Preparation system for soft fixed grain pneumatic grinding wheels

A pneumatic grinding wheel and consolidated abrasive technology, which is applied in the direction of grinding/polishing equipment, grinding devices, manufacturing tools, etc., can solve the problems of insufficient automation, low controllability, and poor practicability, and achieve fast curing time, The effect of strong controllability and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

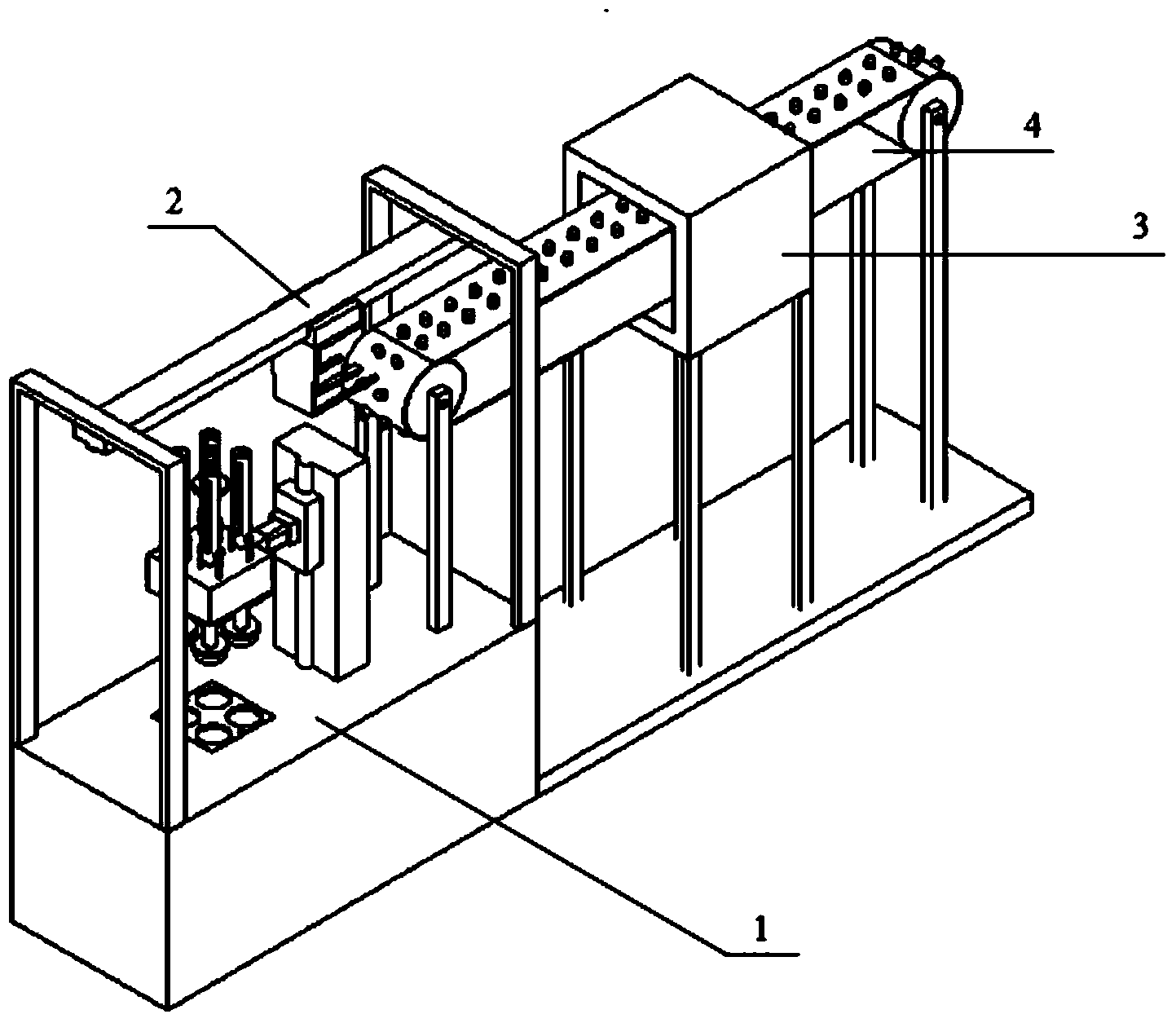

[0027] refer to Figure 1 to Figure 7 , a preparation system for soft-consolidated abrasive pneumatic grinding wheels, characterized by including a material injection system, a compression molding system 1, a pick-up system 2, a surface curing system 3, and a delivery system 4;

[0028] The injection system includes an injection frame 17, an injection frame 18 and a linear motor 19, the injection frame 17 is arranged on the injection frame 18, and the injection frame 18 is installed on the On the linear motor 19, the position is controlled by the linear motor 19, and the injection system controls the dosage of the injected raw material and completes the injection work of the raw material;

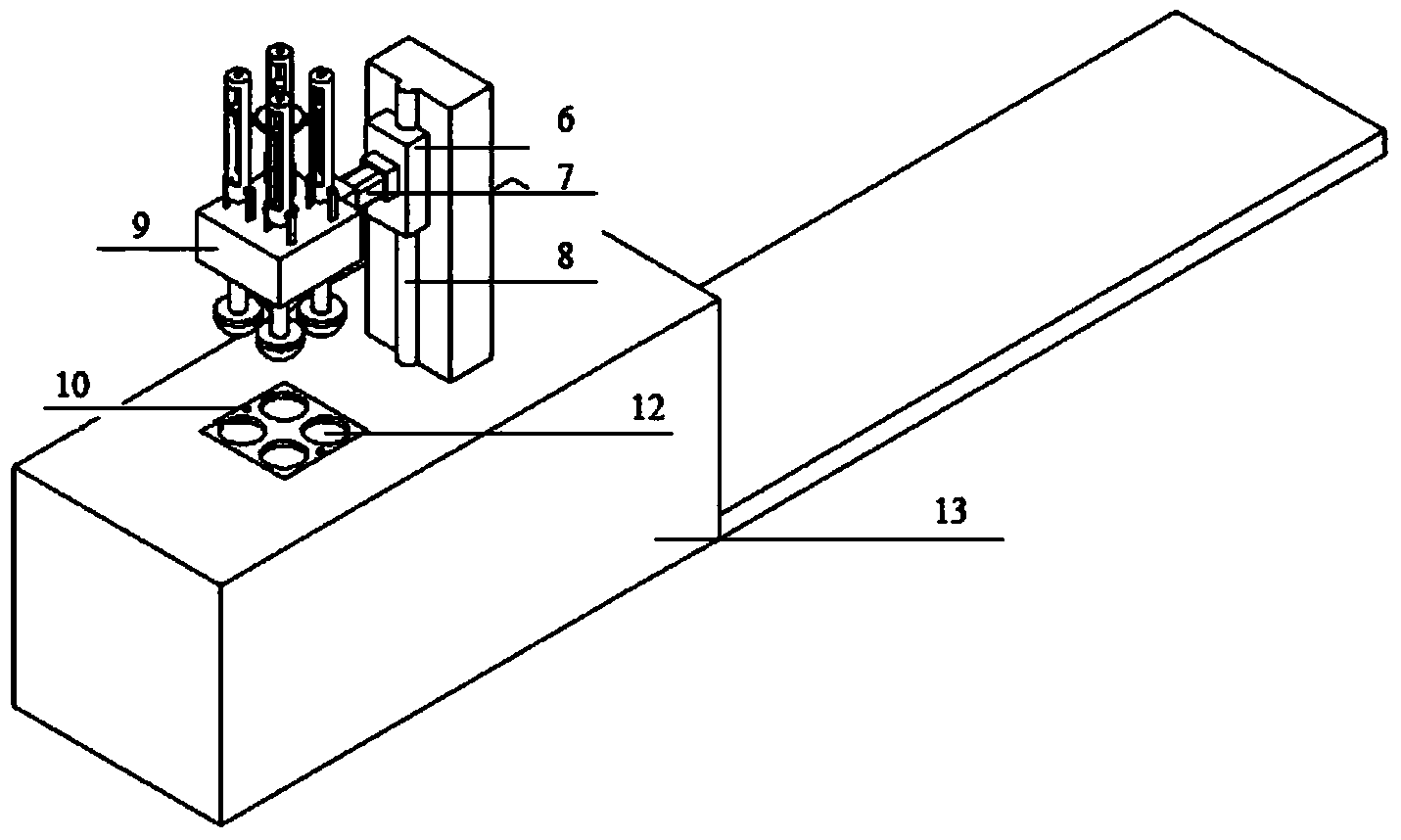

[0029] The compression molding system 1 includes a ball screw system 6, a slide rail 8, a bearing platform 9, a stepper motor 7, an upper mold module for a soft-consolidated abrasive pneumatic grinding wheel, a lower mold module for a soft-consolidated abrasive pneumatic grinding wheel, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com