A method for improving mechanical properties and electrical conductivity of 7 series aluminum alloy

A technology of aluminum alloy and electrical conductivity, which is applied in the field of improving the mechanical properties and electrical conductivity of 7-series aluminum alloys, and can solve the problems that the mechanical properties and electrical conductivity of 7-series aluminum alloy profiles cannot be balanced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

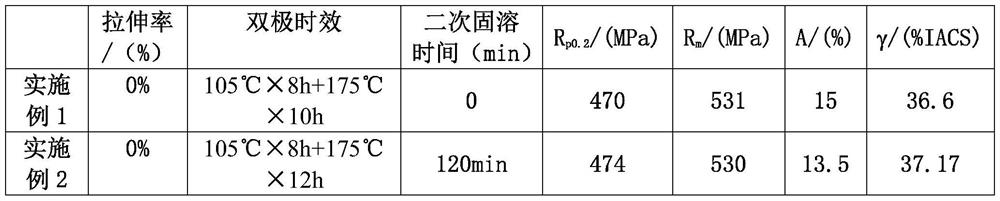

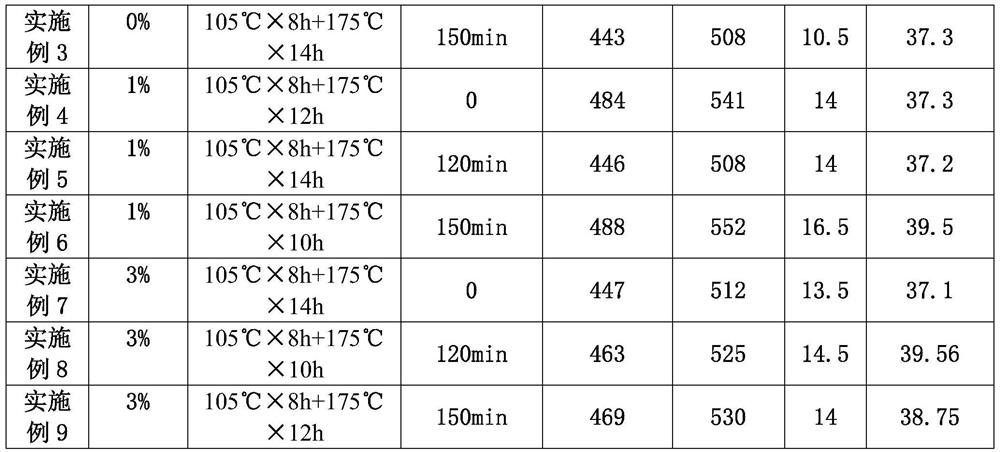

Embodiment 1

[0028] A method for improving the mechanical properties and electrical conductivity of 7-series aluminum alloys, taking the chemical composition of 7075 aluminum alloys as an example, comprises the following steps:

[0029] A. Ingredients: Calculate the amount of each aluminum alloy raw material and prepare the aluminum alloy raw material according to the ratio. The ratio of the mass percentage of each element of the aluminum alloy raw material is as follows:

[0030] element Si Mg Fe Cu mn Cr Ti Zn Impurities Al content 0.07 2.63 0.17 1.62 0.02 0.2 0.02 5.7 0.15 margin

[0031] B. Melting and casting: Add the prepared 7075 aluminum alloy raw materials into the flame reverberatory furnace and evenly mix them to melt into liquid aluminum alloys. Aluminum alloy ingots, where the aluminum alloy raw materials are first baked and cleaned to remove moisture and slag in the furnace before smelting;

[0032] The order of adding 7075 alum...

Embodiment 2

[0040] The difference between Example 2 and Example 1 is that the secondary solid solution time in step F is 120 min, and the dual-stage aging system in step H is 105°C×8h+175°C×12h.

Embodiment 3

[0042] The difference between Example 3 and Example 1 is that the secondary solid solution time in step F is 150 min, and the dual-stage aging system in step H is 105°C×8h+175°C×14h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com