Fabric ironing device for garment processing

An ironing device and fabric technology, applied in washing devices, applications, ironing machines, etc., can solve the problems of inability to meet production needs, low degree of automation, increase labor costs, etc., and achieve labor saving, high degree of automation, and improved ironing. The effect of the perm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

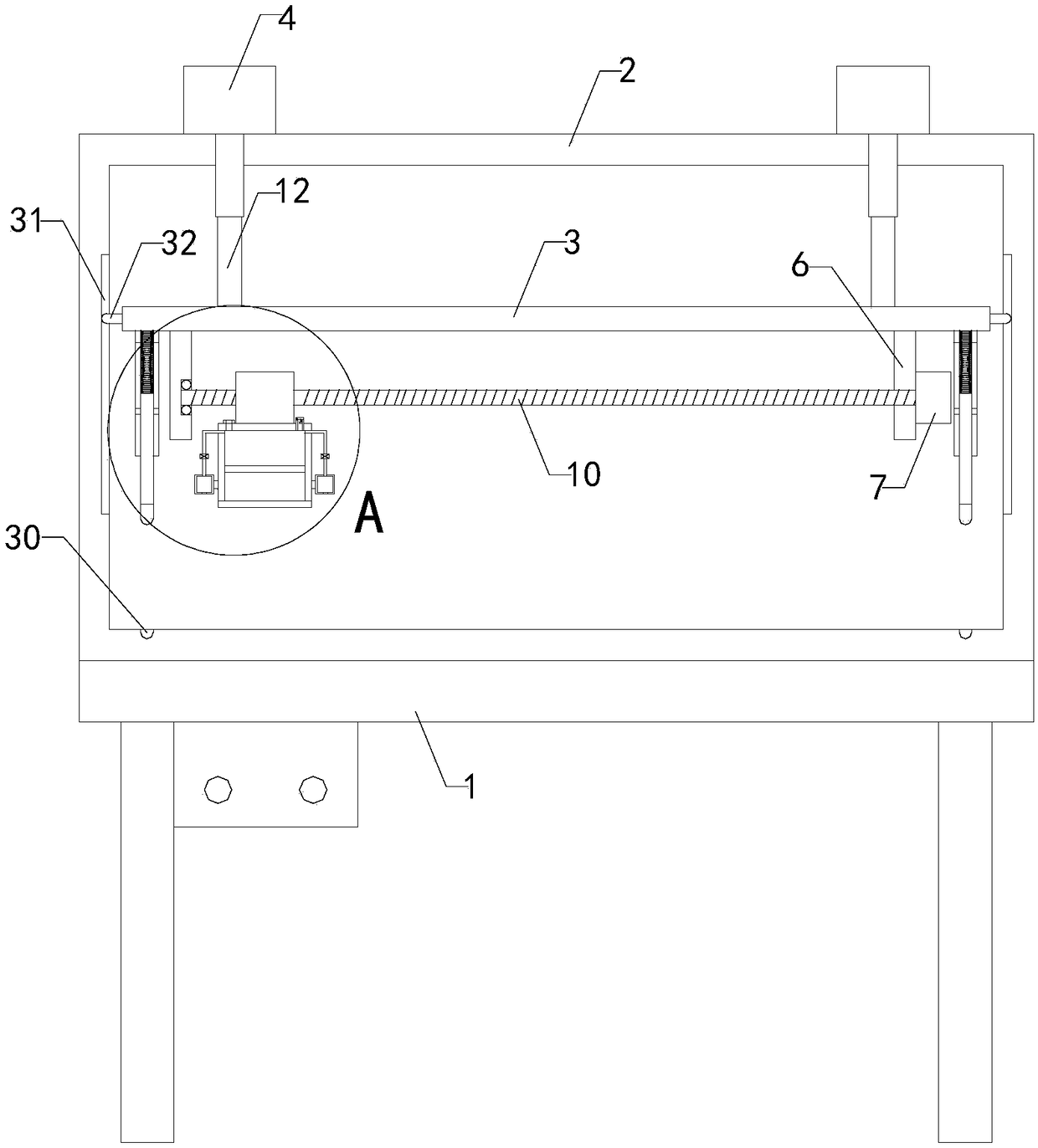

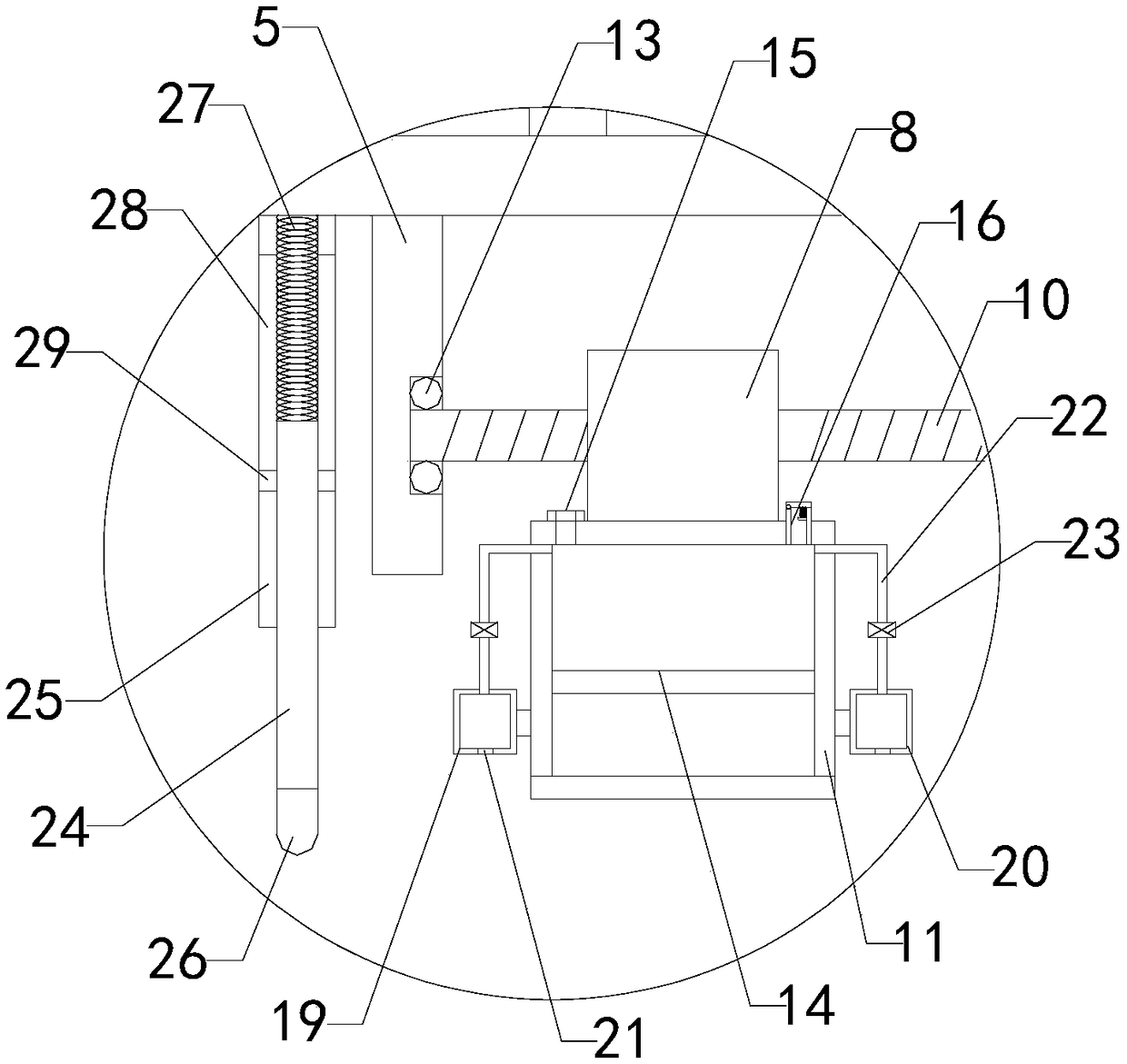

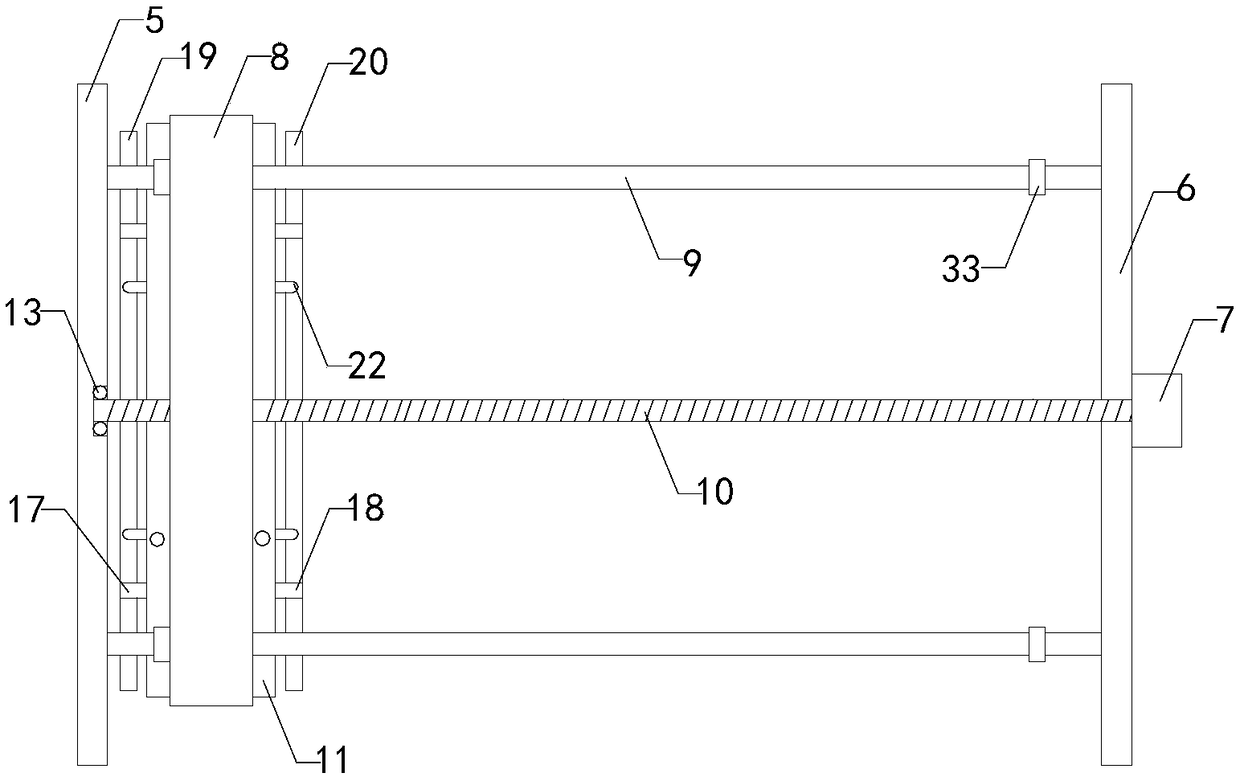

[0016] Such as Figure 1 to Figure 3 As shown, a fabric ironing device for garment processing of the present invention includes a frame 1; also includes a box body 2, a lifting platform 3, a cylinder group 4, a left support plate 5, a right support plate 6, a drive motor 7, and a slide plate 8. Two sets of limit rods 9, lead screw 10 and heating box 11, the box body is installed on the top of the frame, and a working chamber is arranged inside the box body, the cylinder group is installed on the top of the box body, and the cylinder group A piston rod 12 is provided at the output end of the bottom of the box body, and the bottom end of the piston rod extends into the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com