Heat dissipation type photovoltaic terminal box

A volt junction box and heat dissipation technology, applied in the field of photovoltaic power generation, can solve the problems of cumbersome installation, high cost, and complicated results, and achieve the effects of expanding convection space, high reliability, and rapid heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

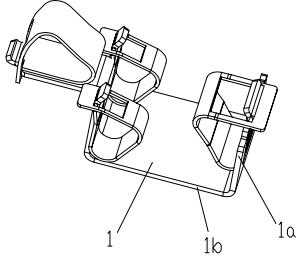

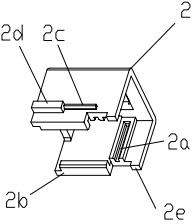

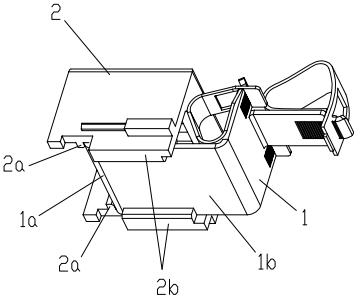

[0027] The present invention consists of the following parts: a terminal assembly 1 , a support 2 , a photovoltaic junction box base 3 , a photovoltaic junction box upper cover 4 , and a diode 5 . Among them, the typical structure of the terminal assembly 1 consists of figure 1 As shown, the terminal assembly 1 can also adopt other deformed structures. The support member 2 can adopt two structures, which are respectively composed of figure 2 , Figure 4 show. The structure of the photovoltaic junction box base 3 consists of Figure 6 show, Figure 6A for Figure 6 A partial enlargement of the .

[0028] figure 2 shows the structural diagram of the first type of support; image 3 An assembled view of the terminal assembly and the first type of support is shown. Such as image 3 As shown, the supporting member 2 is snapped int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com