Carbon-based ultra-black stray light-eliminating nano-composite coating and preparation method thereof

A nano-composite coating, stray light elimination technology, applied in coatings, carbon compounds, chemical instruments and methods, etc., can solve the problems of inability to carry out large-scale production, high cost, high production cost, etc., and achieve stable and controllable quality. , Improve the absorption rate, reduce the effect of stray light interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

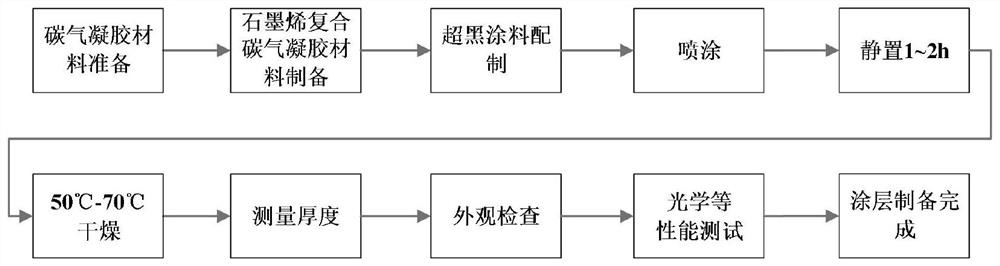

[0034] as Figure 1 As shown, the preparation method of carbon-based ultra-black matting light nanocomposite coating, comprising the following steps:

[0035] Step 1, the preparation of carbon aerogel filler: according to the molar ratio of 1: 0.1 ~ 0.3: 0.5 ~ 1, respectively, called chitosan, resorcinol, furfural resin, by the use of sol - gel method to prepare aerogel; the aerogel supercritical drying; the dried aerogel under certain temperature, a certain time conditions for carbonization; and finally the carbonized aerogel is activated to obtain a graded porous carbon aerogel material. Sol gel method refers to: glycan, resorcinol, furfural resin is added to the alcohol aqueous solution to obtain a gel, and the aerogel is reacted in a hydrothermal kettle to obtain an aerogel.

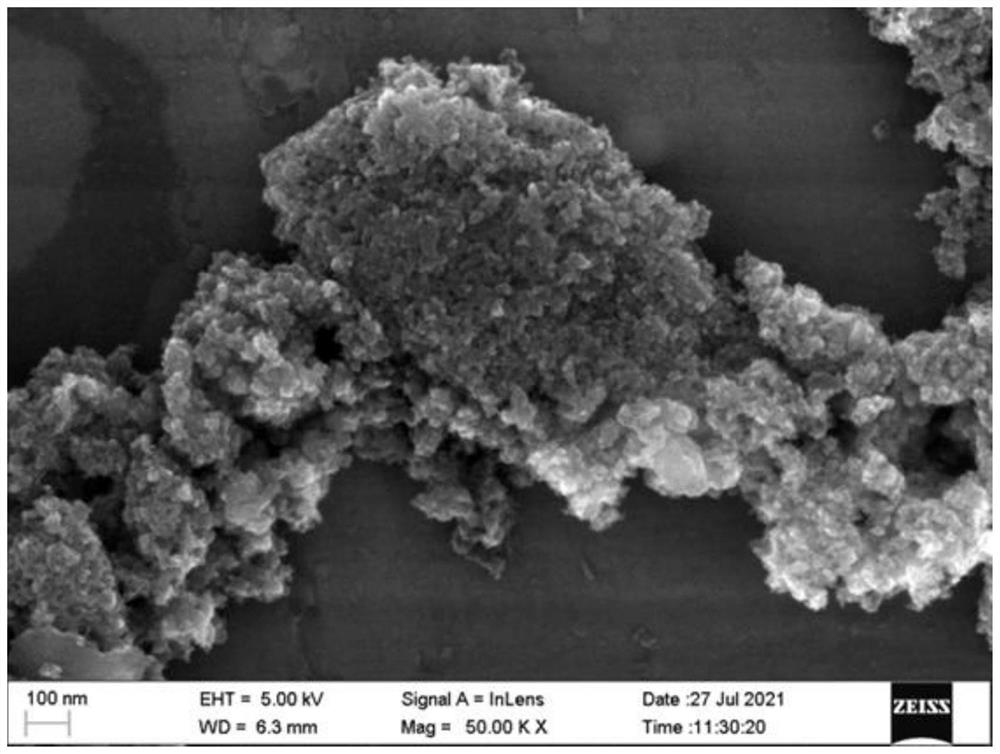

[0036] Step 2, preparation of graphene composite carbon aerogel filler: different proportions of carbon aerogel and graphene powder are mechanically mixed by ball milling, so that it is fully mixed evenl...

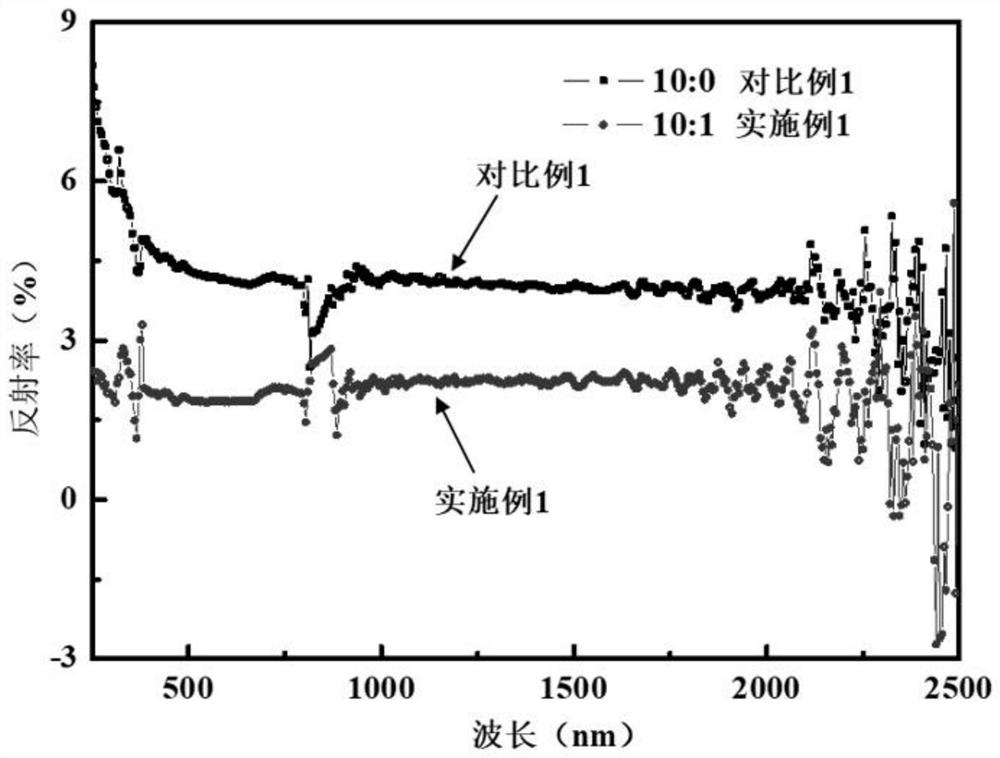

Embodiment 1

[0041]The present embodiment relates to a carbon-based ultra-black matting light nanocomposite coating and a preparation method thereof.

[0042] The ultra-black matte nano coating of the present embodiment consists of a silicone resin and graphene composite carbon aerogel filler.

[0043] According to the molar ratio of 1:0.2:0.8, respectively, called chitosan, resorcinol, furfural resin, by the sol- gel method to prepare the aerogel; the aerogel for carbon dioxide supercritical drying, the drying aerogel at 700 °C carbon carbon 2h, and finally the carbonized aerogel for carbon dioxide activation, to obtain a graded porous carbon aerogel material.

[0044] Preparation of graphene composite carbon aerogel filler: The carbon aerogel and graphene powder obtained in the previous step are mechanically mixed according to the ratio of 10:1 mass ratio, and the ball mill is used to make it fully mixed evenly, and the graphene composite carbon aerogel filler is obtained.

[0045] Preparat...

Embodiment 2

[0047] The present embodiment is substantially the same as Example 1, the difference is that:

[0048] In the preparation of graphene composite carbon aerogel filler, the mass ratio of carbon aerogel and graphene used is 10:2.

[0049]Preparation of ultra-black matting nano-composite coating: In the silicone resin, graphene composite carbon aerogel filler powder is added, mixed stirring, ethyl acetate is added, mixed, ultrasonically stirred evenly to obtain carbon-based ultra-black matting nano-coating; wherein, the mass ratio of silicone resin and graphene composite carbon aerogel filler is 7:3, and the ethyl acetate diluent is added according to its amount of graphene composite carbon aerogel filler powder and silicone resin 6 times the total weight. In the process of coating preparation, the surface treatment agent silane coupling agent is first sprayed, cured at room temperature for 1-2h, sprayed to prepare the carbon-based ultra-black matting nano-coating, cured at 55 °C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com