Drying closet

A dry wardrobe and cabinet body technology, applied in the field of dry closets, can solve the problems of being unable to meet the safety requirements of ships, warships, etc., not equipped with dry closets, low efficiency and waste of energy, etc. Deformation and qualitative change, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further explained below in conjunction with specific drawings.

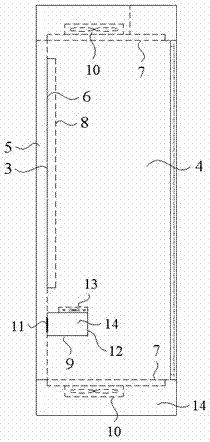

[0017] Such as figure 1 with figure 2 As shown, the drying closet includes a square airtight cabinet 1, on which a cabinet door 2 that can be freely opened and closed is provided, and a hot cavity 4 and a cold cavity 5, a hot cavity 4 and a cold cavity 5 are provided in the cabinet 1 Separated by the partition 3, clothes are placed in the hot cavity 4, a hot and cold air circulation is formed between the hot cavity 4 and the cold cavity 5, and a condensed water reservoir 14 or a condensed water outlet is provided at the bottom of the cabinet 1.

[0018] The partition 3 includes a vertical plate 6 and two horizontal plates 7. The vertical plate 6 is located at a position close to the rear of the cabinet 1 corresponding to the cabinet door 2, and is located in the cabinet 1. The two horizontal plates 7 are respectively provided On the upper and lower sides of the vertical plate, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com