Calibration target for optical axis calibration of multi-band multi-optical axis photoelectric system

An optoelectronic system, multi-optical axis technology, applied in the field of alignment target, can solve the problems of enlarged spot, unable to realize temperature change, low thermal conductivity of spectrum conversion material, etc., to reduce laser energy density, improve laser damage threshold, The effect of improving the accuracy of optical axis adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

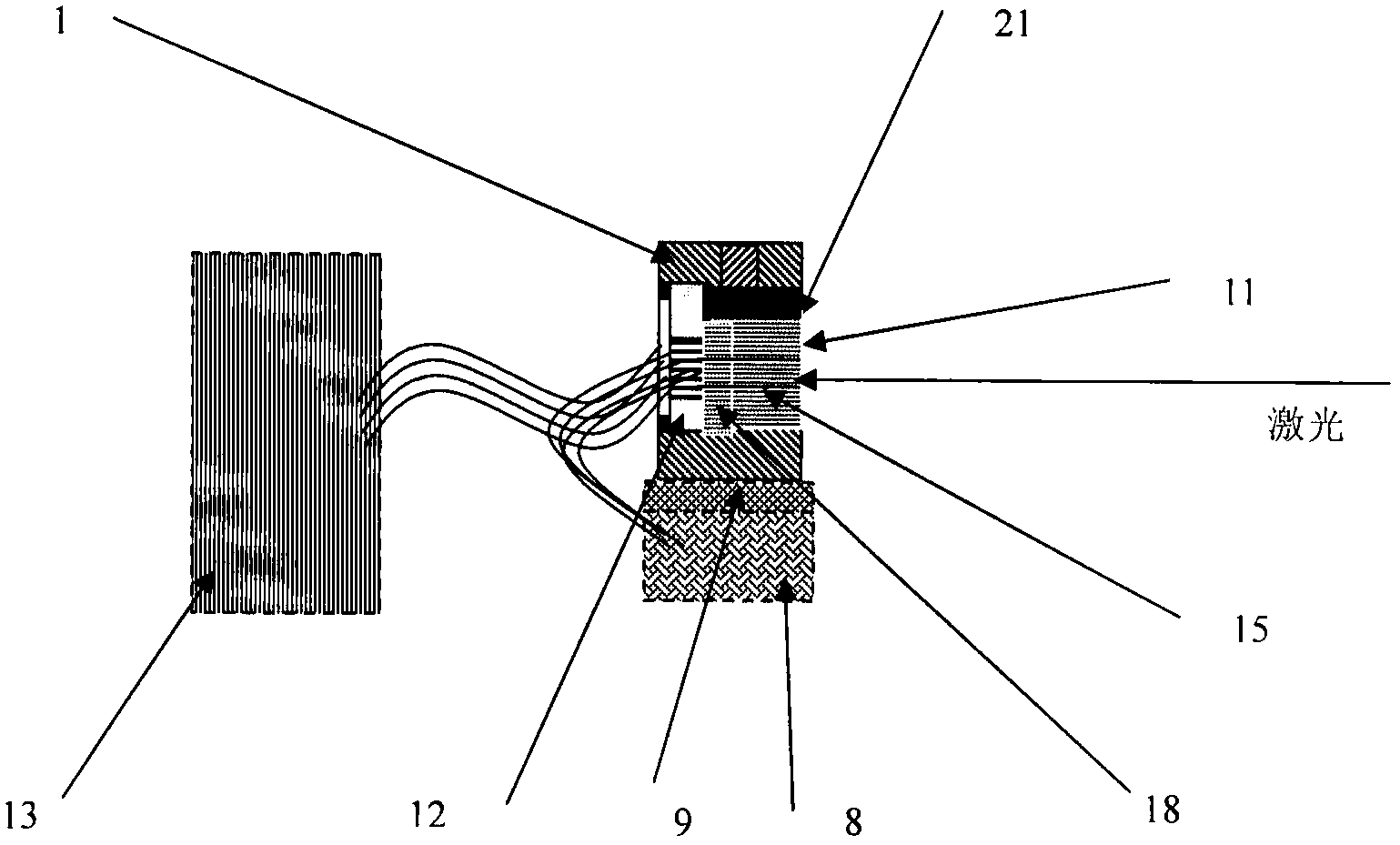

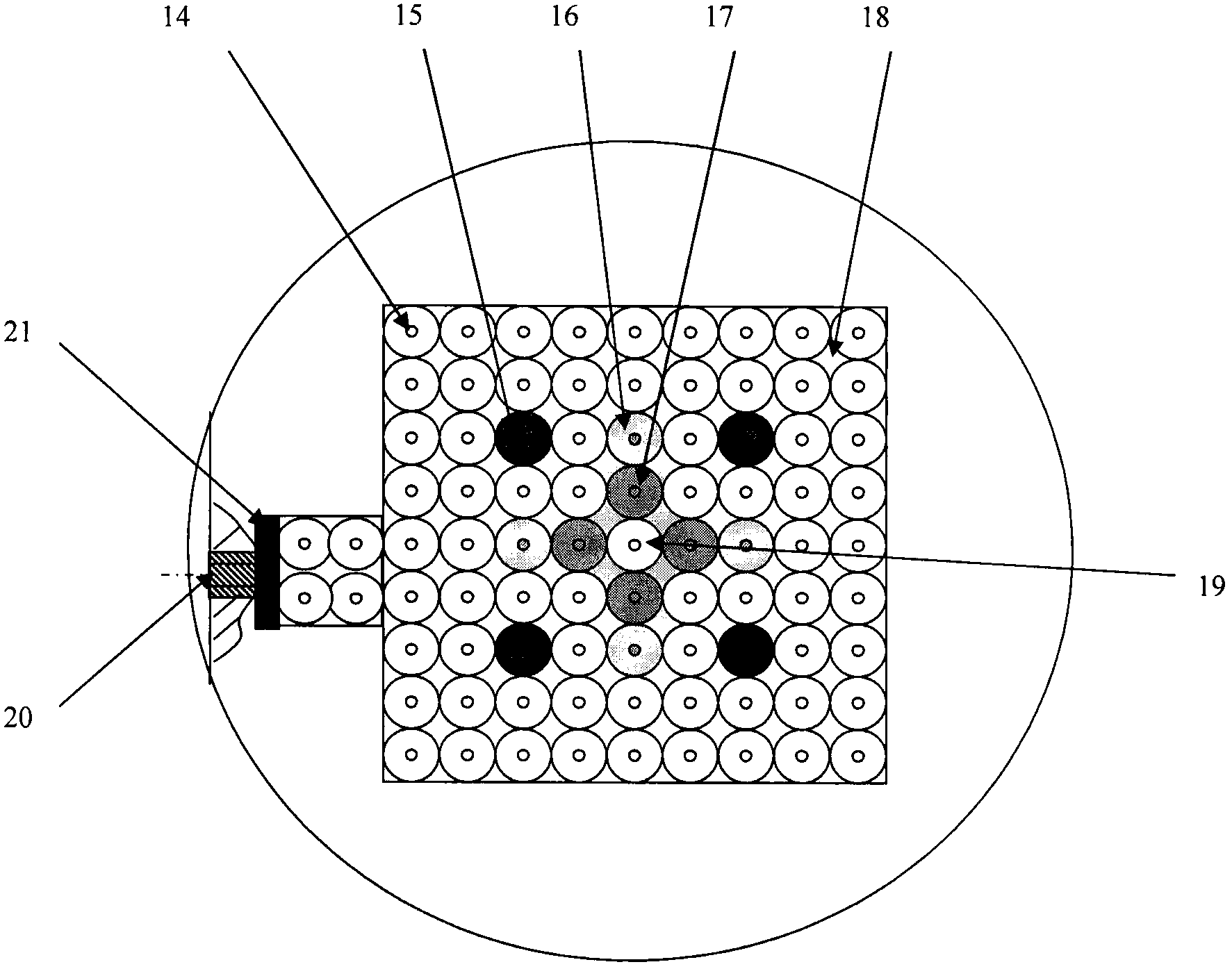

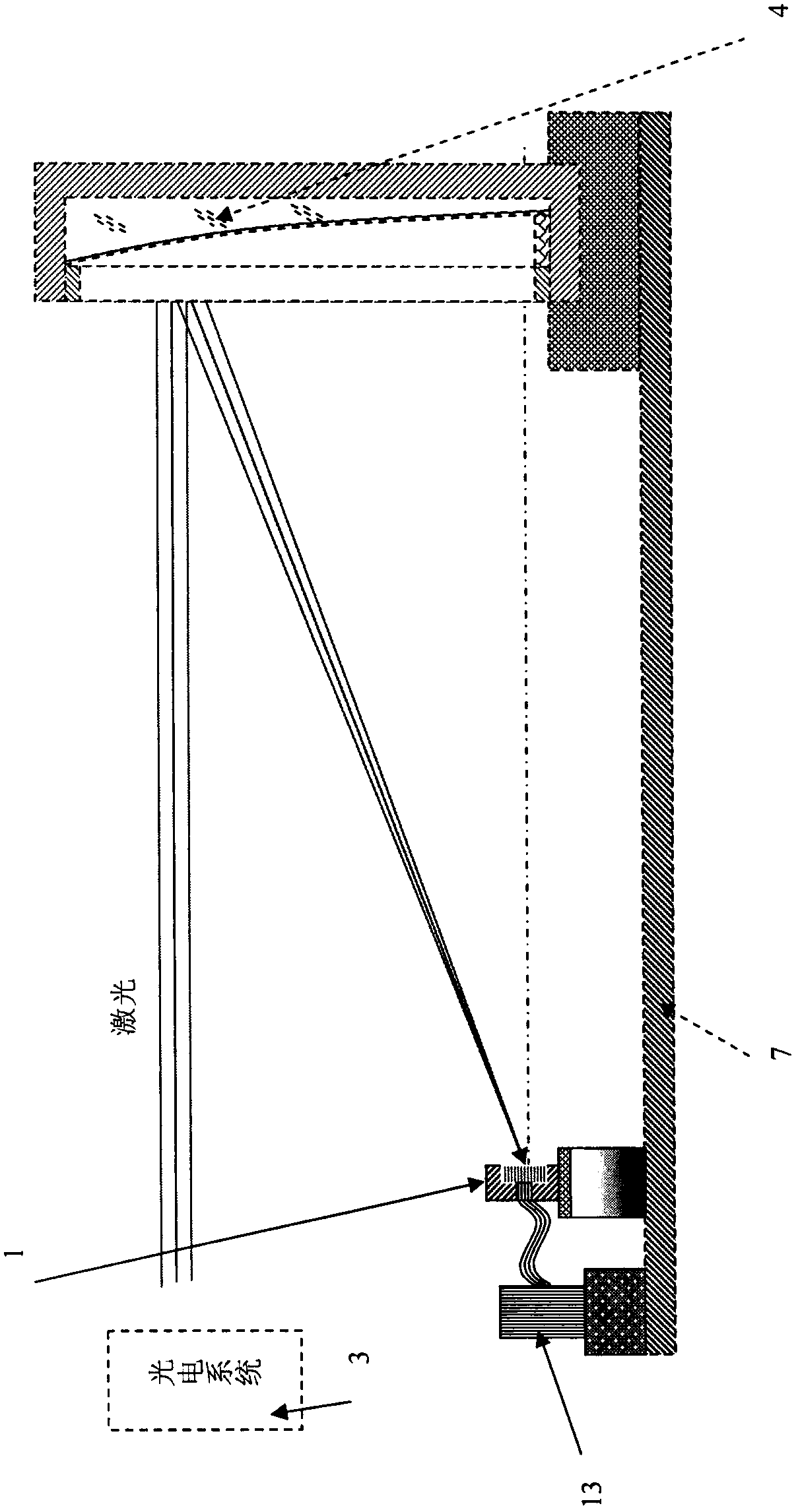

[0023] according to figure 1 As shown, the preferred embodiment of the present invention includes a target shell 1, a pressing piece 21, a plurality of optical fiber rods 14, four high thermal conductivity rods 15, display powder 18, quartz protective glass 12, an optical fiber distance simulator 13, a fine-tuning bracket 8, Vibration assembly9. The shape of the target shell 1 is a cylinder, and a transparent cavity with a square cross section is provided along its upper axis, and the square end face should be larger than the irradiation range of the laser of the photoelectric system under test on the target surface. This preferred embodiment is 4 ×4mm; on the target shell 1, there is also a square through groove consistent with the direction of the transparent cavity, which is located on the horizontal diameter of the target shell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com