Graphite tank for sintering silicon carbide ceramic tube, high-performance silicon carbide ceramic tube and preparation method thereof

A silicon carbide ceramic and graphite groove technology, applied in the field of engineering ceramic materials, can solve problems such as difficulty in ensuring the straightness and roundness of pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

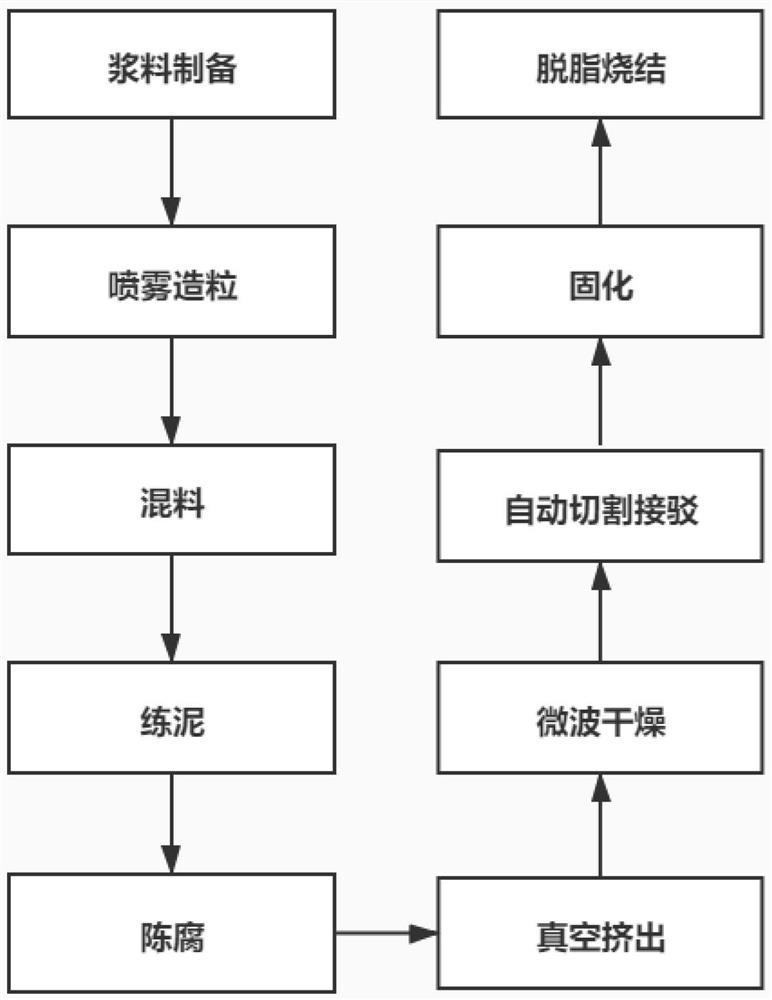

Method used

Image

Examples

Embodiment 1

[0076] 1) Slurry preparation:

[0077] The main raw material is composed of the following components by weight: 99.5wt% submicron silicon carbide powder and 0.5wt% boron carbide;

[0078] Add 1.0wt% polyethylene glycol, 0.3wt% tetramethylammonium hydroxide, and 10.0wt% water-based phenolic resin into deionized water, and stir for 5 minutes to dissolve and disperse evenly to form an aqueous solution of organic additives. The total weight of deionized water is 125wt% of the silicon carbide powder;

[0079] The organic additive aqueous solution, submicron silicon carbide powder, and boron carbide are sequentially added into a sand mill, and there are 200wt% silicon carbide ceramic balls in the sand mill, and stirred evenly to form a silicon carbide slurry. Slurry ball milling time is 4h;

[0080] 2) Spray granulation:

[0081] The above slurry is subjected to spray granulation, wherein the inlet temperature is 220°C and the outlet temperature is 110°C;

[0082] 3) Mixing:

...

Embodiment 2

[0098] 1) Slurry preparation:

[0099] The main raw material is composed of the following components by weight: 99.7wt% submicron silicon carbide powder and 0.3wt% boron carbide;

[0100] Add 0.5wt% polyethylene glycol, 0.5wt% tetramethylammonium hydroxide, and 12.0wt% water-based phenolic resin into deionized water, and stir for 8 minutes to dissolve and disperse evenly to form an aqueous solution of organic additives. The total weight of deionized water is 110wt% of the silicon carbide powder;

[0101] The organic additive aqueous solution, submicron silicon carbide powder, and boron carbide are sequentially added into a sand mill, which contains 150 wt% silicon carbide ceramic balls, and stirred evenly to form a silicon carbide slurry. The slurry ball milling time is 2h.

[0102] 2) Spray granulation:

[0103] The above slurry is subjected to spray granulation, wherein the inlet temperature is 210°C and the outlet temperature is 100°C;

[0104] 3) Mixing:

[0105] The ...

Embodiment 3

[0119] After the obtained spray granulation powder is directly added into deionized water, it is smelted and stale. The rest are identical to Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com