Printing adjustment system and method

An adjustment method and printing output technology, applied in the direction of printing, printing machines, general parts of printing machinery, etc., can solve problems such as resource consumption and time error effects, and achieve the effect of eliminating shortcomings and problems and eliminating complete dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

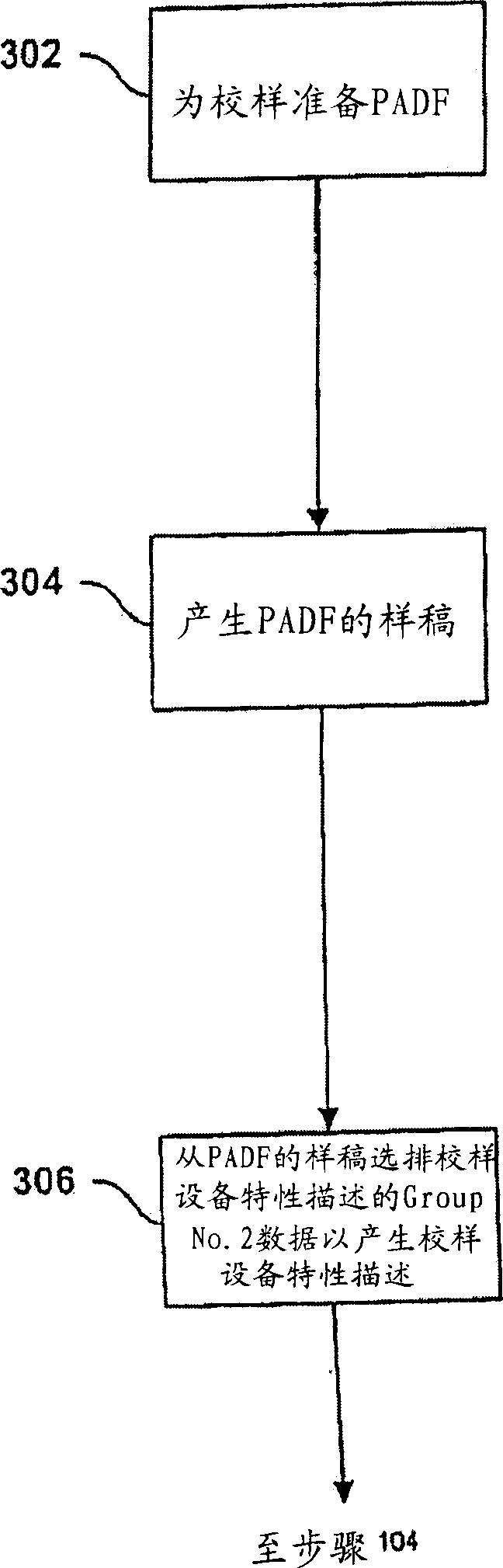

[0046] Color density measurements can be used to allow adjustment of the printing press to conform to proofs in the Printing Adjustment Data Format (PADF). The present invention contemplates the use of various typography or print output devices such as Figure 15 As shown, they are able to use printing presses to provide printed matter with processes such as lithography, type printing, gravure printing, flexographic printing, and screen printing, as well as various modified lithographic printing, such as waterless lithography, based on Printing with single fluid inks, and plateless digital offset printing, and in some cases, processing by electrophotographic printing, thermal printing, and inkjet printing. Aspects of the invention may be used with some or all of these print output devices.

[0047] Four measurement paths are commonly used: C, M, Y, V to provide the color density of any sample being measured.

[0048] C, M, Y and V are expressed as follows:

[0049] C = desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com