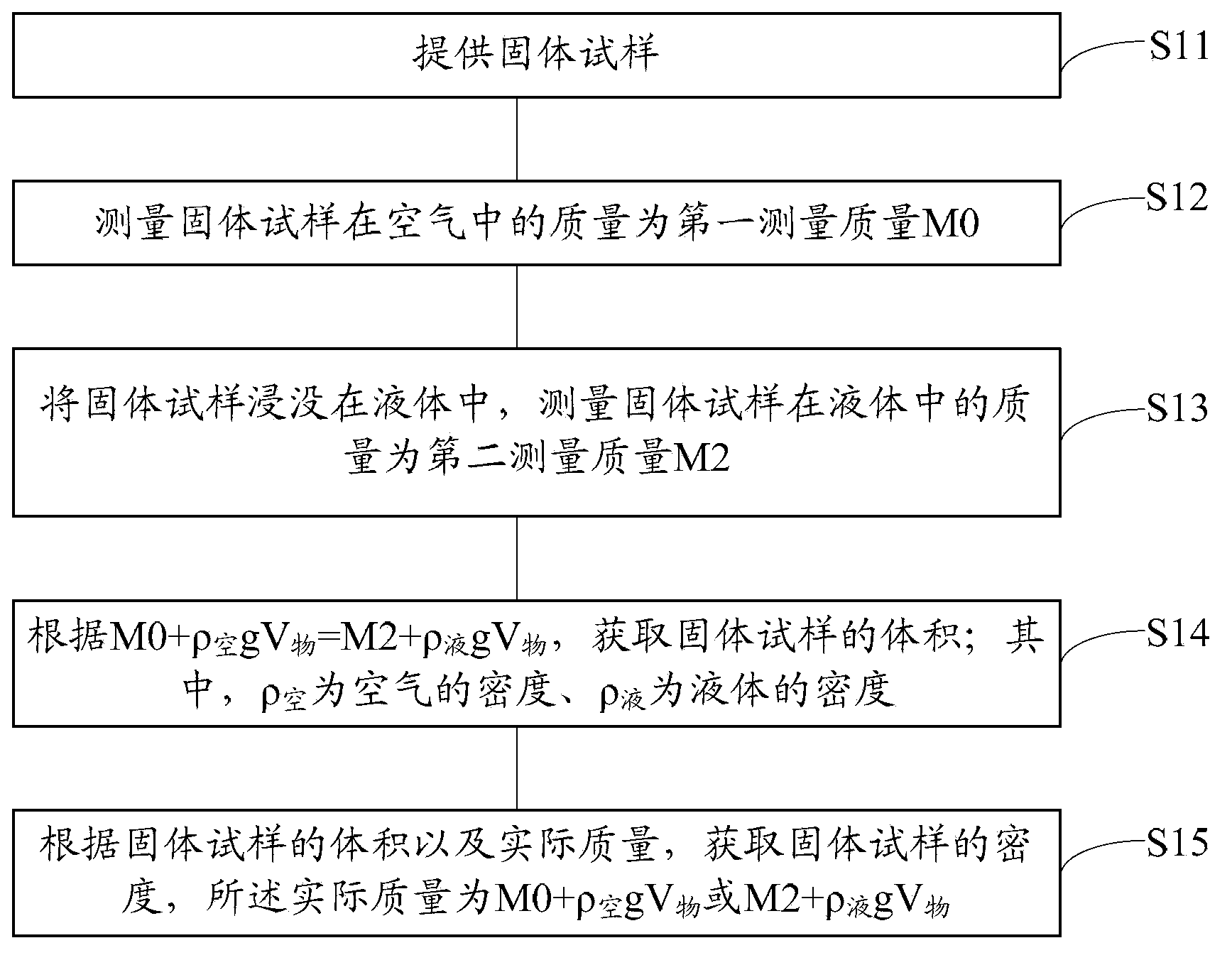

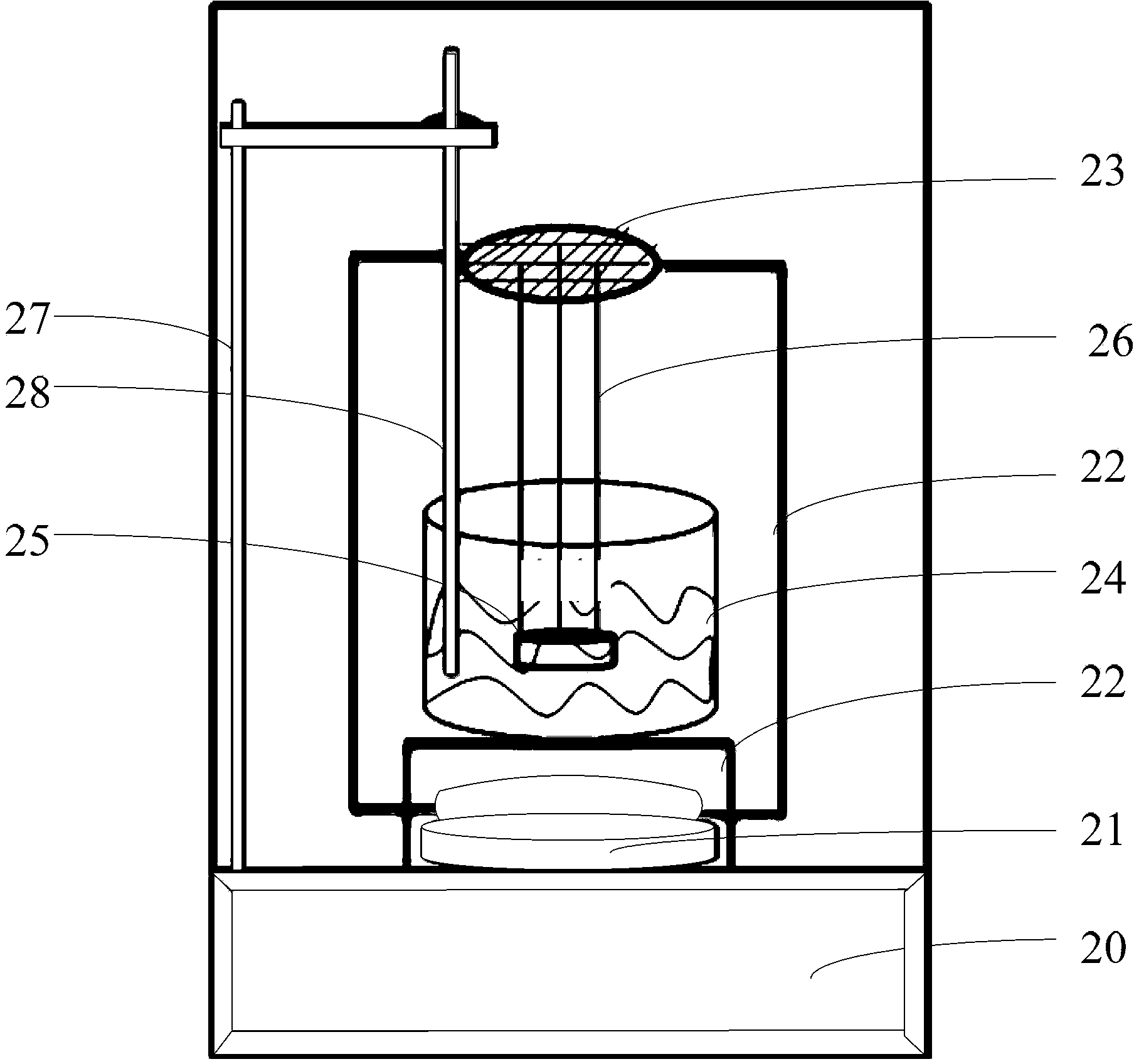

Solid density measure method and method for detecting density qualification of target material

A density measurement, solid technology, applied in the field of measuring instruments, can solve the problem of low detection accuracy of target density, and achieve the effect of accurate method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] After serious research and analysis, the inventor found that the reason for the low detection accuracy of the target density is:

[0047] The material of the target is a metal or hard alloy with high purity and excellent compactness, especially for the metal or hard alloy which requires very high compactness. In the process of manufacturing the target, the metal or hard alloy powder is sintered to form a denser metal or hard alloy. However, in the process of powder sintering and densification, it is easy to generate cavities inside the metal or cemented carbide, and then there are cavities inside the target formed by subsequent processing. If the target with more voids inside is not detected in the subsequent target density detection step and continues to be used in the sputtering process, it will not only affect the progress of the sputtering process, but also the quality of the film on the substrate will not be high. .

[0048]In the prior art, the target density is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com