Synchronous reflection distribution photometer

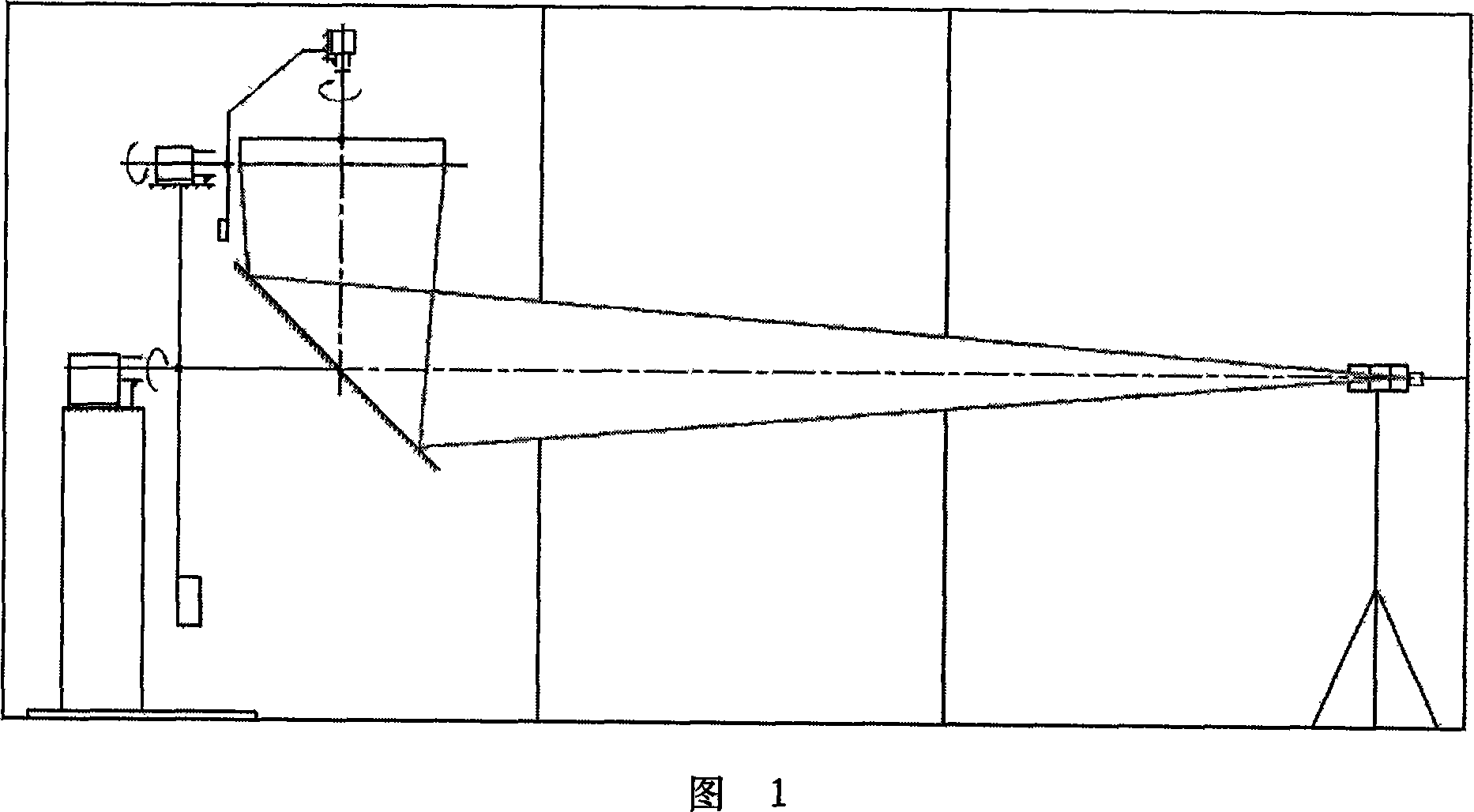

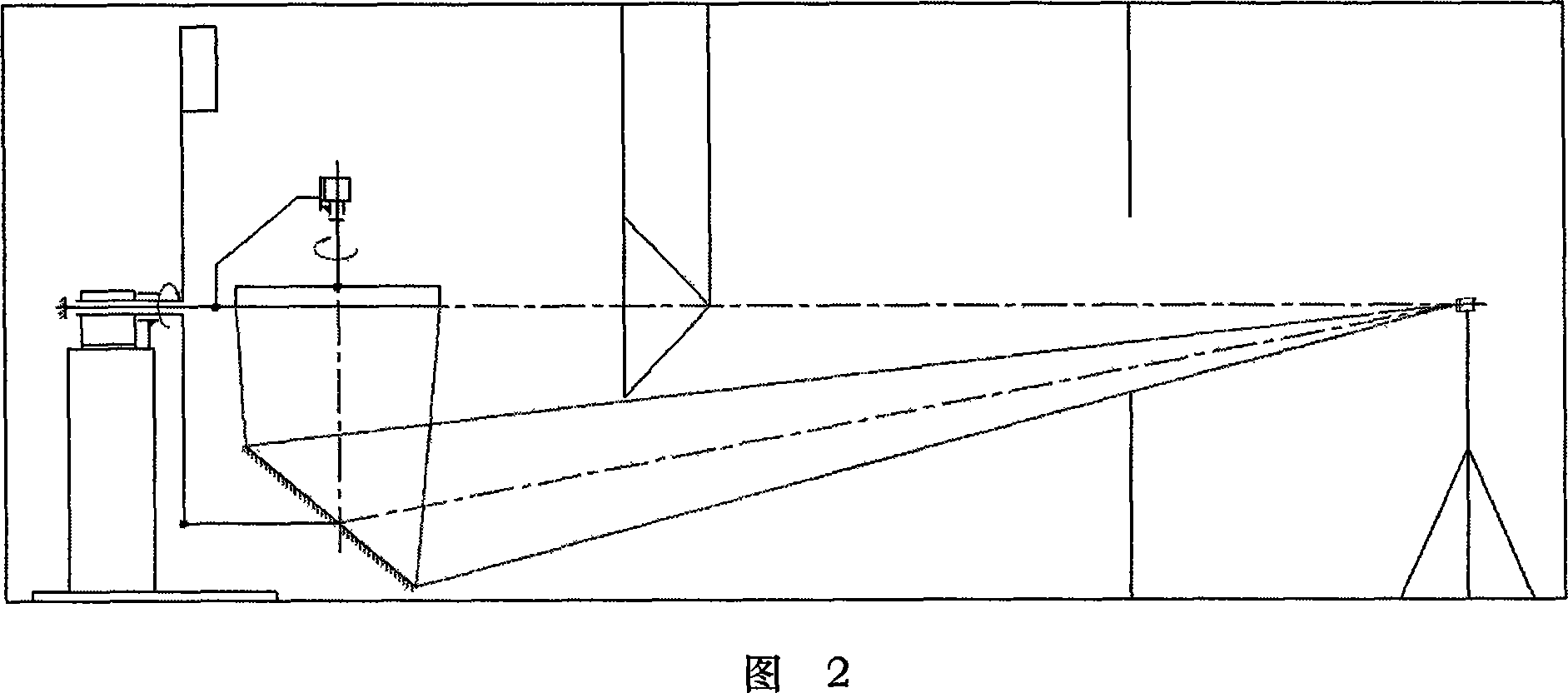

A goniophotometer and synchronous reflection technology, which is applied in photometry, optical radiation measurement, and optical performance testing, etc., can solve the problems of occupying darkroom space, large space occupied by the darkroom, and complicated adjustment, so as to achieve convenient optical path and convenient installation , easy to adjust the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

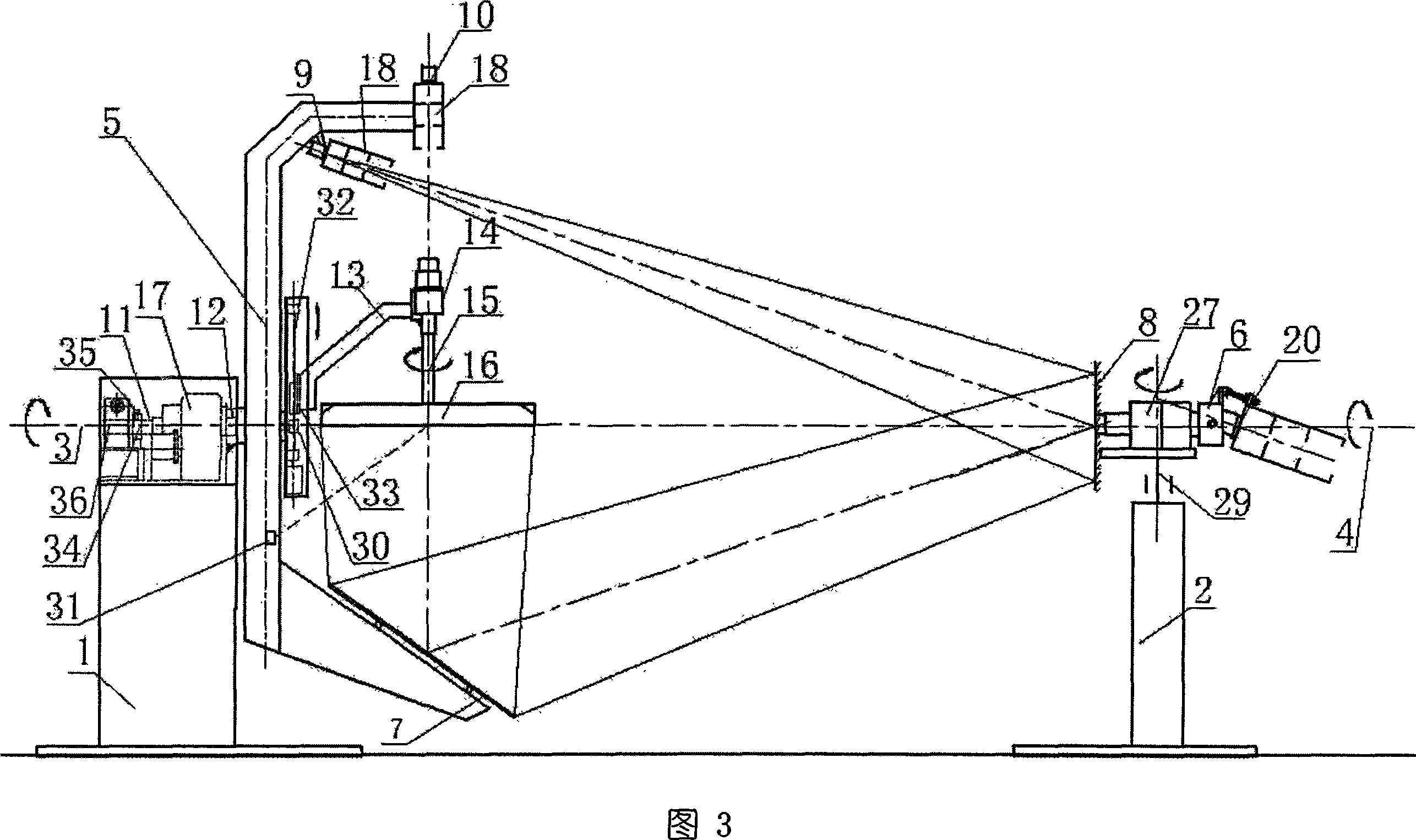

Embodiment 1

[0052]As shown in FIG. 3 , a fixed second optical mirror 8 perpendicular to the second centerline 4, a third optical receiver 20 that can rotate synchronously with the first optical mirror 7 and two optical receivers are set on the second base 2. Or switching mechanism 29. The third optical receiver 20 is connected with the second base 2 through the second rotating arm 6, and the second rotating arm 6 is driven by a drive motor 27 with a harmonic reducer, and the drive motor 27 can realize the first step through coding and automatic control. The second rotating arm 6 rotates synchronously with the first rotating arm 5 on the first base 1, and the optical axis of the third optical receiver 20 intersects with the horizontal rotation center line of the second rotating arm 6 and forms a certain angle. state, the horizontal rotation centerline of the second rotating arm 6 coincides with the first rotation centerline 3, and the third optical receiver 20 is just aligned with the firs...

Embodiment 2

[0058] As shown in FIG. 4 , the composition and structure on the second base of Embodiment 2 are the same as those of Embodiment 1 shown in FIG. 3 .

[0059] The first rotating arm 5 is a hollow cavity structure, the first optical reflector 7 is installed at one end of its outer side, the third optical reflector 21 is installed at the light entrance of the other end, and the first optical receiver 9 is arranged on the first The corresponding position in the rotating arm 5 adjusts the first optical reflector 7, the position of the third optical reflector 21 and the first optical receiver 9, so that the light bundle of the measured light source 16 passes through the first optical reflector 7 that is rotated, Normal incident fixed second optical reflector 8, after being reflected by the second optical reflector 8, just incident to the third optical reflector 21 that rotates synchronously with the first optical reflector 7, and then incident to the synchronous first optical receive...

Embodiment 3

[0063] As shown in FIG. 5 , the composition and structure of Embodiment 3 on the second base are the same as those of Embodiment 1 shown in FIG. 3 .

[0064] The first rotating arm 5 is a truss structure, as shown in Figure 6, the first optical reflector 7 is installed at its one end, the third optical reflector 21 is installed at the other end, the first optical receiver 9 and other several follow-up optical reflectors The mirror 23 is mounted at a corresponding position inside the first rotating arm 5 . Adjust the first optical reflector 7, the third optical reflector 21, the positions of other several follow-up optical reflectors 23 and the first optical receiver 9 so that the light bundle of the measured light source 16 passes through the rotating first optical reflector 7, just The incident fixed second optical reflector 8, after the second optical reflector 8 and the third optical reflector 21, is incident to the synchronously rotating first optical receiver 9 through se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com