Manufacturing method of partition plate in multi-cylinder compressor

A compressor manufacturing method technology, applied in the field of compressors, can solve the problems of processing waste materials, harsh processing conditions, and low processing efficiency, and achieve the effects of reducing processing costs, good dimensional accuracy, and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In this embodiment, the two-cylinder compressor includes two sliding vanes, two pistons, two cylinders, one crankshaft, one main bearing, and one auxiliary bearing.

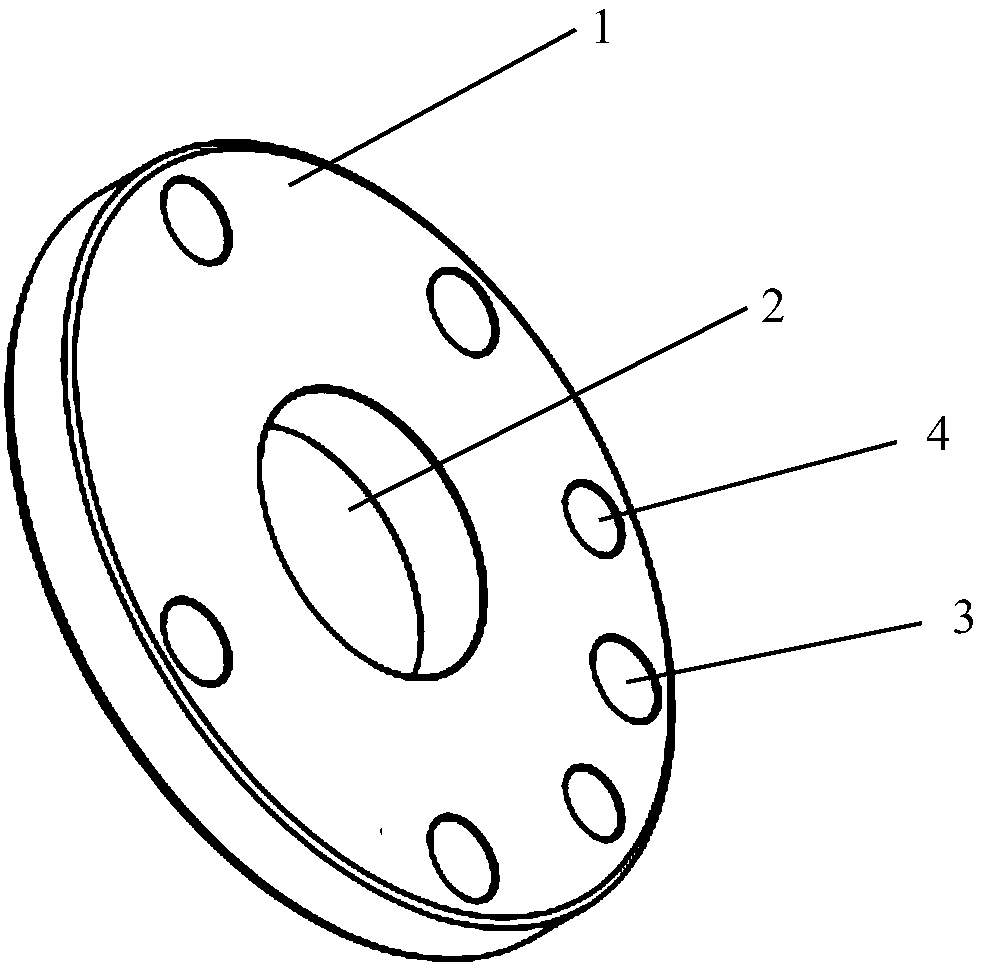

[0036] There is a partition 1 between the two cylinders, such as figure 1 As shown, the separator 1 is disc-shaped. A first through hole 2 is provided on the partition 1 for the crankshaft to pass through. In addition, installation through holes are provided on the partition 1, including five second through holes 3 with a diameter of 105 mm and two third through holes 4 with a diameter of 8 mm.

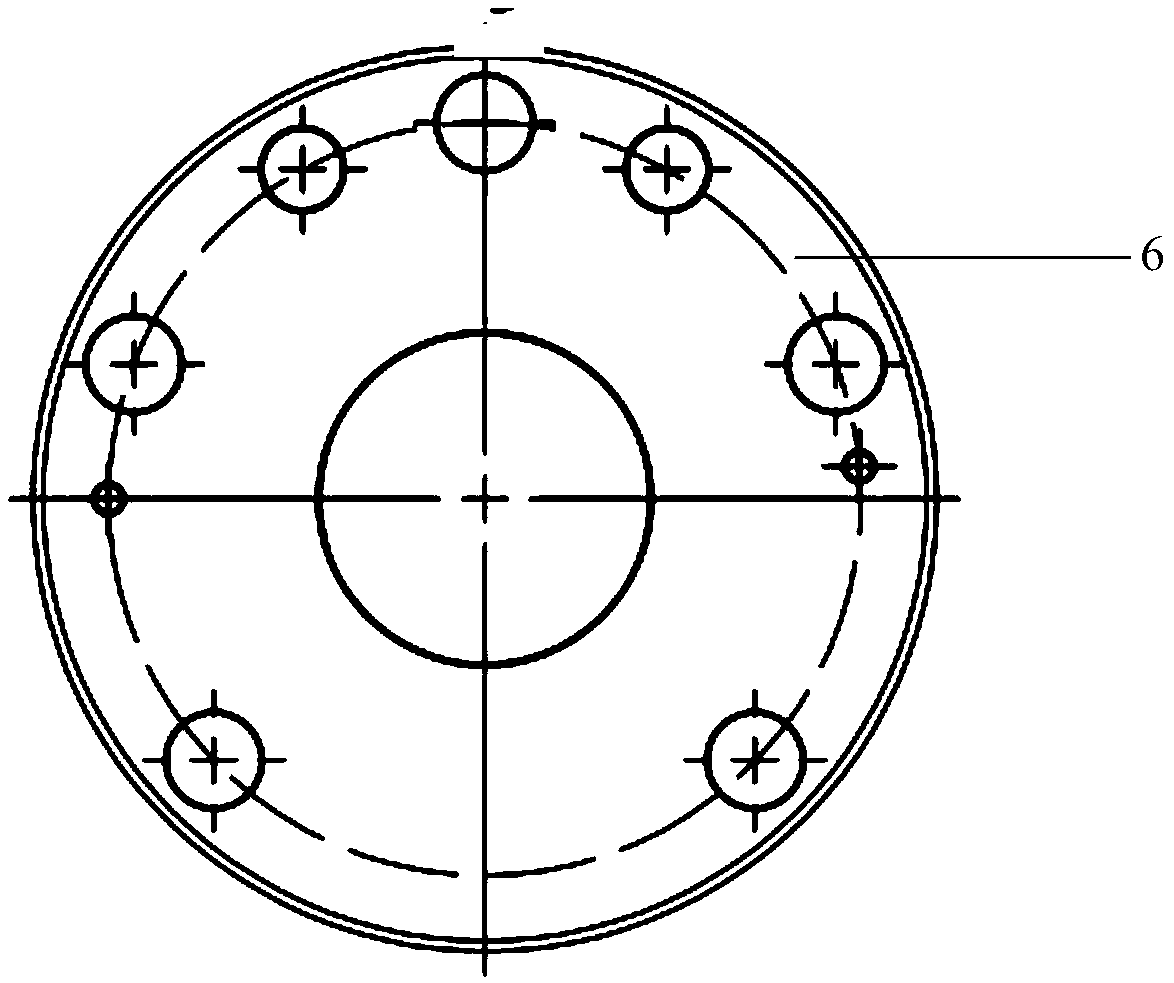

[0037] In this embodiment, steel plates are used to manufacture the above-mentioned separators 1 by laser cutting, as figure 2 As shown, the details are as follows:

[0038] Utilizing formed steel plates 6, according to figure 1 The shape and size of the required separator are obtained by laser cutting with a first through hole 2, five second through holes 3, and two third through holes 4. figure 1 separator...

Embodiment 2

[0040] In this embodiment, the structure of the partition in the double-cylinder compressor is exactly the same as that in Embodiment 1.

[0041] In this embodiment, steel plates are used to manufacture the above partitions through high-pressure water jet cutting process, as follows:

[0042] Utilize the formed steel plate, according to the shape and size of the required partition, cut a cut piece with a first through hole 2, five second through holes 3, and two third through holes 4 by high-pressure water jet cutting, That is, get as figure 1 separator shown.

Embodiment 3

[0044] In this embodiment, the two-cylinder compressor includes two sliding vanes, two pistons, two cylinders, one crankshaft, one main bearing, and one auxiliary bearing.

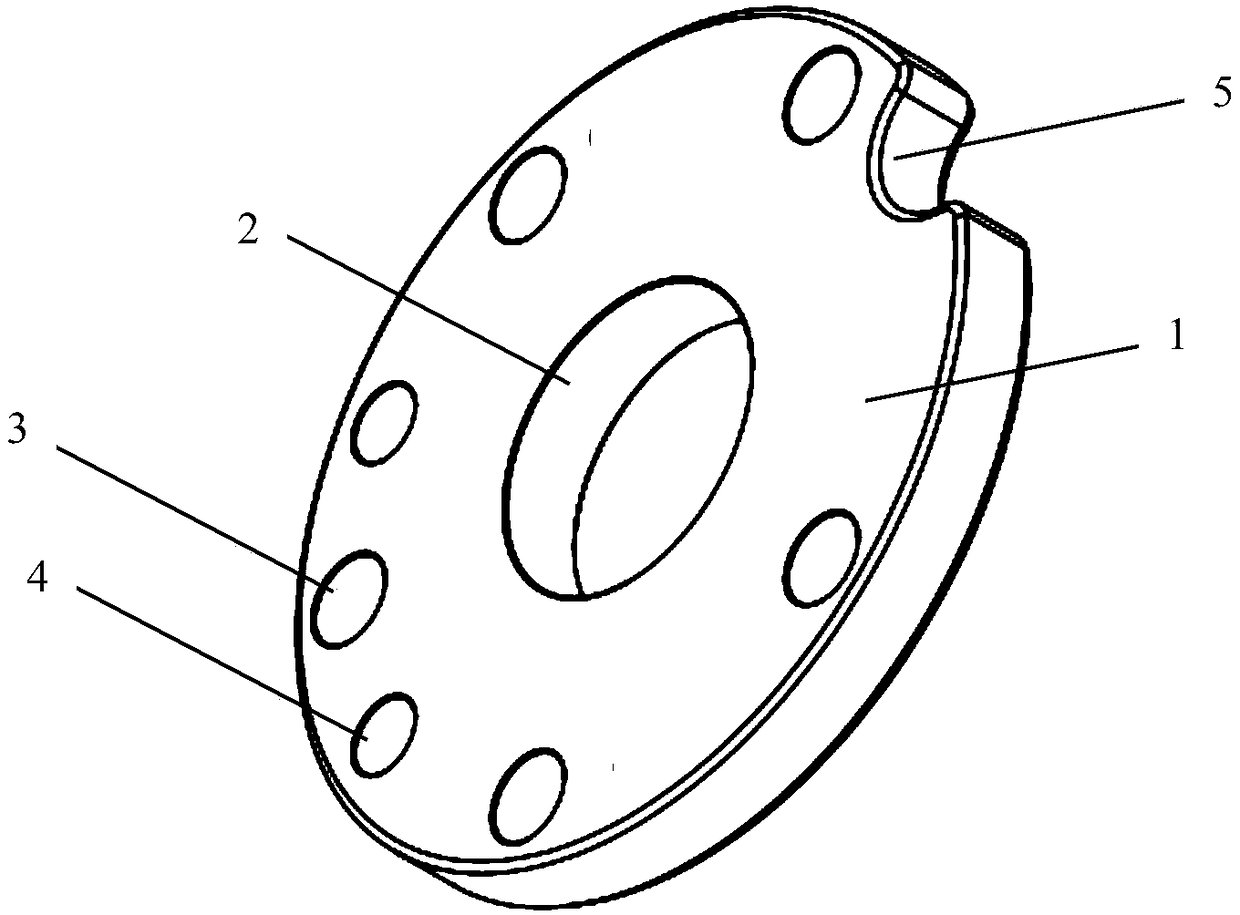

[0045] There is a partition 1 between the two cylinders, such as image 3 As shown, the separator 1 is in the shape of a disk, and the edge is in a concave structure 5 . A first through hole 2 is provided on the partition plate 1 for the crankshaft to pass through. In addition, installation through holes are provided on the partition 1 , including five second through holes 3 with a diameter of 10.5 mm and two third through holes 4 with a diameter of 8 mm.

[0046] In this embodiment, steel plates are used to manufacture the above-mentioned separator 1 by high-pressure water jet cutting, as Figure 4 As shown, the details are as follows:

[0047] Utilizing formed steel plates 6, according to image 3 The shape and size of the required baffle are cut by high-pressure water jets with concave structure 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com