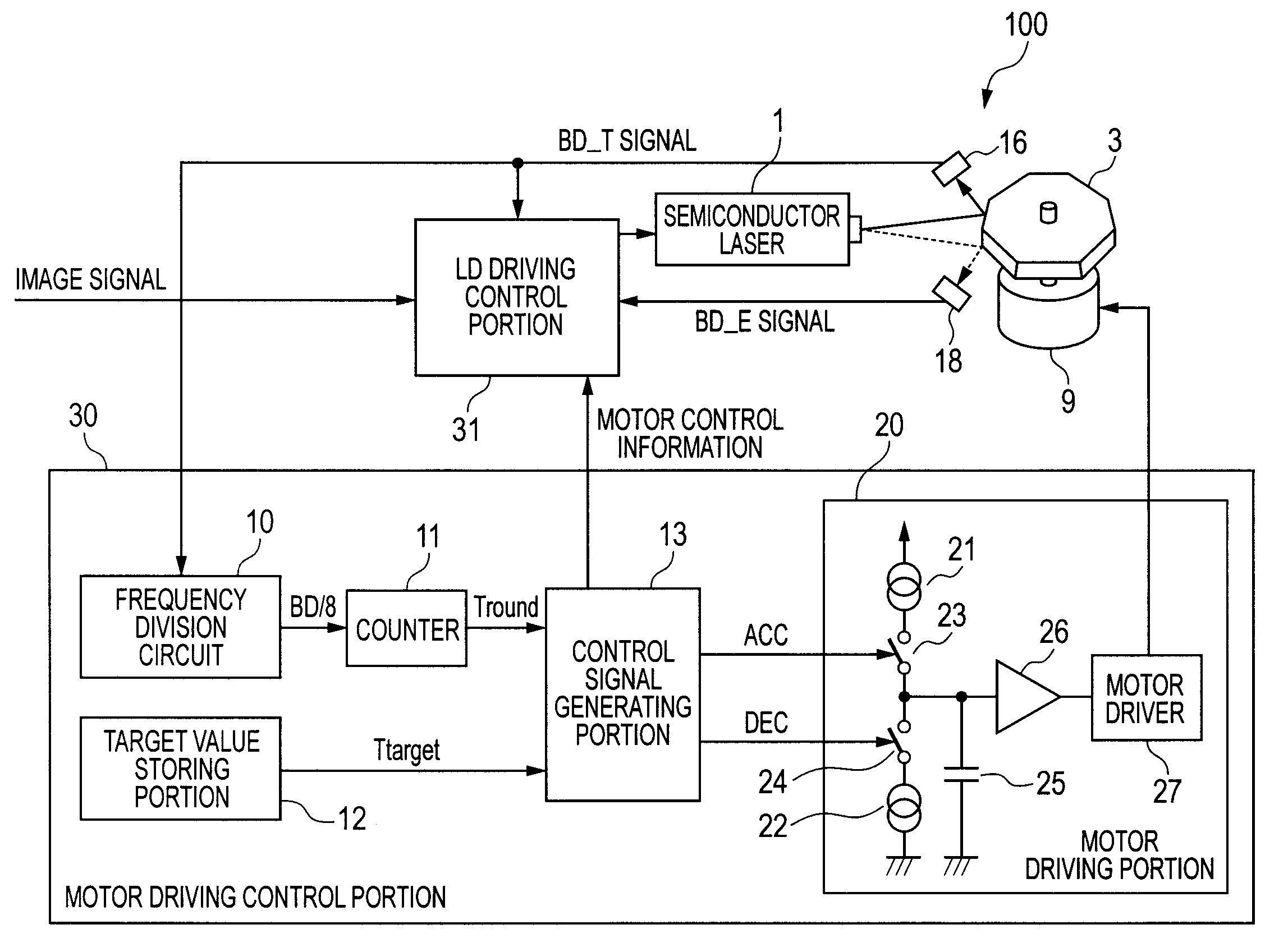

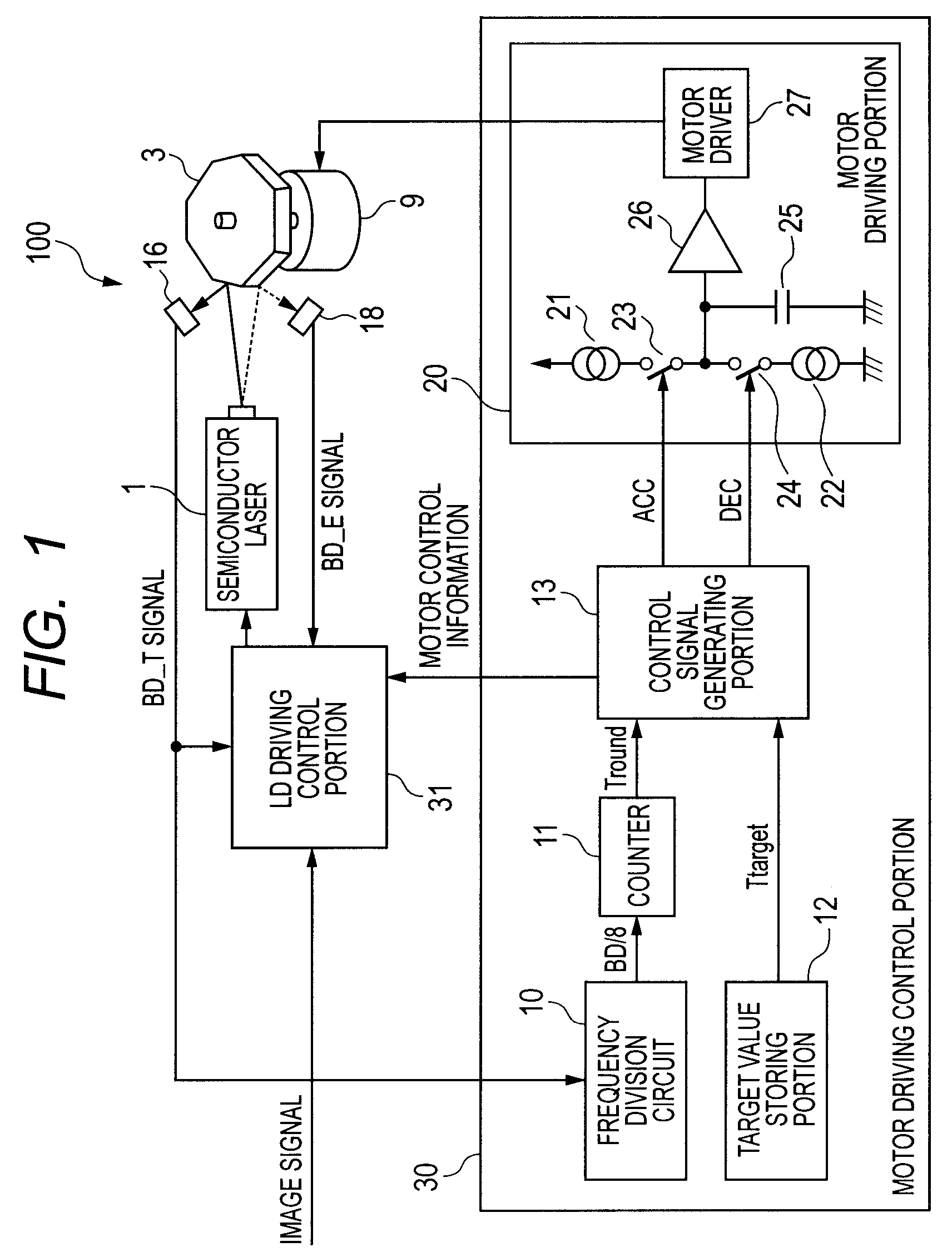

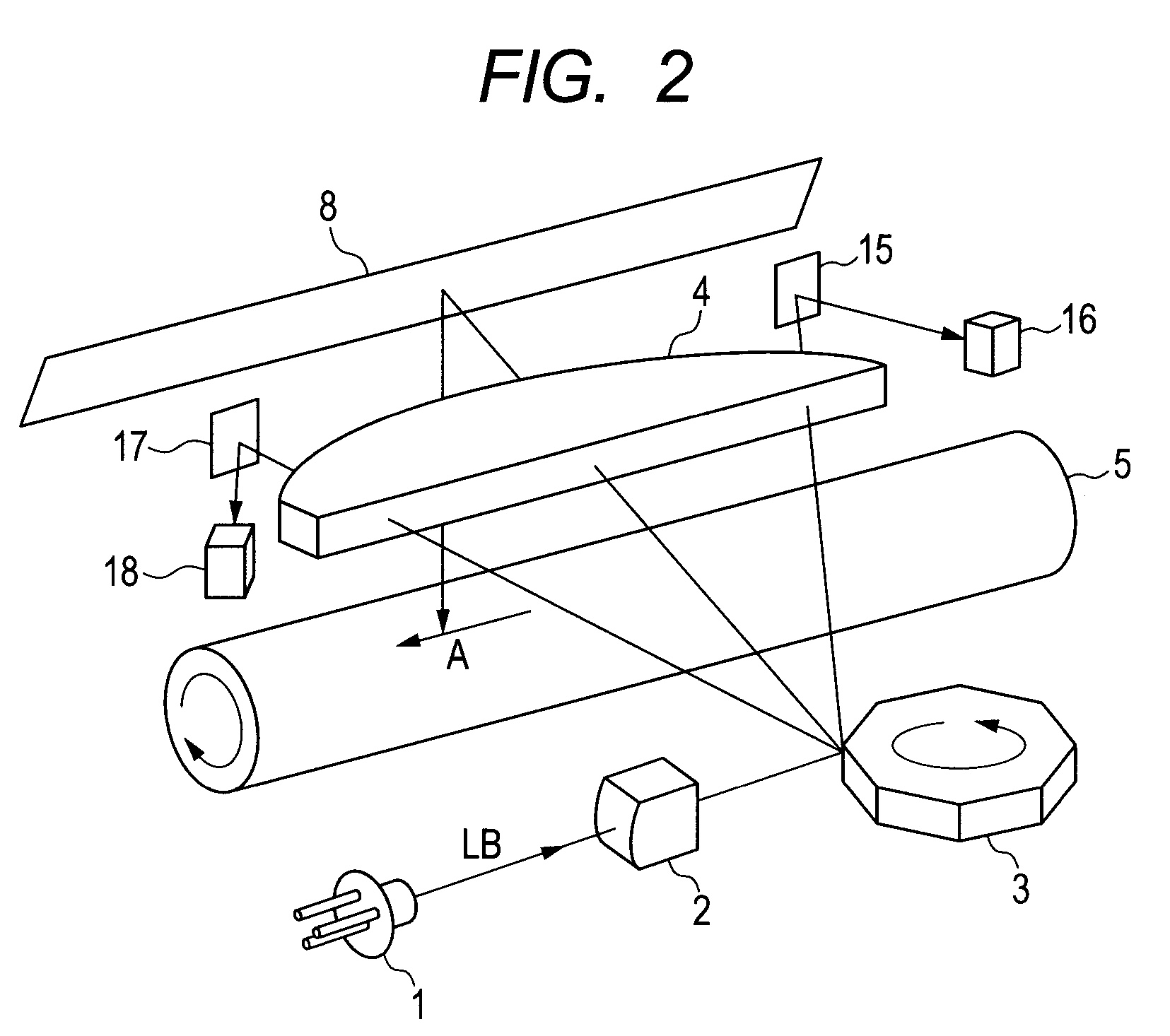

Light scanning apparatus and image forming apparatus

InactiveUS20120033025A1Suppress fluctuationsQuality improvementInking apparatusVisual presentationControl signalLight beam

A light scanning apparatus including: a light source to emit a laser beam; a light source driving unit to turn on and off the light source according to image data and a pixel clock; a rotary polygon mirror to deflect the light beam; a motor to rotationally drive the rotary polygon mirror; and a control unit to control a rotary speed of the motor to generate an acceleration control signal for accelerating the rotary speed and a deceleration control signal for decelerating the rotary speed, wherein for the acceleration control signal, the driving unit corrects the frequency of the pixel clock to be higher than the frequency, which is before the acceleration control, and for the deceleration control signal, the driving unit corrects the frequency of the pixel clock to be lower than the frequency, which is before the deceleration control.

Owner:CANON KK

Projection display apparatus

InactiveUS20090027568A1Improve work efficiencyReduce misregistrationTelevision system detailsTelevision system scanning detailsProjection displayPrimary color

A projection display apparatus includes: a light source; a spatial light modulation device modulating, on the basis of a video signal, each of primary color lights for color display emitted from the light source; projecting means for projecting, onto a screen, each of the primary color lights modulated by the spatial light modulation device; and correcting means for correcting, based on a given correction value, the video signal for each of the primary color lights so as to reduce misregistration between the primary color lights projected on the screen, and supplying the corrected video signal to the spatial light modulation device. The correcting means is configured to correct the video signal according to a single correction value such that a group of correction target points selected in a projected image on the screen are collectively processed as a single correction unit.

Owner:SONY CORP

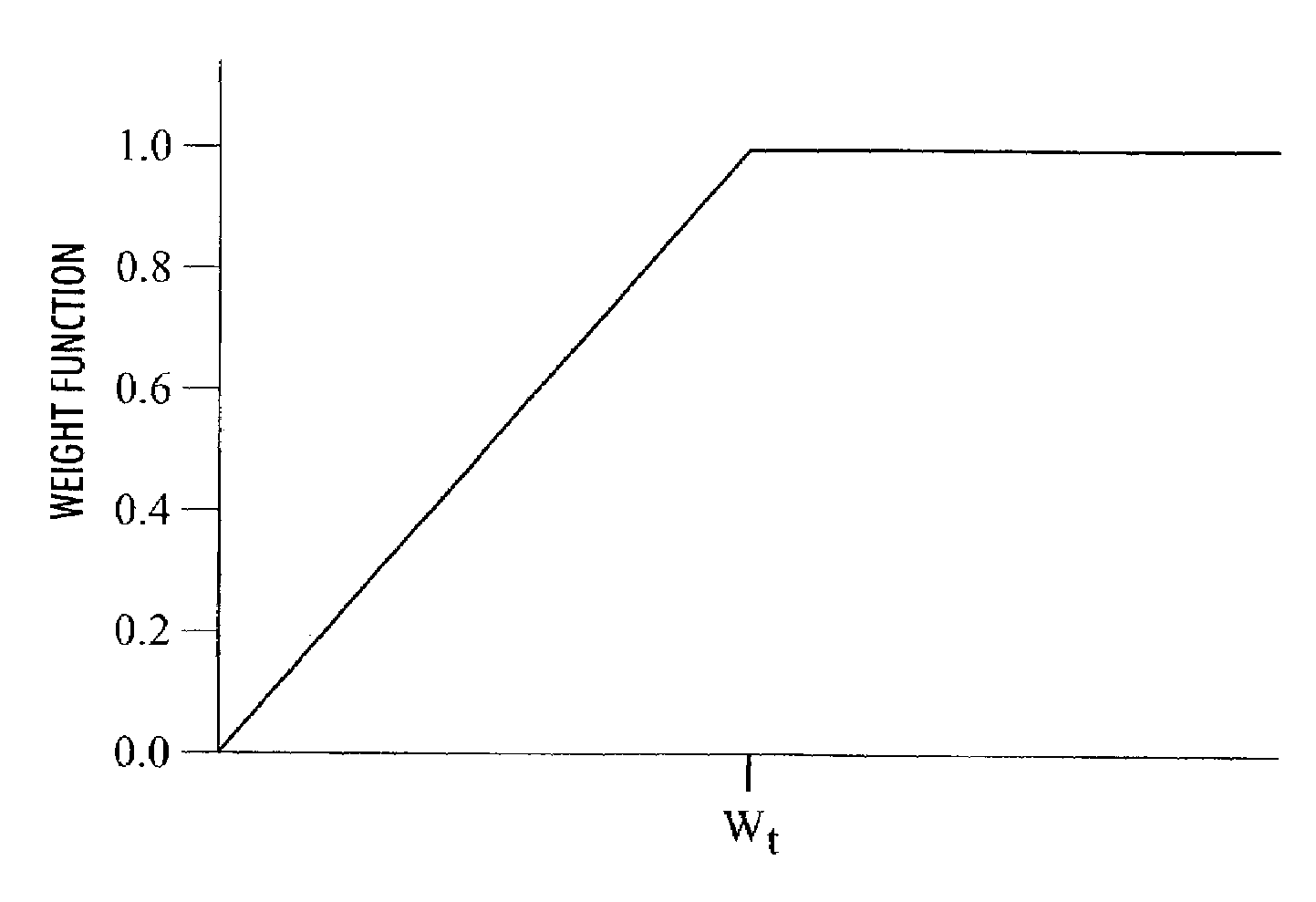

Method for smooth trap suppression of small graphical objects

InactiveUS7146043B2Reduce hue shiftReduce widthImage enhancementCharacter and pattern recognitionGraphicsTrapping

A method for smooth trapping of thin graphical objects, wherein a thin graphical object has a width dimension which is substantially less than the object's length dimension, includes receiving from a trap generator the location of a trap pixel that should be changed in color; determining the width of the object containing the trap pixel; comparing the width of the object with a trap threshold width; if the size of the object is less than the trap threshold width, reducing the width of the trap region according to a predetermined relationship; and applying a trap correction to the trap pixel according to the reduced trap width. The predetermined relationship may be a linear relationship which reduces the trap width monotonically for object widths less than the trap threshold width. The method may be applied to small objects and small font text objects.

Owner:XEROX CORP

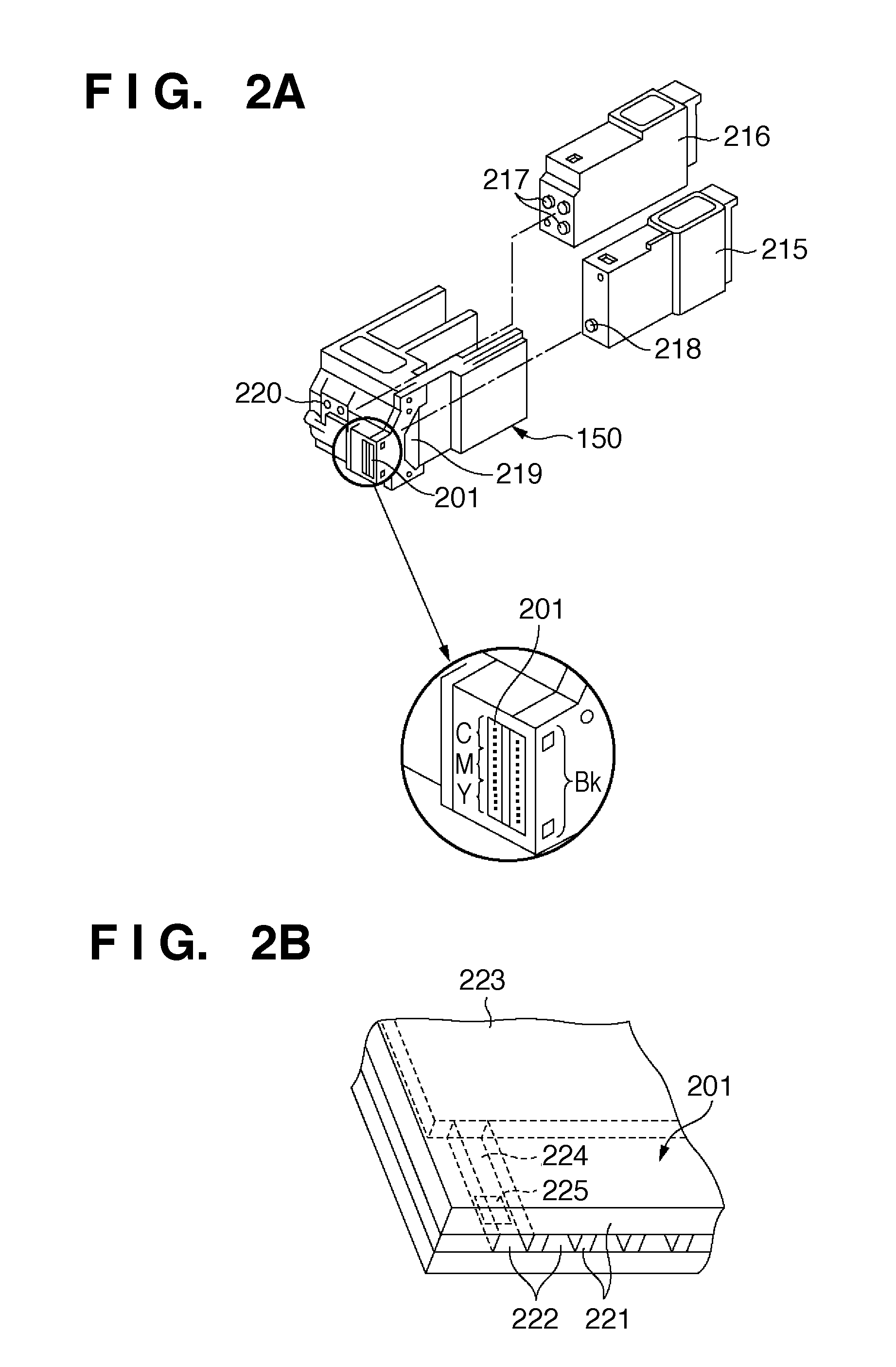

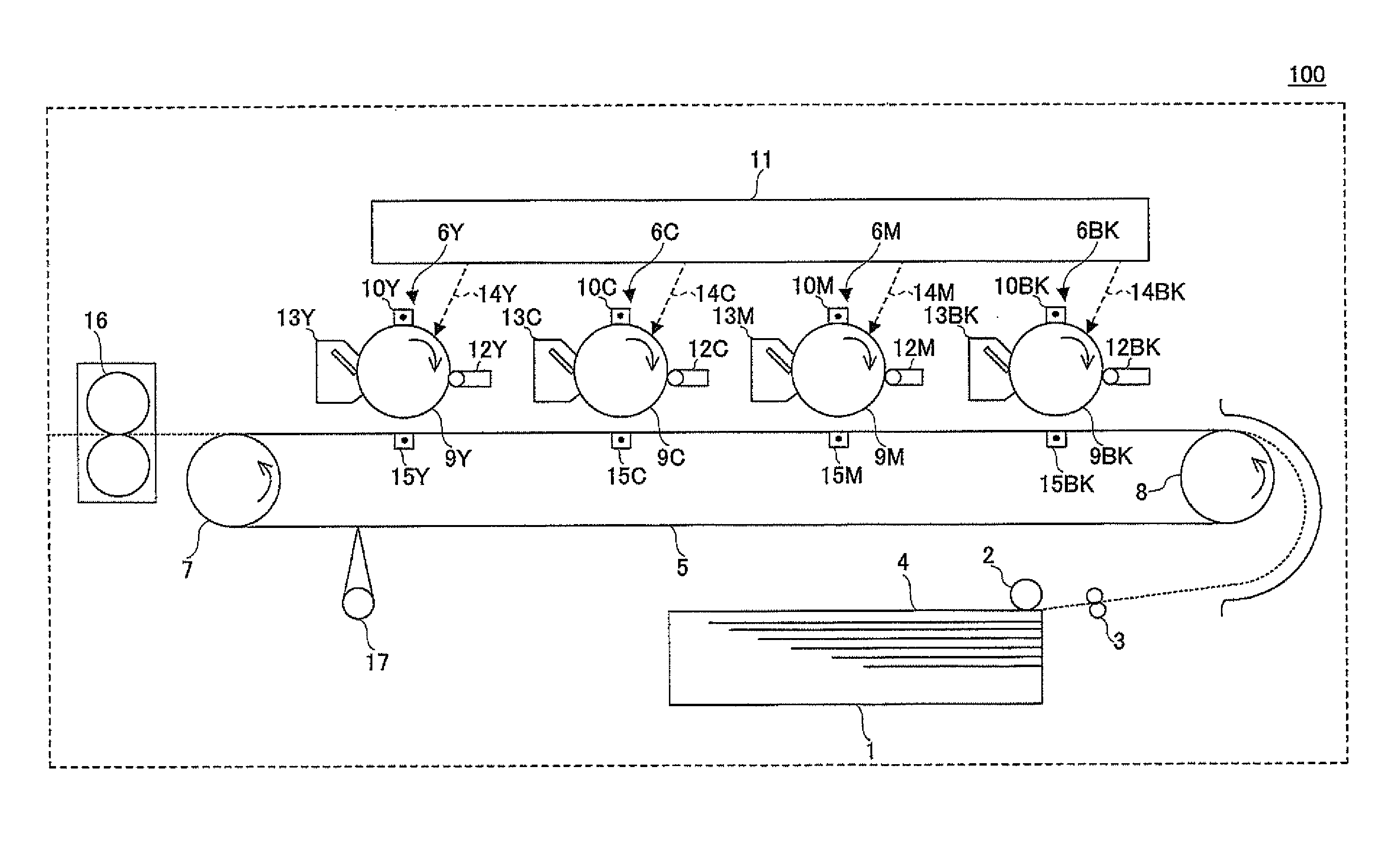

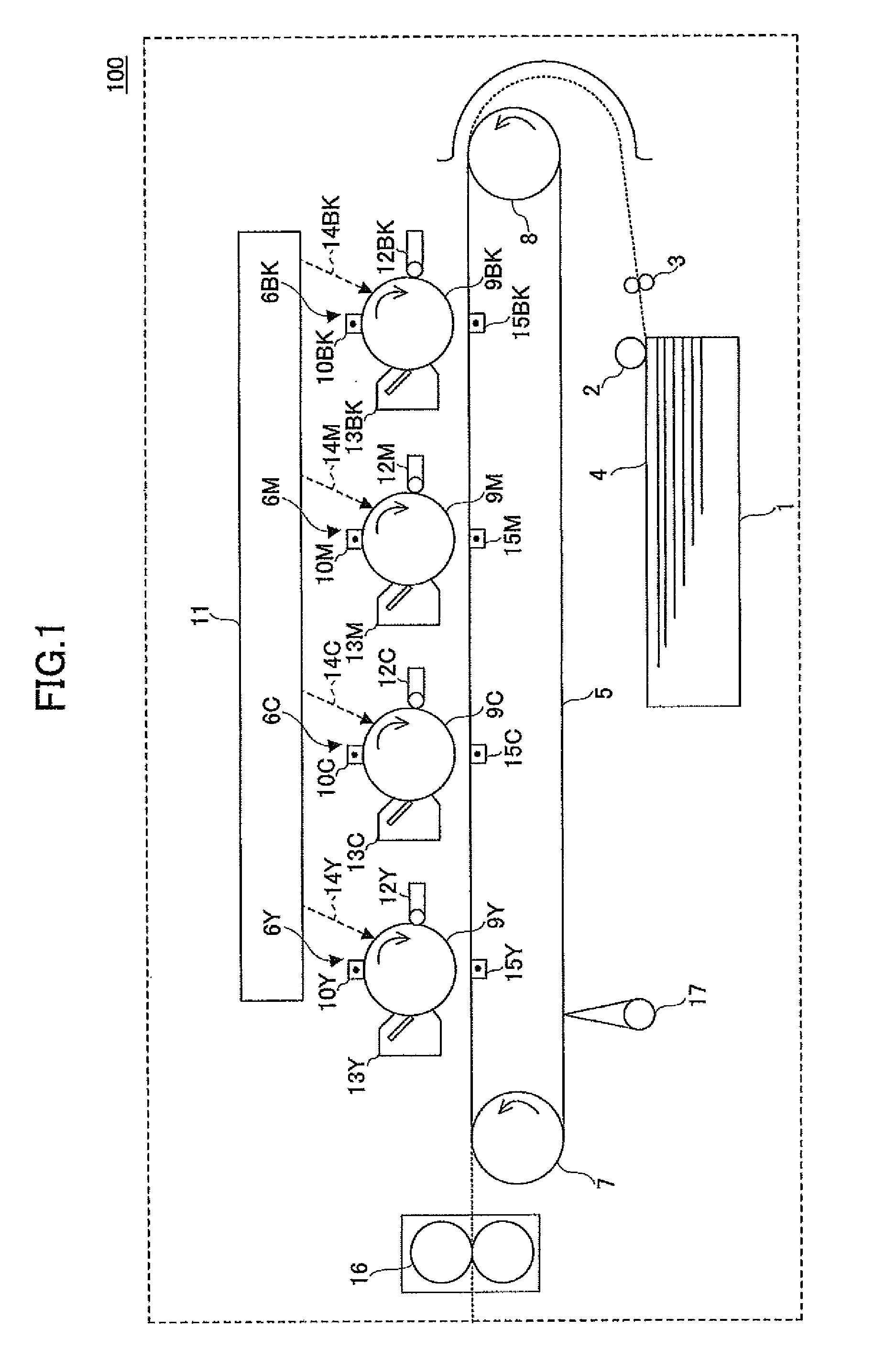

Image forming apparatus

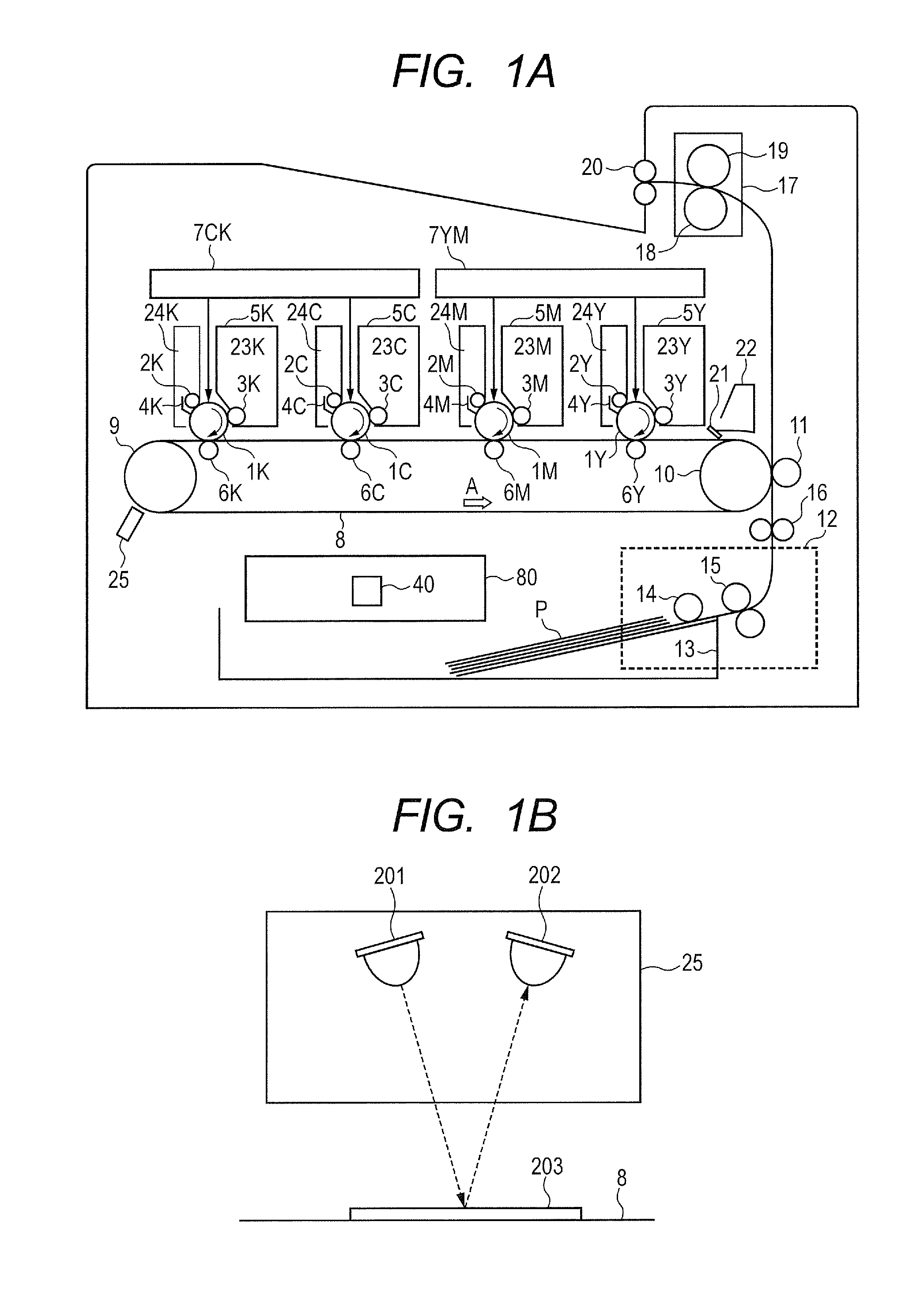

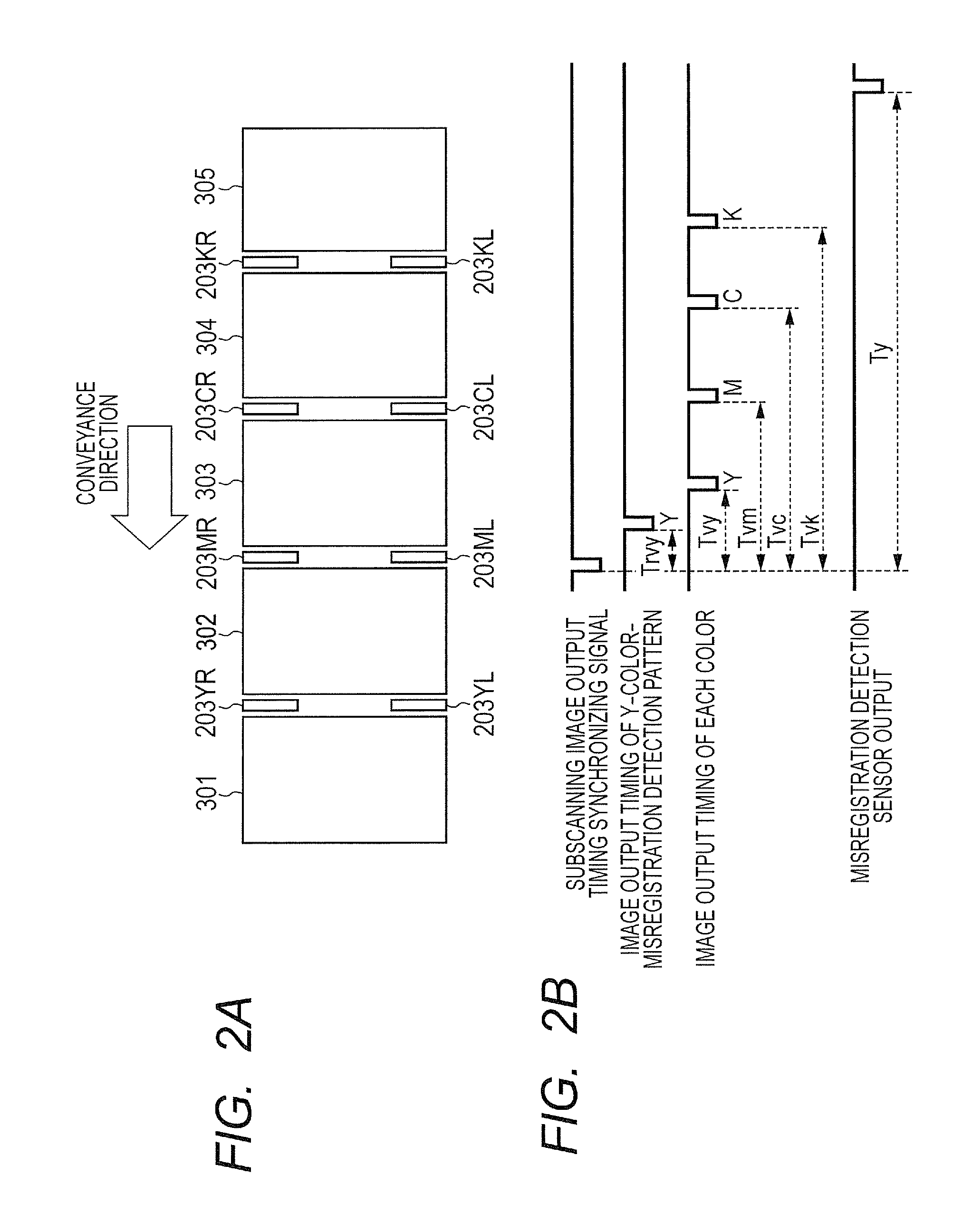

InactiveUS20130142549A1Reduce misregistrationElectrographic process apparatusImage formationLaser beams

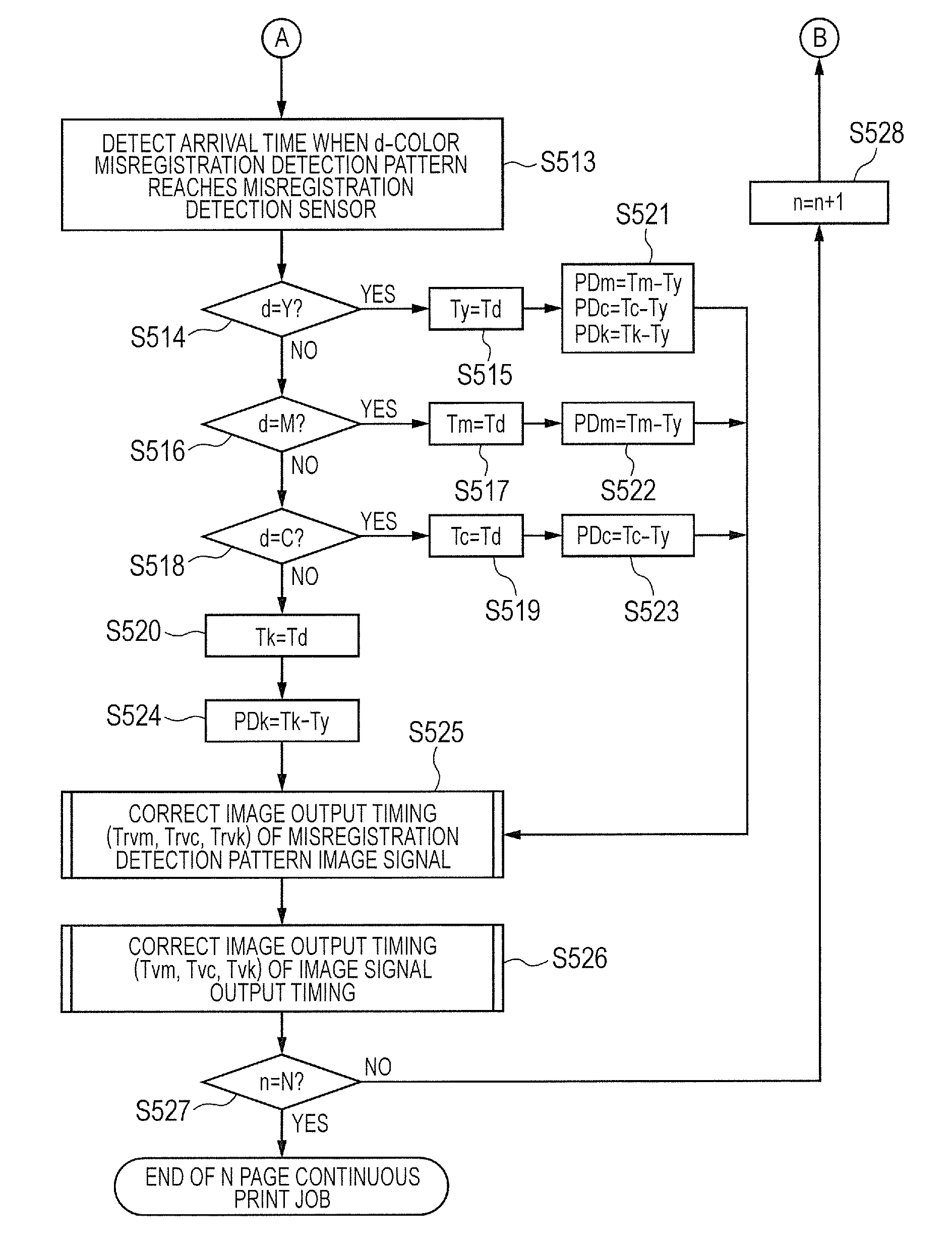

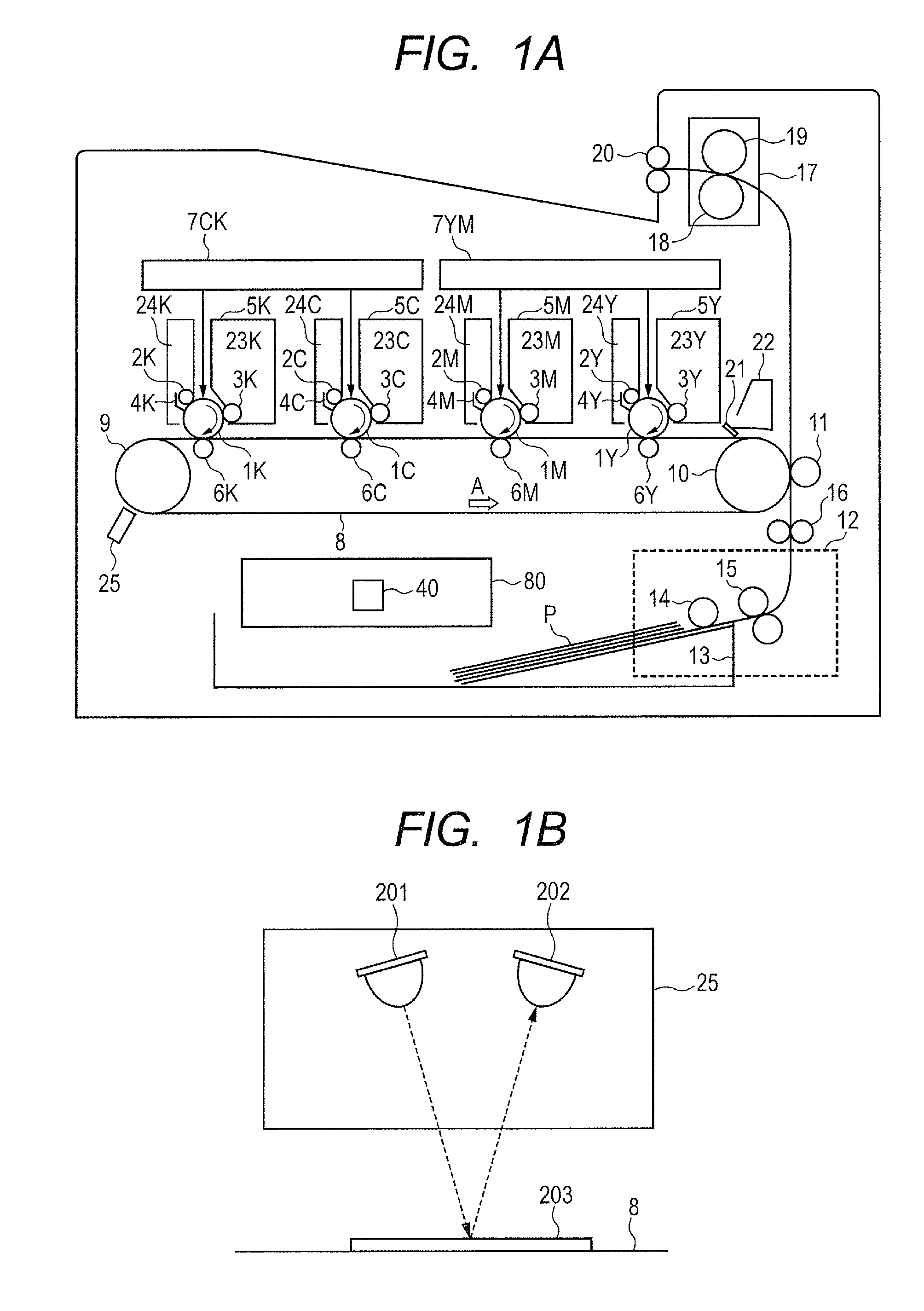

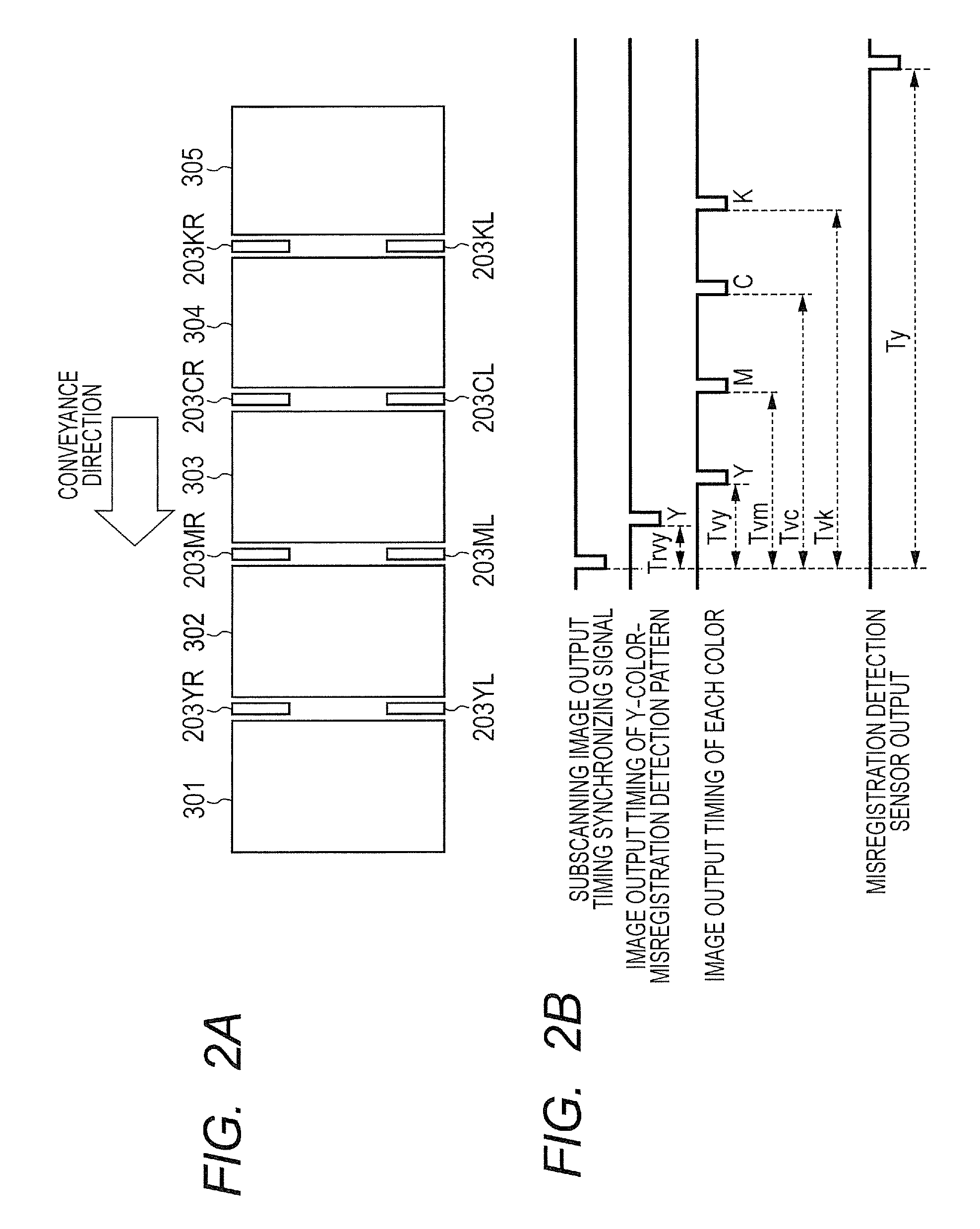

The image forming apparatus includes a plurality of image forming devices that includes a developing device and a transferring device, an exposure unit irradiating the image bearing member with a laser beam, a detector detecting a toner image for detection, and a CPU for detecting and correcting the positional deviation of each color, wherein the CPU forms the toner image for detection on a color-by-color basis between pages in a print job including plural pages of images, and corrects times Trv and Tv from timing on which a subscanning image-writing timing synchronizing signal is output to timing on which a laser unit emits a laser beam based on times Ty to Tk between timing on which the subscanning image-writing timing synchronizing signal is output and timing on which the color misregistration detection sensor detects the misregistration detection pattern.

Owner:CANON KK

Image processing apparatus and method which match two images based on a shift vector

ActiveUS8111947B2Increase speedReduce misregistrationImage enhancementTelevision system detailsImaging processingShift vector

The present invention aims to provide image processing device and method capable of generating a difference image at high speed without occurring misregistration. To achieve this, in the image processing device and method, plural regions of interest are set respectively to input first and second images, a shift vector indicating a misregistration amount between the first and second images is calculated with respect to each of the regions of interest, a filter process is executed to the shift vector, the filter-processed shift vector is interpolated, the first and second images are registered based on the interpolated shift vector, and a subtraction operation is executed between corresponding pixels on the respective registered images to acquire the difference image.

Owner:CANON KK

Projection display apparauts which enables a selected image inverting process to be performed to facilitate registration adjustment

ActiveUS20120147276A1Easy to operateReduce misregistrationTelevision system detailsTelevision system scanning detailsComputer graphics (images)Operability

The present invention provides a projection display apparatus realizing improved operability at the time of registration adjustment irrespective of a use situation of the apparatus. In the case where misregistration occurs between primary color lights, video signals for three colors are corrected (registration adjustment is performed) so as to reduce the misregistration in accordance with an input adjustment value. An image inverting process is performed on an input video signal so that the image is inverted in a display screen. By a configuration by the user, the image is properly inverted in the display screen. When the image inverting process is performed, an adjustment value, with a sign different from that in the misregistration direction in a coordinate system where the image is not inverted, is input by an operation on the display screen.

Owner:SONY GRP CORP

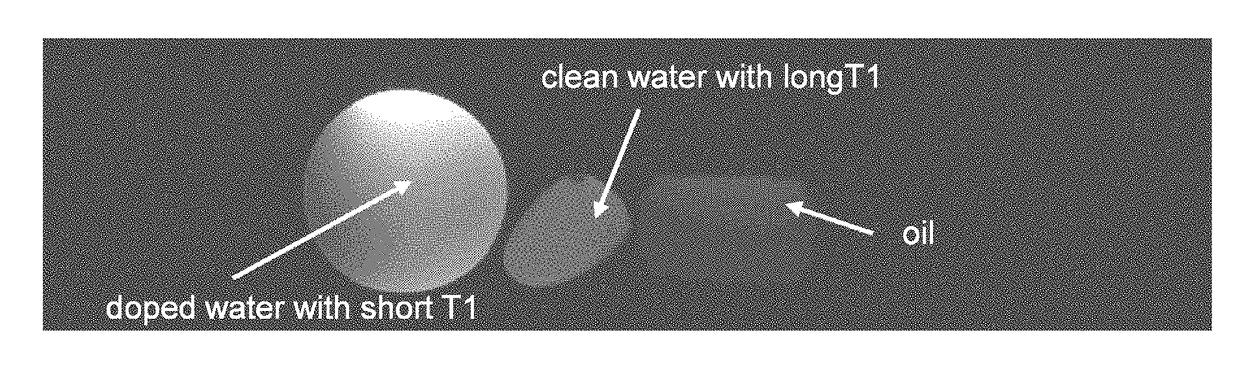

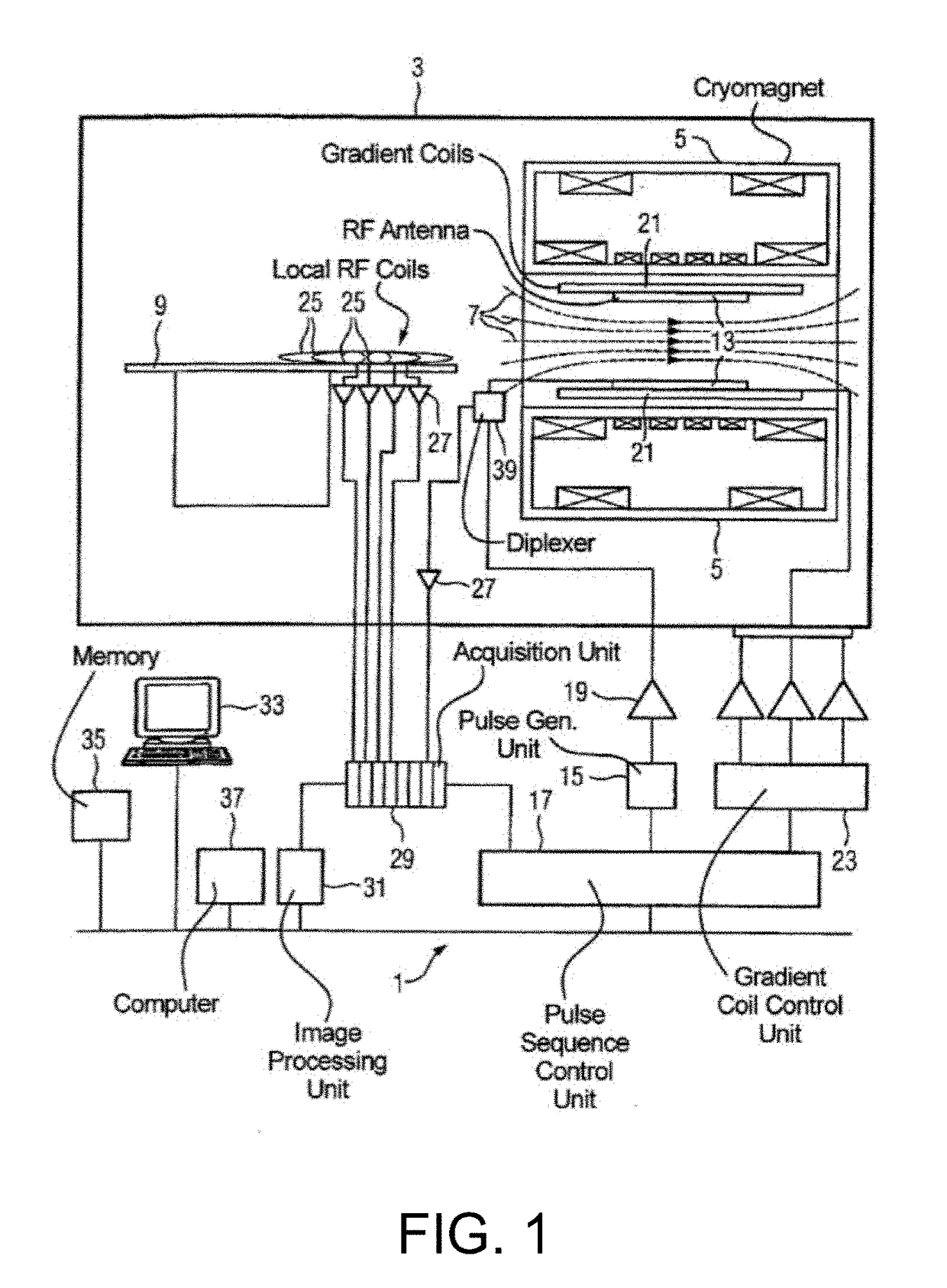

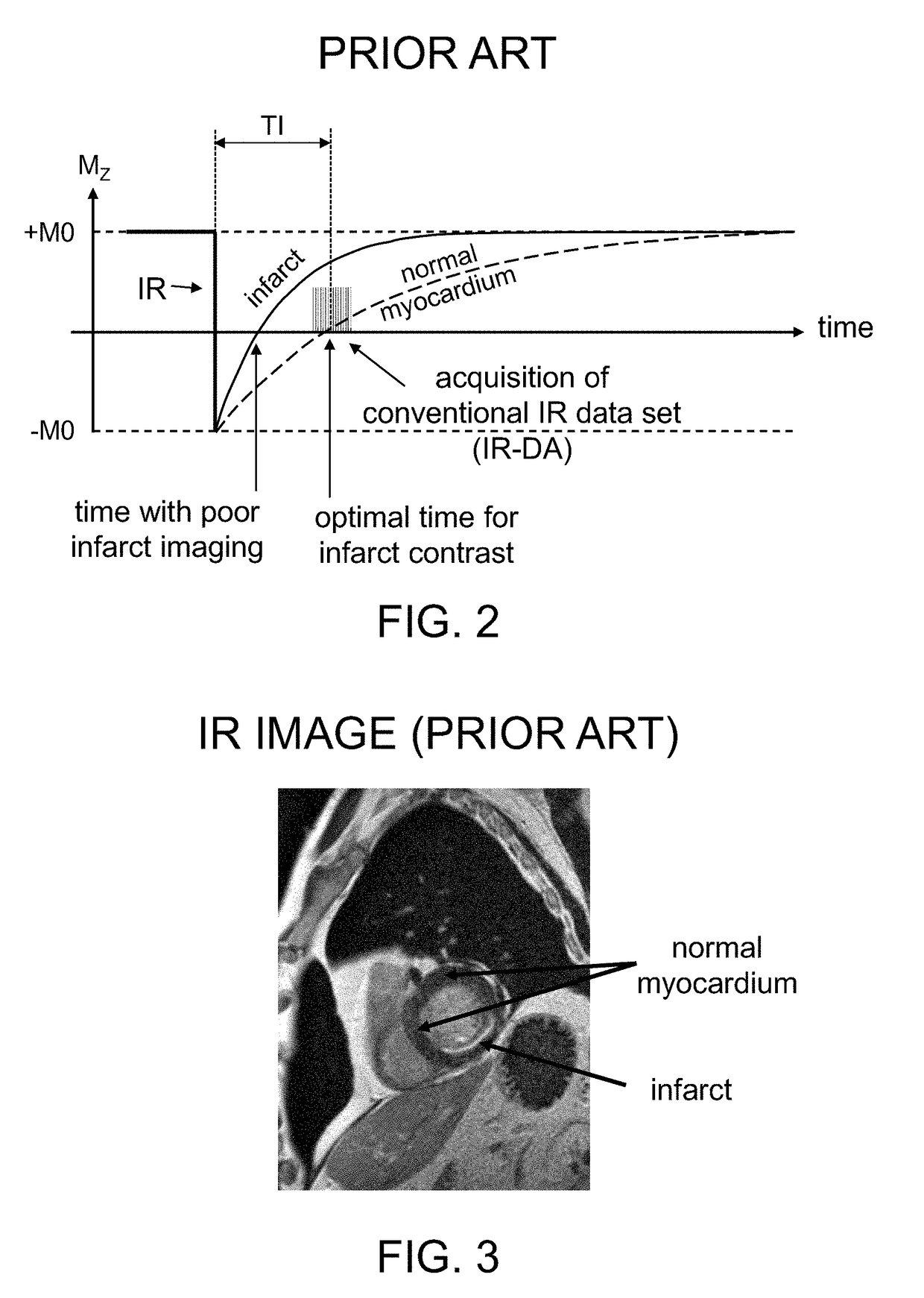

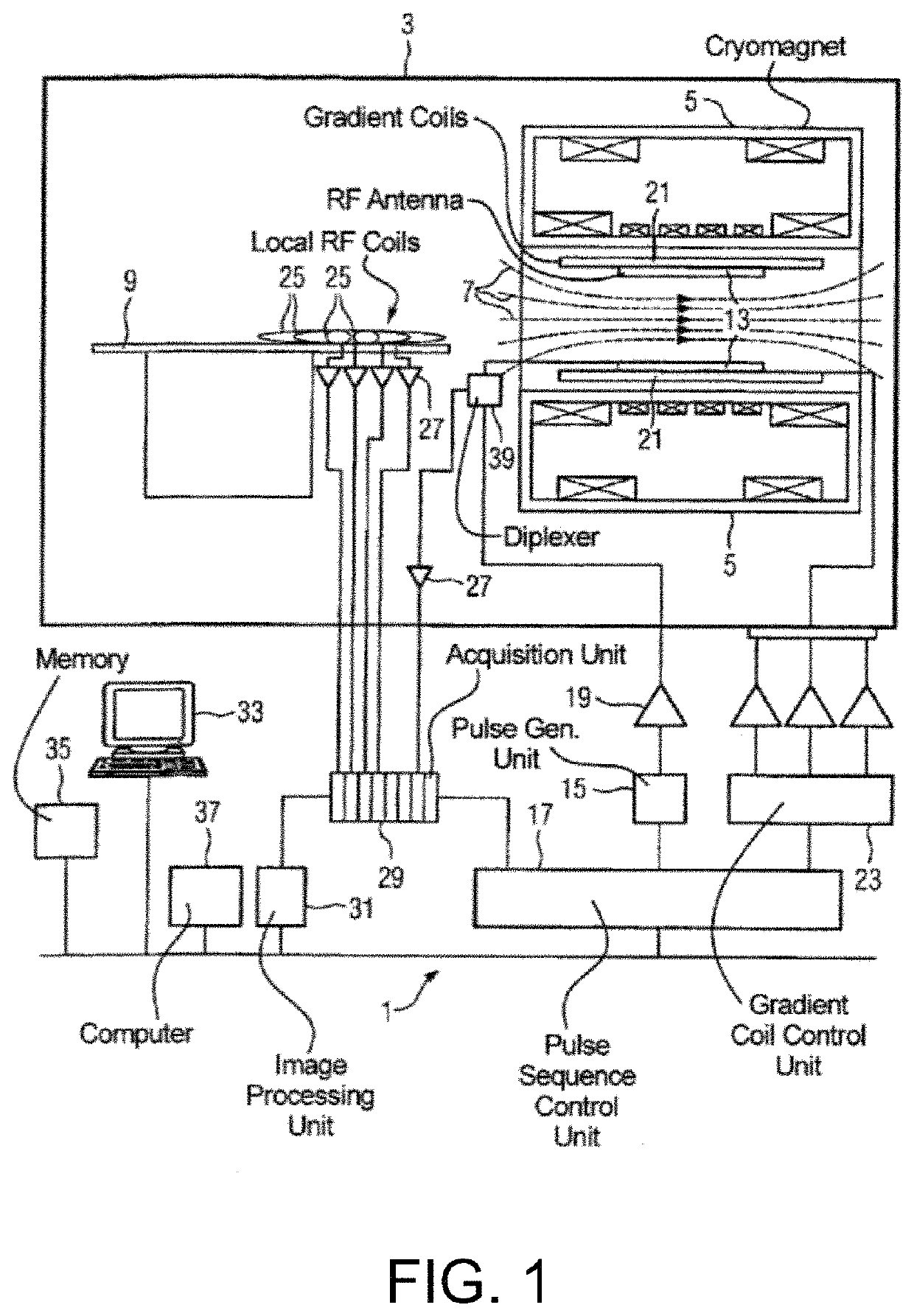

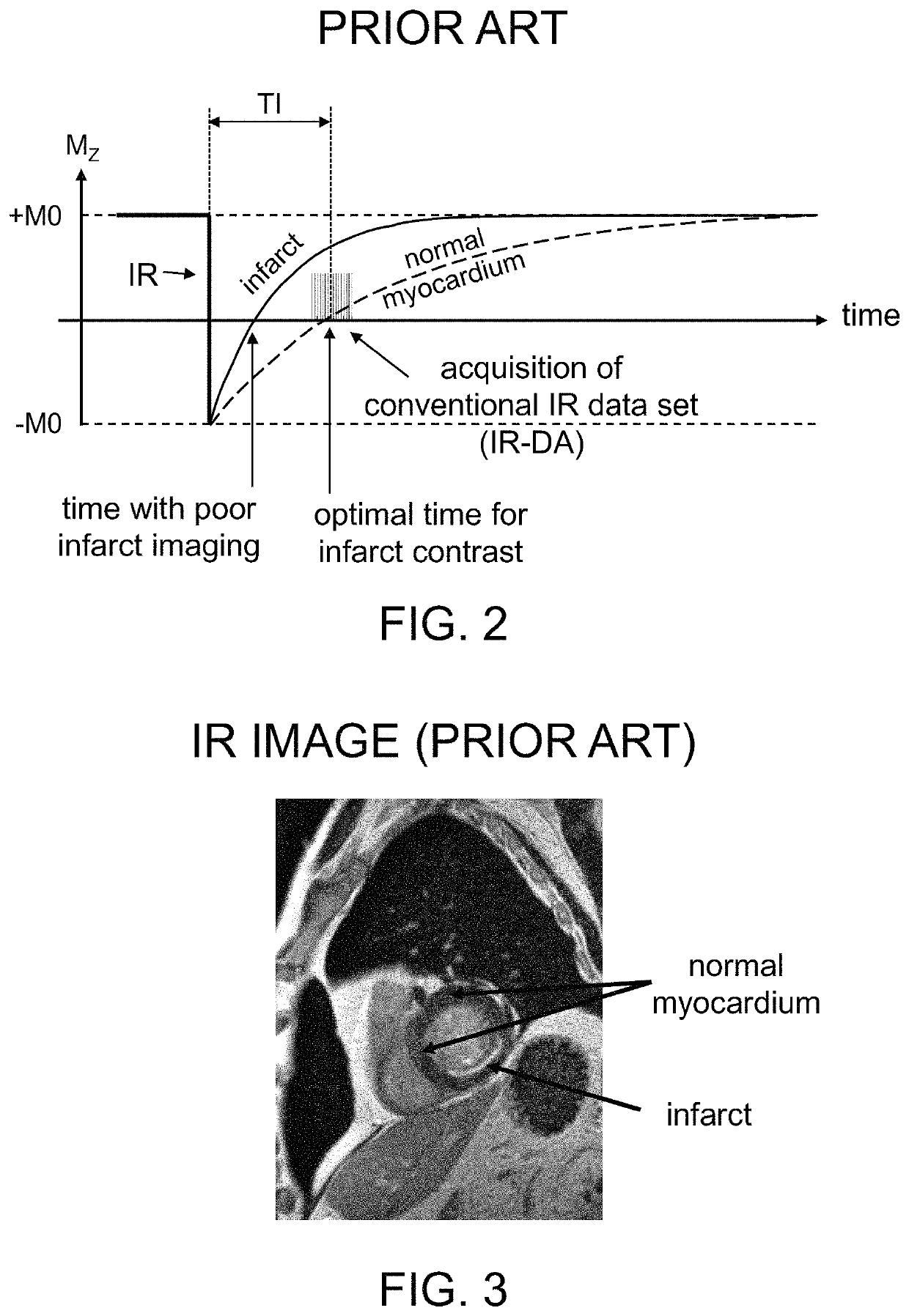

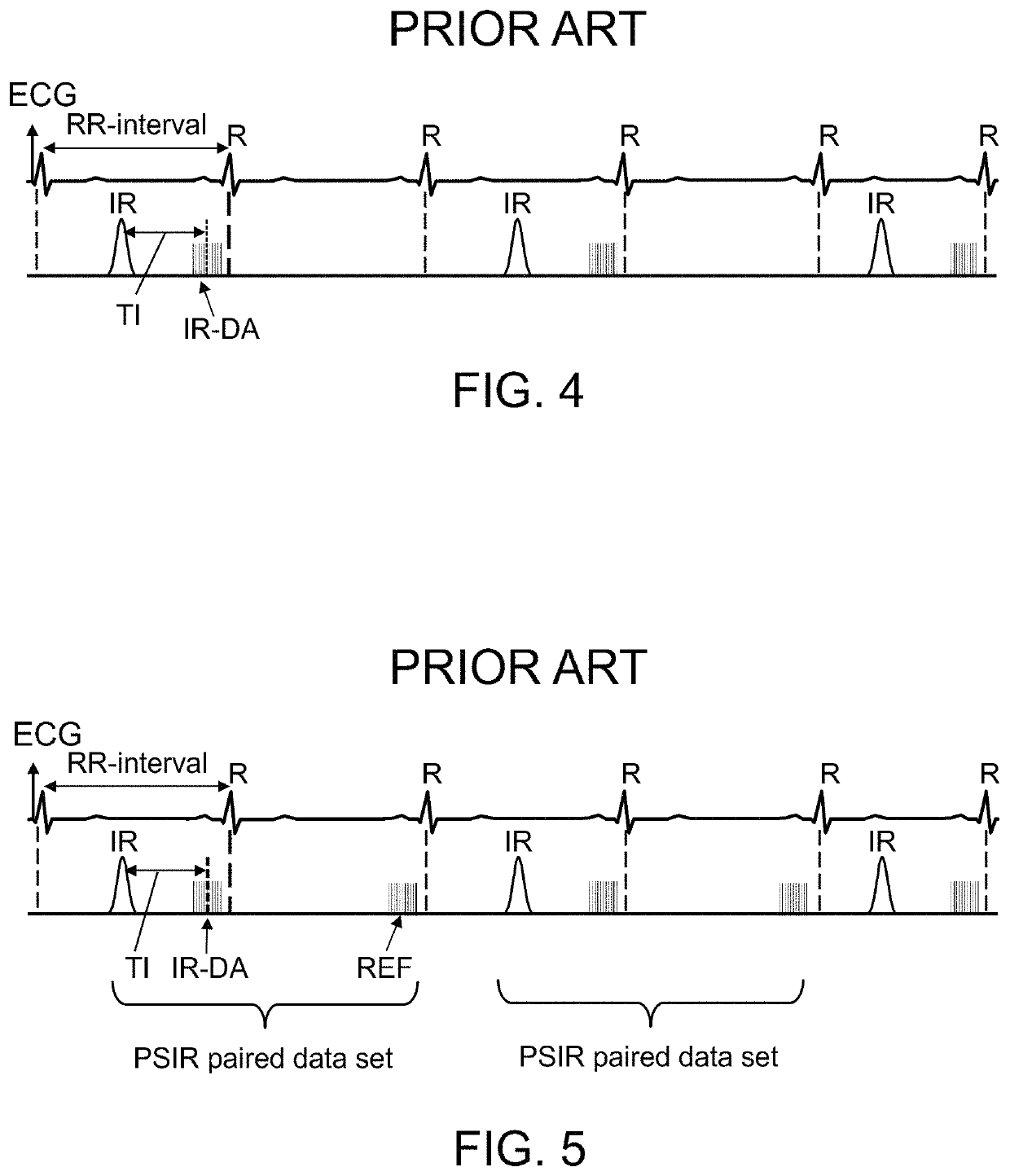

Systems And Methods For Phase-Sensitive Inversion Recovery MR Imaging With Reduced Sensitivity To Cardiac Motion

ActiveUS20180203086A1Reduce misregistrationReduce scan timeMeasurements using NMR imaging systemsData setPaired Data

A magnetic resonance imaging system and method are provided for improved phase-sensitive magnetic resonance imaging of tissues affected by cardiovascular pulsatile motion. A magnetically-prepared image dataset and corresponding reference image dataset (for phase sensitivity) are obtained within the duration of a single cardiac cycle. The paired datasets can be single-shot or segmented datasets and a navigator sequence can optionally be provided with each paired dataset. The system and method take advantage of the shape symmetry of the cardiac cycle to acquire the paired dataset in a shorter time interval, thereby reducing misregistration artifacts. The magnetic preparation can include inversion recovery pulses, FIDDLE sequences, other magnetic preparation sequences, or combinations thereof. The reference dataset can be acquired at a lower resolution than the corresponding magnetically-prepared dataset without compromising image quality.

Owner:DUKE UNIV +1

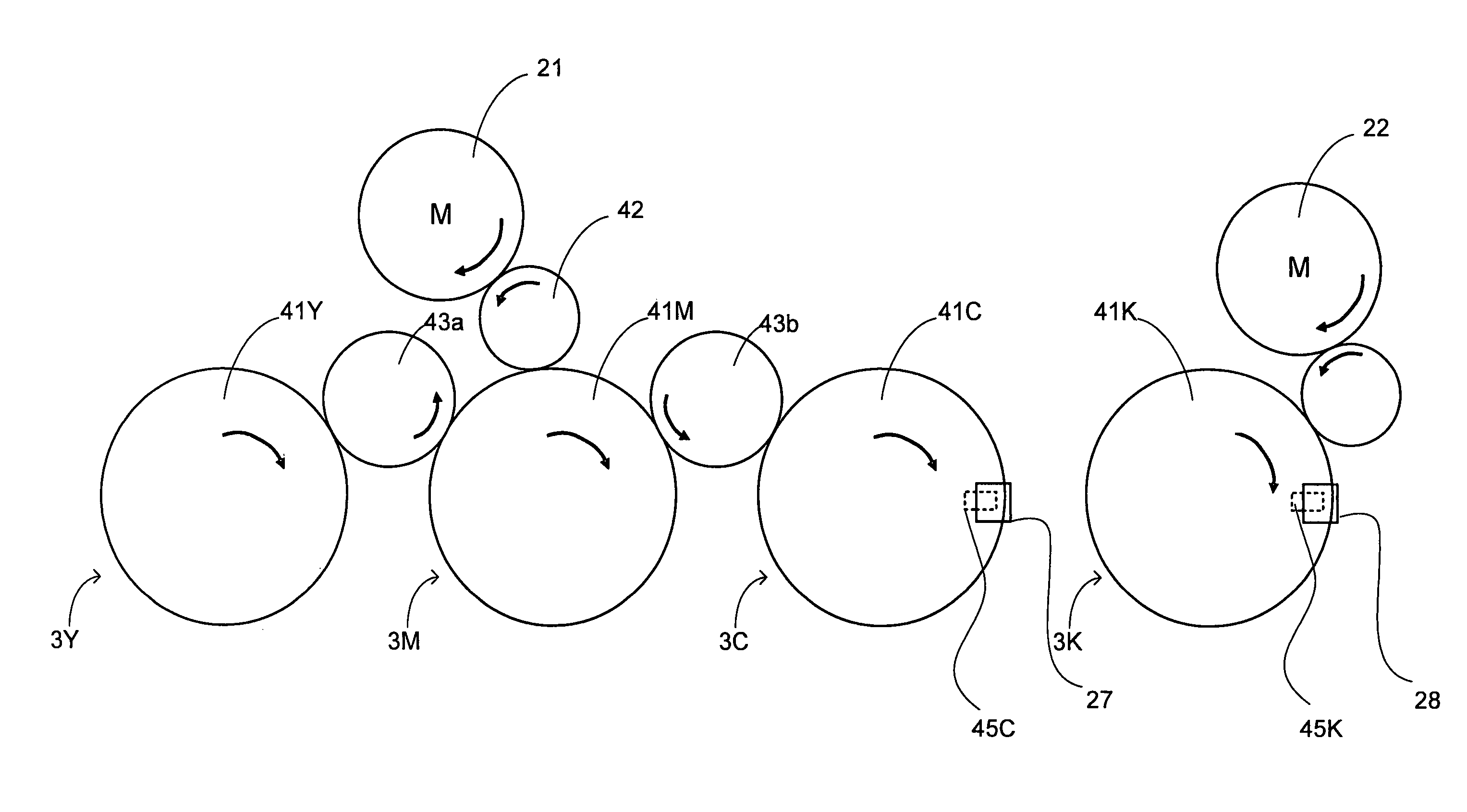

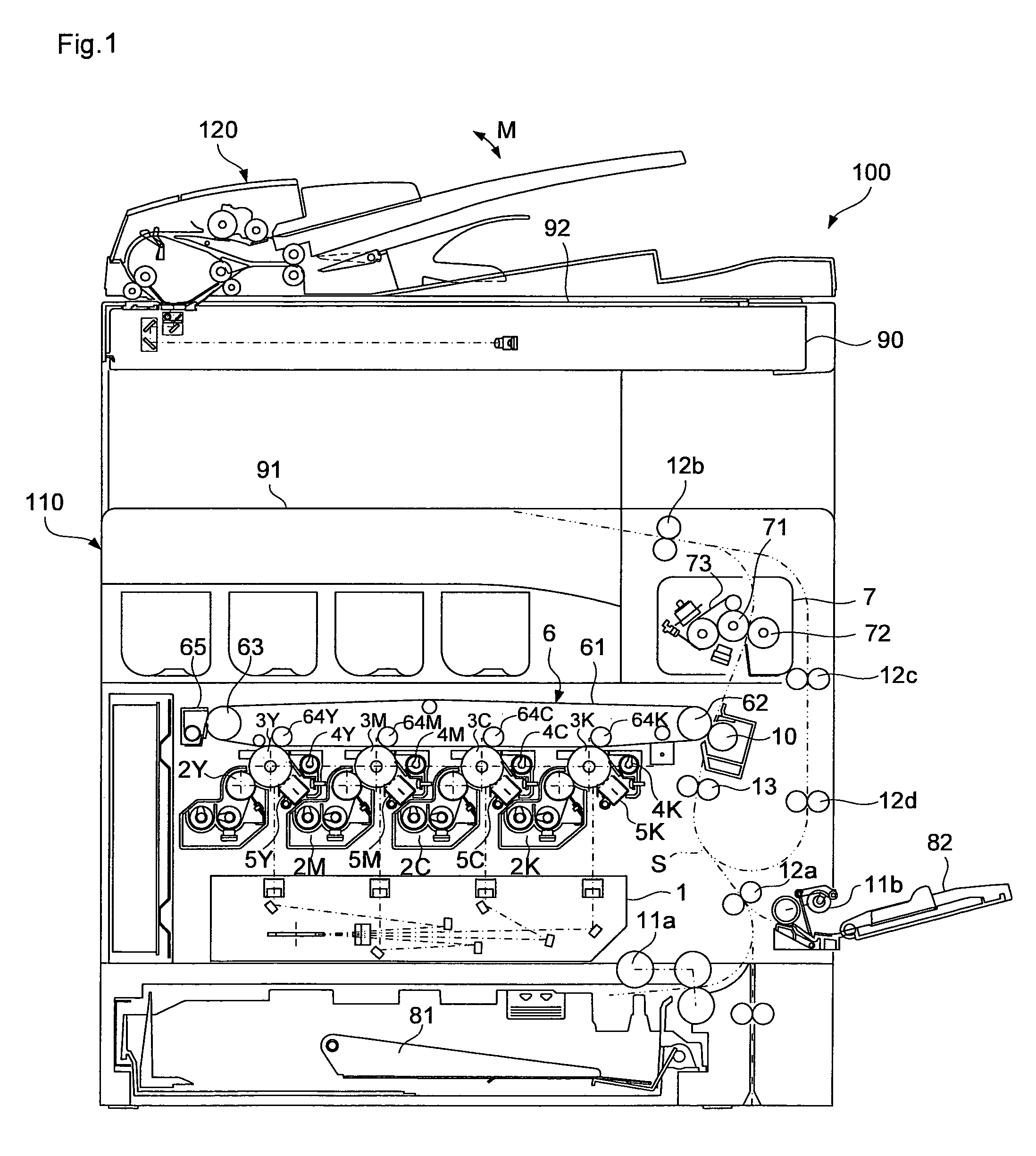

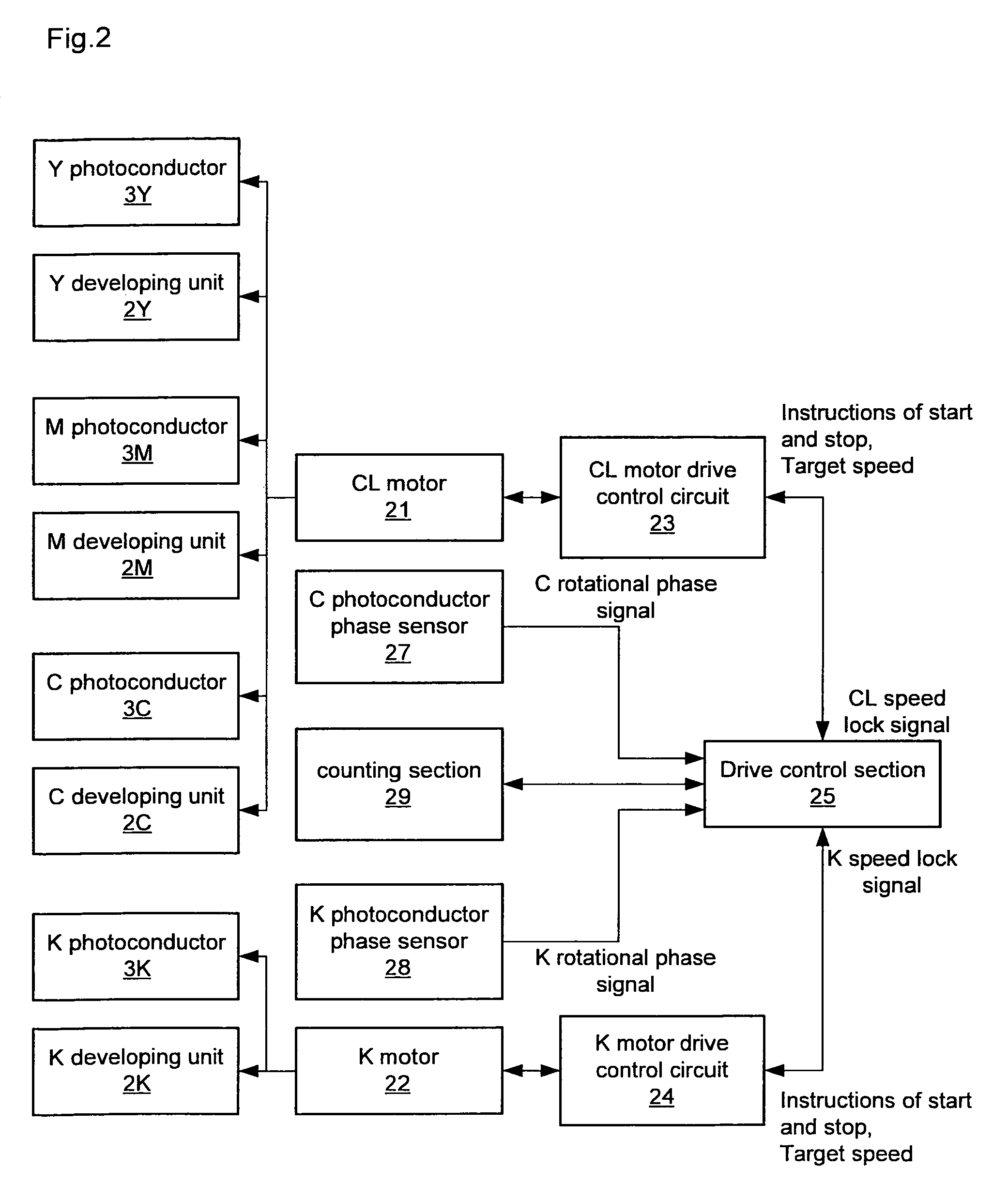

Image forming apparatus

ActiveUS8219004B2Avoid misregistrationHeavy loadElectrographic process apparatusElectrical conductorImage formation

An image forming apparatus including: a first and a second photoconductor groups constituted of one or more photoconductors respectively; a first and a second drive control sections for controlling the drive of the first and the second photoconductor groups respectively to rotate the photoconductors thereof, wherein the rotational phases of the first photoconductor group and the second photoconductor group are adjusted to be matched therebetween; and the first and the second drive control sections control so that predetermined profile of a target speed is applied to the first and second photoconductor groups wherein, in the target-speed profile, the first photoconductor group starts rotating after a elapse of a predetermined startup delay time from the second photoconductor group starts rotating, and both groups end at a same final speed predetermined for full-color image formation, wherein the startup delay time is predetermined based on measurements of times needed for each of the first and the second photoconductor groups to reach a predetermined speed from starting the rotation with the target-speed profile being applied thereto.

Owner:SHARP KK

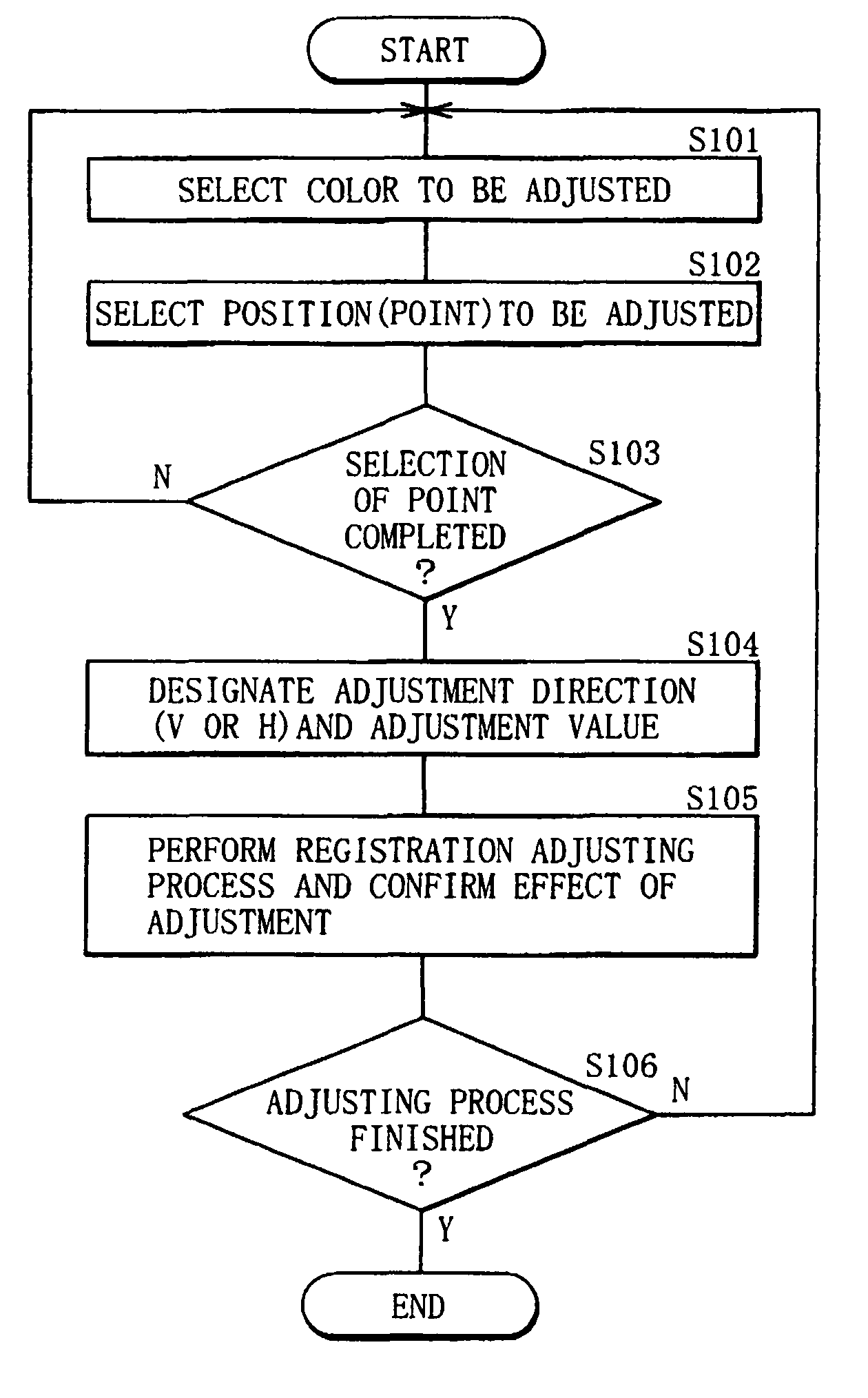

Projection display apparatus for facilitating registration adjustment of colors of a display image

InactiveUS8294834B2Improve work efficiencyReduce misregistrationTelevision system detailsTelevision system scanning detailsProjection displayPrimary color

A projection display apparatus includes: a light source; a spatial light modulation device modulating, on the basis of a video signal, each of primary color lights for color display emitted from the light source; projecting means for projecting, onto a screen, each of the primary color lights modulated by the spatial light modulation device; and correcting means for correcting, based on a given correction value, the video signal for each of the primary color lights so as to reduce misregistration between the primary color lights projected on the screen, and supplying the corrected video signal to the spatial light modulation device. The correcting means is configured to correct the video signal according to a single correction value such that a group of correction target points selected in a projected image on the screen are collectively processed as a single correction unit.

Owner:SONY CORP

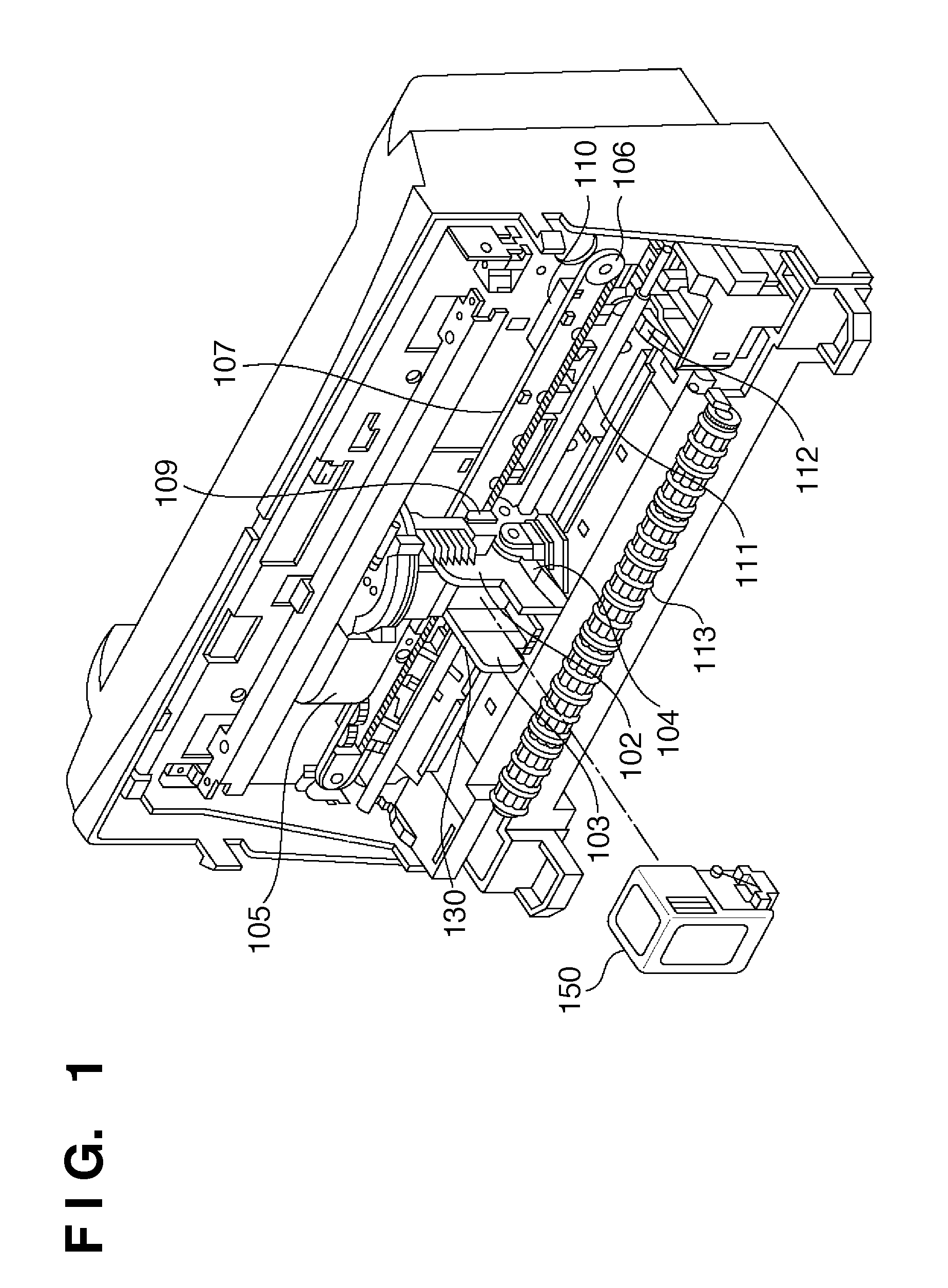

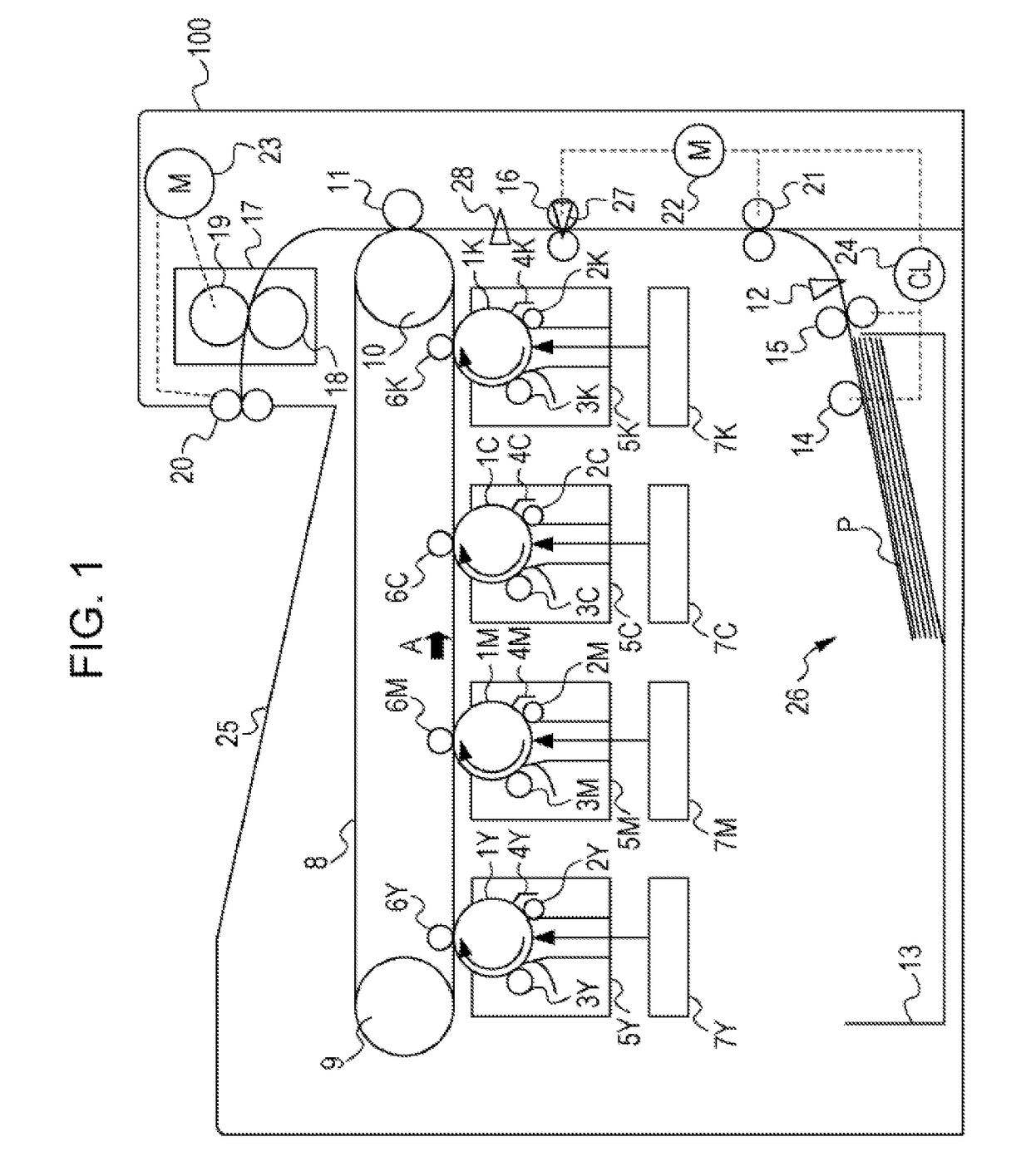

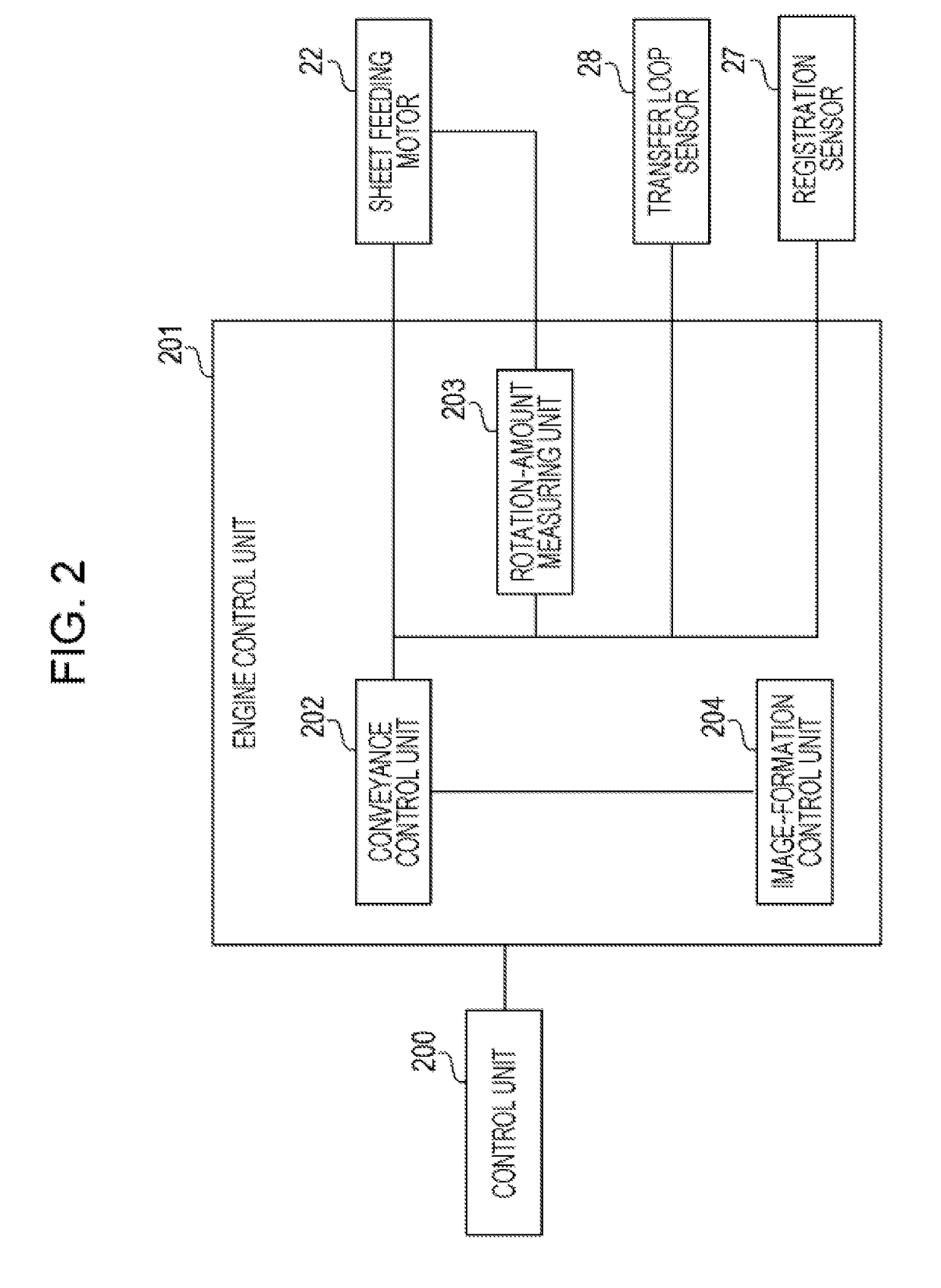

Image forming apparatus

InactiveUS20190018359A1Reduce misregistrationElectrographic process apparatusImage formationMechanical engineering

An image forming apparatus includes a conveying unit, transfer unit, a loop detecting unit, a driving source, a control unit, and a measuring unit. The transfer unit transfers an image formed on an image bearing member to the printing material conveyed by the conveying unit driven by the driving source. The loop detecting unit detects an amount of a loop formed in the printing material between the conveying and transfer units. The control unit changes a rotational speed of the driving source based on the detection result. The measuring unit measures a rotation amount of the driving source while a first printing material is conveyed by both of the conveying and transfer units. The control unit controls the rotational speed of the driving source based on the measured rotation amount so that a leading end of a second printing material reaches the transfer unit per the image bearing member image.

Owner:CANON KK

Projection display apparatus which enables misregistration between primary color lights projected on a screen to be reduced

ActiveUS8199261B2Reduce misregistrationImprove display qualityTelevision system detailsTelevision system scanning detailsComputer graphics (images)Projection display

The present invention provides a projection display apparatus realizing easy recognition of the effect of registration adjustment. The projection display apparatus includes: a light source; a spatial light modulation device modulating, on the basis of a video signal, each of primary color lights for color display emitted from the light source; projecting means for projecting, onto a screen, each of the primary color lights modulated by the spatial light modulation device; and correcting means for correcting, based on a given correction value, the video signal for each of the primary color lights so as to reduce misregistration between the primary color lights projected on the screen, and supplying the corrected video signal to the spatial light modulation device. Validation / invalidation of correction on the video signal by the correcting means is switched in accordance with an operation from the user.

Owner:SONY CORP

Systems and methods for phase-sensitive inversion recovery MR imaging with reduced sensitivity to cardiac motion

ActiveUS10591568B2Reduce misregistrationReduce scan timeMeasurements using NMR imaging systemsInversion recoveryData set

A magnetic resonance imaging system and method are provided for improved phase-sensitive magnetic resonance imaging of tissues affected by cardiovascular pulsatile motion. A magnetically-prepared image dataset and corresponding reference image dataset (for phase sensitivity) are obtained within the duration of a single cardiac cycle. The paired datasets can be single-shot or segmented datasets and a navigator sequence can optionally be provided with each paired dataset. The system and method take advantage of the shape symmetry of the cardiac cycle to acquire the paired dataset in a shorter time interval, thereby reducing misregistration artifacts. The magnetic preparation can include inversion recovery pulses, FIDDLE sequences, other magnetic preparation sequences, or combinations thereof. The reference dataset can be acquired at a lower resolution than the corresponding magnetically-prepared dataset without compromising image quality.

Owner:DUKE UNIV +1

Printing apparatus and printing method

InactiveUS8523310B2Reduce misregistrationOther printing apparatusEngineeringElectrical and Electronics engineering

Owner:CANON KK

Image forming apparatus, misregistration correction control method and computer-readable information recording medium

InactiveUS8305627B2Reduce misregistrationShorten the timeDigitally marking record carriersDigital computer detailsLocation detectionImage formation

Owner:RICOH KK

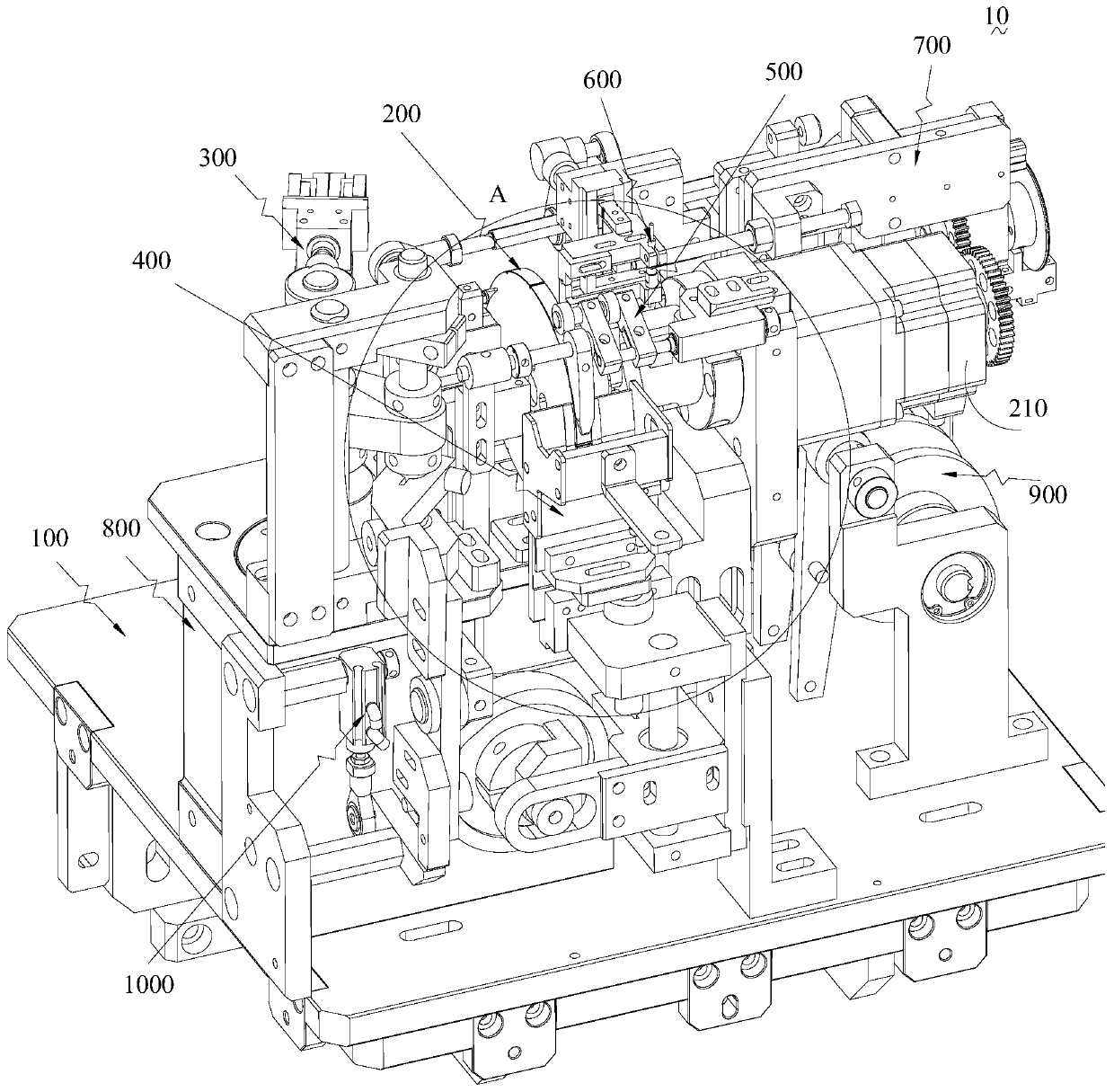

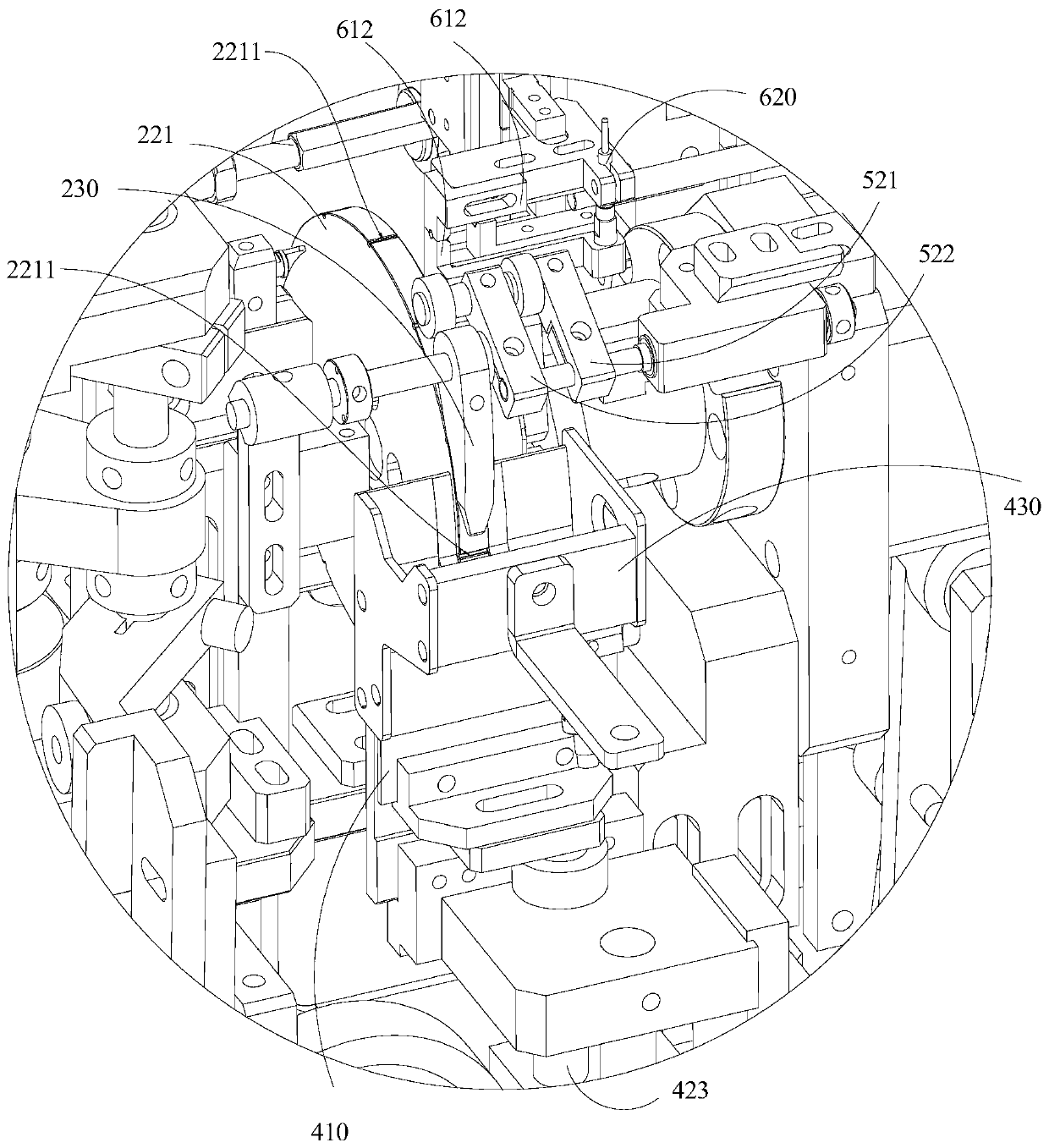

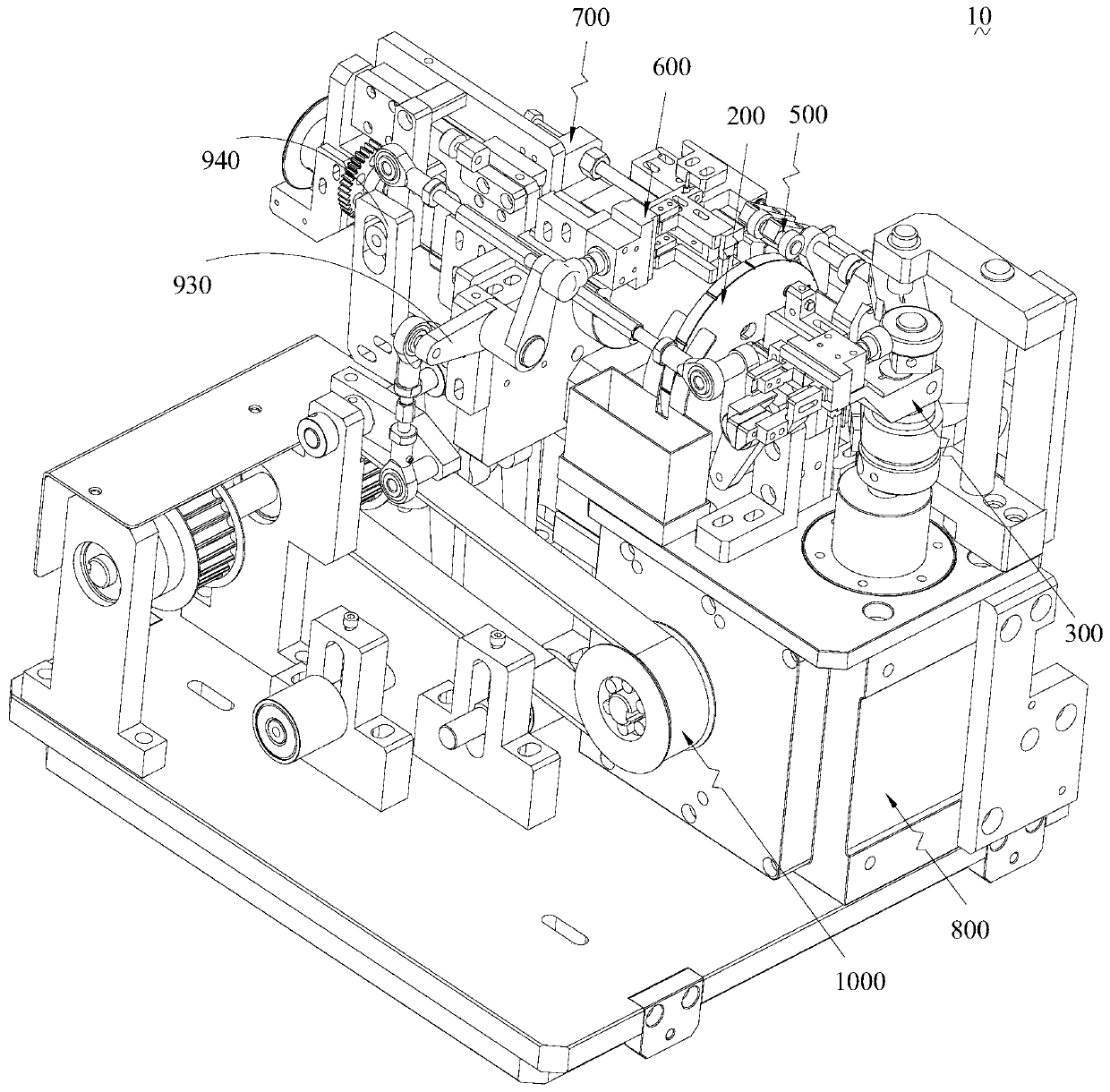

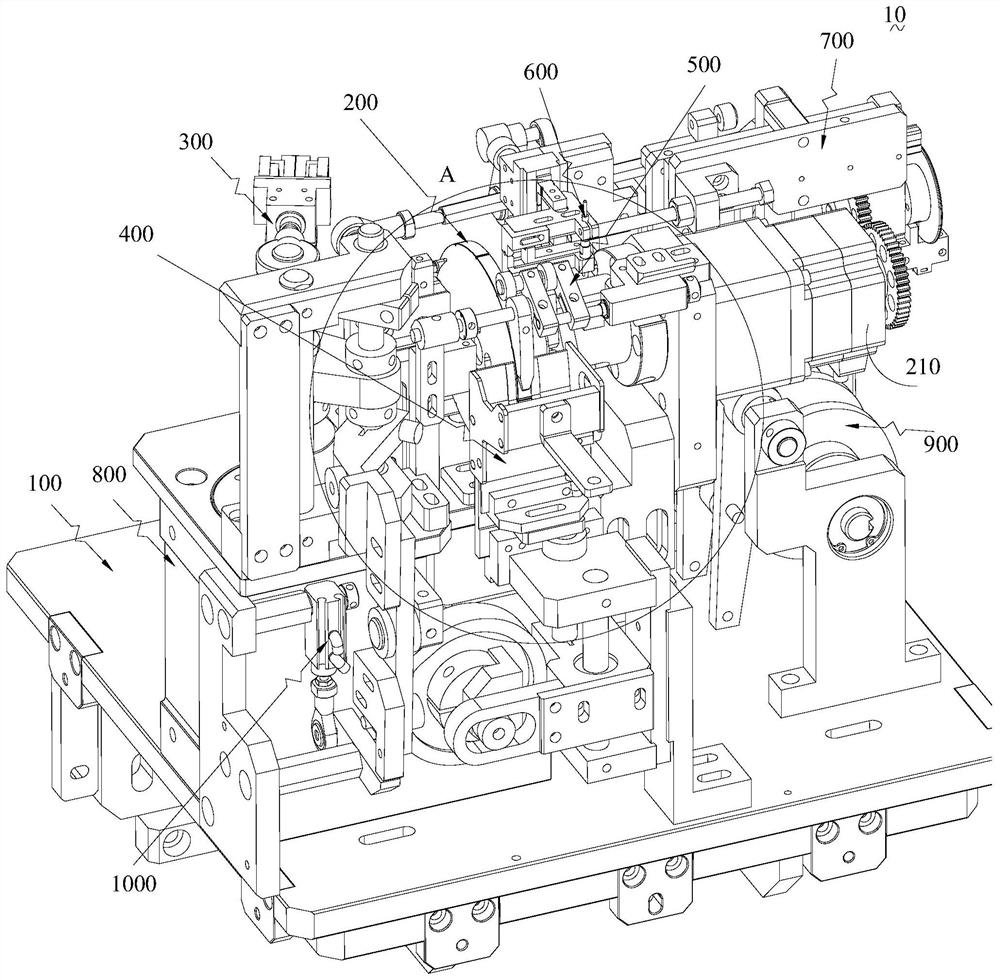

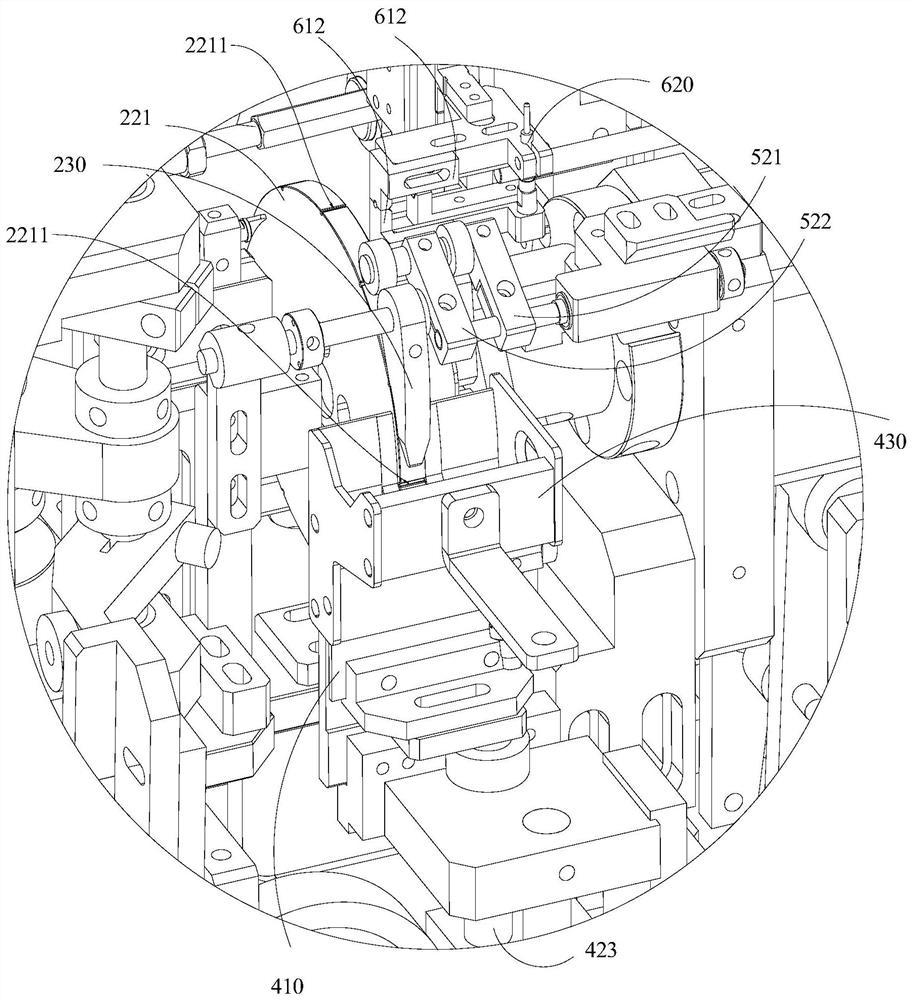

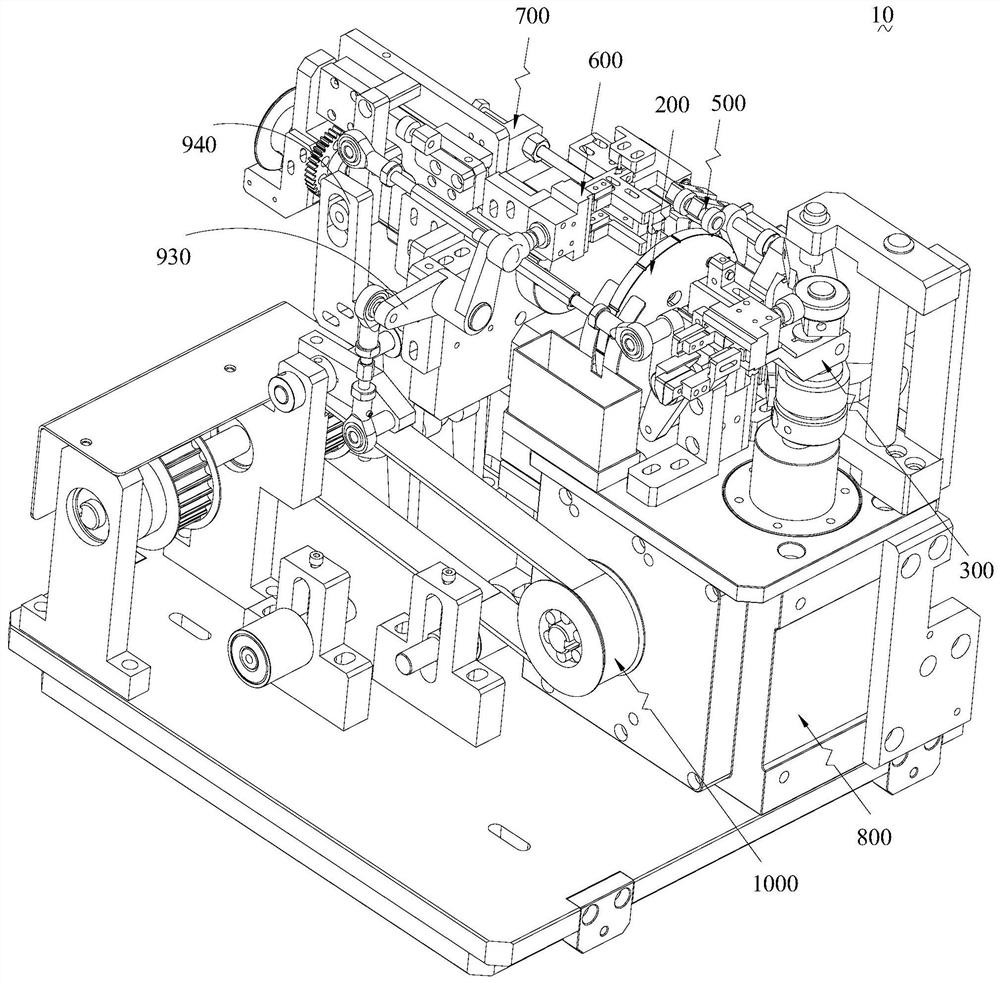

Upper guide pin device and battery machine

ActiveCN110114930AIncrease flexibilityHigh positioning accuracyPrimary cell manufactureAssembling battery machinesElectrical batteryEngineering

The invention provides an upper guide pin device and a battery machine comprising the same. The upper guide pin device comprises a base, a first transfer unit and a second transfer unit, and the firsttransfer unit and the second transfer unit are both arranged on the base; the first transfer unit comprises a rotary disc capable of rotating around the axis of the first transfer unit. The turntablecan adsorb the guide pin and convey the guide pin to the second transfer unit; the second transfer unit comprises a first transmission mechanism, a second transmission mechanism and a mechanical clamp connected to the second transmission mechanism, the first transmission mechanism can drive the mechanical clamp to be opened or closed so as to clamp or loosen the guide pin, and the second transmission mechanism can drive the mechanical clamp to rotate and translate so as to send the guide pin to the next procedure. Therefore, compared with a traditional structure, the upper guide pin device has higher flexibility, the guide pin can be conveyed to the next procedure after being rotated twice and translated once, and therefore the positioning accuracy of the guide pin is effectively improved, the possibility that the guide pin and the foil are inaccurate in alignment is reduced, and the reject ratio of products is reduced.

Owner:SHENZHEN CHENGJIE INTELLIGENT EQUIP CO LTD

Image forming apparatus having misregistration correction

An image forming apparatus includes a plurality of image forming devices having a developing device that develops an electrostatic latent image formed on an image bearing member to form a toner image, and a transferring device that transfers the developed toner image to an intermediate transfer member or a transfer material, for each of a plurality of colors, an exposure unit that irradiates the image bearing member with a laser beam to form the electrostatic latent image on the image bearing member, and a detector that detects an image pattern for correcting misregistration of each color. In addition, a control device corrects the misregistration of each color based on a detection result by the detector. The control device forms an image pattern of one color among the plurality of colors on a first page interval that is between a first image and a second image, and corrects misregistration based on a first period from a timing when a reference signal to form the image pattern of one color among the plurality of colors is transmitted to a timing when the image pattern of one color among the plurality of colors is detected by the detector.

Owner:CANON KK

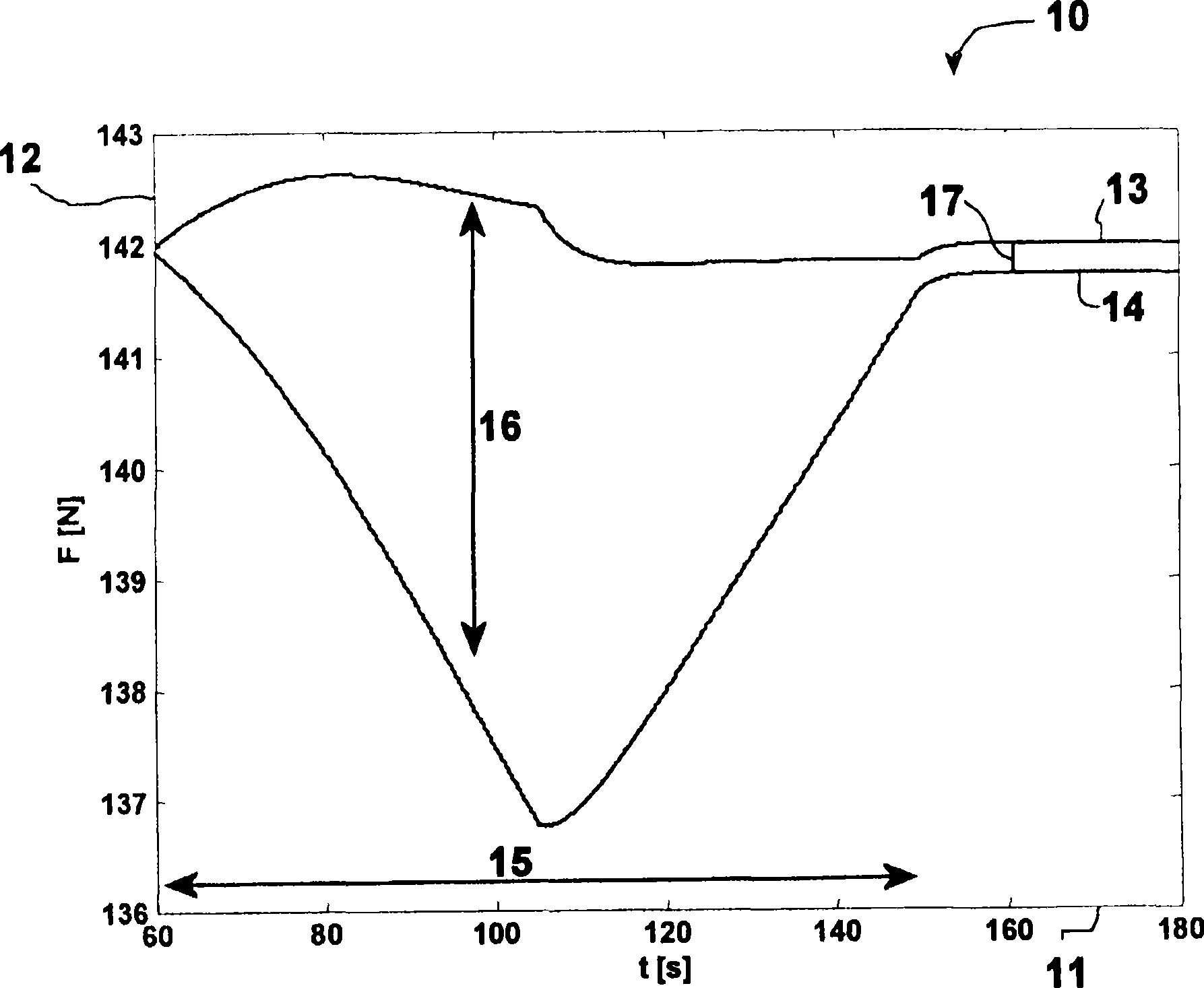

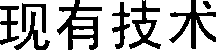

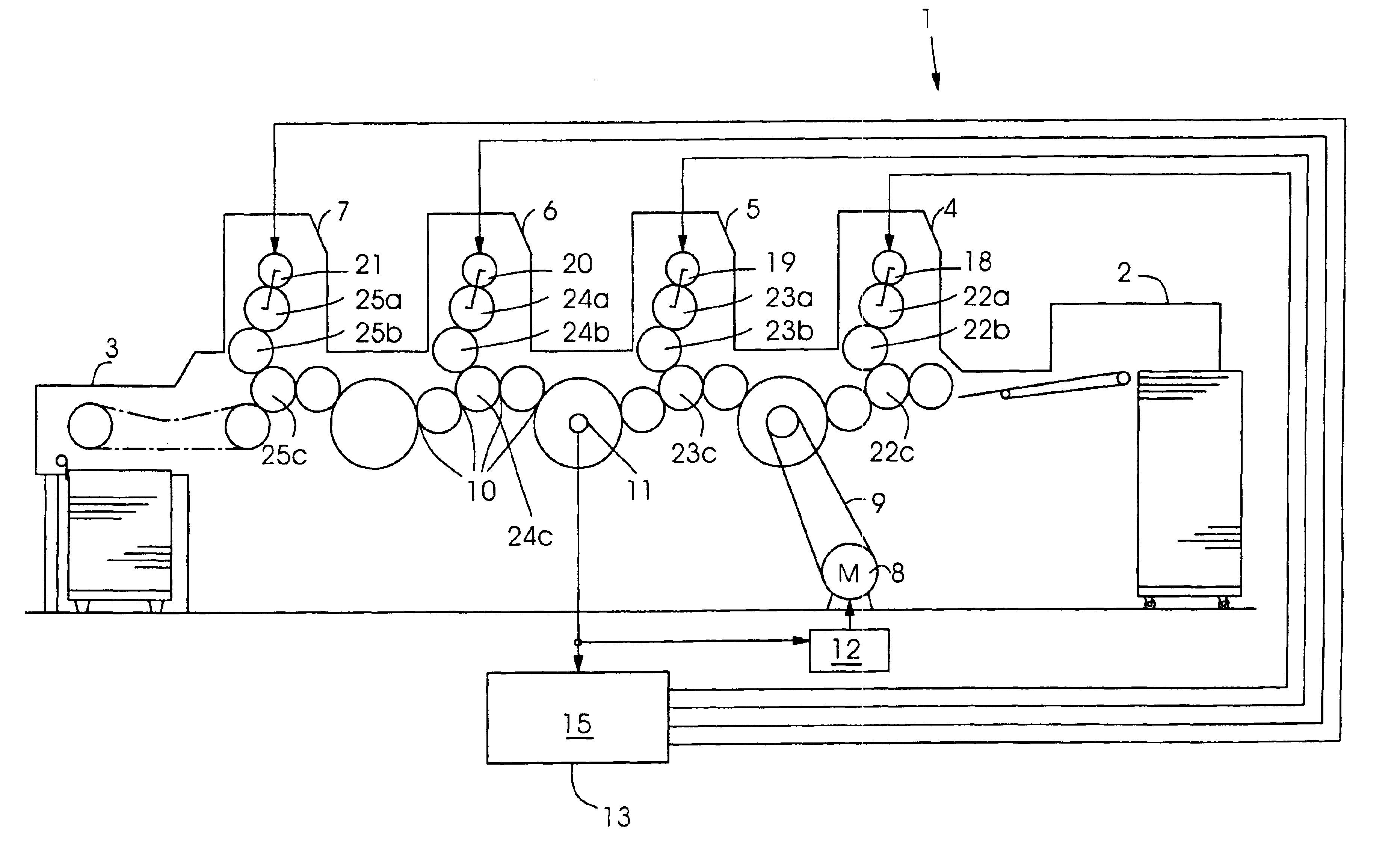

Method of correcting the axis in a processing machine and processing machine

InactiveCN101450544AReduce web tension variationReduce misregistrationFunction indicatorsRotary pressesEngineeringMechanical engineering

Owner:ROBERT BOSCH GMBH

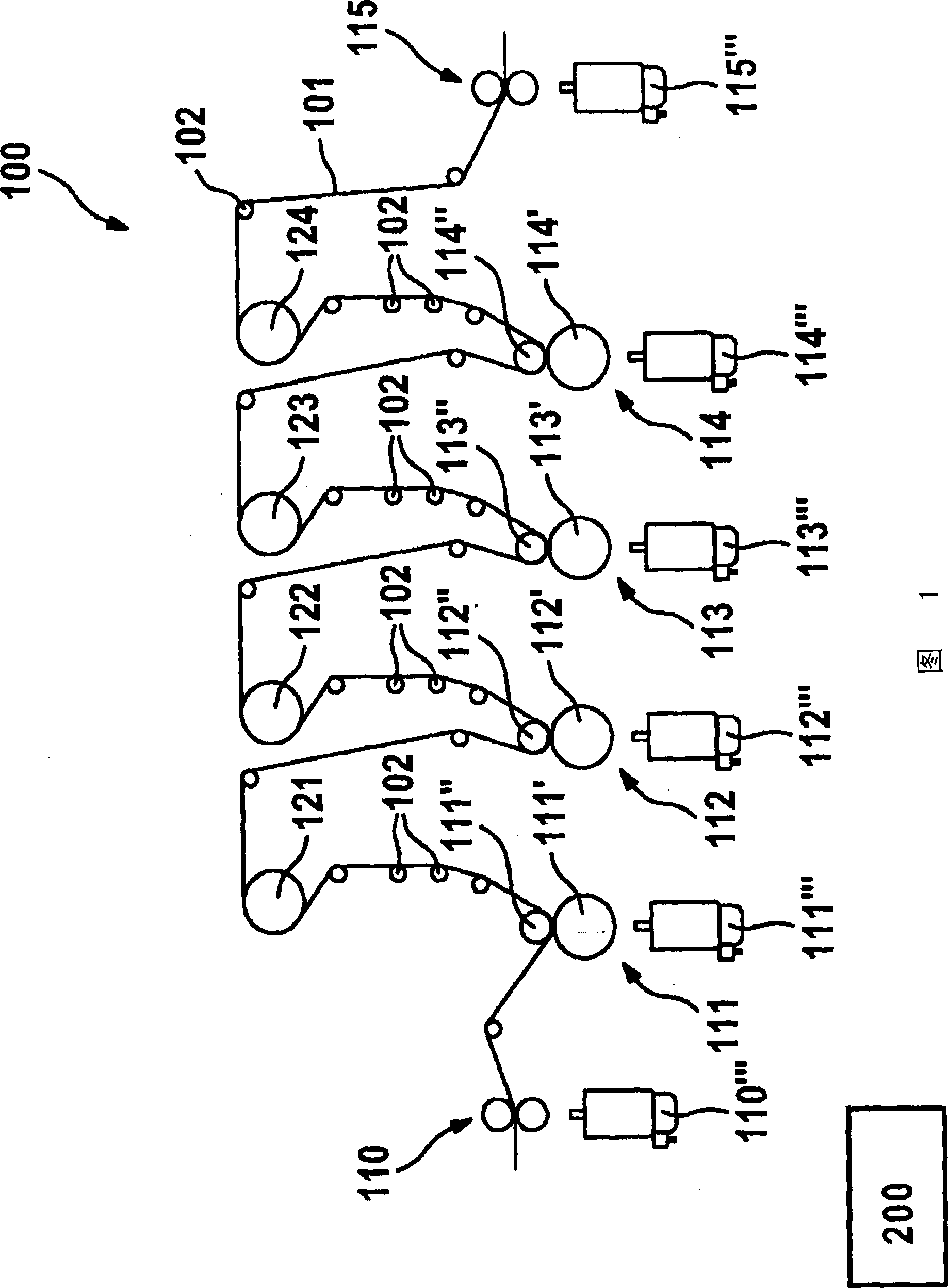

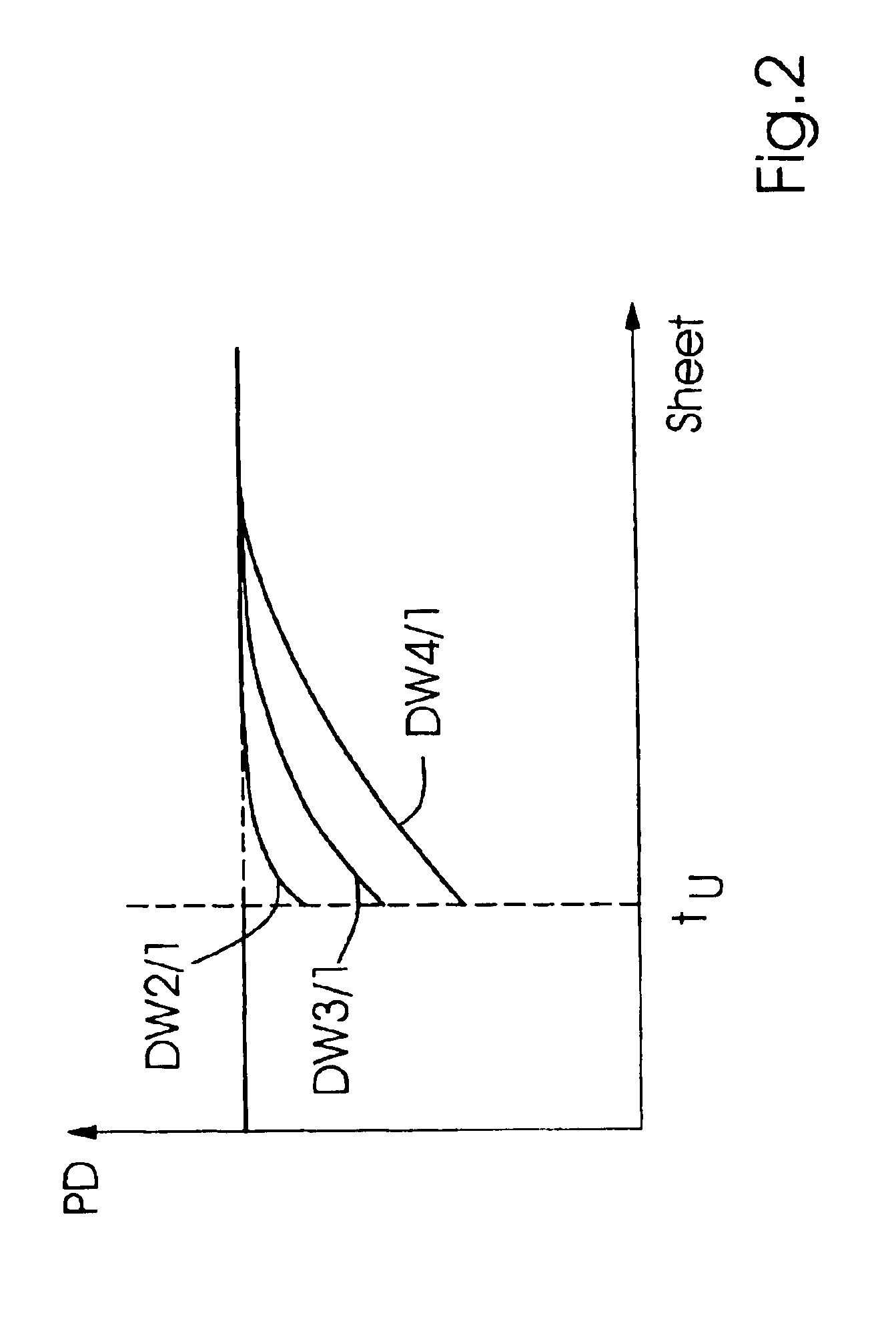

Method of compensating for misregistration during operation of a printing press

InactiveUS6899031B2Reduce misregistrationCompensation control according to the present invention is rapid and simpleAddressographsPlaten pressesPrinting pressElectrical and Electronics engineering

A method is known of compensating for misregistration during operation of a printing press, in particular a sheet-fed offset printing press, in which misregistration occurring in the individual printing units are countered by register corrections. In order to provide a simple method to reduce misregisters after a pause in printing and in particular after washing of the rubber blanket cylinder, the pattern of the misregistration (PD) after a pause in printing is determined in a calibration phase over a sufficient number of sheets, data as a function of the pattern of the misregistration is stored in a memory unit (15) so that register correction values (Ki) may be determined and the register correction values are applied to the printing press upon restart after the pause in printing in order to compensate for the misregistration.

Owner:HEIDELBERGER DRUCKMASHINEN AG

Upper guide pin device and battery machine

ActiveCN110114930BIncrease flexibilityHigh positioning accuracyPrimary cell manufactureAssembling battery machinesElectrical batteryEngineering

The present invention provides an upper guide needle device and a battery machine including the upper guide needle device, including a base, a first transfer unit and a second transfer unit, and the first transfer unit and the second transfer unit are both arranged on the base; The first transfer unit includes a turntable that can rotate around its own axis. The turntable can absorb the guide needle and transfer the guide needle to the second transfer unit. The second transfer unit includes a first transmission mechanism and a second transmission mechanism, and is connected to the second transmission unit. The mechanical clamp of the transmission mechanism, the first transmission mechanism can drive the mechanical clamp to open or close to clamp or loosen the guide pin, and the second transmission mechanism can drive the mechanical clamp to rotate and translate to send the guide pin to the next process. In this way, compared with the traditional structure, the upper guide pin device has higher flexibility, and the guide pin can be sent to the next process after two rotations and one translation, thereby effectively improving the positioning accuracy of the guide pin and reducing the cost of the guide pin. The possibility of misalignment between the needle and the foil, thereby reducing the defective rate of the product.

Owner:SHENZHEN CHENGJIE INTELLIGENT EQUIP CO LTD

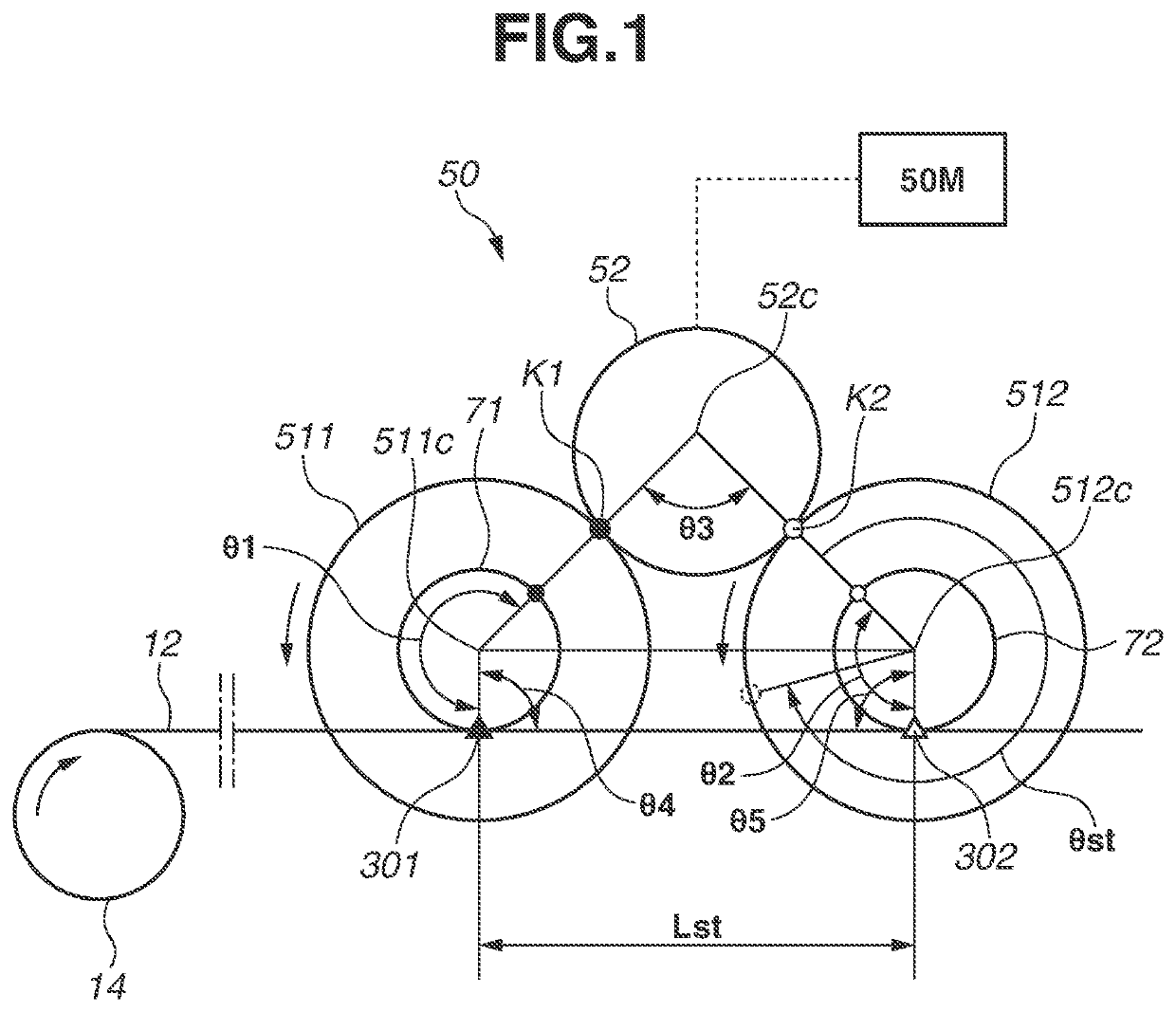

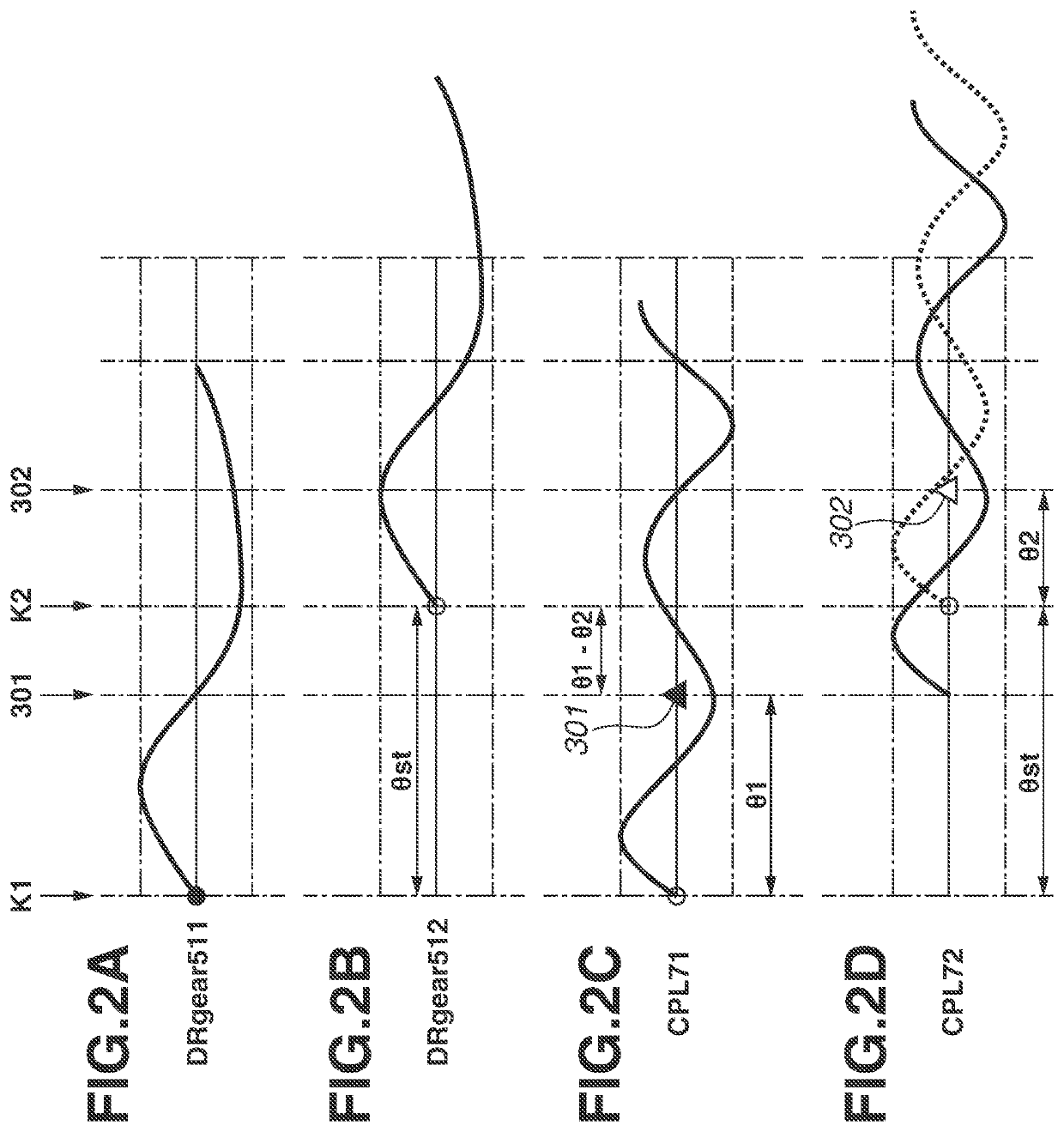

Image forming apparatus

An image forming apparatus includes a driving unit having a first drum gear, a first coupling member, a second drum gear, and a second coupling member. The first coupling member is provided at a first position of the first drum gear. The second coupling member is provided at a second position of the second drum gear and is configured to rotate together with the second drum gear. A first angle from a first meshing position to a first transfer position in a first direction and a second angle from a second meshing position to a second transfer position in a second direction are different from each other. The second position of the second drum gear is shifted from a position corresponding to the first position of the first drum gear by a difference between the first angle and the second angle in a direction opposite of the second direction.

Owner:CANON KK

Light scanning apparatus and image forming apparatus

InactiveUS8466937B2Suppress fluctuationsQuality improvementInking apparatusVisual presentationControl signalLight beam

A light scanning apparatus including: a light source to emit a laser beam; a light source driving unit to turn on and off the light source according to image data and a pixel clock; a rotary polygon mirror to deflect the light beam; a motor to rotationally drive the rotary polygon mirror; and a control unit to control a rotary speed of the motor to generate an acceleration control signal for accelerating the rotary speed and a deceleration control signal for decelerating the rotary speed, wherein for the acceleration control signal, the driving unit corrects the frequency of the pixel clock to be higher than the frequency, which is before the acceleration control, and for the deceleration control signal, the driving unit corrects the frequency of the pixel clock to be lower than the frequency, which is before the deceleration control.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com